Leaderboard

Popular Content

Showing content with the highest reputation on 03/14/20 in Posts

-

Hi In order to get a sembelance of order on the bench I build this tool holder, both tool holders rotate to enable easy access to the screw drivers, the flat bladed ones on the left and cross points on the left. My clock let down tools are fitted to the rear, probes etc down the sides. Saves scrabbling in a tin. heavy clock tools are stoed in two IKEA drawer units. Keeps the place tidy, untill I start working.2 points

-

I have got to the bottom of this:- "The Hatot Company was among the first to embody in their instruments important improvements in horology. Their first patents ware filed on 16th September 1953, but the Hatot Company did not have sufficient funds to exploit their numerous patents worldwide, so they granted licences to several of the principal horlolgical producers in the industrialized countries which is why there exist throughout the world millions of watches and clocks signed L.Leroy & Cie., Ebauches S.A., Junghans, Westclox, Smith & Son, Bulova, Jaz et General Time, all carrying the words 'Lic.ATO.'" Thus it appears that ATO's application of the transistor switch for watches and clocks was patented only in France but license was granted to a few major watch and clock manufacturers.2 points

-

I wanted to add, on't discard the possibility it has just overbankend. Easy to check, nudge gently the balance wheel, it will turn one direction but not the other. If so, loosen cock screw, raise balance and rotate into the direction it wouldn't turn. It will start beating right away.2 points

-

2 points

-

Hi At Your service find attached 7s26 user and tech sheets for your interest. I see you are in the capable hands of jdm and Nucejoe.. With the lack of alcohol use benzine or naptha and failing that lighterfuel, ronsonol. lighter fuel contains additives so may leave a residue, cheers 7s26-36Ctech seiko.pdf 7S26 seiko user manual.pdf1 point

-

1 point

-

No, I don't have experience enough to say whether a barrel should spin freely around the arbor when just puffing some air. In the end of the day it's of course a friction-bearing and even a very bad one too; metal-to-metal. Next to that, even if it would rotate freely (as it also may do when there is too much play), it's hard to tell how the bearing would behave under load, i.e. with a spring under tension in the barrel. Given the fact that it is a (used) friction bearing, to stay within reason all you can do, IMHO, is to ensure that there is enough play such that the arbor can rotate (which it seems to have), that the bearing surfaces are as clean & smooth as possible (you pegged the heck out of them) and to ensure proper lubrication to reduce friction between the bearing surfaces. With to stay within reason I mean to see how far you get working with the materials you currently have and the way the watch was designed. Next is of course to ensure, or try to achieve a as smooth as possible power release by the main-spring. Since it is an old movement, again to stay within reason, there are many things over which you have no control or can't alter. You can work your way from the arbor down to the escapement and do your best in checks, cleaning and lubrication. Than the escapement itself which is (at least to me) a complicated matter and lots can go/be wrong or misaligned (even ever so slightly) reducing the amplitude. It takes a very deep understanding on how the escapement exactly works, interconnects and should be aligned; something which I try to grasp (too?). Once you get down to that, it would get very interesting & educational if a forum member has that deep understanding and is willing to spend the time & energy to guide not only you, but hopefully lots of others here, through that process. Only than we will find out whether something can be / could be done to increase the amplitude ..... (?) I follow with interest your proceedings / progress1 point

-

Ya will do, Coronavirus may rob me of the chance to enjoy my own OK CORAL.1 point

-

Hi Right , the watch is a ronda 513/515 movement and hands are 120/70/20. So in theory any hands with those measurements will fit. Watch material suppliers the likes of Cousins uk , AG Thomas, Gleave&co in the UK Jules Borel, Esslinger, Timesavers, USA and Perrins of Canada will all have on list hundreds of hand patterns for you to check. If thats not what you want and want to use the origional hands you will have to fill in the origional holes and re drill new ones to size. This will take a great deal of skill plus the tools to do the job. Its a question over the level of work and the economic cost. To be cost effective replace the hands, I believe without checking the style is Baton.1 point

-

1 point

-

Amazingly beautiful clock design that. Very modern, so Swiss. Still popular in Switzerland. Every train station has one. Never seen the hands fall off yet! I would have tried a Jerry rigged hole closing tool first. The walls of the hole near the edges of the hand would have got really thin if I did it, and the hand would snap in two, or go a funny shape as it starts to snap on one side. Hopefully you are better than me. Try and move metal from the sides near the long parts of the hand. Bodge wise, I would have tried a smidgen of car thread loc, put it in the bore then try and wipe it all off leaving an inperceptible amount as it is not possible to remove it all.1 point

-

You have to think very, very deeply before you start doing things like that. In fine-mechanics all is done to reduce tolerances. That you can't feel it doesn't mean it isn't there. In fact, if all else stays the same, a few thousands of a millimeter play is enough; play=play. Increasing the hole sizes, as I understood of the barrel, and the barrel will tilt (even more), meaning altering the arbor/barrel contact area which could lead to more wear or in the very worse case gouging of the materials. Next to that, probably through the years, the current contact surfaces have worn smooth. I doubt if you can achieve the same smoothness again and if not, more friction & wear.1 point

-

Below a video about the importance and testing of the rotor bearing free spinning. A Seiko bearing in good state behaves very similarly. Lubrication decreases the efficiency of the bearing but makes it to last longer.1 point

-

It perfectly normal for some Seiko rotors to make a little noise, but apparently some owners are much bothered by that, as the issue keep being posted on forums. You can of course apply whatever you want to your watch, then if does not auto wind as per specifications you will know why is that.1 point

-

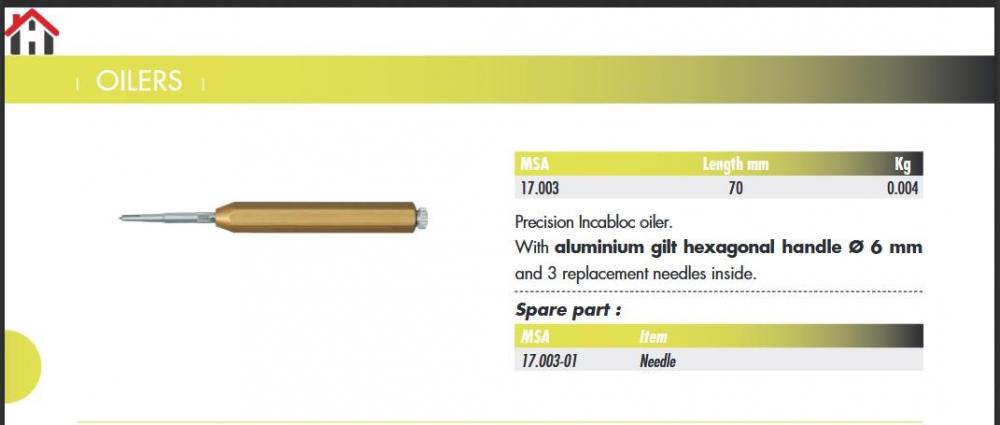

Oh, now I understand! I bought that thinking that it was to drop a precise amount to the end stone, Incablock specifically. When I found that it does not drag any oil I almost wanted to feature it on my topic of tools for laugh. Happy that I didn't, because I would have been the tool to laugh at!1 point

-

Yes, remove the rotor and soak it in alcohol.1 point

-

What you bought is grease for the O-ring of valves, tanks, etc. It must be safe for breathing, so it has different formulation and characteristics. In any case, that will not make any difference for the trivial task of being applied to a watch gasket.1 point

-

Do not use anything but a minuscule amount of fine oil for thr rotor bearing, as that will hinder its working. The service sheet is attached to almost any 7S26 discussion, and here again. You can always use the search function to get answers without waiting for other to reply.7S26C.pdf1 point

-

If a link to the datasheet is already not provided on this forum, I am sure our helpful member watchweasol will soon post the link here.1 point

-

Opps , disregard the last item. Since manual wind.1 point

-

-Note the seconds hand position, shake the watch, see if it runs and for how long or if'it doesn't. -If doesn't want to run when shaken, see if the sweep second rocks back&forth. -Try to give it a full wind, see if the barrel( wind) discharges power. -Pull the crown out to set postion, shake the watch, see if you can push it to run by simultaneously advancing the time. If locked up, Do the same in opposit direction.anticlock, -If a calender complication, advance the time to about six Oclock, see if runs then. -Shake the watch as you listen close, if you can here a noise you didn't use to before.( Sound of sudden power discharge) The results help diagnosis and advice. Good luck.1 point

-

It works, but when you check the oil quantity and it's lacking it's more of a pain than using a pin. Or you leave it lacking. When I was working in a trade shop while in school I did the way you describe but I was getting 10 USD for a manual wind, 11 for automatic, in 1998, not 1950 hahaha. Had to make some concessions. The boss cleaned assembled, barrel out (opened but spring in), then pulled the balance and ran through a second machine with "lube" in the final rinse. I skipped the second machine, disassembled all the movement (he'd leave cap jewels assembled too), did train freedom check etc. I didn't have one comeback. I'm sure the time he saved with the cut rate measures cost him more in his comebacks. Not trying not harangue, it's an old school technique you describe, but pushing through with a pin is a tiny extra step to ensure proper oiling to get it on the cap correctly before assembling.1 point

-

No problems with blowing air. Then about diagnosis, repairs or just servicing have a good read around this website or books.1 point

-

yes; "hand closeing tool" this could be just a hammer and anvil. a jury rig., But it is the measurment of the hole to get a press fit, is the art. vin1 point

-

Finding the correct display will be a challenge. You will find many that look similar but are not interchangeable.1 point

-

Maybe you got a different product. I've received the one below yesterday, the word "silicone" is not printed anywhere but I did a quick test which shows that actually it is. Of course, one can also clean off the supplied grease to use anything of his liking. Please excuse some lack of focus. I'm an absolute beginner to video.1 point

-

1 point

-

Westclox used to make the Big & Baby Ben alarm clocks.1 point

-

Hi there Hayden... 'Failure is your best teacher' I always say to my watchmaking students. jdm is correct about not taking apart the family heirloom for the first watch to work on and also listed the biggest mistakes that are going to happen when someone first starts out on the journey of watchmaking. Springs are one of those things that the more you disengage and refit, the better and more confident you are going to become. If you have a descent pair of tweezers that are well honed and kept clean they will become an extension of your own hand, although this can take some time. I was told when I started that it would take up to two years to use them properly at which I scoffed, but realise that wasn't far off the truth, exactly like a micro surgeon and his knife. I use carbon steel tweezers, because they are hard, don't bend and you can grip really tightly with them. You should be able to pick up a human hair off a piece of glass. I get a doubled over piece of 1000 grit wet and dry paper and grip it with the tweezers and uniformly pull it away from the tips. This puts an ever so slight grain on the gripping faces and you will be able to hold screws and springs so much easier. A sharpened piece of pegwood is a good idea to hold down the spring when you are disengaging or/and refitting it. The more times you do it with the proper tools that are in good shape the easier it will become and the confidently you will hold said piece. Personally, I don't endorse using a plastic bag, because it is akin to riding a bike with always having stabiliser wheels on, or driving at 5 mph, just in case you hit something. But each to their own, it's just the way I do it and teach it. Working on cheap movements and losing/breaking pieces is part of the process. Once you get more confident and better at it, then you will work on some quality movements, because your skills and confidence in what you are doing will have grown. You are doing well, so don't get discouraged. It's like learning how to ride a bike.... you need the bruises to learn.1 point

-

Leonardo da Vinci will be turning in his grave. That thing needs the hammer treatment.1 point

-

There's a commercially made "oil pusher", Bergeon doesn't list it anymore but Horotec does. It has very very fine needle like tips, just for getting the oil through the hole jewel on to the cap. Why it's called an Incabloc oiler is a mystery, as it would be useless on 99% of incablocs (only very few are like Kif, where the chaton doesn't have a "chimney"). It's handy, and fragile, and won't get into the very tiny hole jewels like on an old ladies model LeCoultre or similar (often 0.07mm jewels). For those I use fine hairspring taper pins.1 point

-

Problem solved. It was indeed too much lubrication. The grease wasn't doing it... The manual even states that you should just lubricate the stem area... Thank you guys!1 point

-

Would have been better to save my old Tissot if they where gold. I sold them on Tradera for next to nothing. If i only would have known those screws where gold i could have sell the screws . I think they are brass . Probably plated but don't think that either. Gold is to soft to make screws from.1 point