Leaderboard

Popular Content

Showing content with the highest reputation on 01/13/17 in all areas

-

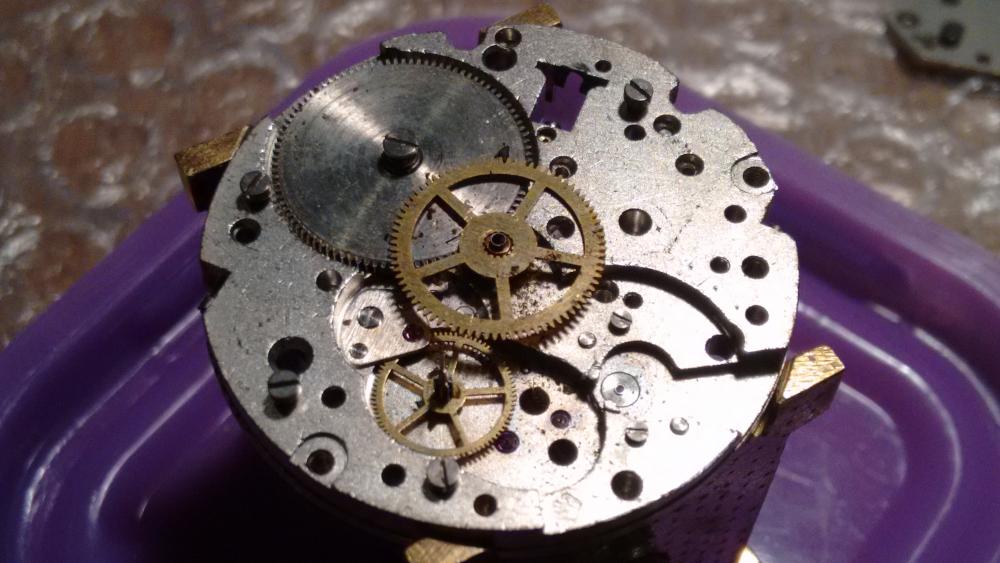

I have been trying to learn mechanical watch repair for a long time. I had never once successfully taken a non-working item and got it back to working condition. Its depressing. I have this old watch its like 80 years old. It didnt run, so I thought I would service it and see if I could get it to work. So yesterday thats what I did, and it all went very well. It was a design I didnt know, it didnt even have a pallet, I have never seen one like this before, instead it had a cutout in the balance staff that allowed the escape wheel to pass. It took me about 4 hours, but I did actually get it working, it ran for 4 hours. I was in a really good mood, as this was the first time I had ever gotten a previously non-working item to run. I felt like I had taken a first step to something. So 4 hours, good, but still, it did stop. The balance seemed to be the sticking point. It just wouldnt turn smoothly. It seemed to run fine until the balance cock was screwed down tight, then it stuck. I thought the balance staff might be too long. Long story short, on perhaps my 20th attempt to seat the balance the hairspring became tangled. My attempts to fix the hairspring destroyed it. It feels so bad after so much effort, to all come to nothing. And I cant find a replacement as I have no idea of the make or model number. The only good news of the whole thing is that once the POS hairspring was out the way, I was able to see the top balance staff pivot was slightly bent. So at least I was able to find the problem after all. Just feels crap to work so hard for nothing. And, really it makes me worry that if a hairspring can tangle so easily, it feels like it can happen at any time, I mean what are we supposed to do if we cant get replacements? Do we only work on watches where replacement parts are readily available? With all the parts restrictions it feels like working on anything is a big risk.1 point

-

What's on your "to do" list for 2017? Just been through my project box and wondering if I will be able to get to "repair rate greater than buy rate" in 2017??! Job 1 - rebuild Pierce 134 now I've tracked down a new pallet fork. Job 2, work out if I have enough bits for 1, 2 or 3 more... After that, it might be one of the 2 Omegas I bought for the wife - each cost me about £30 and one is 9ct gold! Then my Trench watch needs a jewel replacing... I bought a box of 7 junk movements for £35 to get the jewel, but also now have a proper blued minute hand to replace my modern painted one, and some rubbed in jewels to practice with. Then I have this interesting early Record auto, which looks like a standard Record caliber with a bumper winder added on the back! Another Pierce chrono and a Landeron 51 Then I suspect it will be Christmas again before I get to this one...1 point

-

1 point

-

1 point

-

John I'm not sure if I should thank you or not for those links. Oil is like a project all on its own. thanks again Anthony1 point

-

5 mins over 7 hours is probably not wearable it will probably need a bit more fiddling. Trouble with me and fine tuning is I always take it too far and it is not unknown for me to knack something up when really it had passed the line for acceptable, though not quite reached the line for spot on - such is life. Cheers, Vic1 point

-

1 point

-

I think it would be a good idea to remove the other three screws first using the correct screwdriver. Attack each screw with confidence and plenty of downward force to avoid slipping. You will then know whether you have a big problem or just one bad screw to deal with. Also it will give you some more confidence. I had the same problem with an Omega screwed back and I got it out by drilling carefully with the smallest size drill bit in a Dremel then worked my way up in size until I could see the threads being cut. Then it was just a matter of picking out the old screw bits with a fine pointed tool such as a hardened scriber. Keep the Dremel vertical at all times as the last thing you want is a broken bit jammed in the hole. It is no problem if you do slight damage to the threads on part of the circumference as there will still be loads of material for the new screw to grip tightly. Sets of micro bits in solid carbide can easily be obtained on eBay. Go in slowly and carefully and you will have success.1 point

-

I still have a couple of these clocks & there is a cover that clips into the back plate1 point

-

Have you looked on ebay, you find many old machines on there.1 point

-

That's the definition of sentimental value. woah. Sentimental to the custodian of it, yes, but, could you imagine if you got a treasured watch back after so many years after such a scenario.1 point

-

1 point

-

What a great story, thanks for posting it Dave. Although there is no reference to an inscription on this watch I would like to add that I love watches with inscribed history. A lot of folk don't like inscriptions on watches as it tends to devalue them. I think that the added history enhances an old piece.1 point

-

1 point

-

Congratulations for getting the movement working. I wrecked the cylinder movement i came across. Took the balance off and the watch unwound. Never did work properly again. Take the advice and work on more recent movements with availability of spare parts. Also it's your hobby, the failures just make the successes better ! As Oldhippy said what are apprenticeships for and to master, can take a lifetime. I used to get upset, think this is more to do with pride than reality. Now I just laugh the "Screw Ups" off and move onto the next project. Enjoy your hobby and when things do go wrong, spare a thought for the "Professional " if they screw up, it doesn't only have financial consequences but damaged reputation! Sent from my SM-T585 using Tapatalk1 point

-

I go the hands in the mail to @RyMoeller, so thank you very much! They are mostly too big or short, but I found a pair that is OK for now.... With these at least I can see the timekeeping. I am very grateful and will send back the remaining lot soon. If you need any spare parts and I have them, you are welcome to them! More to come.... JC1 point

-

Try here. https://www.cousinsuk.com/product/roller-impulse-pin-jewels-seitz1 point

-

I spent the day literally watching paint dry. I was using black lacquer to fill in the engraving on a pocket watch case to make it stand out. I will send pictures when it is finished. In the mean time I was looking for screwdriver sharpening stone holders on the net. The sticker shock was amazing. So i said to myself, "Self" your only watching paint dry, make your own, you have a sharpening stone and some wood. So I made this from scrap wood while watching paint dry. I'm happy with it & it cost nothing. It is perhaps not as pretty as Bergeon but they have enough money.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.jpg.8a21c5bda26dd240cf8d9417ecce3edf.jpg)