Leaderboard

Popular Content

Showing content with the highest reputation on 09/07/16 in all areas

-

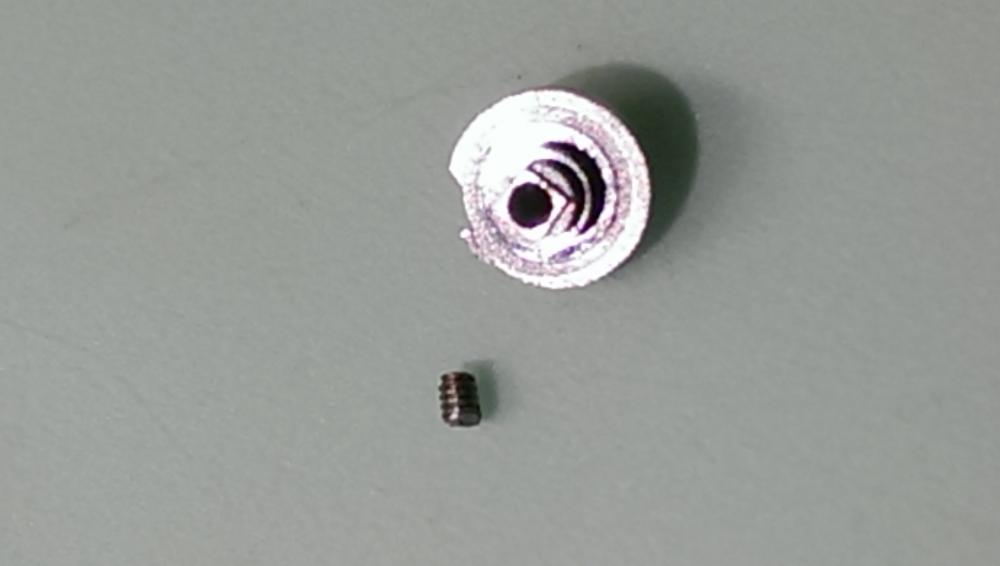

This is my Atmos cal 528 story circa ~1960 – its been years that I’ve put my eyes on Atmos clocks looking in its beauty and clean / sharp looking as well as their technical structure. In the country where I live, I’ve never saw any Atmos clock new or pre-owned for sale therefore I decided to buy on Ebay. At that time, I didn’t think that I’ll have to fix it I just want this “furniture” at my saloon. When unpacking the clock at home, I figured out that the chain is broken. I can’t tell if this happened due to shipment or it was originally broken but no matter - it was broken and here is where the adventure starts…(broken chain means winding mechanism is out of order). As watch/clock hobbyist, there was of course only one option – jump into it, ignoring those who claims that even the experienced and professional clockmakers shouldn’t touch Atmos without the proper skills and knowledge. I’ve started to read the available material on the WEB, spending time to understand each and every step. I bought also the repair PDF notes with explanations and dedicated tools like hands remover since without it, you will damage the minute pivot. Repair notes: Hand remover: Also, I couldn’t find a proper screwdriver since for some reason, the standard screwdrivers blades are 0.6mm or 0.8mm while this screws require 0.7mm blade. Important to mention is that without perfect fit, the screws will be damaged and if there something I hate is to see those signs on the screws because of using improper screwdriver (or sometimes due to non-skilled hands). Therefore, I took 0.8mm and resized it to 0.7mm. Also, need to say that this screws are having a large “cap” so once they are tightened, they are very difficult to be removed. One of the screws: Another mission was to get new chain but this was found easily online. It took me about 5 month to complete the study and buy everything. Before I started the work, I did few inspections looking for other potential issues: 1) I manually wind up the spring to the desired tension (according to the spec). I found the clock is running although the amplitude was lower than the spec (spec is 360 – 540 deg). 2) I checked that the bellow is functioning – measuring at room temperature and after refrigerator. It looks that bellow is ok In order to replace the chain, I had to remove the dial, bellow, motor, front plate and the main spring. I didn’t disassemble the balance system as in my inspection, it was looking functioning properly. I disassemble the motor gears and cleaned the holes. I also disassemble the mainspring and cleaned it and oil it. It looks that the clock wasn’t serviced for a long time. There are only few points to lubricate the clock. Most of the friction points must not be lubricated! Then I installed the new chain following the instructions of the required distance between the ratchet and the bellow to allow the optimal torque for the windup process. Then, I’ve put everything back and wind-up the main spring manually to its base level means that from this point on, the bellow will wind-up the mainspring according to the thermal changes and the power that ran-out from the spring. The clock came back to life and I was able to monitor the mainspring winding up properly. This can be done by following a moving red point located on the barrel arbor ratchet winding system. The chain and the red dot: The clock is running ~2 years keeping excellent time after this service however, the amplitude is about 330 and even less, while the spec requirement is 360-540 deg. I’m trying to look for the reason but so far I didn't found. There is still work to do but so far I’m really proud of it. This is just beautiful, I hope you like it:3 points

-

Aloha All , the post office finally delivered this Rolex Oyster Date Precision to me today . I was held up in customs since April 21 and I had to furnish paperwork to them showing what I paid for this item . After I gave the letter carrier $85 to cover duties , VAT , and another fee I finally got my watch . Yes , it has a repainted dial , but other than that , it's a beauty . I especially like the end pieces on the leather band . It's about 34 or 35mm which is about the smallest case size I will wear . All in All , I do like it .......1 point

-

1 point

-

1 point

-

Szbalogh, if it helps, here is the roller remover stump from my staking set. As you can see it's spring loaded, the spring pulling the conical base of the jaws down into the conical recess of the main housing, closing the jaws. To open the jaws you just press the protruding button at the base of the unit, pushing the jaws up and allowing them to open You insert the balance, release the button allowing the jaws to close, and install the whole lot into the die plate of the staking frame. You can then use whatever stake is most appropriate for the job in hand.1 point

-

Nice and simple tool. I need to make one roller remover as well. But how can one set the jaws distance? Those need to be far from each other to insert the balance wheel first and then tightened to grab the roller table. I can think it is working like a lathe chuck, tightened with the srew at the bottom?1 point

-

1 point

-

I actually found a similar item in the Chicago Manuals. Sent from my GT-N5110 using Tapatalk1 point

-

I don't know the age of your cricket but I found this an interesting read. http://www.awci.com/wp-content/uploads/watch-tech-guides/vulcain/Vulcain-Cricket-Watch-12.pdf1 point

-

looks like portable version of stacking set roller remover. Place balance in the middle piece, roller table up (I suppose roller table should be placed on middle die to allow rest of the balance to fall down), and gently push down with punch, checking if balance pivot in secured inside punch hole.1 point

-

Hello Stian and welcome, lovely group of watches you have. You will get loads of info and help here. Cheers, Vic1 point

-

Welcome Stian that's an impressive collection of watches you have there. I'm sure you'll learn a lot here there's always plenty of people around to help. Mick1 point

-

VERY nice!!! This is a clock I've always want to have. They're so pretty and the technology is awesome. My grandparents had one, and I used to ask my grandfather to carry me so I could see it run on the mantel...1 point

-

Welcome to this very friendly forum. You have a good eye for watches. I've been retired for many years. Do you know I don't have a watch. Plenty of info here for you and yes Marks videos are extremely good.1 point

-

I seriously doubt if any glue in the universe at least our part of the universe would hold gluing the stem back on. If you find some though there should be a big demand for it. I'm not sure if laser welding would have the strength. We've had some stuff laser welded like band parts some worked some didn't. But they don't have the force the stem has. So the symbol on the back of the case is crescent. 18 size doesn't look as popular 16 size but a few were available new. Then I was looking on eBay I suspect to be cheaper to buy another case. I'm seeing there are some stem assortments of some bizarrely strange prices and quantities. So as possible on may show up somewhere at least now you know what you're looking for. http://www.ofrei.com/page398.html http://www.ofrei.com/page397.html Then in the catalog dated 1938 I've attached an image. So a very long time ago the stem was probably available. Then for those working on American pocket watches I also have attached image of Bench keys. Then because I was curious the largest square is 1.36 mm I'm guessing there were some variation here. Then on the same key the next one is 1.17 mm.1 point

-

Hello and welcome from me in Newcastle If you have questions you have come to the right place, I have asked loads in my time and always got a helping hand. Cheers, Vic1 point

-

Hello and welcome from me. We were all newbies to start with and even now when I encounter a problem or a new conundrum, I still am in many ways. Cheers, Vic1 point

-

Hi everybody, I have been browsing this forum for a few months, I suppose just to keep up with the trade, anyway I have found it very interesting I didn't realise there were so many amateurs with such a great span of knowledge. I left the trade in the 80's when quartz watches were destroying the repair trade, I never considered returning to it as I was settled doing other things, I never lost my love of watches. I once worked for the firm that imported "Sicura" watches in Clerkenwell as a "Trade" worker repairing guarantee watches at home, this entailed finding out what was wrong and putting it right, it could be a broken balance staff, button and stem or glass anything in fact. I would be given huge parcels of spare parts and told to get on with it. I used to repair about 200 watches a week for which I received 33p per watch, it was a good living in those days but came to an end during the postal strike in the 70's. When I stopped trade work I was charging £1.80 for a COH (clean and overhaul) for a normal jewelled lever or pin pallet and £2.50 for an automatic, competition was fierce in those days and you had to keep your prices low. A few years ago I was offered £25.00 a watch for a COH but it meant setting up a workshop again, so I didn't bother, I even threw away my old cleaning machine when I moved to France (which I regret now). Now I've bored everyone to death I'll finish and just to say If I can ever help anybody I would only be too pleased. Thanks to Mark for this site and the brilliant videos which I have enjoyed immensely.1 point

-

Hello Consuelo and welcome from me, Lots of help and advice freely given in this forum. Looking forward to your postings. Cheers, Vic1 point

-

The 7Txx series of chronographs from Seiko are basically all made 90% plastic, rogart63. As per the missing/broken part, I will replace the entire plate since I have still a couple of 7T32 movements that have identical structure. As per the chronograph, it does work even with that broken off tip, but the switch lever could be misplaced if you'd were to press the pusher too hard.1 point

-

Welcome to the forum Stian. It is a snap on back and before you attempt to open it take note of the the position, your picture above will suffice. The reason I say this is the alarm striker hits a post fixed to the inside of the back. To remove it you will need a case knife, Stanley blade and a single sided razor blade. Have a careful look and you should see a small notch. Start very carefully with the razor blade to ease the back up ever so slightly. Follow with the slightly thicker Stanley blade which should allow easy access for the case knife which you will use to prise the back off. If the notch is large enough, you may be able to just use the case knife. Whatever you do, please be carefull nit to cut yourself or slip with the knife and damage the movement.1 point

-

Nice article Micky! Now, I wonder about this because most of the stuff I see is an ETA 2824 biffed up...and as you know, ETA has many options that can be added for a price to each of its different finishes of the same movement...Also, being Sellita part of this deal, it makes me wonder what other options not offered by ETA is Sellita providing! I've found this, so I'll have to take any big brand company's claim with a grain of salt when it comes to ETA based stuff: http://forums.watchuseek.com/f2/smoke-mirrors-part-1-eta-grades-explained-458060.html http://forums.watchuseek.com/f2/smoke-mirrors-part-2-eta-modifications-upgrades-459866-2.html The second part is the actual post I'm referring to, but the first one is a good introduction for many of us. I hope there is more to this new STP trend than just a marketing thing! As it is, ETA or SWATCH or whoever ones from there, have made already many mistakes by restricting supplies! Cheers, Bob1 point

-

Hi, Stian! I can't help you with opening the case, but I do have a suggestion. If your watch is running a couple minutes fast PER HOUR, then it's running about an hour fast PER DAY. That is unlikely a problem which can be fixed by adjusting the regulator of the watch. More likely, your hairspring is functionally foreshortened, either by magnetism or by dirt causing adherence between coils of the spring. An easy way to check for magnetism is to put a cheap compass over the watch. If the needle of the compass swings back and forth, that's a definite sign of a magnetized watch. If the compass does not swing, no solid interpretation can be made. Good luck! --Eric1 point

-

Welcome! Yes, I so agree about Mark's videos! What a guy! I thirst to be able to run a pair of tweezers like he does. It's so much fun to see a master craftsman work. Beautiful!1 point

-

1 point

-

Hi! No need to worry, there is always someone willing to help even the newest of newbies.1 point

-

1 point