Leaderboard

Popular Content

Showing content with the highest reputation on 07/30/16 in all areas

-

2 points

-

I was just getting ready to give my collection of pocket watches their annual wind and I wonder why we ever progressed away from them, very sad really Sent from my SM-G920F using Tapatalk1 point

-

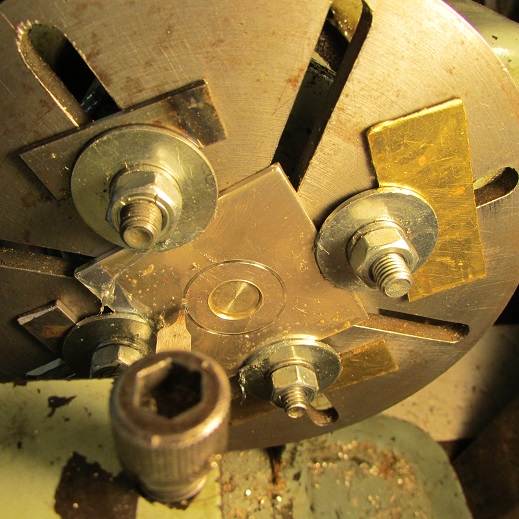

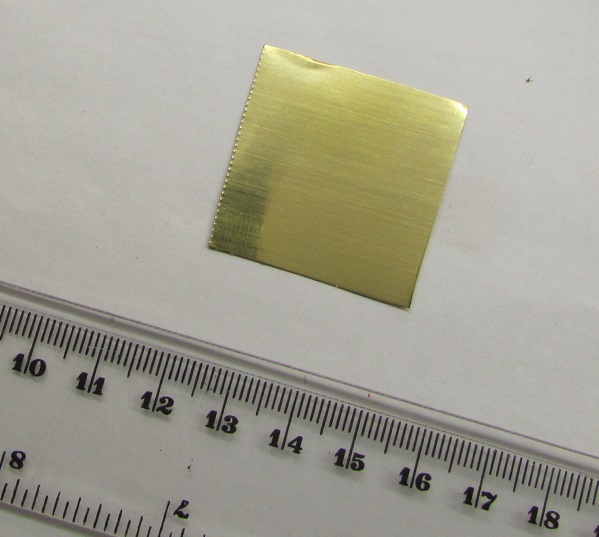

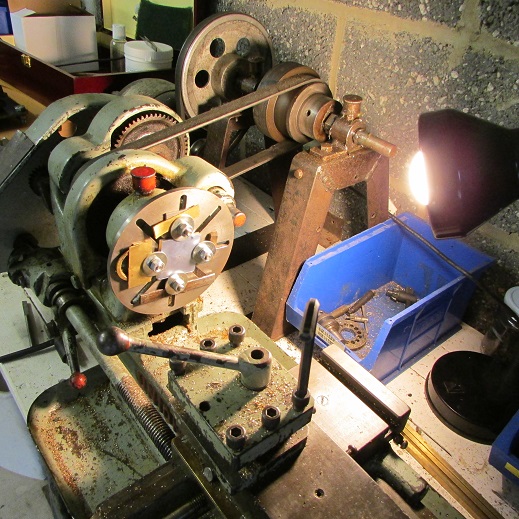

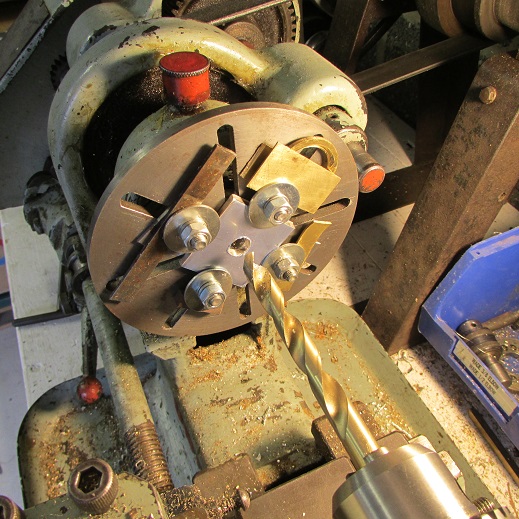

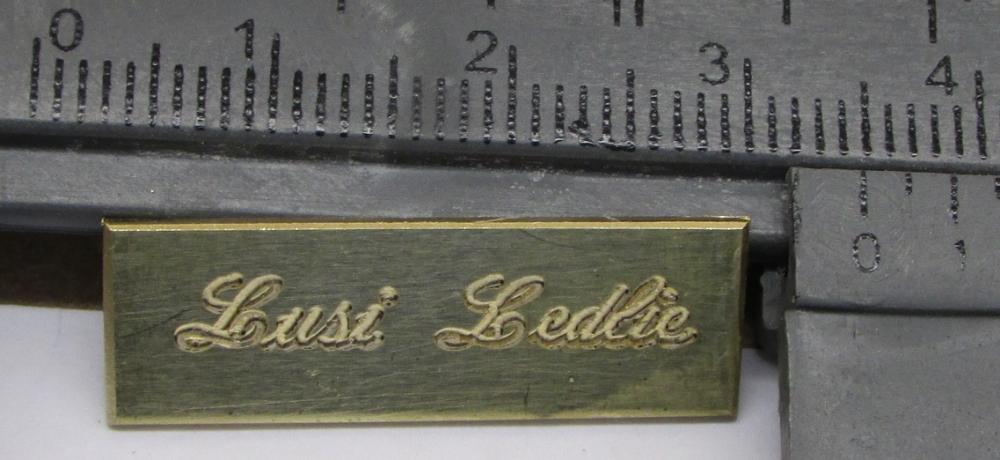

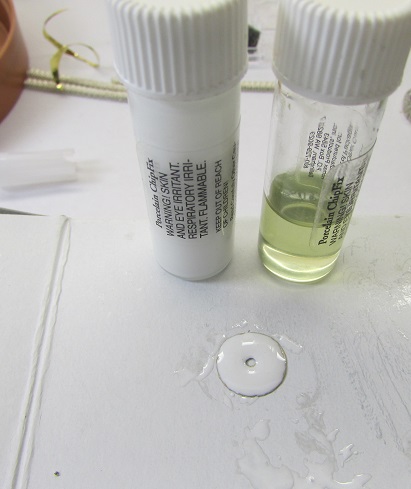

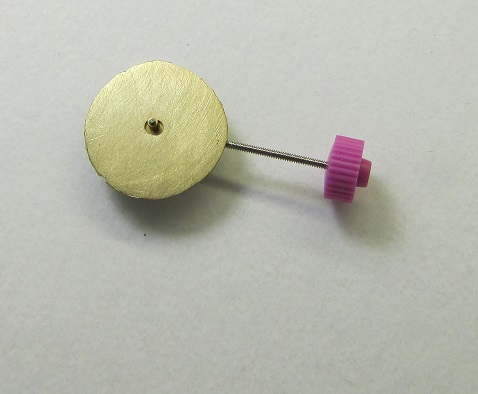

Very limited in time at the moment but want to try and do semi-homemade watches for me and the wife before the autumn ends. First day this year in the garage. Starting with the wife's as this "should" be the easier as it must be a quartz. Total hobbyist at this, and although I have a rough idea of what I am trying to achieve, making a lot of it up as I go along. Hope to share progress on this forum for anyone who is interested Dial 0.2mm brass sheet Cut out and superglued onto a brass 3mm disc (machined from 10SWG sheet) Drill centre hole 1.1mm (was going to be 1.0mm but I snapped the drill bit) Swap onto the smaller lathe Mark out the dial diameter Aldi today selling routers for £24.99. Perfect to fix an old Gravograph I bought ages ago on ebay with dead motor Test piece which will go on the watch box as a plaque. Can now do engraving on the case back of the gents watch (later project still in the head) This is movement for my wife's watch. Ronda 1042. Smallest I could find which suites what I think I will need. Beside is a 5pence piece to give scale. Had to be a quartz as winding and setting the time was an absolute no no for the user Showing with dial in position. Decided I will try to attach with dial stickers rather then solder on feet (more chance of disaster and no time to keep scrapping) Trying bath repair enamel. Will leave this for a week to set. Hopefully not too high and works ok Square lump of silver. Starting the casing 10mm hole to start things off1 point

-

1 point

-

Looks like a AS1906,1916 or 2066 to me the setting is a keyless side problem and it sounds like it needs a service if the winding is stiff don't wind it by hand any more you'll start to shear teeth if its stiff . Get it serviced.1 point

-

I think you're going to find you don't have to be that exact on this. I've attached an image to explain about the poising problem. So as you can see from the Image the lower the amplitude the greater the effect of positional errors. Then as you approach 220 positional errors are no longer a problem. Then as you go over 220° positional errors are less of a problem. This is why it be nice if your watch was always running at least 220 or higher it minimizes positional errors. As far as faultfinding goes and the amplitude has to be correct I would really like to see some examples where having incorrect amplitude prevents you from doing any of these. Most users of timing machines leave them at the default 52°. Then what about the days of the paper tape machine they didn't even have the lift angle only a paper graphical display?1 point

-

I find terminology and watch repair very interesting. Depending upon location and when whatever it is you're looking at was written we can have different terminology for the same thing. So knocking Is also called Rebanking. I have a link to a nice video which shows what it is. https://www.youtube.com/watch?v=Rcqrb3_vin8 List of lift angles http://pczw.uhren-mikl.com/downloads/gamma.pdf Timing machine information and where lift angle comes from http://www.witschi.com/assets/files/sheets/Test and measuring technology mechanical watches.pdf Then I have an image of how timing machines figure out what Amplitude is.1 point

-

Unfortunately when I acquired a timegrapher I was told knowing the correct lift angle was necessary to make accurate adjustments. JDM on a previous thread demonstrated to me that the LA has no practical significance on beat error and therefore timing. If the LA is set to 52° on the timegrapher, excellent results can be achieved in the aid of timing a watch. Always remembering most movements show a variation, according to the position the watch is in anyway. Now I tend to watch what those little dotted lines are doing, rather than what the LA is. Sent from my SM-G920F using Tapatalk1 point

-

fantastic pocket watch display case ! i am working on a key winder now. i find most of them have a broken main spring. probably from winding them with " the elbow on the bar". vinn1 point

-

Please, don't discourage people from using big, heavy watches on the wrist. We Orthopedic doctors have to make a living with expensive spine operations and if they stop using the big heavy watches it will prevent scoliosis!1 point

-

1 point

-

1 point

-

1 point

-

My situation is like yours. For a hobby i cant afford a complete set, although i am always searching for a cheap acceptable one. Currently for my 1-2 watches under repair i make my own stakes and tools. For me this process is just like as exciting as tinkering with watches.1 point

-

As pe the title, here a small comparison video of my Seiko Quartz Chronographs from the 7Txx series. Enjoy!1 point

-

1 point

-

Dear Mr. Clarkson Out of the twenty-two some watches I have in my wearable collection my three favorites are my 7T32's. The one below has a problem. I can put a brand new battery in it and follow the directions in the manual and it will work perfectly for about two hours and then promptly drain the battery and stop. I sent the watch in to Seiko America and they sent it back saying there was nothing wrong with it. I have thought about sending it back with a new battery and tell them to watch (ha ha) it longer than the time they probably spent checking it. The batteries are the SR927W and I'm at wits end. Of those three 7t's this is one I really would like to work, classic Roman numerals etc. Unless it's something my sixty-six year old eyes and clumsy mechanics fingers can fix my question to you is, do you take in watches to repair? Money within reason is no objection.1 point

-

Yes I agree, however some of us wouldn't know how to manufacture tools'1 point

-

1 point

-

1 point

-

No, jdm, not ONLY you, it is a general way of keeping things down and friendly for every one. In no way we tolerate or "untolerate" for that matter - if you allow this make up word -- counterfeiting. It is simply that we can't do anything about that, one way or another. Bigger organizations, with more means than we do have and are trying to...still no success. All I'm saying is: let us all watch the way we say things since in a friendly conversation we share points of view not attack them or indirectly other people that might not think the way we do....which by the way, our ways are not an absolute. I hope this clarify my post and by the way, I won't get dragged into this topic which doesn't really interests me....and of course, don't condone either since it interests other people. Cheers, Bob1 point

-

Ok, guys, what's the point? No one is selling fakes here. In a general sort of way, If anyone like the fake he or she owns, and wants to wear it, so be it! Wear it with pride I would agree since it turns you on! If you agree or don't agree with fakes, that's your problem, do or don't wear it. I don't think anyone of us can actually promote or stop fakes so, what's the point? Yes, thieves and illusions, it is all part of our physical existence: don't worry, in the next life they might go away! As for starting to get pushy against one another because we think different...that is not allowed. As a matter of fact, difference of opinions are a good think...what we think about other's and their opinions may be taken in the wrong way so please, phrase your points so it won't affect another member and please, give the respect we all deserve. To me, attack to others and others' ways are a big infringement and when you turn around, it gets back to your own ways too. It is just relative to who is attacking who. So, live and let live! If you need to fight, do it at home. Life is too short, so try and enjoy it with a smile. Thank you very much! Cheers, Bob PS. Just a friendly "warning" from a friendly moderator...because I particularly care about good order, friends and friendly forums.1 point

-

1 point

-

1 point

-

1 point

-

Staying American is perfectly fine, its my personal taste so to speak, there are watches that are enjoyable to work with and others which are downright horrible, but like food & music its all down to taste I love working on FHF,AS,ETA,Omega,Rolex ,Tissot, almost anything Swiss, but put a Felsa movement in front of me and i just feel like reaching for a hammer and smashing the thing to oblivion ha ha. ( me & Felsa have relationship issues ) Unless you have some good military watch books to reference and learn from i would tread carefully with " trench watches ", there are so many fakes and misleading auctions & sales for this type of watch. I see so many listed on flea bay as "trench watches " or "Officers Watch " but are in fact ladies watches. With the above aside trench or military watches can be a very interesting and rewarding avenue to pursue with a lot of history and fun to be hard restoring them. Ive done quite a few over the years and they have always been a great joy and a very rewarding area of horology. That Elgin is very very nice those hands are pure class.1 point

-

I will look for the before photos. To remove dents in a case isn't difficult, it just requires patience. Go to your Hardware store and by som nice Ash dowels. Cut them down to usable lengths 4 to six inches . Round off the ends of the dowels into smooth shapes sort of like a baseball bat. Smooth the end down until its very smooth so you don't do any damage to case. Now using only your hands push the dowel down on a dent & twist over and over again. soon you will notice it is starting to go away. As I said slowly and carefully Twist Push. Keep checking to see you are not doing damage."(NO HAMMER" just kneading. You can experiment with different shapes and sizes. o see what works best for you. I have one with a pad on one end to keep from hurting my palm. Also make sure the case is on a hard smooth surface or you will engrave whats on that surface into your watch case. I have had great results doing it on four watches including a very small ladies Elgin Pocket watch.1 point

-

1 point

-

Hi guys, My cousin learned of my interest in watches and passed me our grandfathers wristwatch. Its a nice hand-wind Mido, probably from the late 50s or early 60s...oddly a hand-wind. I say oddly as Mido made their name with their automatic watches..starting with the bumper 917 movement. It was probably in the middle range watch at the time going by the fact it has a stainless-steel case, with a Gold Bezel (not too clear in the pic above). It also has a dust cover which is always nice to have. It has a pretty large case tube as well. Back in the day there were many methods to achieve a good crown seal and a large crown tube allowed a large o-ring to be fitted inside the crown. The fact that the crown was missing is not really a problem.. many a watch has had the crown or crown/stem come off and been put away and forgotten in a drawer but the brownish stains around the center of the dial is not good. With the movement out of the case..you can see the brownish stains clearly. It comes away easily so it could be just some oil-residue (heres hoping!) so I proceed to remove the hands. If rust is present, removing the second hand may result in breaking the tip of the seconds pinion.. here I use my Bergeon hand-puller, make sure I keep the tool straight and press (to pull). That went well but....... ...In the picture below you can see the tip of the seconds pinion..and a lot of rust coloured 'stuff'. I'm starting to get a bad feeling about this. off with the dial and..... This is one of the worst case of rust I have seen..I pretty certain the screws will be pretty stuck but then again it may be so bad that I'll be able to break them while they're still in the screw holes..! Anyway this is as far as I'll go for now. I'll keep and eye out for a replacement movement.. this one is marked as a Mido 1020 which is basically a Peseux 170, not too rare so I'll be shopping for one at the right price. I may try to save the balance cock and barrel and train bridges to retain some of this watches identity but we'll see how that developes... the click screw seems pretty screwed too. One thing I just noticed is the cock for the centre-pinion is missing and someone substituted a spring. .. ah well, in for a penny... The only thing making this watch a viable project is that it has a stainless case, the dial and hands are usable, the movement is a fairly common one and lastly...the personal link to my grandfather (who passed on 30something years ago. Anil Drag files here to attach, or choose files... Uploaded Images Mido.jpg 103 kb · Done dust cover.jpg 115 kb · Done dialside.jpg 87 kb · Done1 point

-

1 point

-

1 point

-

So I finished this build...mostly! I'm thinking of it as a "proof of concept"... I decided not to do anything to the dial other than drill the markers at the hour marks, larger markers at the 12, 3, 6 and 9. This actually proved a problem after I remounted the dial and noticed that because the centerwheel pinion is off set from center, the minute and hour hands don't quite line up with the markers...not a huge deal though! Having said that, I think the dial looks Wonderful as it is! The simple dial/ markers really complements the "Busy-ness" of the skeleton movement. I also had to turn a back "Dial" to make up the difference of between the size of the movement and the size of the exhibition back crystal. This picture looks "deformed" but actually was taken at an angle to capture the best light. All in all, It will be something I do again now that I have an idea of what problems can and will arise when combining parts that were not designed to go together!1 point

-

1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)