Leaderboard

Popular Content

Showing content with the highest reputation on 07/16/16 in all areas

-

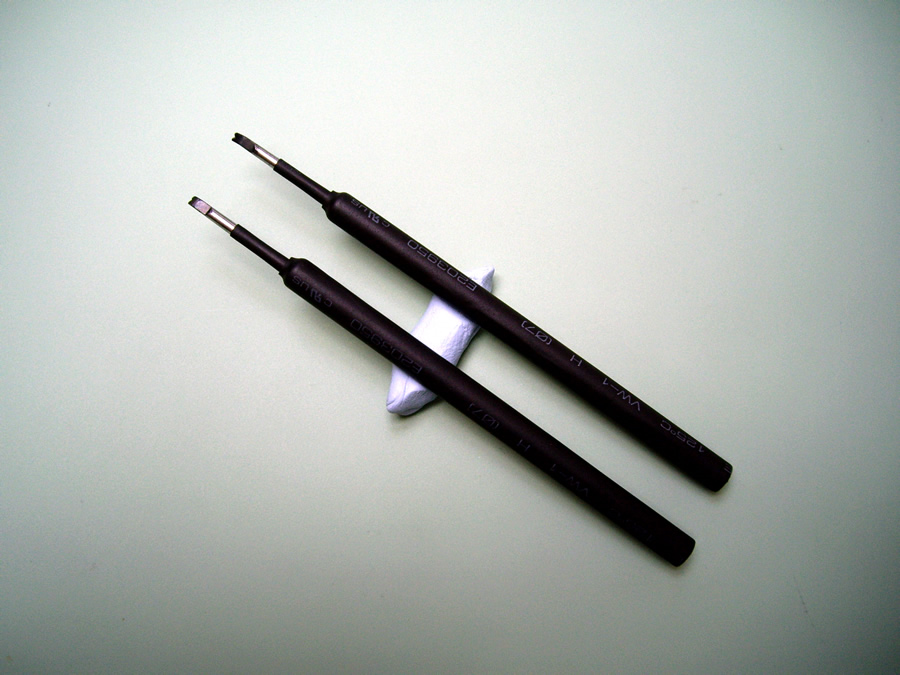

Now looking better after I finished them. I used some 3mm ID aluminium tube and secured the tips in place with epoxy resin. Then finished off by covering the handles and part of the tips with heatshrink tubing. I'm well chuffed with the result. Hint: another alternative steel for the levers is to use a small allen keys ground into shape, and make some suitable handles.2 points

-

Being a bit of a elgin fan I'd give it a go but from the photos there seems to be a few parts missing would you be able to find them and cheap enough the 761 usually commands a high price when running and cased I know ive watched a few slip out of reach because they left my price bracket its not a cheap watch. The 761 had the durabalance which some people hate and others love because of its uniqueness but some people say its unreliable because the little weights can't be poised correctly. I would have to give it a try at least to bring it back from the dead.2 points

-

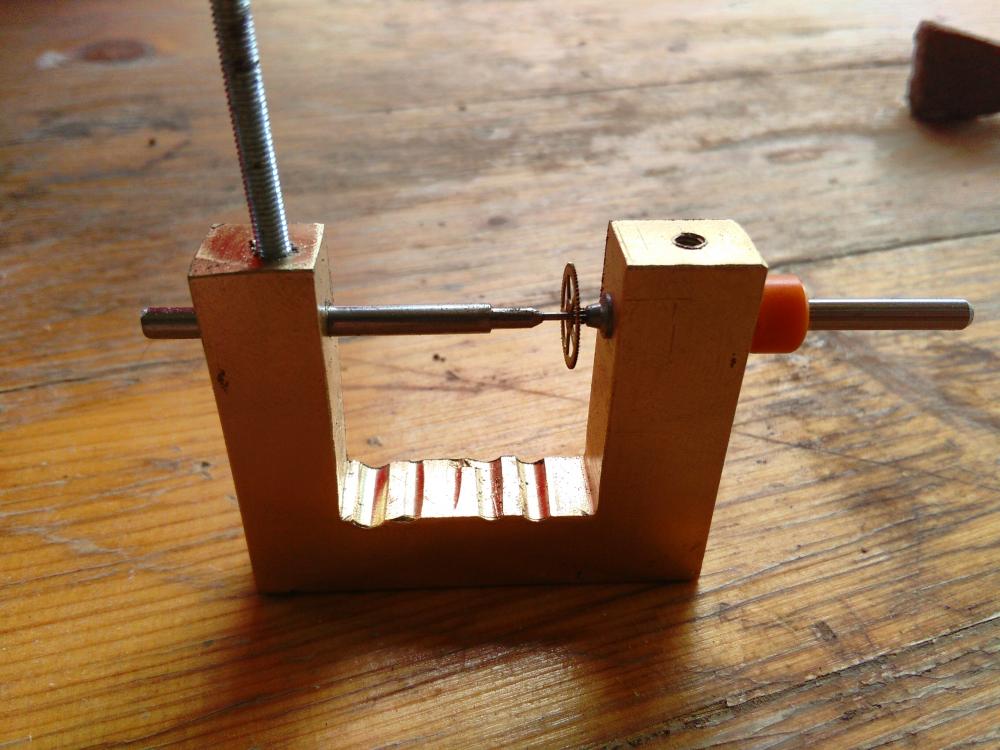

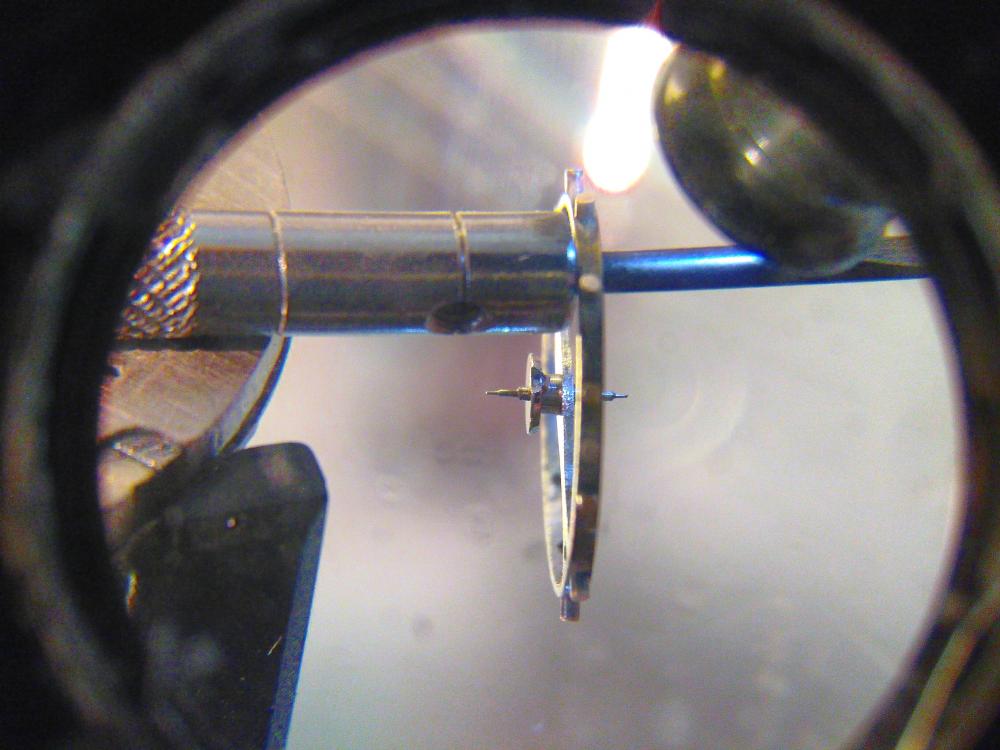

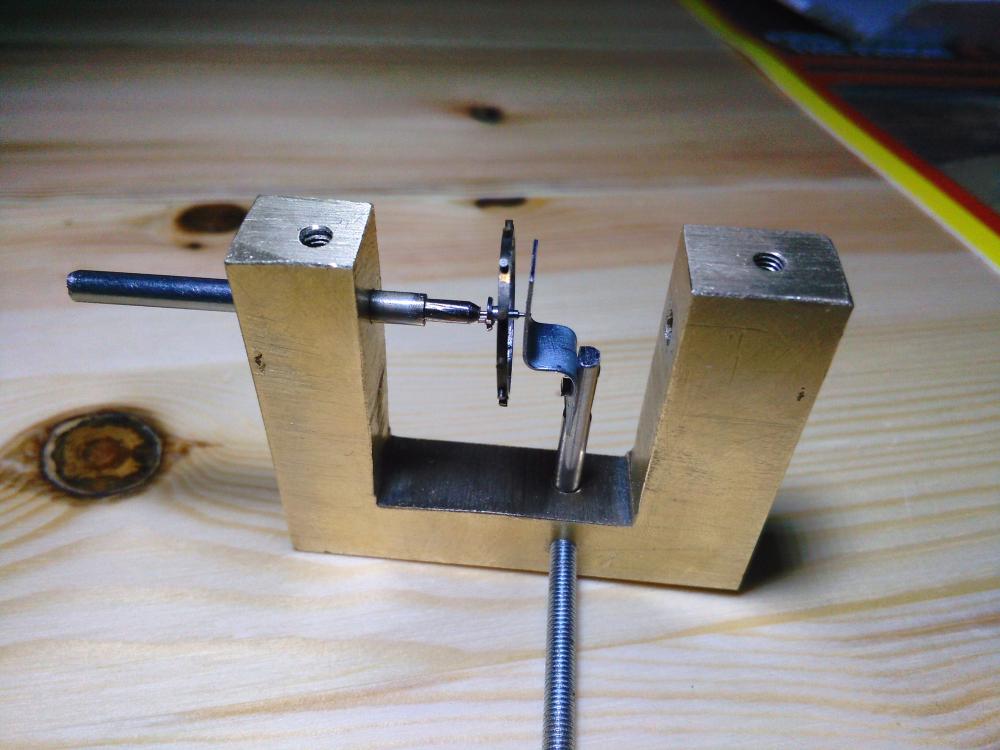

To many watches are waiting the wonder (somehow getting new pivots or staffs) disassembled in the shelf in small boxes. So i decided to put every other projects aside and make a pivot drill. First, the dimensions of the tool were determined after measuring pictures found on google Damn is it tiny! 50x40x10mm brass was drilled through with 3mm drill on a table drill press. The middle was sawed out to leave 10mm and 12mm wide headstocks. The hole on the 12mm side was reamed to 3.175mm for the carbide microdrill shank diameter. Female cones from 3mm blue steel with 0.4mm hole at the end and from 5mm steel with 0.5mm hole were turned on the Dremel and ER20 "lathe" respectively. These holes are for the current gear staff to be drilled but i will need a series of cones later. Well, its ugly yet, i know But the drill cought right the center. And now you can guess if i have big collets to turn the pulley wheel :/1 point

-

I was just getting ready to give my collection of pocket watches their annual wind and I wonder why we ever progressed away from them, very sad really Sent from my SM-G920F using Tapatalk1 point

-

I recently completed work on the timepiece that actually got me interested in watchmaking. I purchased the movement (in pieces) for a vintage Omega Speedmaster a few months back and have been diligently working on putting it back together. It was a pricey endeavor but what I've learned from the experience is invaluable and having the watch ticking away in hand at the end of the project was reward enough. I picked up the movement in February and knew it was missing some parts. I counted the minute recording wheel and hour recording wheel as bits that were missing but also couldn't locate the minute recording pawl and pawl bridge. It turns out they were inside of the semi assembled movement but unfortunately I didn't realize that until I had already ordered replacements- oops! Included with the movement was the front case, hour, minute, and sweep second hands, and some spare parts the previous owner had acquired. He warned me that the watch hadn't worked properly before it was disassembled but I had confidence that I could sort it out. First thing I set to do was assemble as much of the movement as possible to determine what else was missing and what may be broken. It became apparent quickly that there were many screws gone! There weren't many parts missing other than those I've already noted but I did manage to lose the click spring when it shot away from my tweezers. I've since become more adept at dealing with wire springs and don't attack any of them without two hands. When breaking down the movement for cleaning I discovered that the chronograph blocking lever screw had been broken off in the plate. Extracting the remains of the screw from the plate was actually easier than procuring a replacement screw. I placed the plate in a solution of alum and warm water over night and the screw was eaten away. The steel posts and eccentrics in the plate I protected from the alum with silicon caulk which I later removed with a bit of pegwood. After cleaning, I began reassembling the watch but was stopped short when I discovered the mainspring barrel gear teeth were damaged. I replacement was ordered straight away. Now I was ready to assemble the movement. I made sure to inspect all jewels and pivots before putting the gear train together. And I was rewarded with an exceptionally well beating movement. This was a relief since I've spent more than enough time on my previous projects straightening hairsprings, truing balances, and correcting beat errors. Next the chronograph layer came together. This takes quite a while since there are so many bits to lubricate and test the motion of before moving on to the next bit. Also, with so many screws missing I had to stop several times to order replacements. Below is the movement prior to final adjustment. A screw is missing at the top and the chronograph bridge screw isn't correct but it gets the job done. I discovered that the previous owner had already procured the missing hour recording wheel so that saved me a bit trouble. And the dial side came together quickly. The hour recording wheel is turned directly by the barrel and the blocking lever wasn't set properly before I put the dial on so the hour recorder creeped which required me to go back and remove the dial and re-adjust the blocking lever. I'll remember the importance of that adjustment the next time I do a chronograph repair! I needed to purchase a replacement dial and a full set of hands as well. I could have reused the hour and minute hands that came with the movement but since they were scuffed and faded and wouldn't have matched the other four hands I sold them to pay for a whole new set. It's not something I regret though because with the new dial and hands the watch looks about good as new. The case I had was missing the caseback and pushers but I found a gentleman who was selling the case (with pushers) and caseback together so I purchased the lot. I also procured a replacement dust cover since that turned out to be missing as well. No point in doing a job unless it's done right I suppose. And there you go! I'm quite happy with the result here. It was expensive but I now have a complete and fully functioning Speedmaster. The chronograph worked without a hitch and the watch has kept impeccable time too. It took quite a long time to get this one together but the patience has really paid off. I really love working on chronograph movements and am hoping to do a Venus or Valjoux soon but my next project is a bit more eclectic- a Cinderella watch by US Time from the 1960's! This will be my first pin pallet service. (excitement!)1 point

-

Hello All, Just a quick question here. Had a older Seiko watch that is totally rusted and the cell look like it leaked also. I've been looking to see if i could get a replacement movement for it. But unable to get a 5Y39-4120 from any of my normal suppliers. caliber: 5Y39A size: 10.5 stem 351-670 battery: 371 function o. SC-D(3) hands 0.65x1.10 would a VX39 work as a compatible? caliber: VX39 size: 10.5 stem : 354-531 function SC-D(3) hands: 0.70x1.20x0.20 Not sure what the hands size would mean and not sure what 0. sc-d(3) vs sc-d(3) under function means I did call Seiko and they said they to see if i could get a replacement moment from them but they said they don't sell movements but did have it in stock if i wanted to send it to them and then get a quote. Was kinda odd since I've always gotten parts from them before crystals/stems/crowns and so on. Any insight would be great Thank you Mkay1 point

-

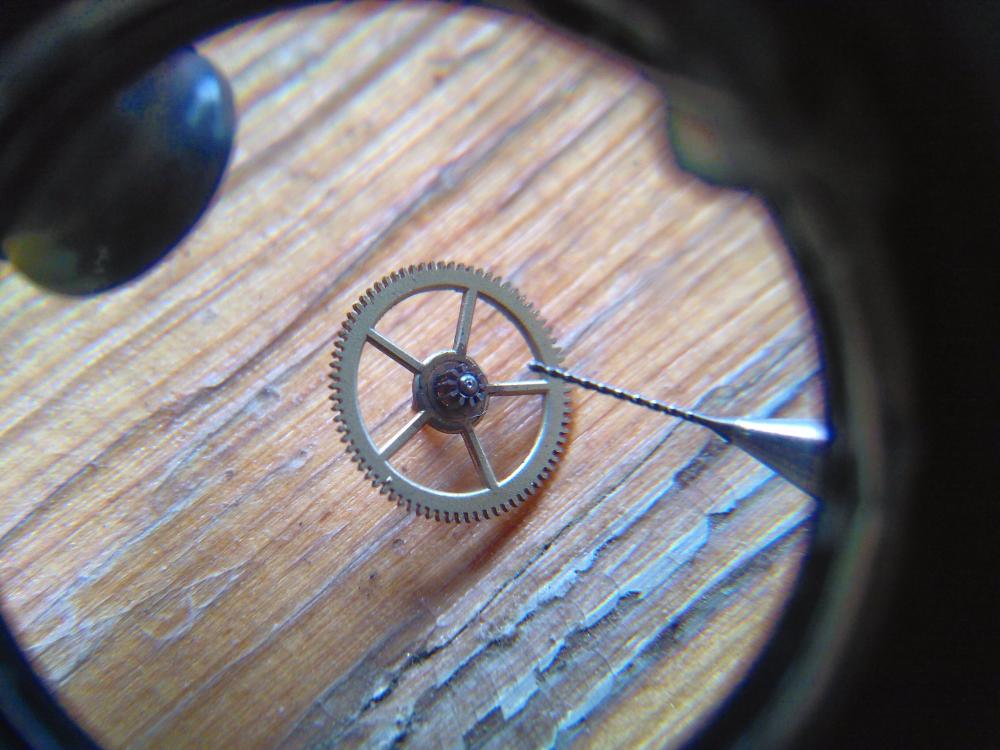

Oh boy took it long to grind down the pinion to correct length... But finally it has basicly no endshake and spinning freely. Quickly added the hairspring and watched it swinging and swingigng.... https://www.dropbox.com/s/1ejz57v9cv2j3cm/2016-07-14 15.11.36.mp4?dl=0 The wheel is not true. This is becouse i was not carefull and started drilling without shaping a proper cone end on the staff after grinding down the broken drill. So the second hole was not centered. Since the video i have trued it to some extent. The roller jewel however broke off when the balance fell off once from the tool accidentally It has oval impulse pin so it will be hard to replace. maybe a new jewel grinding job... we will se The left pinion is the new one.1 point

-

Catch of the day ! On a boot-sale / flea-market these two sturdy old veg-tanned leather bags, complete with patina. With dividers and various thicknesses of leather. Back-sides are flush leather; 33 x 43 cm.....ample length and leather for Nato-straps or any other model (even a new wallet). These two bags set me a stunning £5 (top) + £4 (bottom) = £9.- in fiat money back, but a huge saving on real full grain veg-leather Very happy with my today's market stroll !!1 point

-

After releasing the shock spring, I use a jewel picker that I purchased from Amazon for $2.50 to remove the jewel. Usually the endstone and the hole jewel are stuck together due to the oil. I usually place the attached jewels into a small jar of cleaning fluid (I typically use a hairspring cleaner like Onedip) and that will normally cause the jewels to separate on their own. You can find the jewel picker here: https://amzn.com/B00K7KEN6K You could also use some Rodico to lift the jewel out of the watch. Another way to separate the jewels would be to place the whole setting, endstone down, onto a piece of Rodico. The Rodico will hold the endstone down - you can carefully lift the setting off with tweezers.1 point

-

I think that if there's something well outside the reach of the beginner/amateur restorer is tampon printing. Have you ever done it?1 point

-

luckily for you you have an image of the dial before cleaning, so it would be relatively easy to re-print it. Best results are with tampon printing (youtube is your friend, there are some movies) but you would need some tools first. There is another option to sent it to company which does dial restorations. Just make sure they will do it in the same way as it was, I know that sometimes dials are looking good but are little different than original ones (like font change etc.). This things happens to best of us :). Generally metal dials are pain to clean, I usually just brush them as anything you do to them will fade numbers one way or another and it ends up in full restoration.1 point

-

I'm always amazed by peoples creativeness. A watchmaker/repairer thinks to himself/herself you know what I need to drill holes in a staff to fit a new pivot what shall I use. Oh damn there isn't a tool I know ill draw one up and have it made incredible1 point

-

Lovely job it may have been expensive on parts but look at the end product. Something that was dead and buried has now been resurrected and given a new lease of Life very well done indeed.1 point

-

A very nice resurrection of a great watch. There is something particularly rewarding about starting with a box of bits, not even sure that you have everything, and ending up with a fully functional and complete watch. When it's as desirable and collectable as this it's just the cherry on the cake.1 point

-

Added the pinion-end polishing feature to the tool After finishing the plate (0.4mm thick) with 0.1, 0.15 and 0.2mm holes quickly mounted one balance with one broken pinion. The broken end is on the left side. Recognized that the healthy pinion is barely sticking out of the hole so cones with small drills were made in the plate sinc the picture was taken. Now a decent part of the pinion is sticking out on the other side of the plate. I can change the hole size by adjusting the plate height Yes i have to make the plate narrower and those screws are from a watch so need to make some screws here. And some nice looking M3 screws with good looking heads for tightening the cone rods.1 point

-

Yep, they said it would happen if you didn't use the tweezers correctly, and they were right. Today I was reassembling a pocket watch and when I tried to wrestle the smallest screw I've ever seen (jewel retaining screw as per the attached photo) in my life back into its home, it flew across the room and landed somewhere in the deeps of the shag carpet. I'm going to Lee Valley tomorrow to buy a 150 pound magnet (nope, the magnet only weighs about 10 pounds, but it can lift 150 pounds - hopefully it will manage to lift the world's smallest screw). But, I don't really expect success in finding it, which leads me to my question of how does one go about building up a selection of fasteners for such an occasion? I perused suppliers websites and they don't really sell selections of screws, only specific things like case screws, etc. I realize that after a few years of working on watches, there'll be loads of spare parts accumulating from the unrepairables, but for a rookie like me, that's not an option - yet! And on the subject of screws and fasteners, did the industry standardize on threads? For example are all Swiss movements standard, albeit small, metric? How about the great American pocket watch manufacturers of yesteryear, did they use standard imperial threads or were the threads specific to the manufacturer? I imagine now that the watch movement world has gone over completely to metric, which makes sense, but is that actually the case? Actually, as a suggestion, it would be really nice, and worth at least one beer, if someone knowledgeable would write up a little overview on fasteners, especially screws, what to do if a screw is lost, how to remove a broken screw, how to repair a damaged thread, etc. Actually, that's at least two beers worth of work. The weather's lovely at the moment in Edmonton, and the good folks from Fort McMurray are finally being allowed to move back in after almost a month - it's a good start to June.1 point

-

I feel your pain, we have all been there searching for that one screw/click/arbour/shockspring( you get the point ). Whilst practice with tweezers is something acquired with time it is more important that the said tweezers are in a good state ( or simply put, sharp , no, infact very sharp ). From my experience sharp, well maintained tweezers can save at least 50% of the " omg im flying mum look at me weeeeeeeeeeee " scenario. As a personal tip, when dealing with very small screws or shock springs, i use a silicone tip stick to pick up the parts rather than tweezers, simple tool but with good practices in disassembly/assembly you reduce the odds greatly ( not always though.........damn you pesky inca springs ) MrBeat1 point

-

1 point

-

In this profession expect to spend plenty of your time sweeping and searching the floor, looking in clothing and God knows where for flying parts, some turn up right away others in a few weeks and some never.1 point

-

I think there's about 50 springs etc hiding in my carpet. I now do my watch work in a different room that has laminate flooring, alot easier to find things. I also use a magnet and my 16 year old sons eyes god knows what I'll do when he leaves home1 point

-

I remember one year ago when started tinkering with watch movements had to find the incabloc spring three times in the carpet That poor cheap chinese guy survived all my noob attempts and still working. I wish You luck to find it!1 point

-

To better pick up screws you can get sheets of rubber magnets. Another thing is one of those magnetic knife racks...but wrap in white paper first to make it easier to spot your part. Finally get rid of the shag carpet....if you drop something nonferrous your screwed. Anil1 point

-

Excellent advice from Anil. I would also recommend a cheap, working Russian movement - Raketa, Vostok, etc. to play with. They're generally cheap'ish and quite rugged. A small Molnija pocket watch is a nice size to play with as well. And, while I'm banging on about it, don't disregard Indian HMT watches. There are lots of them on eBay, they're basic, standard-style movements, and it doesn't matter if you crash and burn on them!1 point

-

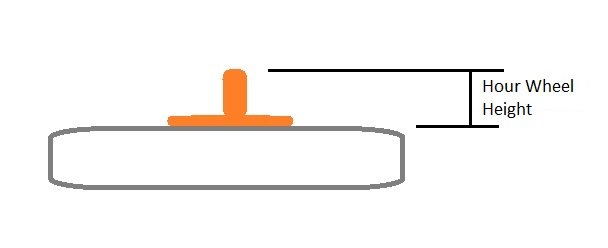

Hi Sdancer, and welcome to the forum I hear what you say a lot where I work, and it's hard to be brutally honest to a client who's spent sometimes over $1000 dollars on this type of watch, without getting them very upset. But on this forum, and on all my threads I want to help and inform people who have taken the time to visit Watch Repair Talk. With that being said, here's the response to your question. These type of watches are classed as "Fashion" watches. They are commissioned by different brand names: yours being Esprit, and they are pumped out of factories in China with only cosmetic input from the brands they represent. The true production cost of these watches are around $15-20 per unit ... no I am not joking. The movement in your watch is a Ronda 762 (2 hand), which cost about $4-11 dollars replacement cost, depending where you source the replacement movement. So unfortunately your assumption that this is a " famous quality brand" is not factual when it comes to watches they make. Personally I despise these avarice companies that play upon people's lack of horological knowledge, and the simple fact that you can't see the cheap movement inside, to make profits margins in the THOUSANDS of percent. These cheap Ronda movements are still very accurate, do their job keeping time, and are exceptional value for money; but they are built to a price point, not to a quality point. Some run for over a decade without any problem, whilst other fail in months ... it's a little hit and miss with a complete movement that costs less than a cup of coffee. The good news is that they are very easily replaced Simply buy a new movement off of ebay, or someone like CousinsUK. You need to measure the Hour Wheel Height of the movement (as seen below), or it may have a large number stamped on the back which is the height number, ranging from (1) 0.95mm to (5) 3.15mm. Make sure you get the correct one or it won't fit inside your case. Once you have the movement, remove the watch hands, gently lever the old movement off the dial (it is only held on with fiction fit posts) install the new movement and replace the hands! Even if you have to buy some hand lifters, it will only cost you around $25 to put a brand new movement in your watch. I hope this has helped, and you are now much better informed when next you purchase a watch .... also we are always here to offer advise and help even when it comes to choosing your next watch1 point

-

Thanks a lot Marc for the walkthrough Hopefully, in a few weeks I get my new diver, different dial as the "Diver Dude", but that has to do with special memories.... 2415 movement, I believe is the same a the 2416B, but without date. I also understood that the movements are interchangeable in the case. Obviously, the this dial is not going to work with the date-version, but ample customization options seems also to be a strong point of this watch Can't wait to have a peek inside.... very excited1 point

-

1 point