Leaderboard

Popular Content

Showing content with the highest reputation on 07/15/16 in all areas

-

Have been wearing this one the last few days. Old photo to save photobucket space [emoji16]2 points

-

I recently lost my Dad who was a life long horologist [2nd generation. He ran a family watch repair business which grew to the largest in Phila. and served as the Authorized Service Agencies for many of the top brands like Omega, Ebel and Movado. Our family all worked at the shop at some time on our lives -- me every summer from age 8 to 18. Losing Dad has somehow lit a spark and I find myself going through his wide collection, changing batteries, doing small job repairs and discovering some unique time pieces he had collected but never really shared. I feel his loss but also his warmth as I fiddle with these watches. I know the basics but look forward to finding answers to some of my questions and attempt to repair some of the partial jobs he put away many years ago. Here is an example of a gem I found in running condition......how cool is this piece from the mod 1800's? Thanks all in advance. If only he had found this site in his last years .... he would have been an incredible wealth of information. Steve1 point

-

I could not single out any one brand as there are so many that have both good and bad points but currently im enjoying working with Seiko movements/watches. Ive repaired my fair share of American pocket watches but i simply dislike their methods of construction/design and cataloging of parts ( especially when trying to find parts ). However with repairs and servicing aside i do like the look and finish to some US Pocket Watches, so its not all bad I used to have 40-50 pocket watches in my collection, mostly Omega or JLC but now all i have left is a Cyma/Tavannes Pleaide, it did seem fair to not use them so i passed them onto collectors who could love them. Hopefully your Hamilton will provide you years of enjoyable service1 point

-

It is hard to tell via the vid but it does not seem to have a very good amplitude. Is the mainspring winding fully without slipping. Just a thought.1 point

-

1 point

-

1 point

-

I was confused when I saw the term "tampon printing". Then I realized that you were referring to "pad printing" Must be a translation thing. Yeah, there are hand machines available that are not too expensive, but like any printing, it seems to be as much art as science. So, I haven't tried my hand at it yet. I may try someday.1 point

-

Following on this - if you do as clockboy suggests, when you give the watch a few winds and the train starts to spin, watch the escape wheel very closely. When the power runs down and the escape wheel stops, it will typically reverse its direction for just a very, very small distance - maybe 1/4 of a tooth. This is a good indicator of adequate gear train freedom.1 point

-

I've seem this one before. I liked it when you first showed, and still like it now. Its a great looking watch. JC1 point

-

There are many, many reasons that this could happen... If you are certain that with the balance removed, the escapement is functioning adequately - all around, meaning all 15 teeth have passed through both the entry and exit pallets, I would certainly look closely at the balance assembly. It would also be helpful to see a timegraph of the watch as this can sometimes reveal lots of clues. What kind of amplitude are you seeing when the watch runs for about 30 secs?? o Jewels seated properly, spotless endstones, oiled approriately o Balance staff pivots not damaged o Hairspring true in the flat and the round o Watch set in beat o Guard pin clearance - having the pin rubbing on the safety roller is a good way to stop the watch o Back to the pallets - proper lock depth, run to the banking, etc o Roller jewel seated perfectly - not tilted or loose o Balance staff seated properly - balance not loose and rubbing on any components o Hairspring not catching on center wheel, etc o Balance poise I'm sure I'm missing much!1 point

-

+1 CAD101. I've had a couple of these in the past and in both cases they were one piece stems Like CAD101 said the way into these is to remove the crystal and hands, and then lift the dial off (no screws for the dial feet, they are friction fit into the movement for this specific reason) to get access to the keyless works. You can then release the stem and withdraw it.1 point

-

I hadn't realised that the bezel was still in situ. As CAD101 suggests try working a (single edged) razor blade in between the case and the bezel where I have indicated below until it is wide enough for a case knife, then using a case knife just pop the bezel off. With the movement clamps removed as I suggested earlier the movement should just come out the front.1 point

-

Looks like a removable bezel to me try a razor blade along the joint to start it off then a sharp case knife.1 point

-

When the words use key whatever appear on tissot watches they are front loaders the tricky bits removing the stem so you remove the glass hands dial and and look for the setting lever between the date ring and the outer case where the stem enters the case lift it a little with a small driver and the stem should pull out.1 point

-

i did not know denture cleaning compound was sugested to clean any thing ; including dentures! BUT if the watch owner knocked your teeth out, you might figure it out! vinn1 point

-

No, sorry if I seemed harsh in my posting. Time ago I cleaned off five of the minute marks on my Mom's $30 Casio. She's a cataract patient, but the day later she said "I kinda recall there was something more on it"1 point

-

Hello all, It is definitely John Masgreave, he married Elizabeth Harlow in St Oswalds Church Ashbourne on 22 June 1807. Elizabeth was the daughter of Samuel Boulton Harlow another Clockmaker. they are on my family tree. Cheers, Vic1 point

-

The Polydent technique is a good one which works well but only for enamelled dials. Yours is a printed dial which is much more fragile. You could try water slide transfer paper for your printer and print a new seconds register, or have the dial professionally reprinted. Otherwise look out for a replacement1 point

-

A little off topic, but since you mentioned dining tables - here are a few shots of mine - which I crafted from this reclaimed 9 foot section of bowling lane. 2.5 inches of solid maples for the first 7 feet. On the left you can see the "splice" where it transitions to pine. The arrows are inlaid walnut. The engine crane I needed to lift this -- the wood weights about 350 pounds. Lots of sanding and finishing: The extruded aluminum base - weights 120 pounds And the finished product:1 point

-

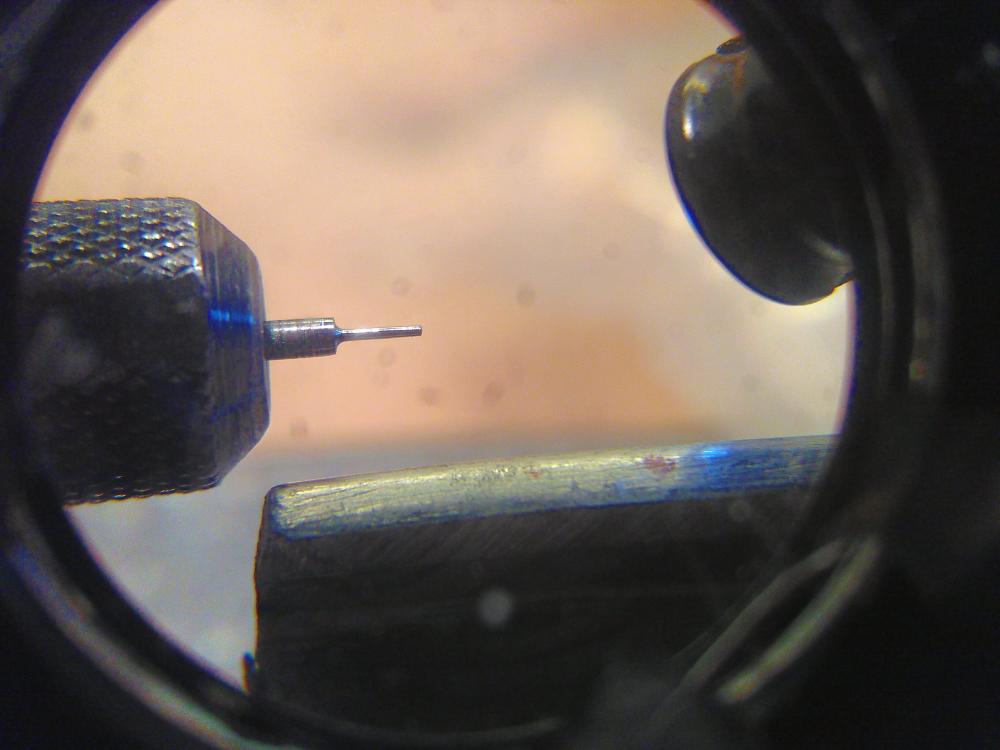

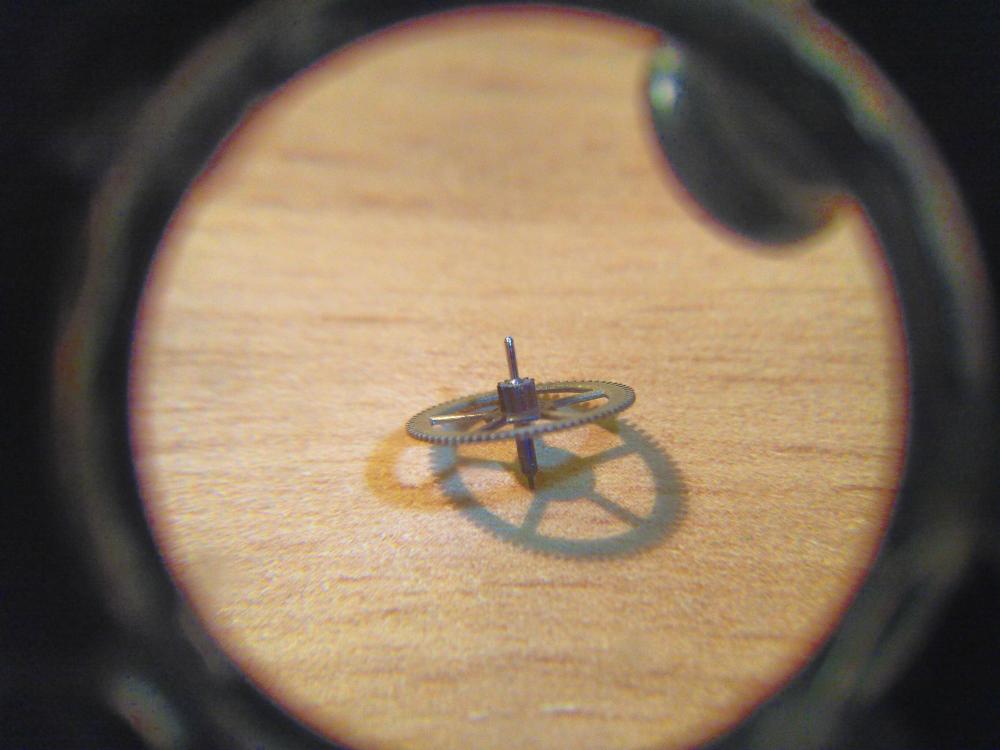

Using it as a staking tool Driving the 0.4mm pinion turned in the Dremel "lathe" from a 1.5mm HSS drill bit into the predrilled 3rd wheel staff. The pinion succeded for the 3rd try. The first one flew on Earth's orbit. The next one was caught with a nylon bag but it was too thin. The first repivoting in my life Now i need runners for pinion burnishing. This is the back of a broken 1/8 carbide drill. Tapered, drilled with 0.4mm and i will grind it down to half. The final pinion will be 0.27mm.1 point