Leaderboard

Popular Content

Showing content with the highest reputation on 07/06/16 in all areas

-

4 points

-

Hello, I have just joined the forum. My name is Deborah Bell and I run a mechanical watch and clock museum with my mother, in Haltwhistle Northumberland- 'Mr George's Museum of Time'. The museum is based around a series of children's stories which my mum wrote about her father who was a watch and clock repairer in Northumberland- the 'Mr George the clockman stories'. My mum became a repairer herself and has a huge collection of watches, clocks, tools and parts so we decided to bring everything together so children could learn all about mechanical "proper" time and Mr George, and adults could look at the collection and reminisce. She still repairs both watches and clocks now and has her workshop on our museum premises! Hope to chat to a few of you on here!3 points

-

It is a 8day 5 pillar Longcase Clock, known as a Grandfather Clock. It has rack striking and an anchor escapement. The movement is almost complete, its missing the bell and nut, two pulleys, pendulum, dial, hands, seat board, screws to hold the movement to the seat board and case. A five pillar movement puts it above as just being ordinary. One other thing about this one is the escapement is set quite low down the train. It has been repaired in the past as you can see on the inside plate for the pallets, this was undertaken a very long time ago as you can see by the colour the brass matches. The makers name would have been on the dial. We can still put a date to the movement by looking at the pillars and they tell me 1660 to about 1740 and it most likely had a brass dial, I can't see all of the hour wheel pipe but what I don't see is a pin or a protruding type pin so this tells me it didn't have a calendar therefore I expect the brass dial would be 12inch square. The movement has recently been cleaned and the screws polished.3 points

-

3 points

-

I he ain't at all bad is he he's a wealth of important information. Although I'm amazed he can remember anything with a name like oldhippy all those psychedelic drugs an all2 points

-

Absolutely stunning! I lean towards these designs quite often, beautiful!!! (I'll need to keep my eyes peeled for one) Today, this is what I have on (past two days too, lol)...60's Helbros that had to be re-cased. The original was corroded and lost half the chrome plus it had a Square UFO, which was kind of odd for such a nice dial. This worked better IMO, very pleased with it!2 points

-

Looks like an old long case movement circa 1860. The barrels are not fusee as they are not tapered. They are scrolled to receive the gut cords that the weights hang on. One for the clock and the other for the chimes.2 points

-

2 points

-

It has been a long time since I made a mistake or found myself crawling around the floor for a flyer but today I had a wake up call. I was in the process of assembling a Valjoux 7750 & hit a snag. When testing the keyless side I noticed that on the third position of the stem the setting wheel & the Intermediate setting wheels were not engaging correctly. At first I thought I had put something back wrong or perhaps I had fitted the wrong wheel for the setting wheel. I fiddled for a long while & I stripped back to find the fault. To my horror the stop lever (hack) end was twisted. What must of happened when I assembled the barrel & train wheel bridge the stop lever must have slipped & gone under it and hence it was stuck & restricted the movement of the sliding pinion. Luck has it parts are still available. Lesson learn't always check the stop lever is free to move before assembling the keyless side1 point

-

Oldhippy you are just the best! I am in awe of your knowledge in this area. I wish I had this level of expertise!1 point

-

You should certainly not apply heat directly to the roller as you can damage it. In Mark's video he uses a simple brass bar - something you can pick up for a few dollars. I suppose you could use the soldering iron to heat the brass - but that doesn't seem too efficient. You can either pick up a cheap alcohol (spirit) lamp or even use a pocket lighter to heat the brass. As far as the gauge - you can use some assorted solid copper electrical wire to find the correct size. If you know the wire gauge, you then know the diameter which should be enough to source a jewel. Can't hurt to try. If you have a micrometer or caliper set you can use any wire or pin and measure that.1 point

-

Hi Hokavan, there is a big market / boot sale type of affair in the large square in central Geneva (near the Patek Phillippe museum), on a Saturday morning. There are quite a few second hand sellers of watch parts, and also some watch tool stalls selling new tools. Definitely worth a look.1 point

-

1 point

-

1 point

-

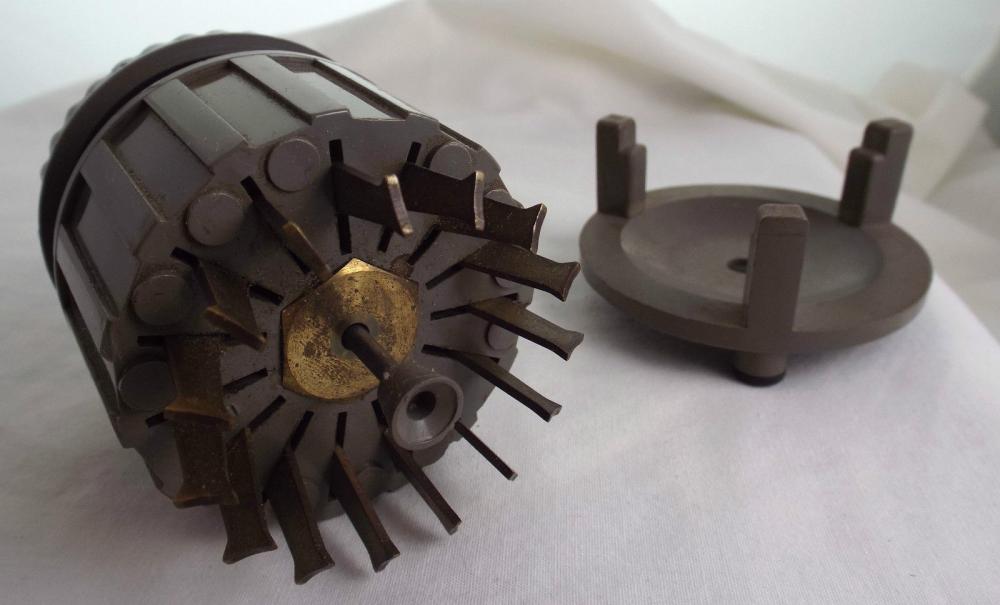

It worked. Mounted the tool in a vice. Sent from my iPhone using Tapatalk1 point

-

Hello from me. Plenty of good info on here for you so have a good look round.1 point

-

Glue would work BUT if any real- positioning is required then you will be snookered . The quickest way is normally the correct way1 point

-

Thank you. Microscope is pretty good. Info here: https://amzn.com/B00A1ZSRH2 Camera not so great, but I regularly use the microscope for certain operations such as oiling endstones and pallets. Also great for close parts inspection. Just takes a bit of getting used to. I wear eyeglasses, so I constantly need to flip them off before looking through as they bump into the eye hoods. I believe they make a special hood to address this but I haven't purchased.1 point

-

1 point

-

1 point

-

1 point

-

I haven't been much around either and wow, stroppy! Not one surprise I will miss! I'm glad you are recovering and are back with us. Just take it easy and don't stress much.1 point

-

1 point

-

1 point

-

you want to have enough fluid so it comes up to the basket's lid - completely submerging the contents - when the basket is in there spinning. but not so much that when you're spinning off the basket, you're still in the fluid. you look like you have just about enough in the video; maybe another 1/4-1/2" or so? if the vortex spins the fluid out so that the central area sinks too much, if that makes sense? when you have the level figured out, make a little mark on the jars. use a grease pencil or paint marker. cleaning fluid will take the sharpie right off...1 point

-

1 point

-

Well it is on its way, a refurbished L&R Master all rewired new bearings and ready to clean. I hope I get good service out of it for a number of years to come.1 point