Leaderboard

Popular Content

Showing content with the highest reputation on 04/22/24 in all areas

-

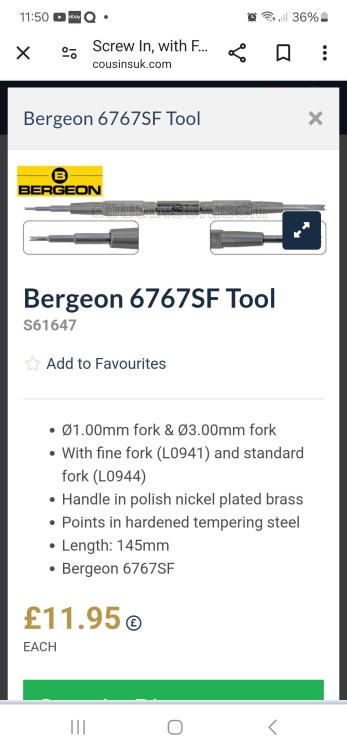

Just a heads up that the CousinsUK branded replacement forks and pins fit the Bergeon tool and look/feel exactly the same. I damaged my Bergeon one and found that the replacement Bergeon parts were almost the same price as a complete new tool, so I decided to try the cousins own brand version. Out of curiosity I tried the fork and pin in my Bergeon tool and found they were exactly the same, and to buy the CousinsUK replacement parts individually is far cheaper than the buying a whole new tool. Hopefully is will save someone some pennies!4 points

-

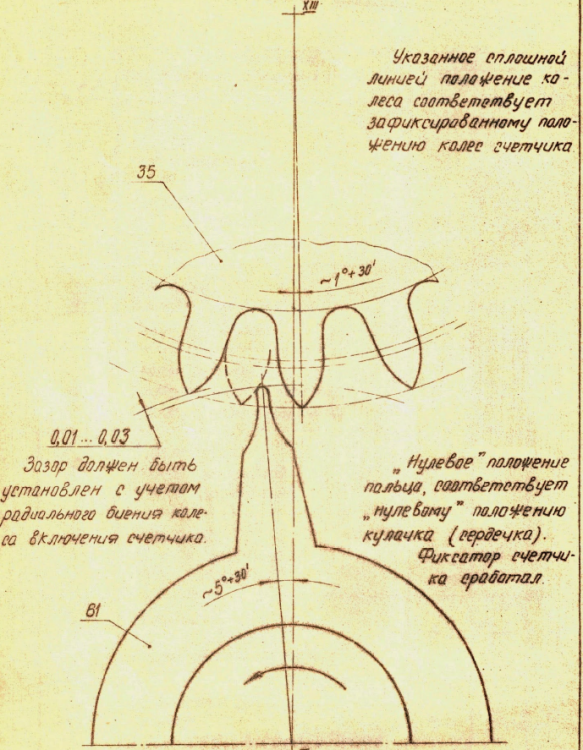

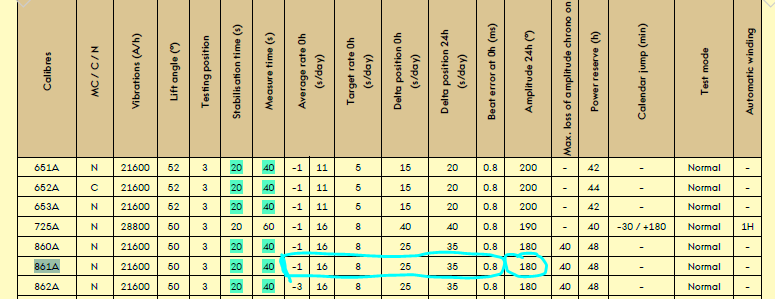

Hi guys, I wrote a set of five lessons for my second year students regarding the Landeron 248 chronograph watch, which incidentally we are meeting tonight. They are going to be polishing pivots and pinion leaves of their 248s, before putting the movements through the cleaning machines. This is number one of five. I posted number two of five the other day HERE There are seven eccentric studs on this movement, so understanding what the studs do, how to set them, their actions and interactions with other parts of the chronograph mechanism is vitally important. I found there is very little out there on the internet to help understand the principles of these eccentric studs, especially video content to show various faults and alleviations, so I put together quite detailed walkthroughs of various complicated movements usually consisting of 15 to 18 hours of learning/servicing in the workshop per movement/module With any watchmaking, especially with complicated work, only make one adjustment and measure the results, if any. Be methodical in your approach. The lesson was originally in PowerPoint and I had to convert it to PDF to post here, so a lot of the video content won't play, but the PowerPoint version is in my cloud storage here. https://docs.google.com/presentation/d/10KJJ58P0v2BglKZSilIv9o69xBsbrQPI/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true You'll need quite a newer version of Microsoft Office (PowerPoint) so the video content will play, otherwise it won't. I hope you find this lesson useful and begin to get a better understanding of how to set eccentric studs. Sometimes you'll come across a stud that is too loose, or even too tight. Usually if one is problematic it will be because it is loose. This can't be left, as the stud will turn whilst the chronograph is stopped, started and reset, throwing the chrono mechanism setting off which could lead to the movement grinding to a halt. Don't fool yourself in thinking it will hold. Either a replacement stud is fabricated to suit the enlarged hole, or the hole can be closed up. In turning and setting the eccentric studs prior to disassembly of the movement, we are able to set the chronograph mechanism, especially the minute register mechanism correctly and test for any faults, such as a bent wheel over fourth arbor, or incorrect depth of the dart tooth with the sliding gear, or a mis-set minute runner jumper spring, to name a few possible faults and mis-settings. Also in turning these eccentric studs we can gain a 'feel' for how tight they are in the mainplate or bridge. The more they are turned the more the chance of the stud becoming looser increases. So once set correctly prior to cleaning, the less chance they will need setting once the chrono mechanism is assembled, only if a stud isn't tight enough in its setting in the first place. This is for setting Landeron 248 eccentric studs, but once an understanding of their uses and actions is gained through theoretical aspects together with practical application, then this skill and knowledge can be used in most vintage chronographs to set their eccentric studs and even in modern timepieces where you'll find very few eccentric studs, such as an Omega Speedmaster or Tag Heuer Calibre 01 chronographs Enjoy! Lesson 22. Landeron 248 Chronograph.pdf3 points

-

Funny enough, I'm working on an Omega pocket watch which has an amplitude of over 300 and I'm planning to use 9415 to bring it down. So far, my experience with this "wonder-grease" 9415 has been rather poor, especially on older movements. When changed the oil on the pallet jewels / escape-wheel to Dr.Tillwich 1-3, which would be about the equivalent of Moebius 9010, the amplitude gain is remarkable. Try that ..... And as JohnR725 asked, what is the amplitude after 24hrs? My 50-years old Omega 861 runs 250-255 at best when fully wound, around 215-220 after 24hrs. It gains every day 1 second, day after day, week in, week out. Perhaps not an amplitude "high-flyer", but It's the best time-keeper I ever had!2 points

-

I opened it too, and can asure that it is good and thorough. I can add something little for the minutes counter adjustment (will use the terms from this presentation) - sometimes is prefferdd that the T-line will be slightly tilted as to alow little bigger gap between the the tooth A and the dart tip, and the gap of C tooth is reduced to almost 0, as shown on the picture (from manual for 3133) Also, there is one more option, offering the same result as the changing lenght of the dart or slope of the hammer head - this is changing the position of the heart on the minutes counter wheel. Sometimes just turning hte heart upside down changes slightly the wheel position and thus one can choose the better between the two. Then, the heart position can be totally changed by making new hole for the screw that fixes the heart2 points

-

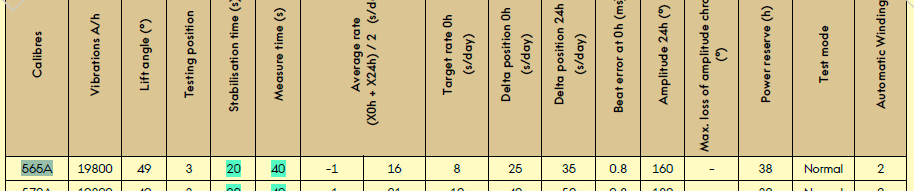

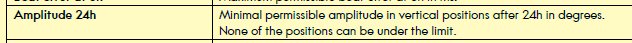

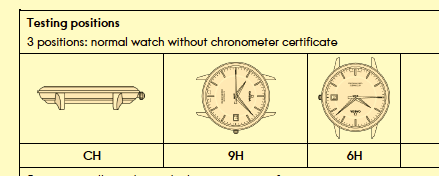

Typically for this group anything less than 300° is unacceptable. What's interesting is the Swiss Do not pay attention to this group at all. Swiss are more concerned about timekeeping than they are amplitude. Then thinking about timekeeping I don't suppose you can show us the watch in perhaps three positions on the timing machine? Like dial-up and dial down And crown down would be nice it often helps for diagnostics Oh and thinking about amplitude I see your timing machine is 52° and according to the specs you're supposed to have 49° so that will cause a minor change of the amplitude. Than very very disturbing for this group so I would suggest the old-timers run away and don't even look but amplitude at 24 hours for this watch is 160°. As I said the Swiss are only concerned about timekeeping. So at the end of 24 hours you have 160°. Then the definition of amplitude at 24 hours is Then they three position as an Omega uses for timing for three position watches like yours is found in the image below although I would still make sure you do dial-up and dial down because those should be identical and other good diagnostics do that Then thinking of lubrication what sort of lubrication's did you use and how did you lubricate the escapement?2 points

-

I started 2 1/2 years ago. Watched Mike on Myretrowatches to learn about Seiko and tried Sekonda on my own. Mike and others, including Wristwatch revival who even this week, recommended Mark Lovick's course. I Obtained 1,2,and 3. Not looked back. See my posts. (6 month, 12 month, 18 month and 2 years) I still consider myself a novice but can do a basic service. Chronographs are still on my horizon. The best thing I did was join Mark. It was after a short time of doing the course that I joined this forum. I did not feel that I was good enough, or could converse well. I have dyslexia. This forum was the next best thing. Whilst I still do not feel able to to stand with the greats, they actually spend their time and speak to me, offer advise, very rarely criticise, and even then offer constructive comments without rancour. Oh! believe it or not, I am still on level 3. I have done level 2 a number of times and will do the same with level 3. I can now understand what level 3 means. Watchmaking. WatchFix. Good to go. Value for money. In my opinion. Yes. Will I do level 5? Yes, but I've given myself to the end of my self imposed apprenticeship of 5 years. Same as my engineering apprenticeship in 1964.2 points

-

2 points

-

That endshake of the barrel arbor is huge! That needs closing up. I'm assuming the barrel cover has been bent in a convex way to create that excessive shake. Put the barrel cover on a staking block and check how flat it is then bend it to suit a better endshake1 point

-

1 point

-

Oh yes. Both of them. Pdf document and PowerPoint in 'Office Libre'.1 point

-

It could be that the amplitude is higher than your Timing Machine shows. In my experience, TMs unfortunately don't always show the truth. Try to increase or decrease the gain on your TM (if it has one) and see what it does for the readings. Or, you can try to mount the movement holder on the microphone to decrease the noise from the movement which in my experience is necessary for Omega calibre 268 (the only Omega calibre I've serviced). You might find this post and other posts in the same thread interesting!1 point

-

You've replaced the mainspring with a new one? 48 hours after oiling the train and pallets can increase the amplitude dramatically. I serviced a vintage Omega 552 and saw an increase of about 30 to 40 degrees after two days.1 point

-

or this? https://www.ebay.co.uk/itm/186193866558 All three for under £15. I feel the need. The need for... mini lathe1 point

-

Hi Looks like a pin. Looking at the removed pusher at a guess I would say I pushes up from th inside with the spring and the button is then fitted the pin acts as a stop, pure guess work.1 point

-

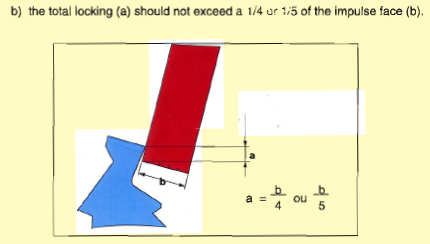

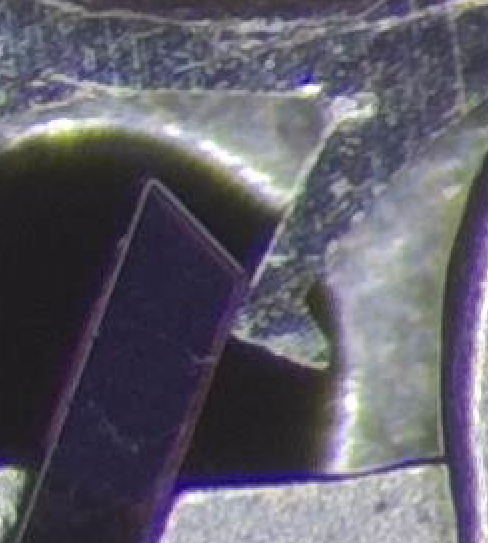

It's actually quite amazing how much amplitude you can lose if you walk is too much like yours is in the picture. Technically the pallet fork should be light as possible to move really fast. But shellac isn't overly heavy. I would be more concerned if you had too much shellac and it was rubbing on something. The problem with rules are there so many of them and it also depends upon the construction of the watch. Then we have other rules like this The problem with your image is if you measure carefully it looks like your lock is about 50% which is much greater than it's supposed to be. How does it compare to the other side? Then out of curiosity how did you lubricate the escapement?1 point

-

Are the timegrapher results you show immediately after re-assembly/lubrication? If so, these numbers often improve after 24-48 hours (20-50 degrees) as the oils and parts bed into their respective positions. Hold you nerve and re-test after 48 hours on a full or near-full wind an you may be pleasantly surprised.1 point

-

Hi are the pusher heads made of brass, if so you could soak the broken one on alum solution to dissolve the steel portion if all steel then it’s a no go and probably as @RichardHarris123said replace the whole pusher. Place to start it’s Cousins uk, material supplier. one could also drill it out ,but that would need precision drilling not to damage the thread and the pusher.1 point

-

Another option that is becoming popular is to get new watches from Ali Express or other similar site, some for <$10 each (see examples below), they are often Chinese clones of popular Swiss movements, so you are learning useful movements, not some strange movement you will never see again. The primary advantage is that you are starting from a known starting point, ie the watch works, if you service it and it doesn't work or works less well, then you know you messed up (and vice versa). If you work on a scrap non-runner and it doesn't work after your service, was this your fault???Also if you buy 3 of the same type, if (when) you loose a part you can use one movement of the 3 as a donor and still have 2 working movements to practice with. The short answer is yes, but you will have a lot more misses than hits when starting out, simple things like handling twee zers, knowing how much to torque on a screw, which springs will ping away..... this comes with practice, so use cheap movements before you take on anything of sentimental or monetary value. Hope this helps Here is a popular youtube watch repairer servicing an Ali Express/Temu/Amazon watches, and he echoes much of what I mentioned above:1 point

-

Hairspring looks OK. What else to check - all the usual stuff ! Endshake in barrel arbor, not too much play in arbor bridge hole. Check gear train runs freely, end shake on all gears and balance, jewels dirty/damaged/loose(pallet/roller), too much tension on centre seconds spring etc etc How long does the balance swing (no pallet) when given a blast with a puffer?1 point

-

Yep, I have one of those too. Got mine from Cousins (now discontinued). Yes, a total waste of money! That is 100 % my experience as well. If I were a pro with daily use of a tool, perhaps by several people, I would definitely go Swiss. When buying tools I always try to get used Swiss tools if I can find them for a reasonable price, and if not, I go Chinese.1 point

-

Got the time? I found this on YouTube. Made of wood. I'm looking forward to getting a mini lathe and to cut my own wheels would be a bonus. I intend to try to make one of these. Fiddly but fun https://www.youtube.com/watch?v=axQCooNSmiw Hope this helps1 point

-

Thanks guys, will give this a try. I have some piano wire on order. I've never replaced one of these, should be fun1 point

-

My son donates his broken guitar strings and I use them frequently for making replacement springs - as long as I can bend it to the right shape I get good results.1 point

-

Hi. You can build a diy tool for about £30. That is every bit as good as the $250 job look for. Wesley R Door on the net. AWCCI MEMBER and Horological Journal contributed, Or failing that. Dirk Fassbender who did the same. I built one no problem, simple and easy to use not had a failure to date in use.1 point

-

1 point

-

You can buy standard 2.5mm endmills, which should fit the 2.5mm reamer holder, if that is a collet fitting? eg. https://www.cutwel.co.uk/2-5mm-4-flute-k2-coated-carbide-end-mill-g9432-series-yg-1-g9432025 Just be sure it's a type like this that has the same shank and cutting diameter - many small ones have 3mm shanks for such as Dremel tools.1 point

-

Thanks for the PDF lesson. I've never really considered the effect of changing length on spring force - I've always focussed on primarily matching thickness (remembering bd³/12 from old structures lectures), and accepting 20-30mm difference in length only effects power reserve. I hadn't considered it changed the strength. But, as you point out, the effect on strength is not great - a quick search online revealed little, but I found this from David at vintagewatchstraps https://www.vintagewatchstraps.com/mainsprings.php Effects of Length If you can't find a spring that is close in length to the one that you want, can a longer or shorter spring be used? The theoretical torque generated by a spring is inversely proportional to its length, but this supposes that the spring is free. In a watch barrel, many of the coils of the spring rest on top of one another and friction between them must come into play. But if it didn't, then a spring that was say 380mm instead of the 360mm you really wanted would be in theory 5% weaker. By the time friction has also had its say this is negligible. Even a 400mm spring would be only 10% weaker in theory and less in practice. This is less than the difference between fully wound and 24 hours later. So there is quite a scope for using springs of lengths that are different from the ideal. It is the thickness of the spring that is the most important factor, which is why it is often called the "strength" of the spring.1 point

-

I have a cheap version of this been using it for nearly 3 years now. Works fine, i sometimes reshape the fork and when i past reworking i fit another fork insert. I try to save the pennies with cheap general tools that add up to the pounds for the real goodies. Everything takes time Michael, you take it steady. Bet you cant wait to start setting up, I have a new room planned its been on the gonna list for ages. One day . Watch the recip saw and fibreglass spells , a grinder does the job but you will get covered in fine fibreglass dust if thats what the tub is made of.1 point

-

1 point

-

I have said this before and repeat the BHI has researched this subject and published their findings. Overall the biggest difference between the Chinese and Swiss tools is the quality of the materials used. So for an amateur the Chinese tools are OK but I have found the build quality is not as precise as the Swiss. Also for example I had purchased for me a hand lifting tool.See link below; the pusher just did not align correctly so it’s very fiddly to use but works. https://www.aliexpress.com/item/1005004261155255.html1 point

-

1 point

-

The watch is automatic, but hte automatic module on the picture is missing. All the problems that You are afraid of actually are not problems at all. The only thing that You must take care is when pressing the seconds hand in place. You must then support the movement by the stone of the 4th wheel (in the center of the movement) in order to prevent shifting of the stone.1 point

-

See, what has happen is a normal consequece of the reducing the hammer size and changing it's shape by the removing metal from it. But here the hammer is adjustable and just adjustment is needed to correct, and this is what You have done. There is a rule for the adjustment and it is that the hammer must lay firmly on the seconds counter heart and there should be a litle free play in the same time of the minutes counter heart/hammer which alows counter movement of about 0.5 min on the small dial hand (+/- 0.25). Of course, there is no way to make one hammer to delay from the other, as they are one single part. What has changed too is the slope of the hammer head and thus the orientation of the heart has changed, and thus the switching finger position. This led to need of the finger position correction. The rule here is that switching of the minute counter has to start when the seconds counter hand is on '59'. Of course, the seconds hand must be positioned as so the resetting is at '0' exactly. If switching is earlier than 59, there will be no problem, but it will be wrong as reading can be not correct. If the switching starts later, the problems that You described can happen.1 point

-

Never and others. Yes, like you I do spend a fair amount of time reading the contents of this forum. I find it better that any other. Clear, lucid, no Prima Donas, and most of all an easy access without adverts. All thanks to Mark. God bless you mate. You give so much to many of us. What if? No Mark? Hypothetically. A forum. I did run a forum for a few years. Really enjoyed it, but became so engrossed that it did affect my health. I gave to to others to run. Not been back. It was very successful and rivalled a number of large paying sites. No adverts, no others but me. I did ask and listen to members comments and it worked well. Costs Having a domain name, £10 annually. Register the site with a forum company, free. Build the site using the forum company guide lines, free. It looked and ran almost the same a Mark's. All the same facilities. The cost was only £5 per month, but counted visits (views). If I recall, it was that price for 5,000 views. Each extra 5,000 views increased the price by £2 per month. Success was my own personal undoing. From £5 per month initially, it rose to £60 a month and looked like increasing. This was 10 years ago. I could not afford that, and asked it anyone would like to take over and someone did. I would assume that this is the price that Mark is funding for us all. His return is our continued comments on the internet about his course, and the fact that many of the big names on YouTube mention him as their Tutor. Those of us who have done, and are still using, his course, benefit. In comparison to other courses, I can't believe how cheap it is, and the value is exceptional. It is the structure that gives the value. Long may Mark reign. Ross1 point

-

This forum is a big part of my life. When I retired from horology many years ago due to poor health I missed what I had trained for. On here I can still do my bit in helping and advising others and have a little fun as well.1 point

-

Before putting it back in the case I would fit the hands and use a pin vice on the stem to make sure the hands were in line.1 point

-

1 point

-

Tips for how you can minimise the risk of pinging parts. Make sure you have a decent set of well-dressed tweezers. When you're new I'd recommend a new Dumont No.2 or Dumont No.3 (Fine Tips). Those are well-dressed from the start and don't require maintenance for many, many years unless you abuse them. Finer tips than No.3 increase the risk of pinging parts. When gripping a part never use more force than is required to hold it without dropping it. When moving the part keep the tip of the tweezers as close to the work mat as possible, and always try to minimize the distance the part needs to travel. Practice this by placing some small parts on your work mat and then moving them around to designated places on your work mat. You can also scratch up the insides of the tip of the tweezers for improved friction between the part and the tweezers as shown by Kalle Slaap here. However, be extremely careful not to overdo it as it will risk creating a gap in the tweezers. Don't ask me how I know! Relax! This is more important than anything else and something we talk too little about. Relaxing is especially important when we're doing something which we perceive as difficult like replacing a tiny, stiff spring. In those situations, we tend to become very tense and that's when disaster strikes. Relaxing physically and mentally is something we need to practice but once we get it we can say goodbye to shaky hands. You have to honestly ask yourself "Am I relaxed?" If the answer is no, close your eyes, take a deep breath, and relax. Then repeat the question until you can relax no more. Be especially watchful of your shoulders. Try to relax them as much as possible. If we don't relax watch repair can become exhausting and in the worst case can kill the interest. On the other hand, if we learn to truly relax it becomes meditative and extremely enjoyable. BTW, did I mention the importance of being relaxed when working on watches?1 point

-

1 point

-

One more thing I’d add to the excellent list by nevenbekriev, check that you haven’t accidentally switched the top and bottom endstones of the balance wheel. The endstones are sometimes of different thicknesses, and switching them can cause end shake problems that can result in a watch that won’t run dial down. Hope that helps, Mark1 point

-

Voltage on the probes is no constant: it depends on the connected resistor. In fact they output a current, no voltage. Important: voltage across the coil under test must be lower than about 1 V, else the circuit can spoil the result. Therefore special watch testers. The lower the test result compared to full range, the lower the voltage on the resistor/coil under test. If you test a separated coil, no Fluke or other meter can damage your coil. Fran1 point

-

Just a minor clarification here about less? If you look at the above Omega documentation they also cover how much oil to put an pivots. But to make the point more clear I'm attaching an image from Rolex something they used to give to their students. If you look at older documentation or even when I was in school that conflicts with the image attached. The definition of too little would've been an acceptable amount. The ideal is almost unacceptable for too much. Then the unacceptable is still unacceptable. If you look at the Omega PDF attached above basically you have to Be able to see the top of the pivot otherwise you have too much.1 point

-

I use my ipad and take pictures as I go, working in the reverse order as the reassembly progresses I also group the pieces in separate areas and, once completed, take a picture of the completely stripped watch parts. I do that just in case bits get mixed up or, heaven forbid, lost! It's no use relying on the "oh, I don't need to take a picture of them bits, I'll remember what I have just done and where they go." No, you won't! And chances are, if you are unsure how to do something..................you'll try the wrong way first and use up a lot of frustration and time in the process. The problem with that, is the frustration never runs out and is self replacing. (Unlike a nice pint!) I also keep most of the pictures to use as a reference.1 point

-

I just use a compact camera. There's no secret to it. What I find an absolute must, is to keep the sub-groups of parts together and photograph them. Then, If anything gets mixed up or goes missing during cleaning, I can get it back in the right group, with the right screws.1 point

-

Hello, I'm an expat watchmaker in Switzerland for the last almost 2 decades, been in a lot of prototyping in that time but the last few years doing a lot of vintage repair and restoration. I've been enjoying Mark's videos for some time and hope I might be able to offer some advice here and there but am mostly here to learn.1 point

-

So if anyone is interested, I made the print-outs for the box lid (at least for my version). You can fin bellow the pdf and the editabler corel file. boley3.pdf boley3.cdr1 point