Leaderboard

Popular Content

Showing content with the highest reputation on 03/30/24 in all areas

-

LOL, good luck with that. It's really just an example of the golden rule -- whoever has the gold, makes the rules. Is it any surprise that huge swaths of people can be convinced of a deep state shadow government conspiracy or whatever terminology you want to use to identify a corporate consumer rule under the guise of the "free" market. If you truly want absolute freedom, then you must accept that people (and corporations) have the freedom to do the absolute worst without regard to others. Oh, but try to force companies to behave fairly then it's an attack against rights, liberty and quite possible your mother. For the most part your average voter gets more upset about a controversial call during a sporting event that has exactly ZERO impact on their daily life than they do a foreign trade policy that has the potential to price them out of the market for certain goods or impose restrictions on their profession. It's no wonder that the western countries tend to vilify Chinese manufacturing. They are scared of a country with capacity and capability being able to serve the world market and not play by their rules. Now, I am not saying I approve of the "rules" that China or other countries play under, but play they do and have been winning in many respects. And that winning comes from the defensive western posture of attacking the competition rather than improving your product, service, price or process. Let's not forget that Rolex, Swatch and Richemont are essentially a marketing companies that absorbed well-known brands of obsolete technology and turned them into fashion and status items. And they did it exceedingly well. The general watch-buying public holds the belief that if you have a Swiss made watch from an iconic brand you are somehow better than the person with the drug store Timex regardless of the fact that a $20 Casio is more accurate than a $100,000 Patek. Omega, Rolex, Longines, et. al. of the mass produced luxury watches bring some of that elitism to the masses. The harder you have to work to get that luxury, the more elite it makes you feel, which is ironic since it is the "elites" that get blames for what's wrong with everything. Swatch is protecting the Brand and not the quality, craftsmanship or value, hence the disposable Omega moon swatch or the 50 fathoms monstrosity. The more elite and restricted it seems the more people will stand in line to throw money at them.5 points

-

Certainly all the big high end makers haven't supplied parts in many years. Swatch will provide parts if you meet certain requirements, and for a professional those actually aren't that hard to meet (certain equipment, training etc.). Richemont forget it. For a long time Rolex would supply parts to professionals who met their requirements for training and equipment. Then those requirements became harder and harder to meet, and finally they just stopped supplying to any other than Rolex dealers (who still had to meet the requirements). But they actually put in place a service network of their own during this time that works (pretty) well. Other makers tried to cut off abrubtly and suddenly "factory" service took 2-3x or more than before. I do kind of get that they want to control the quality of service. But ultimately even they often mess up- I have seen and repaired the results (from upset customers who absolutely didn't want to send it back again, even under warranty). Geez 25 years ago Patek would sell you parts! Not long ago I made a ratchet wheel for a fairly recent JLC perpetual calendar; customer had dealt with JLC before and waited like a year or more just for the watch to go back again, wait again. They were happy to find someone who would/could do it. But it's nerve racking work: if any part is lost or damaged, which can happen any time to anyone, woo-boy. Mechanical parts I can make, haha, but a scratch on the dial or something is another story. It actually makes more sense for car makers to restrict at least some of the parts- I was a mechanic as a very young man before watchmaking, and I've seen stuff on brakes, suspension, etc. that were definitely from a shade-tree mechanic and a definite safety issue. But you can get whatever you want and do the work however you want on your _____ car.5 points

-

i would like to add # people that have more money than sense or have more stupid than money #4 points

-

@VWatchieis correct, once bought the product is yours, whatever the product is and therefore you should be able to do as you feel fit.4 points

-

In my opinion, manufacturers should be obliged to sell parts for a "reasonable price" to anyone. If I own a product I should be eligible to handle it in any way I see fit. As the owner of a product, you should have complete control over it. When it comes to safety issues, like with cars, there must be an independent inspection authority. Simple as that!4 points

-

For a year or so I was a member of the management team of a manufacturing company. One of our main suppliers was to be replaced and a contract was signed with the new supplier promising unchanged quality, lower prices, and faster deliveries. I strongly suggested that we retain the previous supplier for a transition period to ensure reliable supplies so as not to risk our good reputation. My proposal would mean lower margins during the transition period but I firmly argued that it would be worth it in the long run. Our CEO opposed my proposal and I was eventually fired from the management team because I refused to be a yes-sayer. The new supplier did not live up to its promises with quality degradation, delivery delays, and dissatisfied end customers. In the end, it became significantly more expensive to change suppliers and eventually the previous supplier gained renewed confidence. Of course, it is critical to always be prepared to make changes, but there are good and bad ways to do it. A good start is to eliminate greed and dreams of a higher profit in the short term.3 points

-

This is where our right to repair has been removed. If you can't access the parts then you can't repair.3 points

-

Thats kind of reassuring and i bet makes most of us here feel at least a little less incompetent I was thinking maybe more of us should start learning to make parts, some of the simpler ones at least.3 points

-

We all know aliens roll up the windows and lock the doors when they pass by this planet. Even Klatu rolls his eyes every time he recalls his last visit.2 points

-

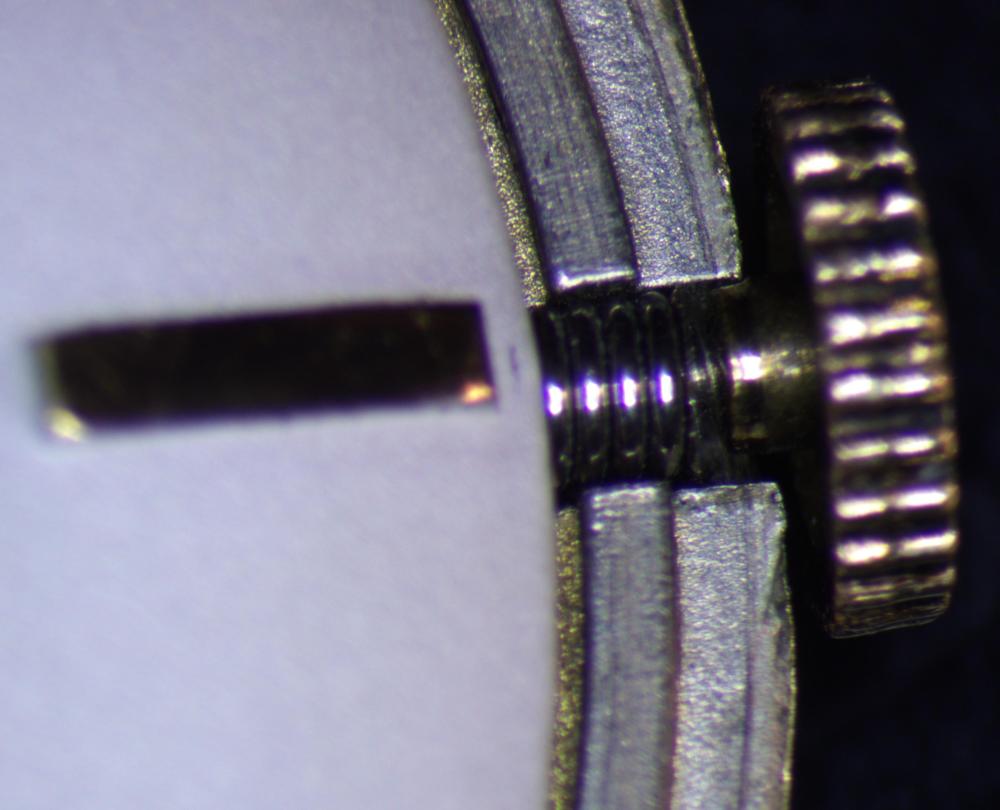

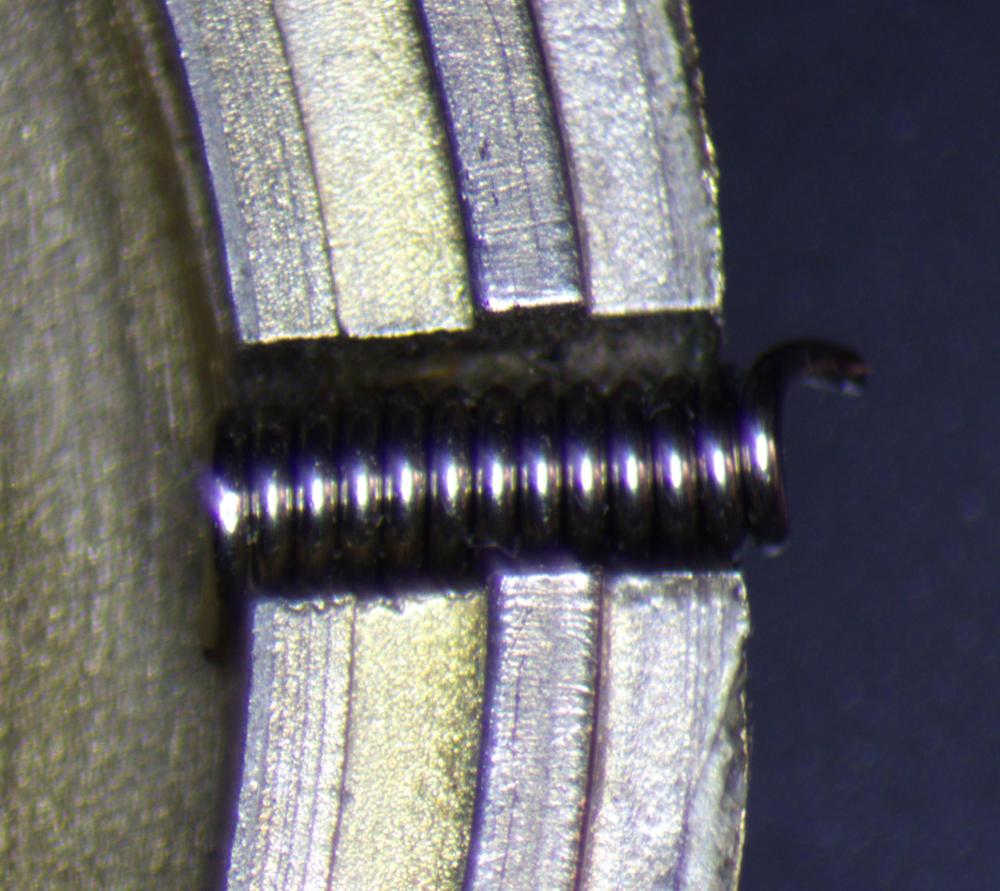

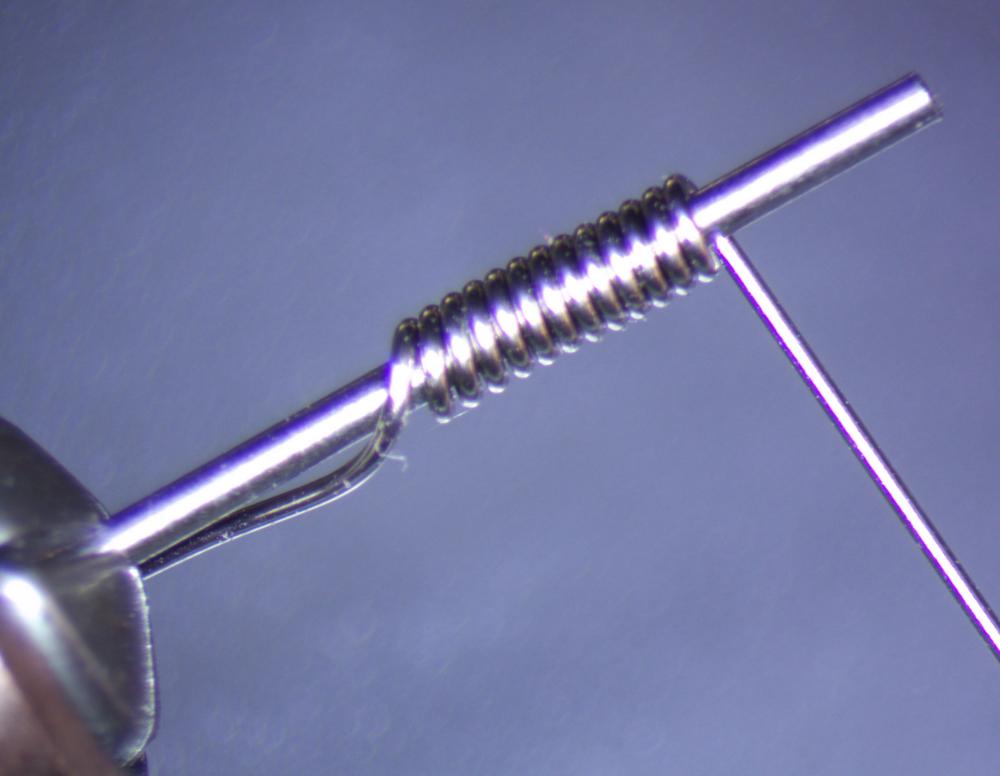

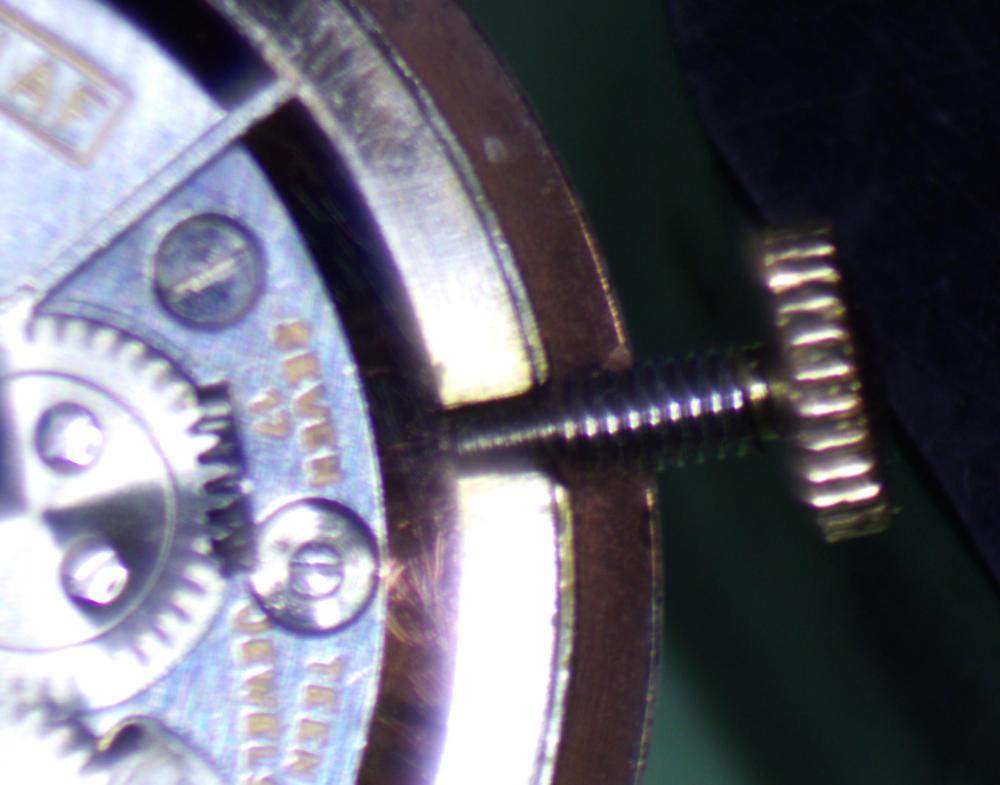

I had to uncase this guy recently because it stopped running. Looks like I'd pressed the hour hand on too far and it was touching the dial. While I was in there, I took the opportunity to take @Jon's advice and make a little spring for the stem to keep it from rattling around in the case when it's in the setting position. I had some thin stainless wire I got from Amazon for a different project. I found 0.3mm wrapped around a #64 drill bit seems to be the best fit. A little cleanup on a diamond wheel in my shop, and I think it's pretty nice. First try was too small. Second try with 0.4mm wire was too thick. Third try with 0.3mm and a larger mandrel was just right. After cleanup.2 points

-

Don't forget; "Rules & laws are written by the rich; for the rich"2 points

-

To make the many variants a bit less frightening, we should mention that most variants belong to a special shock protection system. So if you know that (Incabloc, other, no protection…) you will get one or max. two variants. Frank2 points

-

Yes, and many others I'm afraid. I checked the availability of parts from A. Lange & Söhne (to pick some) and they state that they don't provide parts to independent watchmakers as they would "destroy the entire watch just by opening the case back" which according to Lange takes many, many years of education and practice. Why not be honest and transparent!? "We do not sell parts because we're greedy".2 points

-

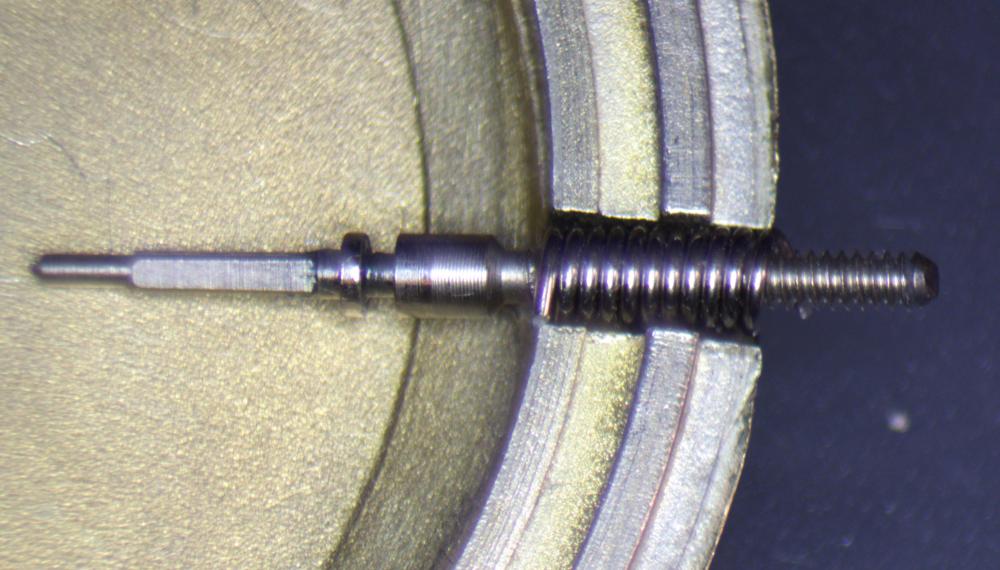

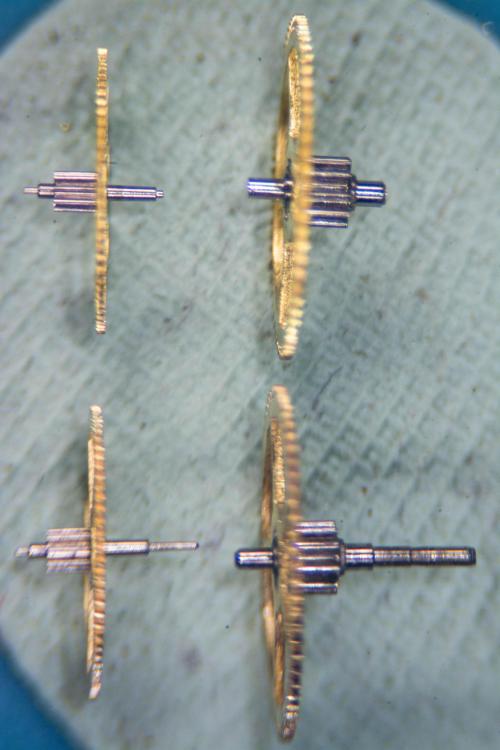

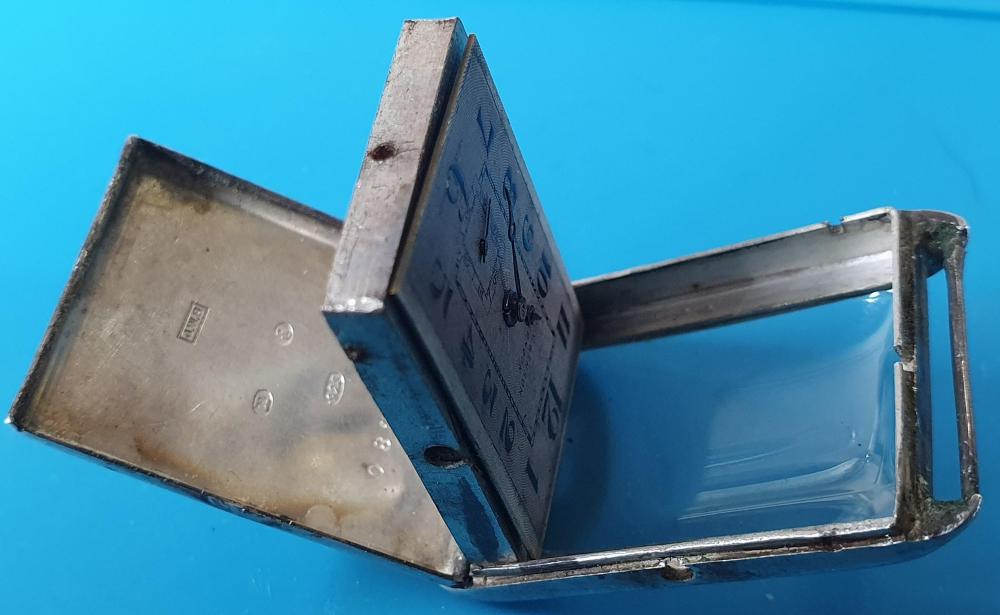

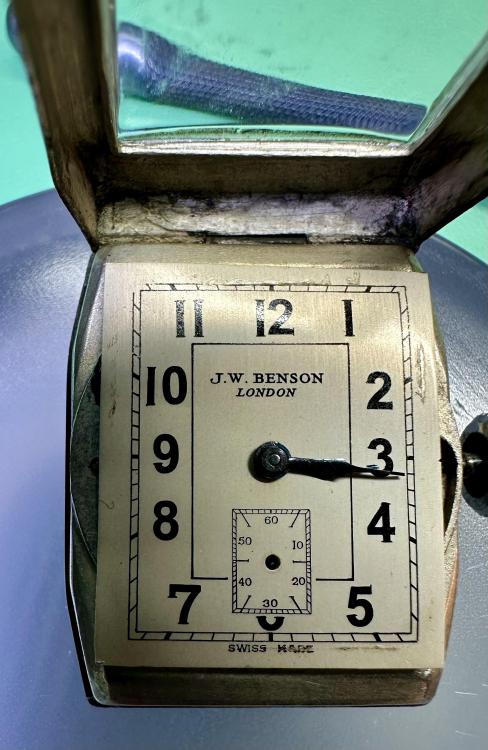

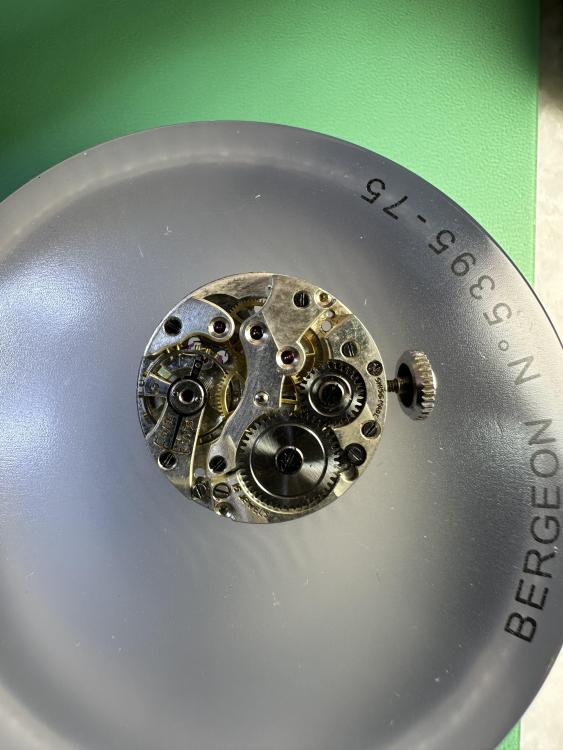

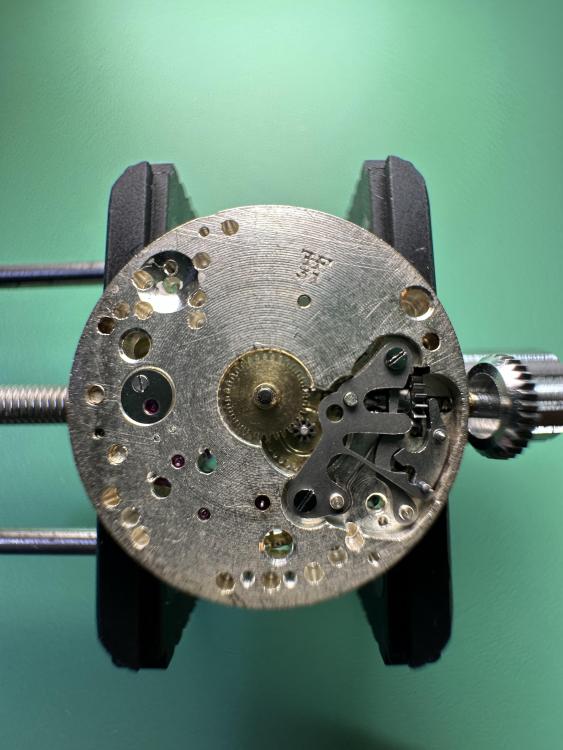

I have an almost identical J. W. Benson sterling silver tank with a hinged case on my bench at the moment, only mine has a Cyma REF: 836 movement, also not easy to come by. Mine also has a textured dial and different hands. Mine had a rough life and came to me with the extended seconds hand arbor broken off of the fourth wheel (not uncommon) but also the minute hand arbor broken off the center wheel which I've never seen before. Like yours mine also had a dial foot broken off. Your dial is in much nicer order than mine too (envious ). Both yours and mine are imported cases (not British made), hall marked at the Glasgow assay office, yours in 1933, mine in 1929. I don't have any finished pics of mine yet as I'm trying to source a replacement seconds hand. The original had been glued in place as there was no arbor to install it on and I couldn't get the glue out of the boss. However, here are some as it came to me including a comparison between the damaged wheels and the replacements. Fourth wheel on the left, center wheel on the right. Originals top, replacements bottom.2 points

-

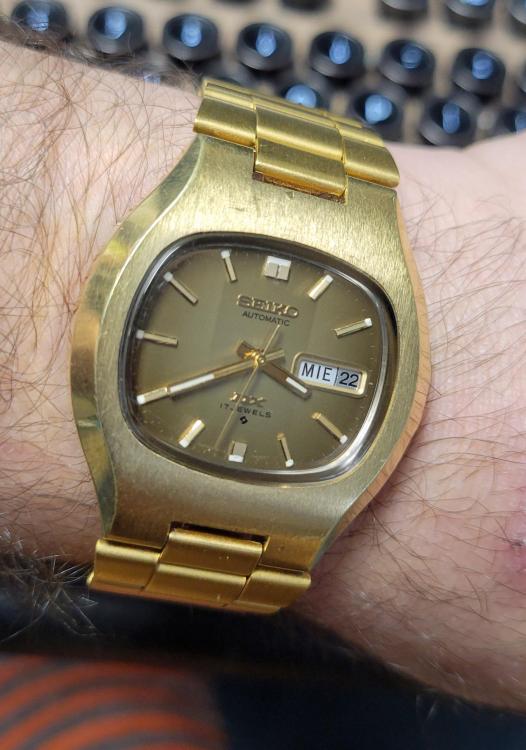

If you are interested in the hobby of watch repair then why not. There is no indication on the dials that can be seen that they contain anything other than quartz battery powered movements. Repairable ? depends on what the batteries have done inside. Cheap fashion watches will contain cheap quartz movements available for just a few of your low value currency, by far the most time - cost efficient way to have them working again. But by all means try your hand at actual repair, this is where the true value of these lay which is the personal experience to you, the knowledge and skill you will aquire. Enjoy matey.2 points

-

If you intend to repair them yourself then have a go. If you are thinking of taking them to a watchmaker then the answer is no they are not worth it.2 points

-

And that was an American that brought them up to speed , now the big Swiss manufacturers what to shit on them and everyone else, they should have been left in the dark ages.2 points

-

They are cheap fashion watches, the pocket watches probably have a very cheap quartz movement in them, the wrist watch appears to be a chronograph, which if it actually is, is still probably not worth more than what a proper watchmaker would charge to change the battery.2 points

-

Hi all, Longish time Swedish lurker here, who finally have joined this community for real. I am still in the beginning stages of learning watchmaking, meaning that I recently successfully disassembled and reassembled my first ETA 6497, primarily using tools inherited from my late father-in-law who was a professional in the Stockholm area back in the 50s and 60s. Here to learn more and hopefully share tips and tricks in the future as I hopefully get slowly better... Best regards, /Lesuedois1 point

-

Yep, it was not having the cap jewel in place All sorted now.1 point

-

1 point

-

There’s a larger galactic senate conversation to be had what would annoy the censors so I’ll save it for my tri-point tin foil hat club…1 point

-

Glueing... Don't forget htat after staff has been attached to the rim, the next operation is trueing. Will the glued staff stand it? I have seen many glued staffs. This is because I am like the last instance in my country. All important antique movements that has not been made well enough by another watchmakers will come to me. For this reason I usually work almost only on movements with serious problems... Well, all the balances with glued staffs i have seen were ugly and worth to be shown in the 'monster gallery', may be that's why I don't like the idea of glueing. This doesn't mean that glueing can't be made well. But shellac will not hold strong and reliable enough.1 point

-

if they hairspring looks perfect out of the watch then they hairspring is fine. If the hairspring does not look perfect in the watch they hairspring is still fine but it's probably bent at the stud. In other words it's very common for people new to watch repair and other times where it gets bent and that's the commonplace. So I would put the balance wheel with the old hairspring back in the watch and carefully study the problem before bending anything. yes is going to hopelessly screw up the poise. But you're trying to figure out which screws to use. So if you were to take a small screw if you had a small screw and place it on the balance wheel and you slowed down by about around seven minutes plus or minus a couple of minutes that tells you that this is a good screw and you can put the other one on as opposed to trying a pair and seeing what happens but if you want to do them in pairs fine. I just find that the more you play with screws and the balance wheel the more likely accidents can occur to even do a quick check and only do the timing either dial up or dial down where the poise is not to show up you can see if you're getting close at all. typically with American pocket watches unless their railroad grade they're not poised because people of played with them. But current lay the drama is to get the watch within a reasonable timing range. Then it will definitely have to be poised because somebody's been playing with their mean time screws and that would definitely screw the poise up if they were not turned out in exact amounts like they're supposed to be. So the procedure would be to see what we can do to get the balance wheel close to time. Timing screws are screws off the other balance wheel be the fastest way you might have to do a little mixing and matching in other words you try a screw what does it do if you can figure out if you have a light or heavy screwing your balance wheel you maybe take your screw often swap with these and yes for poise ultimately they all have to be in pairs and matched. But it's really fast just try one screw. Then once you're reasonably close for timekeeping we can do a quick dynamic poising to see if you're going to have to static poise. If the watches grossly often poise static poising is a lot faster to get things close and then finish up with dynamic poising. Often times people think dynamic poising is the perfect solution and they end up hopelessly lost and will have to go back to static poising to clean up the mess they've made. Then yes static poising really does work I can usually get within about 15 seconds with static poising and I'm not even obsessed with doing that perfectly.1 point

-

It all boils down to " they are breaking the law " plain and simple. As they say " the laws an arse". Or is it ass? Either way what's the point in laws if they can be broken so easily1 point

-

I guess the big brands think that the reputation of their product should lay in their hands and not be compromised by amateur repairers and unprofessional professionals. How that should differ from anything else mechanical purchased1 point

-

Low melt bismuth solder works for dial feet reattachment, ive tried it on what i considered to be a delicate dial without any issue.1 point

-

…so I’ve been occupied with an uncooperative Venus but here’s one I’m calling done. A JW Benson from the country auction house. The shipping to the states cost more than the watch. The flabby before… …silver ya? It was gummed up but actually ran fairly well @ 250 amplitude. fhf 31 which I discovered was not extremely common. The barrel arbor hung on to half of the screw and twas clear there was lots of rubbing so I managed to find nos for each. There was the tar sticky thang supposed to be subbing for a dial foot- what was that? I kept the crystal- lots of rubbing and some old school GS glue. Someone swapped in a fabu alloy mainspring so I kept that too. A bit of wrestling to make the hour hand straight(er)- apparently the second hand had it’s way with it… Cleaned up with over 300 amp now… …new footie… …I thought about downsizing the stem/replacement crown but given this one’s had a long life and the purchase on the crown is easy so I left it. The Hirsch strap cost more than the watch… …imma keep this one. It will get wrist time and lots of interest from a US audience unfamiliar with JW Benson…1 point

-

The dial is indeed rose engine turned which is lovely once you get it clean. I have a couple of ideas for achieving that but need to sit down with and do some careful experimenting. Your case actually has a lot more shape to it now that I look properly, with the width reducing towards the lugs whereas mine is pure straight sided rectangle. I think they are both very lovely in their own way with a subtle, understated elegance typical of their era. As to the originality of the crown on mine, it could be the original, it's certainly quite old and is very much in keeping with the rest of the watch, but after 95 years who can tell Like you I intend to hang on to mine. I have developed quite a fancy for watches of this era with their quiet, unassuming presence and quality, in complete contrast to my other particular watch partiality which is field watches and divers. I currently have this little beauty on my wrist.1 point

-

Yes. I’ve only used the modern adhesives where heat may pose a problem, like the dial. Clearly others here with more skill are comfortable with lower heat soldering. …and yes- for this application shellac is the preferred method…1 point

-

Maybe we should start a list of manufacturers who restrict the sales of parts.1 point

-

Try installing them and see what happens1 point

-

Now that you have a replacement on the way, no reason not to attempt a repair on the original. Drill out what remains and glue in a new post, any material of the correct diameter to fit the hole and an adhesive that will accommodate both materials. You will need some magnification to complete the task.1 point

-

Schellac is already used in this vicinity and we know its safe to use in a watch. Sticks like the proverbial, i think of it like nature's solder. Thinking again about this, the staff rivet would probably need to be removed and not used to allow capillary action to take place. Likely the roller jewel will have to be reset, schellac probably being the better option as it requires less heat than solder. Thinking again about this, the staff rivet would probably need to be removed and not used to allow capillary action to take place. Likely the roller jewel will have to be reset, schellac probably being the better option as it requires less heat than solder.1 point

-

A bit like back in the day when the Swiss were decades behind the mass manufacturing processes of the American watch industry. Tom1 point

-

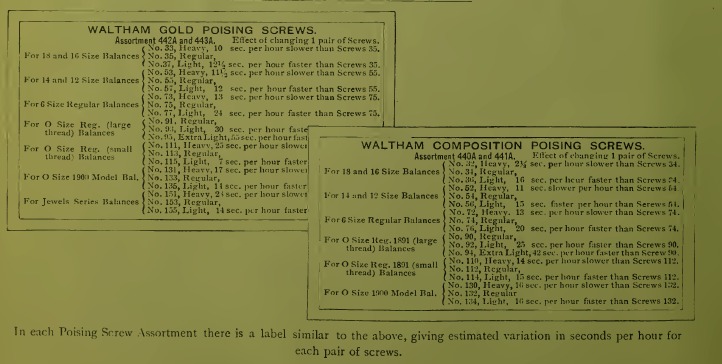

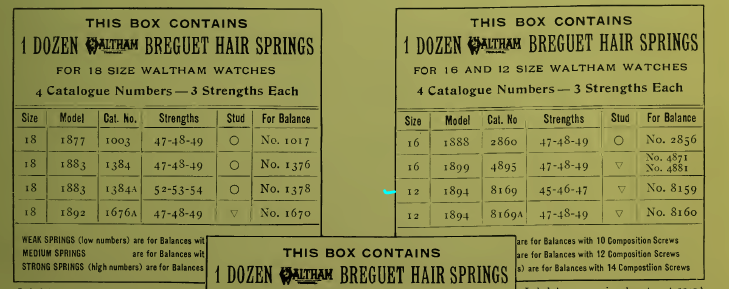

in other words that's not the hairspring for that balance wheel it came from somewhere else? providing the hairspring is flat and not touching the balance arm or the over coil isn't rubbing on the upper bridge. Yes it's common for over coil hairsprings to not be exactly where there supposed to be and their hard to see that they are where there supposed to be. Normally if you are running really fast around 15 minutes it would be because you are missing one of the timing screws. Timing screws have to come in pairs one on one side one on the other if one falls out about 15 minutes is how fast you'd be running. check your balance wheel to make sure all your screws are there in pairs. usually not this fast but you do want to be careful that the balance arms form a nice round circle often times with bimetallic balance wheels people will squeeze them and the wheel will not be round that causes interesting timing problems but not usually as dramatic as this. then just a reminder on modern watches with flat hairsprings a procedure called hairspring vibrating adjusts the hairspring to that exact balance wheel. If you look at parts list for modern watches you typically never see the hairspring separate. In the case of vintage with over coil hairsprings to get the hairspring into the exact shape it's easier to pre-make them. Then the factory would match the balance wheel to that hairspring. then because hairsprings were available separately back then you would also have things like this assortment of screws. Notice in the image the screws are rated per hour and came in either gold usually found a nicer great balance wheels and standard brass. So like your watches about 14 seconds per hour you would mix-and-match the screws to match your balance wheel to your new hairspring. so this is why this isn't working the mean time screws are fine adjustment not meant for matching the balance wheel to the hairspring. oh thinking of assortments is another image out of the catalog it's a shame they overlap the images notice the reference to strengths even for your model of watch? Then unfortunately they covered up part of the image at the bottom but there's a reference to the type is screws found on the balance wheel. the idea would be to find timing screws otherwise you could do a timing washers but typically the maximum effect they have would be three minutes per day and you're going to need a few of them. Then ideally you're only supposed to put one washer under each screw head is not good the double up not that it can't be done but you're really not supposed to. another option you have here is if you still have the other balance wheel see if you have some slightly bigger or heavier screws and do a little mixing and matching just remember to keep them in pairs or you're going to have a heck of a poising issue.1 point

-

I think that the only thing you would need to be cautious of, is whether or not the adhesive you use could off-gas. I've seen threads on other boards where super glue was never to be used for this very reason.1 point

-

…check the bench for the missing cap jewels . Seriously but not seriously I’m nominating you for best cinematography…1 point

-

The saying " who dares wins " comes to mind. If you dont try something you wont know the outcome of your attempt. Mark the position of the roller on the staff1 point

-

It would be nice if Sellita stood up to the block and advertised their products as hard as swatch. We all know what brands use the swatch movements but it’s not that commonly known which watches use SELLITA movements, that way the public could avoid the SWATCH brands, The parts availability and service data being good points to put forward. I have when asked for advice on a watch purchase told the customer to avoid the Swatch brands because of the high cost off parts and servicing in-house. I think they ,SWATCH are trading on the known names which in the past were quality pieces and people were used to them and therefore bought them on that basis only to find out later when requiring a service it was out of their reach and the watch was deposited in a drawer lo languish un loved and un used for many a year1 point

-

1 point

-

Heres my watch of today, a Smith 13'" RY . My missus bought me this for this Valentines day a bargain 14.99 with a reduction, the seller has occasional 20% off offers now and then so it was about 15ish with delivery. I love Smiths and i love bulleye dials, this is my first one. The watch arrived non working as stated and i knew what was inside and what would be against me, but i enjoy a challenge, we dont expect a lot if anything from pin pallet movements. A balance pivot was broken and i didnt have another staff but i did have another RY with a battered dial so i robbed the balance and tweaked it around to make it work apart from that mostly just a good clean and relubrication. Keyless works are pretty rough by design and the crown is a bugger to get in and out with the dial on, the setting lever hits the dial before it releases it, so a little mod is needed to help that along. Major problem was the pins on the lever were quite worn which make the old tg have a snow storm fit. Its a similar read for most pin pallets, these were brass as was the escape wheel. But perseverance is me, i didn't change the pins but i did spend some time dressing and polishing the worn areas which improved the trace a lot with some straightish lines and a beat error of .5 . Not sure what the lift angle should be on these and i Wasn't in the mood to work it out and who believes timegraphers anyway, but at the default 52° it runs with 260ish full 210 after 24 hours dial down , the verticals rates were pretty much all over place. So lets just put it in it's superlight aluminium case and see what happens. Been wearing it now for 3 weeks and it's consistently losing around 1.5 minutes a week winding each morning i think pretty good for an old pin pallet watch. I just love this dial, thanks wifey heres my Valentine's gift for yer sweetie x1 point

-

all done! thanks for the help guys. John I went ahead and gave the pegging thing a try but no luck. so heres what I did: First of all, under closer magnification I found out they weren't burrs, but stake marks. 3 of them spaced around the diameter. Have you ever seen that before? staking the bore on a balance wheel? I have a jeweler's countersink in my staking kit that, along with a jewel reamer I gently teased the stake marks from the bore. riveted the new staff in and it worked great. again, thanks.1 point

-

Hey, bit late to the party but I use the Elma 1:9 too. I have spent a lot of time trialing different strategies for cleaning parts. The best I have come up with is Elma 1:9 in an ultrasonic at about 40C for 4 minutes, then rinsing the parts basket in distilled water at 40-50C twice, the second time in the ultrasonic. For some but not all parts I use pure Isopropyl alcohol as a final rinse. I have a gallon of the Suprol rinse here doing nothing but posing a fire hazard. Because I hate the smell of it and also, no matter what I tried it would leave some residue on the parts after drying. I have an Elma S10, non heated ultrasonic cleaner, it works very well. I just run my tap to get the water temperature right, and considering the short cleaning times the water doesn't cool down much.1 point

-

1 point