Leaderboard

Popular Content

Showing content with the highest reputation on 01/06/24 in all areas

-

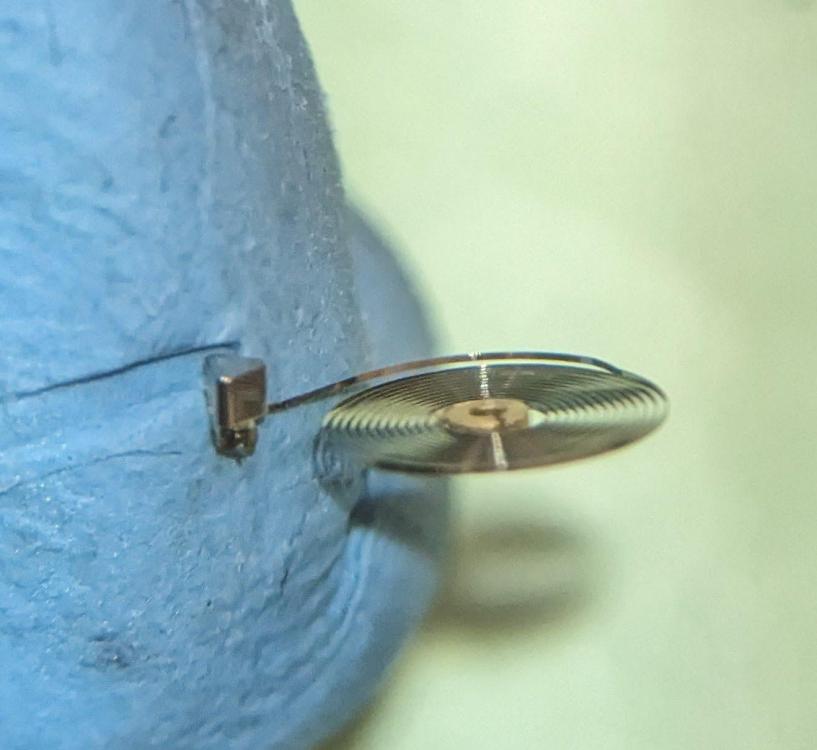

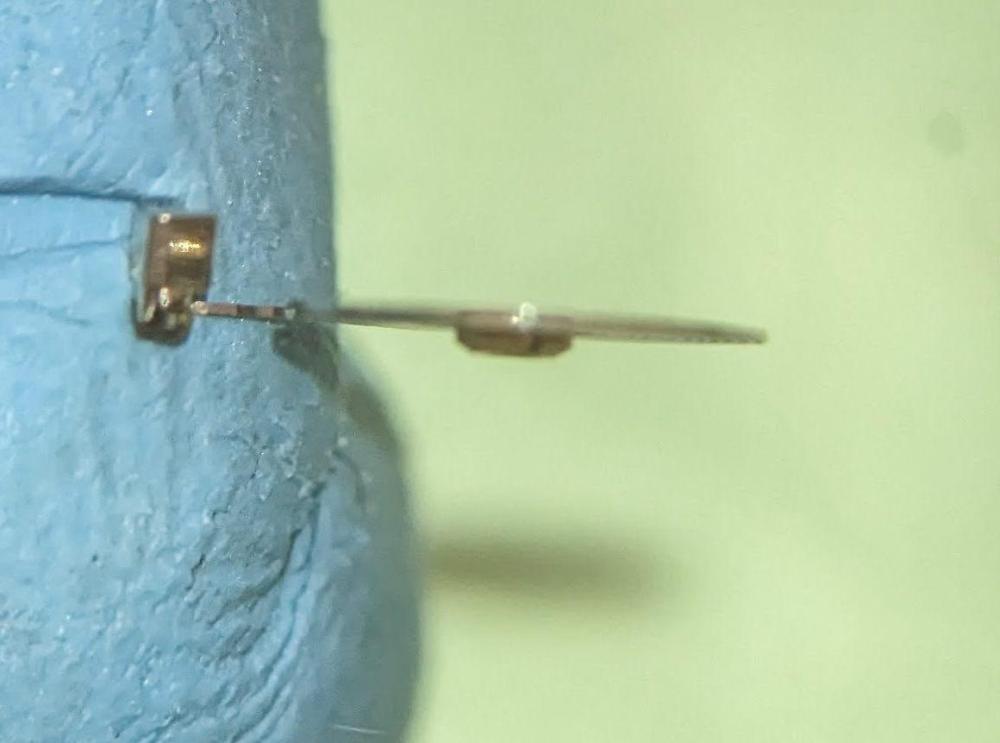

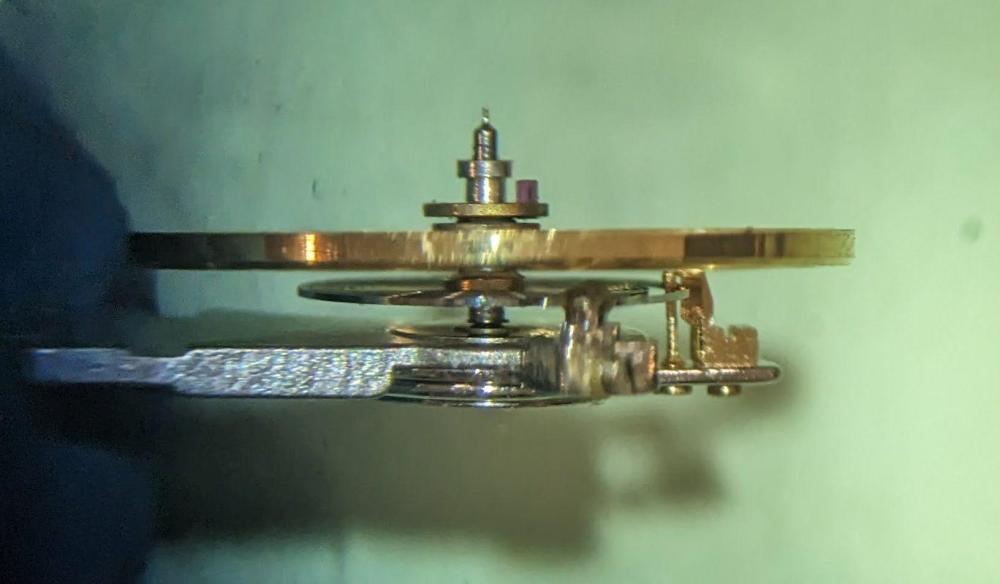

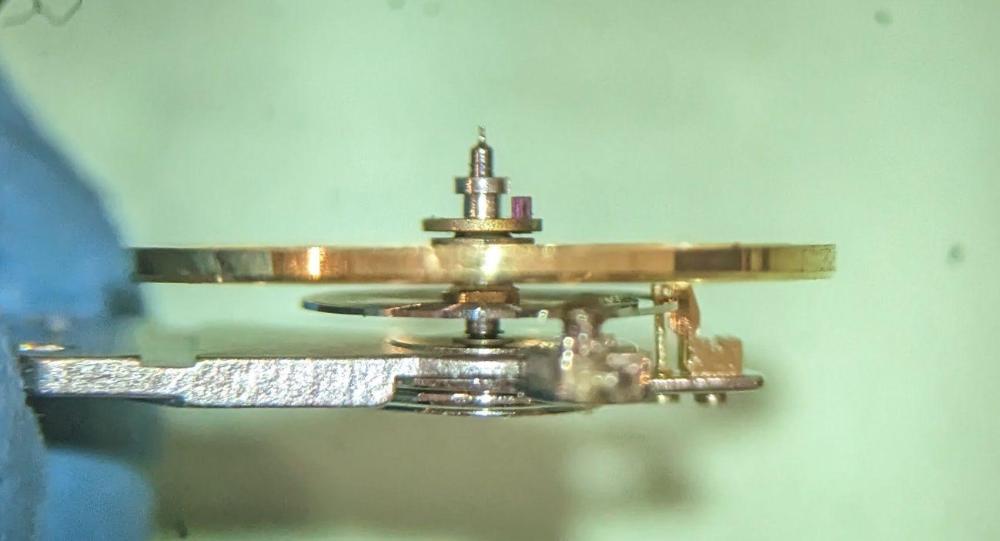

It's out of flat at the collet. To correct that you really need to put it on the balance and true it in calipers, hairspring truing calipers preferably but you can do it in regular balance truing calipers. You can also slide it onto a smoothing broach and true it at the collet by eye, this will get it close. All adjustment should be on the first 90 degrees coming out of the collet- though you might find you have to coax it a little 180 degrees from the pinning point. It also seems to be out of flat at the stud, you can correct this with the spring off the balance, spring installed on the cock (cock upside down), and make the corrections. But you will inevitably have to make final adjustments installed with the balance, so except for severe cases, it's easier to do the stud adjustments in the watch with balance.6 points

-

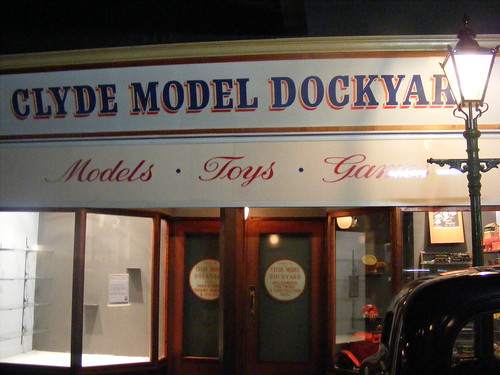

Most of the really interesting places that you used to see this sort of "toy" in, have sadly closed. There were a number of clock and watch repair enterprises who's windows I used to press my nose against when I was a child. Speaking of toys and toy shops, there were also a number of model and toy shops in the Glasgow of my youth. Arguably the most famous was the "Clyde model dockyard". Here is an example of the sort of "toy" that it used to sell. https://antiquetoyslibrary.com/toys/clyde-model-dockyard-engine-depot-side-wheel-river-boat-engine/ This was such an interesting enterprise, that it inspired many a budding young engineer to take up tinkering with all things mechanical and electrical. If you are in Glasgow, take a trip to the Transport Museum, (allow a full day, there is a huge amount to see). It was such a well know place, that they have a static exhibit of the Clyde Model Dockyard shop. While you are in Scotland, never mind Edinburgh castle and the "Royal Mile", everybody goes there, take a trip instead to the Museum of Childhood and the National Museum of Scotland. There are some great toys in the former, and some spectacular Victorian engineering models in the latter and, of course, my favourite clock (and a few others). https://www.nms.ac.uk/exhibitions-events/past-exhibitions/the-luxury-of-time/ Also worth a look is the "Camera Obscura". @luiazazrambo What are your plans for those new toys? What do they do, and are they complete and functional?4 points

-

Hi. Well done for a first time indeed very good. Watch repair teaches you several things. Patience, dexterity and observance. And you have achieved that.3 points

-

Quartz testers do not use microphones. John is correct, it picks up magnetic fields with a pickup coil. If you take a magnet and waved it over the sensor, the unit will beep. The line release tool uses a fluctuating magnetic field to turn the rotor of the movement. It does not require the pcb to be functional or even present in the movement during testing. Most of the cheap 4 in 1 tester use a magnet fixed to a small dc motor to create the rotating magnetic field. A cheap blue box demagnetizer can also be used as a line release tool, however, I do not recommend it as it could weaken the magnet in the rotor.3 points

-

Hi. As you can see it’s distorted at the collet once back into the flat, job done refit spring to original mark fit balance to the cock and re check. Then fit .3 points

-

that's an interesting thought I wonder how that works? I was under the impression that those testers pick up the magnetic field produced by the functional coil. No coil no magnetic field. But if you have test equipment the right test equipment you can place it on the output to the coil to verify that the circuit is trying to drive the coil whether it's there or not.3 points

-

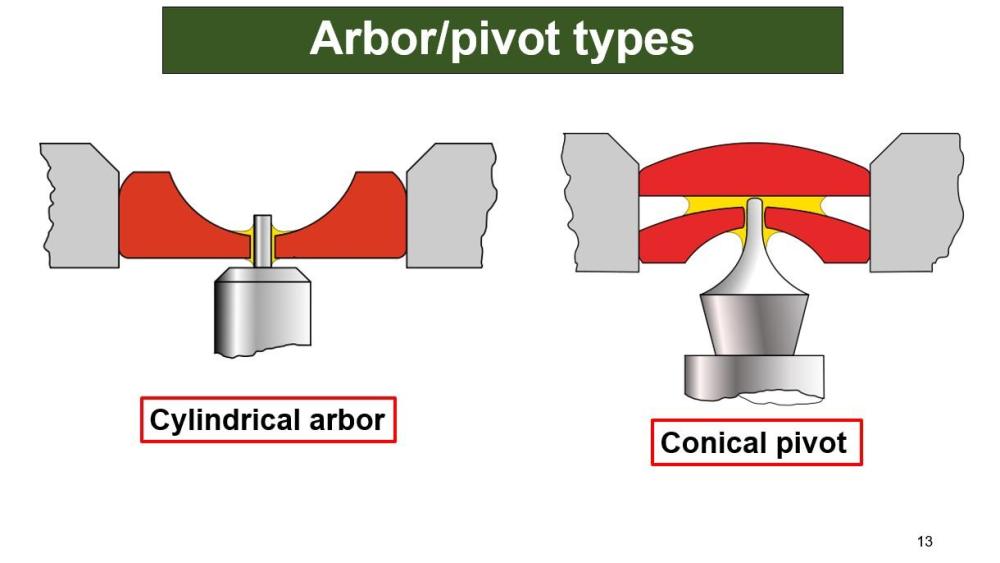

Sometimes manufacturers would make a base model with 15 or 17 jewels and then they would also make a model with a higher jewel count, so it made no sense to make the main plate any different from the base model. The higher jewel count version would have a cap and the jewel would be convexed (olive jewel) with no oil sink and invariably the wheel that sat in the capped jewel would be a conical pivot/arbor rather than a cylindrical pivot/arbor with an oil sink3 points

-

Just made a program to download all issues I could find of the AWCI Horological Times to my OneDrive. I hope I didn't do anything illegal, but I'd be happy to remove the files in case I did. Enjoy! https://1drv.ms/f/s!AnVrKJ9agkNWkfFk72cqE5ISkNJ78A?e=mYbidJ2 points

-

My daughter and her husband came down from Sydney with the grandchildren for a vist just after Christmas, but here for New Years. Brought a clock with her. You would have seen them in the shops. Great big piece of MDF with a print on it and a battery operated quartz movement in the back. Well, Amy said it had been stopping and they would get it going again, but it would run slow and then just stop randomly. So there's me. Off with the hands. Movement is double sided taped to the board. Not any more. Doesn't need to be as there is a whopping great nut that secures the spindle to the board. Popped the cover apart, cleaned all the parts, checked movement of gears in their respective places. All seemed OK. Put it all back together and popped a new battery in. Clock has run for at least a week now and hasn't missed a beat. So it was only a $15 movement probably, but my daughter brought it all the way from Sydney to Melbourne to ask me if I could look at it and get it going. What was I going to say?2 points

-

Not sure Andy, they seem to be in an excellent condition. They look like they were just used yesterday, the topping tool even have a pile of brass shavings so it seems someone was using it, not sure who and when. I do not have any practical experience with them, I buy them because I love them. In my dream I have a watch- or clockmaker workshop where I service watches or clocks, and by service I mainly mean that I would serve coffee and talk about watches and play with them instead of doing difficult time consuming work. Unfortunately I do not have the funds and the time now, but these pieces could serve decoration purposes just like the cash register I earlier bought for my non existent workshop. Thanks for the links and info you provided, a few years earlier we visited Scotland every year, still thinking about moving to Scotland, so checking properties in Scotland is a regular activity we do. My first attempt to make a whirligig - might end up as a whirliwatch. Leafs are made from firewood not pallets this time.2 points

-

Hi NEW. These things are made in India by Rohan products and by looking at the cut board it was cobbled from somthing else. A lot of redundant tracks and holes for components. When I contacted Rohan there was a deathly silence I now use two analysers by Israel Angeles in the Philippines they are custom built to order, not cheap but good tools can be seen on his web site pinoy clockmaker, they use leds to indicate the state of the watch. Hi New. A better site is le arsi watch repair tools you will get a better idea of what I am talking. About.2 points

-

Yes, on an Accutron the power for the train is actually generated at the escapement, so counter-intuitively that tiny delicate index wheel generates a lot of torque by the time you get to the hands. This is why you see Accutrons still running after decades of no oil, but when you get them apart, you see pivots almost completely worn away and such.2 points

-

Unlikely the rotor at this stage, the circuit board will pulse just on its own as long as it has a power supply. It doesn't need the coil attached, as long as the quartz crystal, circuit and cmos are functioning correctly, power supplied at the terminals and pulse tester works you should hear a pulse signal from the tester.2 points

-

unfortunately for this particular watch that is a standard problem. One of things that would happen is the lubrication on the tube that the wheel goes on would go bad to get like a rust. So locking that in place the watch would continue to drive with the wheel frozen to its tube but the gear free to rotate.. Then yes the standard practice is to flip it over and most of the time that works. so classically on a 218 watch the description is the second hand turns but the rest of the hands do not. Yes unfortunately it's a very classic problem I would take a different lubrication other than what was recommended.2 points

-

The shape of the jewel hole would determine if the hole was designed to have a cap jewel or not. If the jewel hole is convex on the side facing the supposed cap jewel, then there should be a cap jewel. But if the jewel hole has an oil sink instead, then it means that the manufacturer decided to leave out the cap jewel in the final production.2 points

-

If you pop out the pinion and flip the wheel over it will often increase the friction. Should get it to last a few more decades.2 points

-

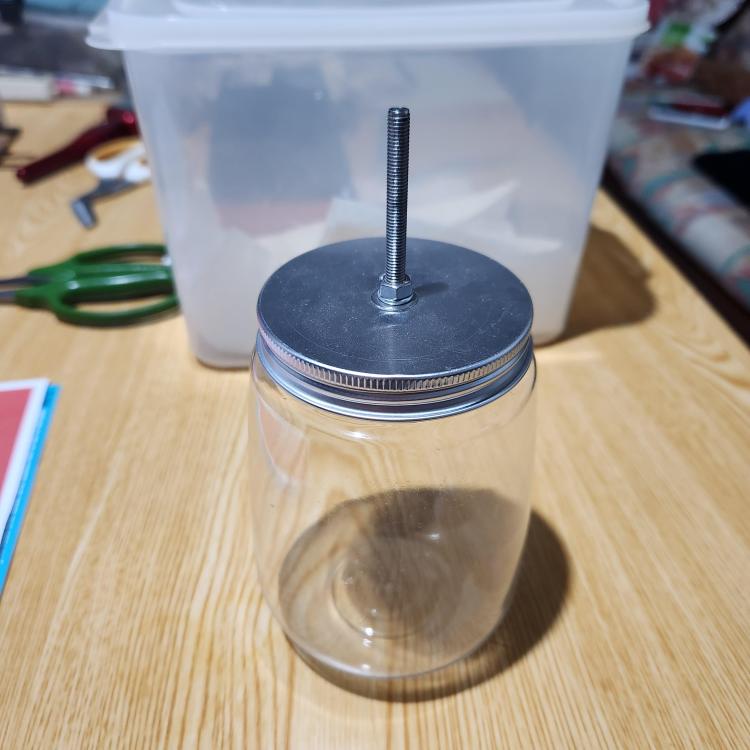

Here you go. I used a thin walled plastic bottle to minimize the weight. Then I drilled a hole in the centre of the lid and made a plastic washer and glued it to the underside of the lid to reinforce the lid to reduce wobble. Then I put a M5 bolt through it. All this was done on a lathe to reduce vibrations when the bottle is spun at speeds of about 1000 rpm. The distribution of parts in the basket is already unbalanced, so you wouldn't want a off axis bolt to make ot worse. The basket came from a jewelry wash bottle from AliExpress. The tiny parts baskets are from Cousins. After each ultrasound cycle, the basket is transferred to the spin bottle and spun for around 15 to 20 seconds, then the basket goes into the next bottle of solution. With each spin cycle, I can spin out about 1 ml of solution. This would have either been transferred to the next solution and end up contaminating it or dried up on the watch plates, etc. I know it can be rather troublesome transferring the basket from bottle to bottle but now the jewels come out squeaky clean. Even the endstones come out clean. This would probably be replaced in the future with something like what Alex Hamilton showed in his video on a DIY cleaning machine.2 points

-

AKA "pallet fork" (if anyone should be feeling confused). https://www.awci.com/wp-content/uploads/ht/1995/1995-09-web.pdf https://www.awci.com/wp-content/uploads/ht/1995/1995-10-web.pdf1 point

-

For testing the crystal ocoscillator Bergeron produced a tool which was in effect a crystal filled inside a rod either the two leads extended to enable you to piggy back the fitted crystal with a known working one which should in theory start the watch if it was the crystal that was at fault, the same can be achieved by checking the cmos output to the coil. The coil should either be full scale deflection on a meter for good. No needle movement the coil is open circuit, ot a resistance value indicating a fault within the coil.1 point

-

Well done it looks much better. The low amplitude could be due to many different things. Breaking the movement down and testing individual function groups is a great way of narrowing down where the problem is. Similar symptoms can be experienced with issues in any individual function group or a combination of them and also at the junction of change between them. Sherlock holmes built the picture of a mystery piece by piece by applying and eliminating ones that fitted and made sense and ones that didn't in logical and elementary way.1 point

-

A qualified clock maker can cut and insert a piece of brass and shape it to size to make it complete or the other alternative is to cut a complete new escape wheel, but he will have to match the old brass to make a really good job. On close inspection it looks like cast brass so it should never be cleaned in any ultrasonic cleaning tank, it must be cleaned by hand.1 point

-

Wow, thank you very much, all of you, you are great helpers! My skills and toolset are very limited, as I am really a beginner, but after working hard on it for like 4-5 hours, I could reform the hairspring finally to look somewhat better. It is very far from ideal shape, and this was my really very first time manipulating hairspring so I'm proud that I haven't completely destroyed it. I really don't want to make a watch of +/- 5 sec a day out of this one, as it was bought as damaged/for parts, I only wanted to try out how far I can go servicing it, to be able to run at all. After agitating the hairspring about 50 times, and put together the balance like 10 times, installed it like another 10-15 times, but finally, it started working! I only gave a very few winds via the rotor bearing, and it looks like the amplitude is very low, so I can check it with timegrapher to see the horrofying numbers later, but for now, it was a long day with a lot of ups and downs, and a final result I dare to say success. Thank you all for your kind help and wish you all a nice relaxing weekend!1 point

-

All is good- I had a duplicate movement for parts and switched in a “fresh” jewel. Very much appreciate the tips- I’ll go hunting1 point

-

As far as i know testing for true like a wheel would be tested in calipers . As the collet is held fixed square to the balance, hairsprings bent at the point of exiting the collet would show out of true at the caliper register arm same as a bent wheel would be. Tweeks at the collet are made until the hairspring runs true. You could also do it by eye using a depth gauge or even make up a temporary reference point across the runners. In a similar manner when the stud is fitted to the cock tweeks are made for out of flat correction. As we know the hairspring is held at two fixed points disregarding the regulating pins. The pins should be checked also and the main body of the coils for damage. But from either of these 2 points or a combination of both out of flat and out of round ( concentric ) can happen. Collet bends and twists seem to be less common than stud bends and twists.1 point

-

Never heard about that and a quick Google search made me none the wiser1 point

-

Correction: power reserve is 48.5h. So barely over nominal. I guess that excludes the worry of the mainspring slipping too late. I've not observed/heard any knocking. And timekeeping on the wrist is exquisite - so no signs of knocking. I'll just be happy with the high amplitude..1 point

-

Questions are not always picked up first time murks, just keep posting till someone answers. But pictures are nearly always needed unless its just a general enquirly. One reason is your question might need someone advanced or watch specific to answer and they may not be available. As an example i never answer anything clock related as i have next to no knowledge in that area, also very rarely seiko questions or pocket watch questions. My knowledge lays mostly with vintage mechanical wristwatch era 30s -70s , Brand history, tool related , making tools, general all watch related issues and a little quartz knowledge. This is what interests me at this time, but sometimes you just need to be patient for the right person to answer.1 point

-

I would have assumed the same at first glance Rich, but who knows what alteration a watchmaker made to continue his work uninterrupted. But yes makes sense to manufacture a one for all purpose plate.1 point

-

I assumed that the plate was missing, it was pointed out that the plate may not of existed, the jewel was turned around and now the jewel was replaced. Is watch repair interesting.1 point

-

You have the left one yes ? Is there any evidence of the right thread hole ever being used ? It is possible the right jewel was swapped but the pivot would need to match the new jewel. Inspection of the pivot heights should give clues, is the top pivot hanging out or low in the jewel ?1 point

-

Pictures murks, pictures are almost always needed. There be folk that dont know what this movement is.1 point

-

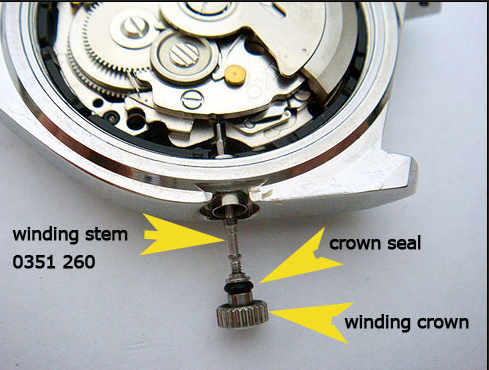

The crown seal stops water and dirt from entering the case. Loctite will work, you only need a tiny drop.1 point

-

The plastic baskets I use have a central stem. I give them a twirl by hand, then I blow through the pots with a blower, then a hairdryer to get most of the solution off. I use Elma WF Pro cleaner, which isn't as volatile as the rinse, and takes some drying off. The rinse evaporates off readily with the hairdryer, as does the IPA.1 point

-

The movement in @quantieme's picture looks like an A. Schild 2066 21-jewel Swiss movement. In my limited experience, that's a pretty decently high quality movement. It sounds like you have more than one problem. Just so we all use the same names for things: If your crown unscrewed from the stem, it can be screwed back on and held in place with a dab of Loctite. I think most folks use the blue, which is easily removable for repairs later, but I have very limited experience there. If the stem has popped out of the movement, that's something else. The screw that holds it in place may be loose, or there may be something damaged inside. If the watch stopped running sporadically, it could indicate something else wrong inside. Maybe a screw came loose and is getting into parts of the movement to stop it, maybe it just needs a good service. Someone with experience would have to get in there and check it out.1 point

-

No i mean testing just the bloc by itself. When i first got into the hobby i aquired around 500 quartz movements and spent weeks pulling them apart figuring out how they worked. It was fantastic for developing manipulation of tweezers and drivers. Sorting through working and non working components i realised that the coil wasn't necessary for testing the cmos with the tester i had. It also seems to sort through non functioning crystals , i cant honestly say how accurate that might be but it does appear to pick out ones that do and dont work. To fully explain the process i used, a complete movement with power supplied would be tested. If working the tester would indicate this with a one second interval audible bleep, this then verified visually with a rotating rotor and moving train. Occasionally the train would need to be freed up, sometimes if the train did still not move, a resistance test on the coil would show a defective coil or often see visual damage to it. The bloc still provided a pulse when tested separately. When no pulse was detected, coil and train would then be checked in the same manner sometimes working sometimes not,depending if there was a multiple issue. Testing a crystal was also thrown into that mix, but through trial and error testing the bloc, the bloc's circuit traces, the coil , the train and the crystal either separately or combined i managed to find seperate issues or no issues with each component . The tester is only a cheap device so only indicates the symptoms of a working or non working components not a diagnosis. But after sorting through hundreds of each one the process seemed reasonably full proof .1 point

-

It was more of an assumption Hector , the audible signal volume varies depending on how close the bloc is to what i thought was a receiver. But the circuit bloc doesn't contain a magnet ? If i could figure out how to post a video i would provide a demonstration.1 point

-

Its a while since ive used it, but as i remember the device actually has some kind of microphone.1 point

-

1 point

-

1 point

-

perhaps a minor clarification here I was thinking more of pallet forks. Yes he should have less friction and the lubrication should stay where it's supposed to be better perhaps. But often times beyond a certain jewel count well some of the jewels are basically just a waste of time plus even an example up above how much better would it be to have one with the conical jewel and one with out that seems a bit strange doesn't it? Either all one type or all the other would seem to be a more appropriate. But unfortunately all four types can exist and it depends upon a variety of factors for the watch in other words if you're looking at parts list you might actually see all for escape wheels listed which I always find amusing. Especially if you order the wrong one it doesn't work well for you.1 point

-

Oh well I had to buy one too lol. I've been looking at used Rollifits but they go for pretty high price. This looked like a nice bargain for a new item. I have a jacot tool and know how it operates but I haven't found much info on the Rollifit. Is there a manual available somewhere or tutorial videos or books or something? It is fairly simple machine but I'd like to check things like setup, maintenance and rotating speed.1 point

-

Nice work Leon, and thanks for sharing your experience. I think your idea of using a pin vice to hold the staple is an excellent idea. Although I said I use tweezers, that was a lazy description, I actually use locking forceps such as used in medical procedures which securely grip the shank much like a pin vice. As you have discovered, you can control the manipulation of the staple much more precisely with something that has a locking grip. The fact that you prefer to place the spring on the arbor instead of placing in the drum illustrates how versatile these winders are, you can modify the order of things easily to suit your style or sequence of work. I honestly feel these winders are an excellent option for both hobbyists and more serious horologists alike, and they offer some significant advantages over traditional winders.1 point

-

interesting link coded up above but I found one that for the most part I liked better down below. so the link below is nice pictures basically beta was better in recording sound even the manufacture the cassette tape is outstanding. But the HS you cram more video on the tape which is a selling point because a lot of people didn't care about the quality difference or any of that stuff. Then towards the very bottom of the link above which I think does a little better job unfortunately Sony didn't want to share and you had the license. Which limited the number of people to just a few manufacturers. Although lots accompanies initially made beta tape until VHS came along which is basically open source and that was the end of beta. Well kind of the end I do know that a lot of studio recorders were using beta tapes. Or for instance the Boeing company used to have a surplus store south of Seattle all sorts of interesting things would show up there including when they dumped all their archive grade studio tapes in really nice plastic boxes. So he didn't get quite as many hours out of the tape because they're all shorter works are much heavier tape it still was really nice tape. Then of course they all went away and at least for a brief period you could even buy DVD recorders. I have a Panasonic VHS and DVD recorder. I think is getting like six hours per disc. Then those discs were so much nicer to store than the tapes. But of course all of that is gone now a thing of the past. oh and thinking of discs one of the retailers in the USA I don't know if they are worldwide offices Best Buy is no longer going to sell DVD or Blu-ray discs. So it looks like discs are going away also. although I think some of the other online retailers will probably sell them but it's an indication of their time is limited also. https://www.zoopy.com/vhs-vs-betamax/1 point

-

Read this about video recorder's https://kodakdigitizing.com/blogs/news/what-is-the-difference-between-betamax-and-vhs1 point

-

Surprised about interest in the topic about the great state of Texas! ...and cowboys. I own over 45 acres...not all contiguous. I lease 20 acres to run cows and 25 acres to run exotic deer. I own a cowboy hat and cowboy boots and a John Deere tractor and associated implements. ...and I play guitar... I drive a pickup truck. None of this is incongruent with my watchmaking hobby, my expert-witness work in patent litigation, nor my past work as a college professor and textbook author. My choice of beer: Shiner Bock. If you lived near me, you would find that I am the best friend you could ever have.1 point

-

It is missing, the arrow points to the screw hole, it should have a plate with the cap jewel in it , like the one below the arrow.1 point

-

Jon I think someone has begun a replacement ranfft database using the ranfft data. https://ranfft.org./ Regarding your comment about watch prices. I too have noticed that watch prices have increased nearly 3 fold in the 2 years I have been enjoying the hobby. I now hardly ever purchase a watch, except low end for spares. Even they are at least double what I originally paid. On the plus side. I notice that the prices of tools, mainly Chinese, have decreased. These are the only tools I can afford. They do however appear to do all I require. Swiss are out of my league. Saving up for a Chinese jewelling tool with dies. Half way there.1 point

-

Wow! So Bergeon had the foresight to make skinny screwdrivers so that they could sell us Extra Grip drums later. Brilliant!1 point

-

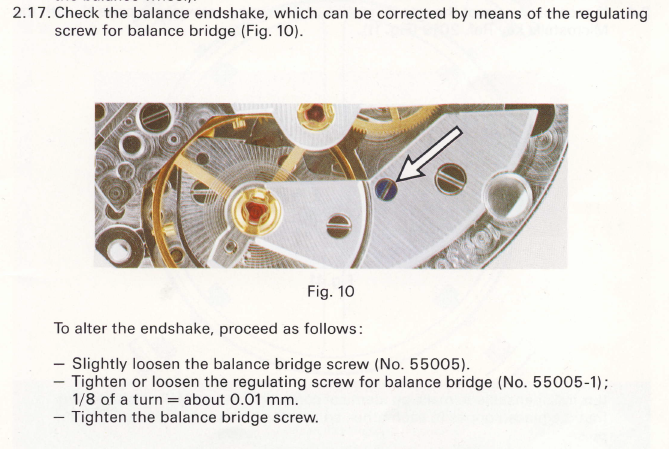

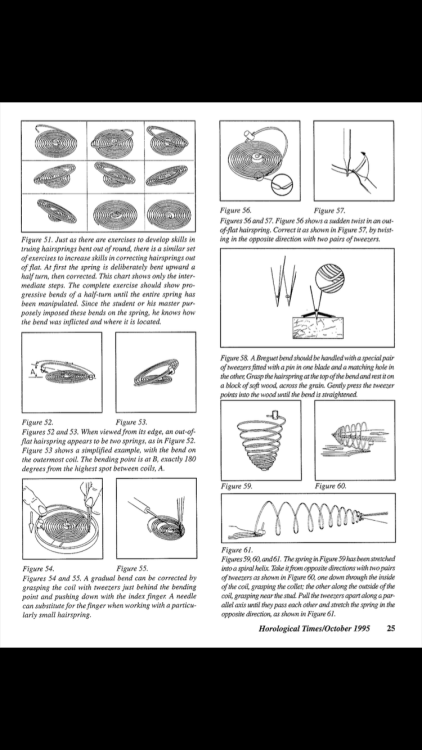

The Sep 1995 issue of the Horological Times has two articles on hairspring manipulation by Archie Perkins and Henry Fried. The October 1995 issue has the second part of Fried’s article. My copy of Fried’s bench practices does not have the chapter on bent hairsprings which I believe these two issues reproduce.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)