Leaderboard

Popular Content

Showing content with the highest reputation on 12/30/23 in all areas

-

There is a plaque at the site of his old shop. https://openplaques.org/plaques/9382 When he lit up the pipe in the film, it reminded me of my old boss in the electronics service department where I worked in the 70s. He would light up his pipe after lunch each day and I can remember the nice smell and the good times there.4 points

-

Well, greetings everyone. Thanks a lot for all the help and advices. Finally I managed to finish my work on this watch. Now it has almost perfect accuracy,320 amplitude and 0.1 ms. After 1.5 years of finding parts and cracking my head on why does this watch can't work normally, I finally did it... Here're are two pictures of polishing. Hope you all will have even better New year's gifts than me and your beat error want be more than 0.1 ms! Thanks again!3 points

-

OK, I shouldn't get excited over just a roll of wet and dry on a bit of plastic, but this has changed sanding cases and small parts for me. I used to glue bits of wet and dry to lolly sticks, but they didn't last long, and it was hard to get in to tight corners. I saw Kalle using one of these sanding sticks on Chronoglide, and decided I needed one. I'm preparing a brass case for replating and find that the 600 grit is ideal. You can use them wet or dry, and when a bit is worn, you just roll the paper round a touch. Although Excel make them, if you search for "sanding stick", they all look the same. They are sprung loaded for fitting the paper, which is 1/4" wide.2 points

-

In testing now. Not as good an outcome as I usually achieve, but good enough for now. Felsa 690 came in a Pesag branded dial/case—looks like a late 1950s/early 1960s vintage. Movement had several issues—broken mainspring, broken pallet fork pivot, fouled hairspring. Was able to source the mainspring and pallet fork on eBay. Spent 2 days working the hairspring back to a point that the watch runs with good amplitude, but still has significant positional timing issues in dial right position. Since this is a project watch that I intend to re-sell on eBay as-is, I’m going to call it a day. I could invest further in a balance complete but simply don’t think this piece is worth any further investment since it keeps time within 30-60 secs per day depending on position.2 points

-

Yes, that could be option if you have the equipment / lathe. That's where it all went wrong ...... The good news is; I managed to find a NOS barrel (complete with new arbor and perhaps a new spring in it(?)) for a very good price, so hopefully the problem is solved2 points

-

This might be useful, post by watch guy. https://watchguy.co.uk/service-rolex-oysterdate-1601-calibre-1570/ Thoughts on this!! Was the balance staff broken when you received the watch or was it damaged during the service. If it was damaged during the service was the balance running free before. If so then the new balance is incorrect either in it’s fitting or the wrong balance. Also have you done this test when fitted. https://www.facebook.com/watch/?v=5800612864572452 points

-

I'm confused What's the history of the watch? Why do you work on it? What have you done so far? I mean, if you change a Rolex balance staff out, I would assume that you know a thing or two. What was the reason to change out the staff? Did the staff cause a "wobble" in the balance wheel? If not, IMHO, balance staffs, unless (partially) broken, don't shorten themselves, so why would the problem be in the balance staff? Likewise, jewels don't move out of themselves, neither do bridges bend themselves. It seems to me that there is more to the story than the brief description above. Please enlighten me ...2 points

-

I know this seems silly to some, but I have taught Kuatsu most of my adult life. It's part of the training for my black belts. I can get rid of your pain, but not the cause of the problem. Try this. Get something round about the size of a rolling pin, No, it's not to hit you or me with. I am being very serious. Sit down and place the roller on the floor. If the pain is one the right side, you are going to use the right foot. Left side, left foot. Without shoes on, place your foot on the roller, just on the toes, then roll your foot gently forwards so the heel is now at then end and on the roller. Repeat this back and forwards movement very gently for a few minutes. Do not press hard. Just do it resting the foot on the roller. This agitates the medial nerve that is for the back Removes pain. If you move and the pain has eased, great. But don't make sudden moves as the pain is less. The problem has not gone, just a little of the pain. I learned it as Kuatsu, some people call it reflexology, others sell machines that are on the floor and vibrate. This is cheaper. It works, it has cost you nothing. It it doesn't, then nothing lost. Hope this helps Regards Ross2 points

-

Can the depth of the jewel on the mainplate be adjusted on this caliber?2 points

-

I have resistance to anything to do with training. Gym is a swear word to me. Hehe.2 points

-

1 point

-

1 point

-

I found that the barrel was tilted and occasionally rubbing against the centre seconds wheel as the clearance there is so small. I made the barrel upright again by using a smoothing broach on one side of the hole in the barrel bridge. This made the hole oval. I then used a small domed punch to make four or five indents on the other side of the hole to take away the ovalness and make more round. In effect I moved the barrel arbor bush in the barrel bridge towards the centre of the watch and made the barrel upright again. This has solved the issue fingers crossed.1 point

-

Gyus, we don'd seem to help OP much this way. I generally work on antique movements, which means 200-300 years old, and have claimed long time ago that don't work on contemporary watches and work on such only when have to save some of my friends-watchmakers when thyey broke something or are not able to find parts, so yes, I don'have much experience partiqulary with Rolex. But, some general things I am able to say: I can not imagine that something in the lewel setting of the shock device can be adjusted in order that the position of the endstone will change. And, the problem is for sure in the position of the endstone in high, so no point yet to talk about bent bridges or shiming or so. First thing to do is to find what is the problem and it is in the plate, not in the cock To OP: I don't know You level, but will say that You did some mistakes: Before replacing the staff, You could compare the lenghts of the downside parts of the old and new staffs. Replacing the staff just to see what will happen is silly thing. Hope that You are able now to true the balance wheel, as this is important for solving the problem. Then, after acheeving correct high position of the balance wheel and normal amplitudes in all positions, You will have to do the balance adjustment in order to minimise position errors. All this would be avoided by not touching the balance... The first thing that I would check is if the whole shock device has not sinked in the plate. Then, if it is in correct position, would check if the jewel settings of the cock and plate are not replaced by each other, as they sometimes are different. Or, may be the plate shock device setting is not original.1 point

-

You need to grease the lever under the date wheel, where the finger rides on it, also its pivot point and where its screw touches it. Heavy oil like HP1300 on the date wheel and finger. Grease where the spring touches the lever. The spring is a weak point; they are often broken (yours looks OK), but they have just enough oomph to kick the date over. So lubrication is important. Also the date jumper needs proper lubrication on its pivot points including the shouldered screw that holds the little plate on- and the plate, and where its spring rides, and a little smear of grease on the faces that touch the date ring. The quick set wheel is clutched so as long as it's free (and lubricated) it shouldn't be an issue. If you are in setting trying to advance the date with the dial off, the hour wheel tends to ride up releasing the built up energy in the lever, you might have to hold it in place gently with a piece of pegwood.1 point

-

the barrel can have a bushing pressed in, a convex punch and flat base could be used to close the hole, round the hole with smooth broaches if too small, just some ideas that come to mind.....1 point

-

1 point

-

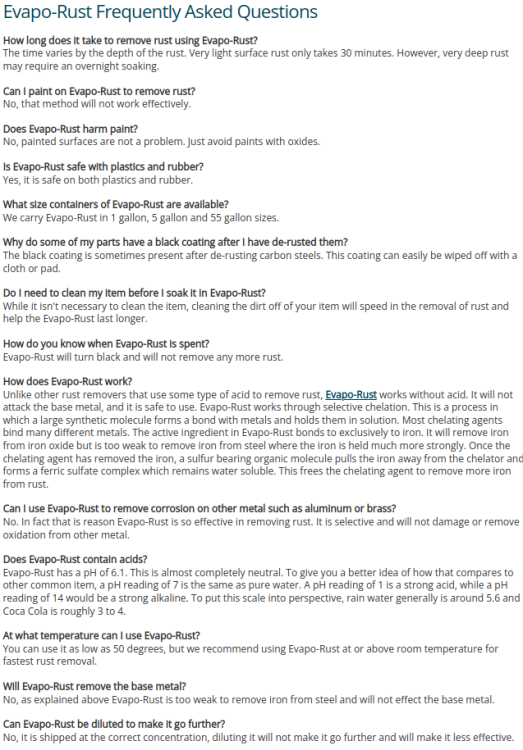

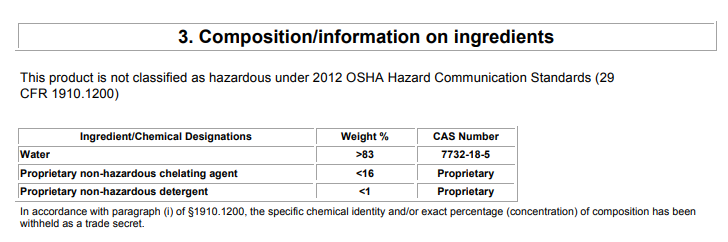

The composition is below (from the MSDS sheets), but it's mostly water: The active ingredients are proprietary, but there is conjecture on some forums that the "the chelation agent [is] most likely EDTA (ethylenediaminetetraacetate). It's synthetically manufactured and many people swallow small amounts for health reasons" Here is an excerpt form the FAQ, basically saying that the only thing it can hurt is your wallet $$$ I usually decant 50ml or so into a small glass jar and use it that way, sometimes it comes out sticky, so I usually dry it off with some paper towel or a rag once I am happy that the rust or rust stain is gone and and then dunk it in a small jar of IPA or naphtha for 30 seconds. Sometimes I find it helpful to use one of those fibreglass pens to when it is sitting in the solution to accelerate the rust removal process if there is excessive rust, but generally I leave it alone (apart from the odd swirl of the jar, to do it's thing.1 point

-

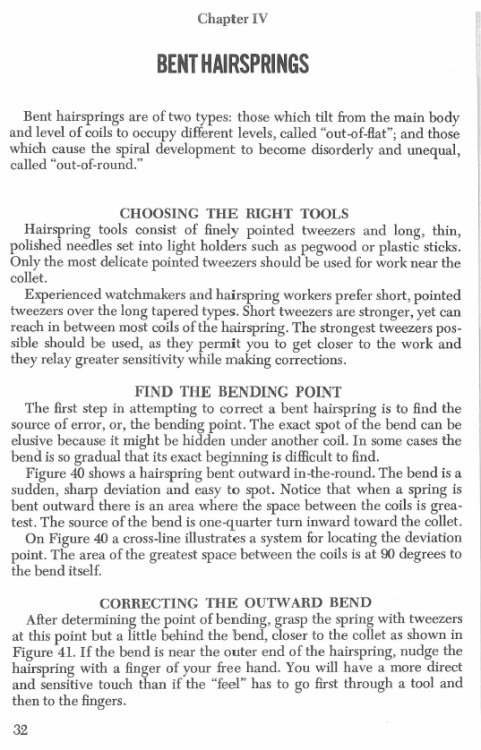

Previously somebody was asking about the 783 which falls in the series from 781 through 784. There was one last document which I did not physically scan when I was scanning the others because I really despise scanning altogether I really have to pay attention we end up with duplicate pages etc. and then I get annoyed and start over. But fortunately your question is one piece of paper front and back so I scanned it for you. I'm attaching the PDF so now you have an answer what the differences is. Then if you need the other service information you can find it at the link below. https://www.watchrepairtalk.com/topic/27574-tissot-783-several-questions Tissot Service Technique No 35 Calibers 781-1 782-1 783-1 784-1.PDF1 point

-

1 point

-

Might be zero end shake on balance staff, to check for that loosen cock screw . Rgds1 point

-

Hi NEW. By the time you have done the job it will be priceless in the skills it has taught you, that’s worth more than money as it stays with you money soon vanishes .1 point

-

Rolex_Movement_Calibre_3130_3185_5.pdfRolex 3135 parts (1).pdfThat's not bad for 7-8 years after the service! Congrats on a good job back then. But I guess it's time for a service indeed. It should be above 190-200° in VERTICAL positions after 24h. Don't wait too long. I recently serviced a Rolex 2035 had it's last service 10 years ago and both the reversing wheels and the rotor axle needed to be replaced. Cost of 350 EUR (for NOS, original parts))... and I'm pretty sure that this could have been avoided if it had come for service 2 years earlier. You'll find my thread about that service on the forum, too. Here is everything you could possibly find on the forum in one place. Except my "special notes" (sorry, only phone pictures of those). CALIBER-3135-3155-3175-3185-TECHNICAL-INFORMATION.pdfRolex oil chart 3135.PDFRolex 3135 parts (1).pdfRolex_Movement_Calibre_3130_3185_5.pdf Indeed. It seems to be irresistible to lubricate the centers and the clicks of the reversers...1 point

-

Hi All, I am a hobbyist and really like traditional forums for my hobbies. A little about myself. I am a professional designer that includes a lot of technical skills so this is a natural fit for me. I look forward to learning from everyone here. I always liked watches since I was a kid through college but stopped wearing them long, long ago. A little less than a year ago I decided to start wearing them again to help me stop looking at my darn phone and getting distracted. Fast forward between a bunch of Casios, to modding Casios, to used SKXs (I used to actually Scuba Dive), to modding SKXs to building a couple of watches from Chinese clone parts to now taking Mark's class. Now I've got two watch boxes with a mix of mechanical, automatic, quartz and digital. Some new, some used plus a few inherited vintage. (Still not sure when used becomes vintage in Horology.) I tend to dive crazy deep into my hobbies and go overboard. However I can see myself doing this for a long, long time. I love learning and building skills and there is so much I see in watchmaking I know I can keep learning until I drop some day. So that is very exciting. My goal going forward is to continue what I've been doing with the modding and building but also to be able to service the watches myself. Especially if I buy a used watch to mod or restore. I just gave a few away mods and builds as gifts to family members and I think they found it the most thoughtful gifts in a long time. If you read all of that then thanks for taking the time, I appreciate it and again looking forward to learning from you.1 point

-

1 point

-

Some vintage tools can be a good deal over the cost of new. I have some nice vintage Dumont tweezers and some other vintage tools that were a good deal. Then there's some vintage tools that go for pretty insane prices. I'm still trying to understand why people would buy a JKA-Feintaster micrometer off of eBay for more than you can buy them new.1 point

-

Just the sense of achievement and lessons learnt can be more than worth it. I'm battling at the moment with an old cylinder esc. movement that is worthless. Trying to make a new plug for the cylinder or slowly but surely file in a new pivot on the old one. In the process I've learnt that turning a balance staff is a real skill but not beyond my ability. All lessons learn are worth the effort.1 point

-

I'm sorry John, I didn't mean to come across like that. You are far from incompetent and I never meant to offend you, so if I have, again, I'm sorry! Most of the time they are spot on. I don't want to alarm anyone, but just a heads-up that if something is broken or defective they tend to say the supplier may not entertain it depending on who the supplier is when it's Cousins you have the contract with and not the supplier, although I bought a Bergeon EtaChron stud adjusting tool some years back and it broke. When I contacted Cousins about it they promptly sent a new one and didn't want the broken one back because Bergeon, who made the tool, has a policy of replacing any defective tool without question. Now that's what I call good customer service by Bergeon!1 point

-

I cant say i have a problem with it I always manage to work out what you are explaining, sometimes its just how you say it. We all talk differently especially me, because well I'm just wierd anyway.1 point

-

Good old Norm, he'll have forgotten more about watchmaking than I'll ever know. I wonder what it was like in his shop in the 30s when wristwatches were becoming ever popular taking over from pocket watches. I bet there wasn't a watch brand he hadn't handled, what a mentor to have for vintage repairing.1 point

-

I was thinking that he probably knows where everything in the entire shop is. Then I was curious where the shop was and whether it still existed and the building exists of course he is no longer there the article explains when he died. That I was wondering if his apartment was above the shop? http://westhampsteadlife.com/2014/01/15/a-moment-in-time-on-mill-lane/99211 point

-

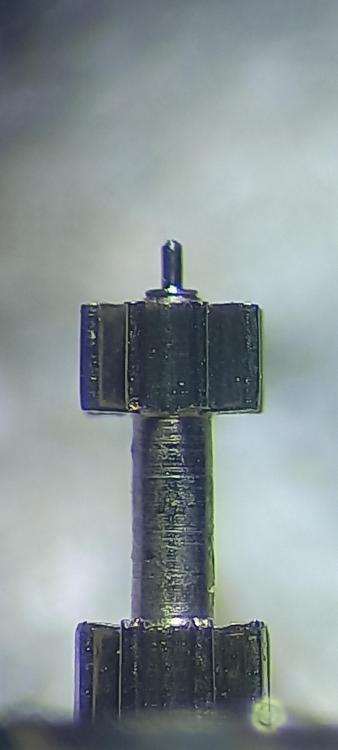

Here is my first attempt with a Seitz pivot straightener. Tbh i thought this was just a very expensive gimmick gadget. But it works and it works well, straightening an escape wheel actually took me an hour carefully figuring out the most efficient and safest way but with good results. The next would be half an hour, the next i would guess about 15 mins. It works by placing the bent pivot wheel in progressively smaller pivot holes and turning the wheel against a register that you pull up to the wheel ( this is where the most time is spent being careful ). Eventually the pivot is placed in the smallest hole it will enter, here under 40x mag the bend is very evident and turning no longer straightens the bend out . I finished by finding a midway spacing between the wheel and the register and gently pushing the wheel over, the register stops you pushing too far and snapping off the pivot. See pictures for the start and finished pivot.1 point

-

I'm not entirely sure, i wasn't able to find any instructions, but that is how i came to do it in end. I could see the register arm lifting up and down, which surprised me as the arm has to bend to be able to move up and down. I think it was just designed for balance staffs, i had a bent escapewheel pivot on a restoration from a while ago that had been put aside so i thought why not give it a go, its my first time using it. I've literally just gotten around to casing up the movement, busy sorting out a load of old movements i bought and making washing machine devices. Here we have it running dial up and crown down an hour after a full wind, i think the pivot survived the ordeal and is doing well.1 point

-

Remove the balance wheel => block the escape wheel carefully => remove the pallet fork => let go the escape wheel1 point

-

Apologies, I was looking at the wrong place. I can now see it is a Felsa 4033. No further reply needed to this topic. Thanks all1 point

-

1 point

-

At home I have just the disc with jewels all the other bits and pieces are either missing or somewhere else. On the other hand when I was at work once with a bent balance pivot and not wanting to replace the staff The tool came in very handy and I basically didn't use the bits and pieces that are a guide. I started with the biggest hole and eyeballed it and it worked out really nice. Nice straight pivot didn't have to replace the balanced staff and everything was good conceivably depending upon things are probably break the staff and I don't remember if I refinish the pivot afterwords are not. I'm tending to go with I just straightened out and everything was fine then because the Swiss can they've upgraded the tool probably updated the price also. There is with the new version looks like and a PDF attached of how you're supposed to use the thing. 7135 7136 30350 new.pdf1 point

-

Nice write up. I have had success with this tool as well. There was one in my Seitz press set…I’ve only tried it with a balance so nice to see some success with other parts as well Not according to the instructions from Seitz. As neverenoughwatches says it is there to steady the wheel in the pivot hole. I have been placing the arm on top of a wheel to hold the pivot as vertical as possible then I rotate the wheel from the opposite side with a couple horsehairs. Start with a larger hole and slowly work down near the pivot diameter. As you start to straighten there’s a slight bit of resistance in a new hole that lightens up after a few full turns. It is actually a quite satisfying tool to use when it works…1 point

-

1 point

-

They would have to pay me to take it away (and then I'd bin it) Cheap pin pallet movement, radium dial, lots of entertainment. You could put a lot of time and effort it, and it still might not run very well. I'd go for something Swiss with at least 15 jewels, that way there's a fair chance of it running pretty well after all your effort. It's amazing what you can find for £10-£30. I recently bought two great quality ladies watches (Movado and Longines) for less than £30.1 point

-

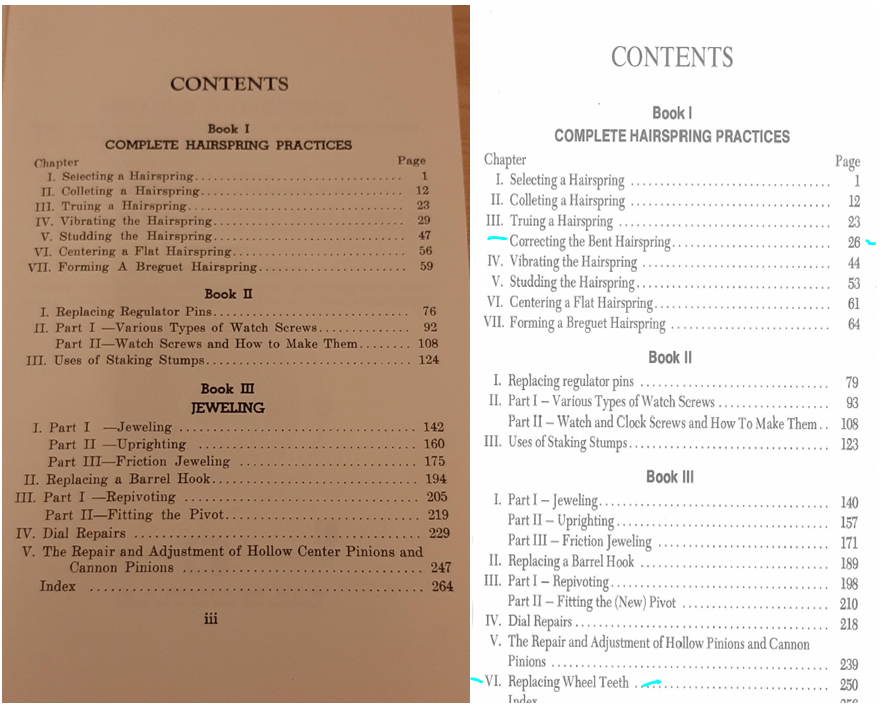

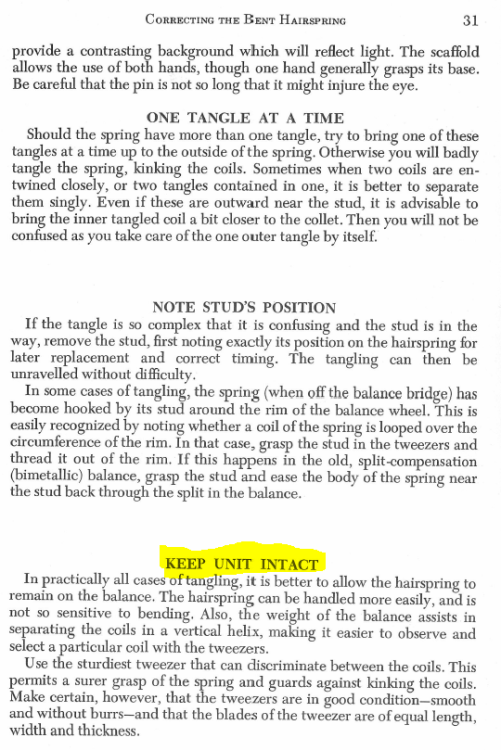

The title that has the "Correcting the bent hairspring" and "Replacing wheel teeth" section is titled "Bench Practices for Watch and Clockmakers" as shown above. The other book without the two sections is titled "Bench Practices for Watch Repairers". I have both because I wanted the hairspring section. I am not sure why he had two separate books like that.1 point

-

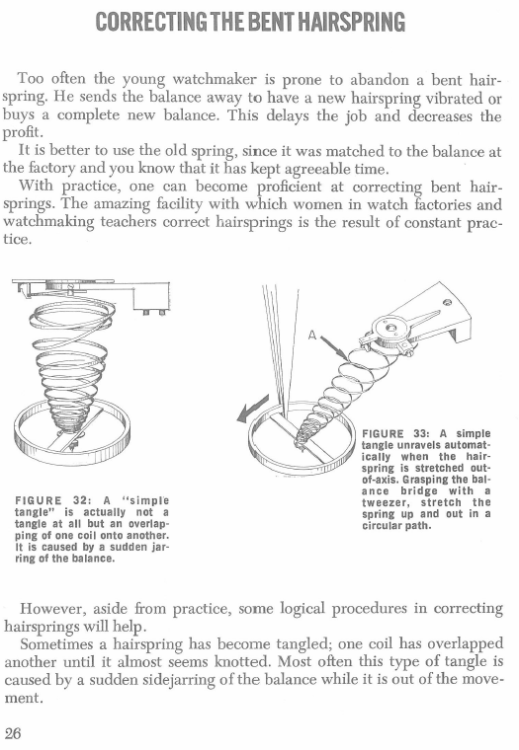

Sometimes my dictation software doesn't do the best job so let's try again. The book comes in variations are those variations importance maybe maybe not. But let's compare the table of contents and see if it would be of it of any help at all to anyone in this discussion So basically they're identical except there is a section starts on page 26 ends on page 43 it's titled Correcting the bent hairspring wonder if that would be to use? Then much farther down something about replacing wheel chief which I doubt any of us would ever do I might've done it wants sometime in my life it's the other section that's the more interesting section is why gave you the page which explains which edition that I have why made the reference to separate editions because? The table of contents of this book doesn't exactly agree with the contents itself for instance what do we find on page 26 of my book well it looks like this Then as I scroll through the missing section of your book page 31 has something interesting on the bottom. This often comes up when people are dealing with their hairspring crisis often times in the group people say remove it from the balance wheel and it's not what's recommended it's easier to work with it when it's all together although it be easier to not to have to deal with this at all. Now we get the page 32 which is weird because it's section what exactly and in the next section has the exact same Number and it's almost like this section is into separate section so it was inserted at some point in time or possibly removed from the other books but it's back to my caution the book comes in variations make sure you get the right variation otherwise you're missing what I consider a really useful section on fixing distressed hairsprings.1 point

-

1 point

-

You need to take it out of its case, remove hands and dial and take a good clean photo of the keyless work and upload it for us. That is the way to I D the movement.1 point

-

1 point

-

1 point

-

1 point

-

Oh dear - The watch came back. Developed a tendency to stop after 12 hours and checking on the Timegrapher we have 185 amplitude DU and similar DD etc - this thing is not happy. So we go back to basics and go systematically from the barrel upwards. There was a little side wear on the barrel arbor hole - very slight but I closed this up with my staking set and got it broached out. No change. Barrel arbor runs freely and little wear apparent. Assemble the train wheels after getting their pivots under the microscope - all clean,true and shiny. All run freely. No change. Pallet guard pin looked very slightly bent down - on this balance design that should not foul anything but made sure it was straight and true. ( The Omega 600 series is very slim and impossible to get photographs or see in this area when assembled )At this point the amplitude increased slightly - interesting. I gave the impulse jewel a test with the tweezers in case it was starting to become loose - looks good but under the microscope there was a slight discolouration. Could this be some coating I had not noticed ? Gave it another good Rodico and clean and hey presto, We have 235 degrees at DU and half wind with a clean trace. So, what have we learnt ? Poor initial observation on my part and sometimes normal cleaning will not shift every deposit. Vintage watches need closer examination and methodical diagnostic skills - they are endlessly entertaining.....1 point

-

I checked around where you linked and it seems that this is the 7522 is the closest match I did a bit of extra searching and after a bit I found a similar looking movement and watch here and after looking through the thread it turns out that it is the same movement, I may try and reach out (if its allowed) and see if they can give me any advice on the model of the watch. thank you for the suggestion by the way, that's going to be a very useful website in the future.1 point

-

High folks. I had the escapement apart and found a tiny piece of lint hiding around the escapement wheel. I could not see thus even under the microscope. Problem now gone away and running to 2 secs a day when worn. Thanks again.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)