Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/23 in all areas

-

I would like to give my support here. You may or may not know I've been retired from watch / clock making for years after around 30 years. I still learn a lot on here about many things, how you go about trying different things with some wonderful results. So members old and new keep up the good work and a Happy New Year to you all.8 points

-

6 points

-

Hi guys, I joined this forum a few years ago now and have enjoyed reading the posts and offering help where I can, as well as learning things I didn't know. Although I am a professional watchmaker and watchmaking tutor: https://www.jonthewatch.co.uk/ I still learn a lot from you guys on subjects and watch movements I haven't come across before. I especially enjoyed a post this week by @eccentric59with his walkthrough of an ETA movement that had a plastic fork and escape wheel, which I haven't worked on before. All watchmakers, including professional watchmakers, are always learning something new. It would be incredibly arrogant to say 'I know it all'. Even WOSTEP-trained watchmakers with many years under their belts are always learning something new, even from those relatively new to the art of horology. I trained a watchmaker from Christopher Ward Watches recently and hopefully will be writing them a service manual this year for their in-house movement, the SH21 because they want the expertise I have to be able to train their guys how to service it, which I feel quite honoured about, as I am not WOSTEP-trained. I know I'm rambling a bit, but the point I'm trying to make is that we can all learn from each other no matter where we are on our horological journey, be it professionals, seasoned enthusiasts, or the weekend fettler. I would like to share something with you which is a word of warning, that some of you may not be aware of. This isn't a character assassination or a resentment I have, it's just a fact that might help some of you. Cousins UK: https://www.cousinsuk.com/ ONLY sell to what they call 'Trade Buyers' it is stated in their Terms & Conditions; that means that you need to be a professional watchmaker in the trade to have any real binding contract with them. They are happy to take your money as many are not in the trade, but if what you buy is defective, damaged, missing, or you want to return it to Cousins for whatever reason, you don't have a legal leg to stand on and you may not see your money again. So if you are planning to buy an item that is quite pricey keep this fact in mind if that item is not working properly or stops working a few weeks or months later, then you won't get any redress. Companies such as HS Walsh and Gleave and Co. sell a lot of what Cousins sells for a very similar price and sometimes cheaper, but at least you will have a chance to contact them and make a claim. I buy from Cousins from time to time, but wouldn't buy an expensive tool or item for this reason. Mainly watch crystals, gaskets, batteries, and the odd mainspring. I mainly buy from Gleave and Co in Clerkenwell, London, as they have the expertise to be able to help you on the phone and they are also a small family-run material house that I have trust in and would prefer to put my money their way. Gleave and Co. have integrity. Their website is getting better and sometimes what they have isn't listed on the website, but a phone call (8.30 am to 10.30 am) or WhatsApp message (anytime) will sort that out. Expensive equipment, such as Elma watch cleaning machines, or Bergeon case back removal tools 5700, etc. can be bought from HS Walsh or even cheaper from a German Company called Beco Technic: https://www.beco-technic.com/en/ You have to set up an account with them, but even with shipping and VAT thrown in, it will end up cheaper than buying from a British company. You get a 10 to 15% discount on their prices once you register with them. I was a consultant for watchmakers in Essex who saved about £25000 buying through Bec Technic. I can only tell you my experience and some may have had a good experience with Cousins getting a refund. It took me once over six months to get a refund for a £40 quartz movement that was delivered to the wrong address in an order that was several hundred pounds and after spending about £5000 with them, as I was the buyer of a watchmaking college. Only when I threatened to buy from elsewhere that they refunded me/the college for the missing movement. I hope this helps some of you in some way, as there are more material houses out there other than Cousins.5 points

-

May I second this sentiment- I am grateful for the contributions of everyone posting here in the forum but specifically everyone in this thread. Thank you all for assistance over the last year and We all look forward to your contributions and continued involvement4 points

-

Hi NEW. By the time you have done the job it will be priceless in the skills it has taught you, that’s worth more than money as it stays with you money soon vanishes .3 points

-

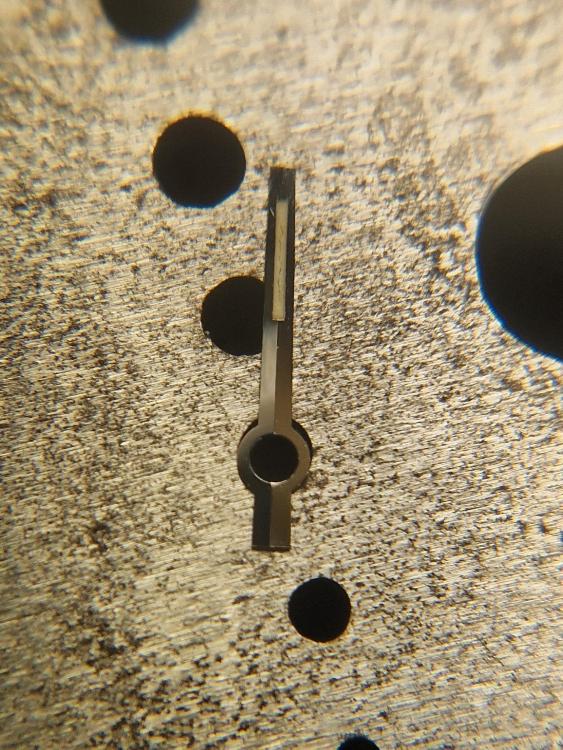

Well explained @nickelsilver Escapement handout wostep nscc.pdf This hand-out that I talked about earlier in another thread shows what has just been explained, but it also gives a pictorial view that sometimes is easier to understand. If the stone gets moved into the pallet without making these checks the stone might unlock before the guard pin or horn stop that from happening when the movement receives a shock. If you rob Peter, you gotta pay Paul!3 points

-

When moving stones or bankings, there's an order of checks to be done before moving anything. Copied this from another post: All checks done with balance in, some power on train rotate balance slowly and observe drop lock, it should be minimal and equal on both sides at the moment of drop, manipulate the fork to check for freedom, this is "corner clearance". There should be freedom, and the escapement shouldn't unlock move the balance further a few degrees, check the fork freedom again, this is horn clearance to roller jewel face, should be small enough the escapement doesn't unlock continue moving the balance, now you will be checking guard pin clearance. Should be smaller than the horn clearance, and if so it will also be safe The above checks are checking the function of the pallet jewels relative to the roller jewel and safety roller. Observe how much lock is left with the fork horn against roller jewel- this is an indicator of how much adjustment you have as far as moving the stones in. The lock must remain safe with horn in contact with the roller jewel. All checks done on both stones of course, and in theory over the course of a whole escape wheel revolution. This will get the stones in more or less their ideal position- and disregards the bankings completely. Next, moving balance slowly, at the moment of drop lock, observe the travel of the fork to its banking (looking at the escape tooth/pallet stone, not the banking). This is the "run to the banking". It is essential, but can be very small, bearing in mind that there are sideshakes that can eat up some of the clearance between fork and roller table in vertical positions. Run to the banking plus drop lock = total lock. So to boil it down as simply as possible for practical use, you can check the fork horn clearance, observe the lock remaining, and that amount "minus a little" is about the max you can move the stone in. *** If the total lock is large, and there is a lot of run to the banking, you can close the banking. Easier said than done on many movements, as this might entail forging the banking with a punch in numerous cases. ***One very important thing to keep in mind with drop lock: moving one stone affects the drop lock for both itself and the other stone. If you move the entry stone into the fork, you reduce drop lock on the entry stone, but the escape tooth will also be released sooner on that stone, reducing the drop lock on the exit stone as well. And vice versa. After moving a stone, you must recheck for safe drop lock and safe fork horn clearance. Moving a stone affects drop lock similarly on both stones, and total lock on that stone. Moving a banking affects total lock for that stone, and run to the banking for that stone. No effect on the other stone.3 points

-

I'd like to second this. I'm not at home right now, so I can't consult my own list, but I think Beco have two separate online shops, for trade and hobbyists. The range of part and tools offered by the trade (wholesale) shop is very good. The retail shop is very limited. You can get an account for the wholesale shop without declaring your company i.d. or VAT number, so you pay the VAT up front, similar to the way most of us have our Cousins accounts set up. The problem is, you have to (falsely) declare that the goods are for your business use, so as a hobbyist you are breaking their trading t&c right there. The way I see it, when I deal with Cousins or Beco, I am entirely relying on their goodwill, especially if things go wrong. Fortunately, bad experiences are uncommon, but it's worth understanding the risk.3 points

-

I apologize I was born with dyslexia. I use dictation software sometimes it has a mind of its own. I usually do try to proofread but I'm sorry that my incompetence bothers you I will try better to be more competent. Then if you would please quote the offending text I will see if I can decipher what I was trying to say versus the dictation software. Then once again I apologize for my incompetence.3 points

-

Is this what it was like in the 80s and 90s for retiring watchmakers ? Poor old sod https://youtu.be/29oO__D8wf4?si=BB54z38LUqm8suMH2 points

-

2 points

-

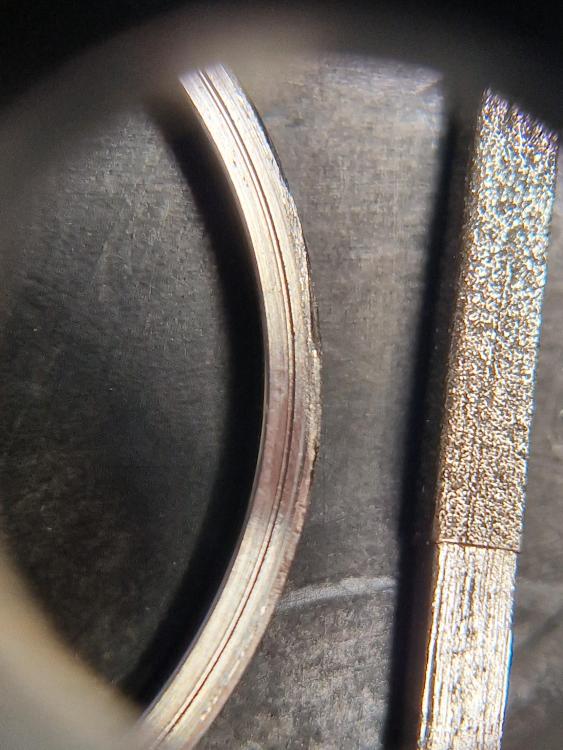

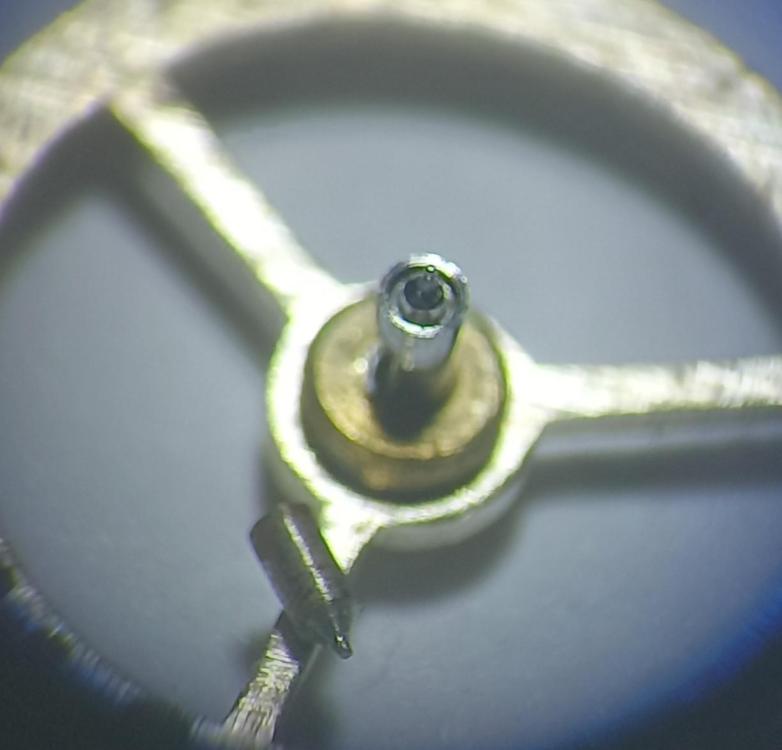

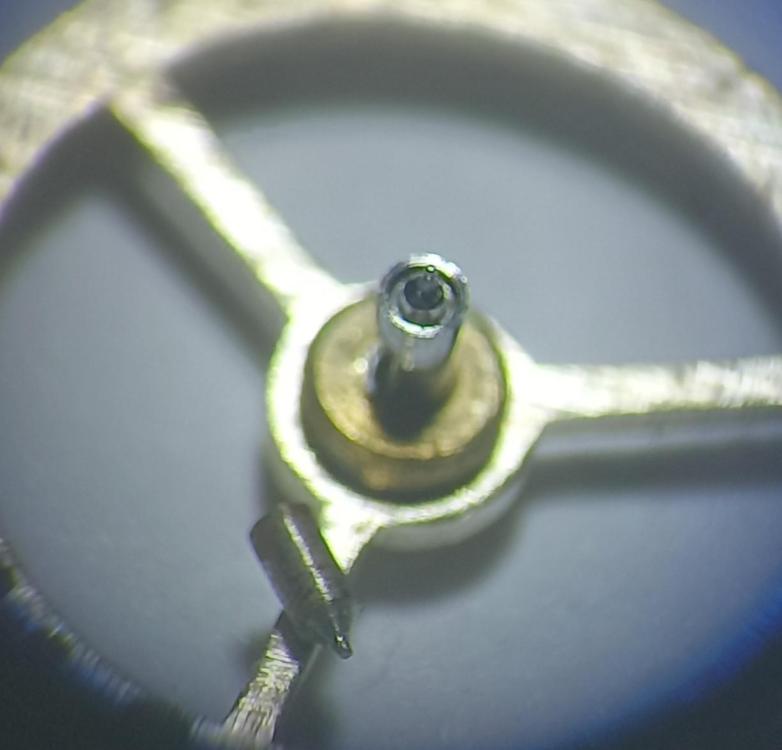

A diamond file and a Jacot provided me with another pivot, its not there yet it still needs a cone adding and the pivots sizing and polishing. The broken one was hand made with just a rough taper up to the pivot and seemed more than long enough to re-use so i filed the taper out to extend the pivot, i didnt trust my lathe skills so I used the Jacot to clean it up. If the movement tick for a few minutes I'll be more than happy.2 points

-

2 points

-

Just the sense of achievement and lessons learnt can be more than worth it. I'm battling at the moment with an old cylinder esc. movement that is worthless. Trying to make a new plug for the cylinder or slowly but surely file in a new pivot on the old one. In the process I've learnt that turning a balance staff is a real skill but not beyond my ability. All lessons learn are worth the effort.2 points

-

Now I'm frightened, i have a £300 order to make with Cousins. I have a business account with them, a business that may exist one day but probably not.2 points

-

I’m sorry to hear there have been issues with CS at Cousins. They once sent a sealed mainspring with what looked like beard clippings inside but otherwise I’ve never had an issue with them. Frankly I’m pleasantly surprised with their accuracy given there are humans involved2 points

-

If it is a fake they faked a Must and not a Cartier? You may have been innit just for the treasure hunting but If you like the idea of improving this tis true you could replace the movement without much expense and cleanup the case and band. The dial is in good shape… I have no suggestions on the..bezel thing? What is that? Could that have been plated or painted at one time? Ugh…sorry, now I vote bin…2 points

-

2 points

-

2 points

-

I was thinking that he probably knows where everything in the entire shop is. Then I was curious where the shop was and whether it still existed and the building exists of course he is no longer there the article explains when he died. That I was wondering if his apartment was above the shop? http://westhampsteadlife.com/2014/01/15/a-moment-in-time-on-mill-lane/99212 points

-

Have you dealt with them? I should be careful about sites and companies that you haven't had experience with. As you know there are so many cons on the net. Google cant even translate that page. I wouldn't touch it with a barge poll . As far as I know you are with in the rules but I wouldn't take it further.2 points

-

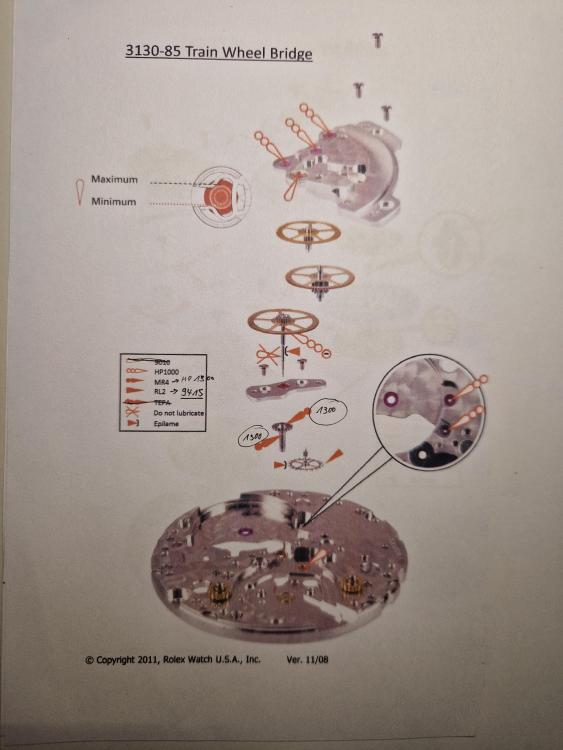

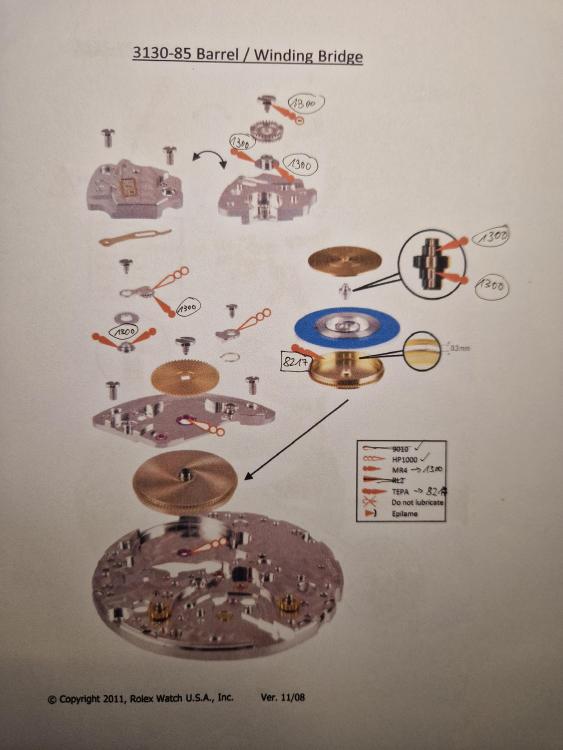

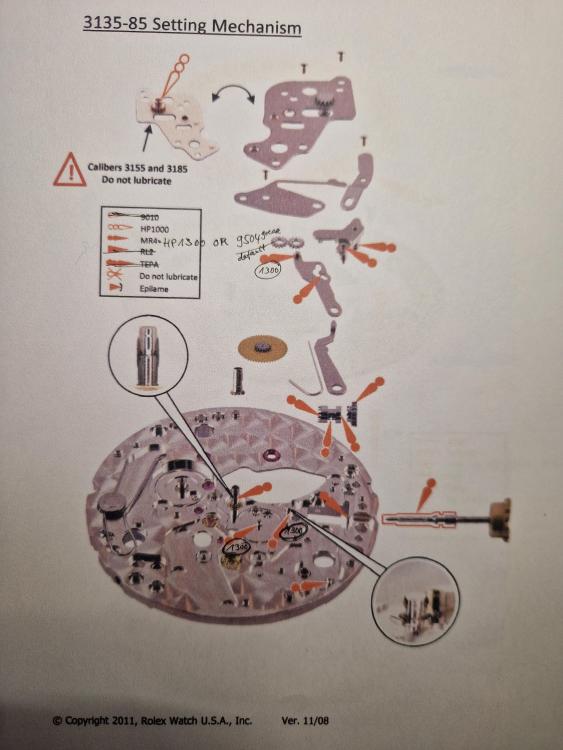

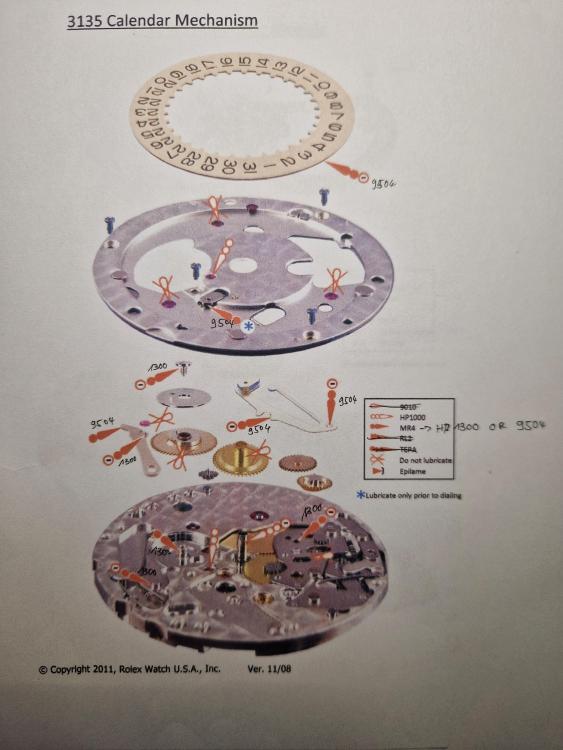

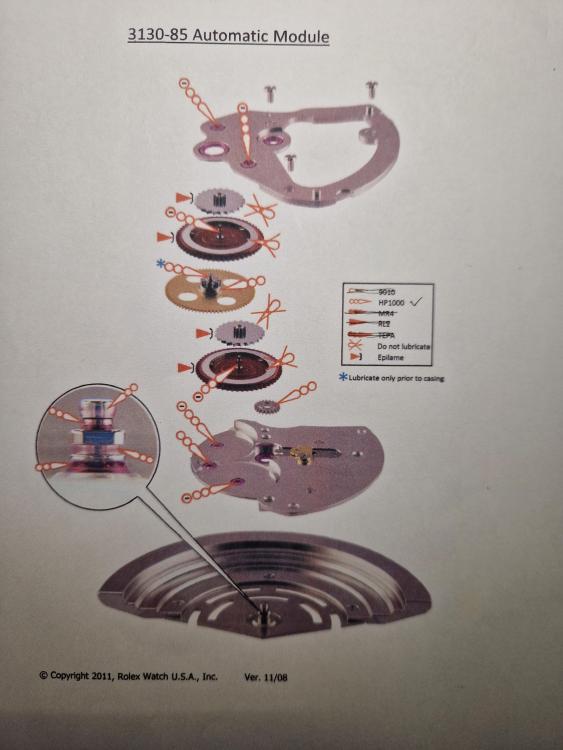

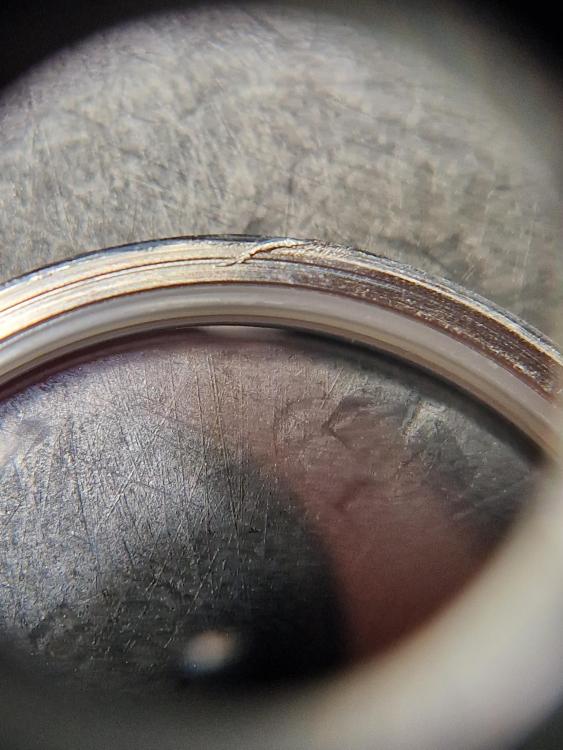

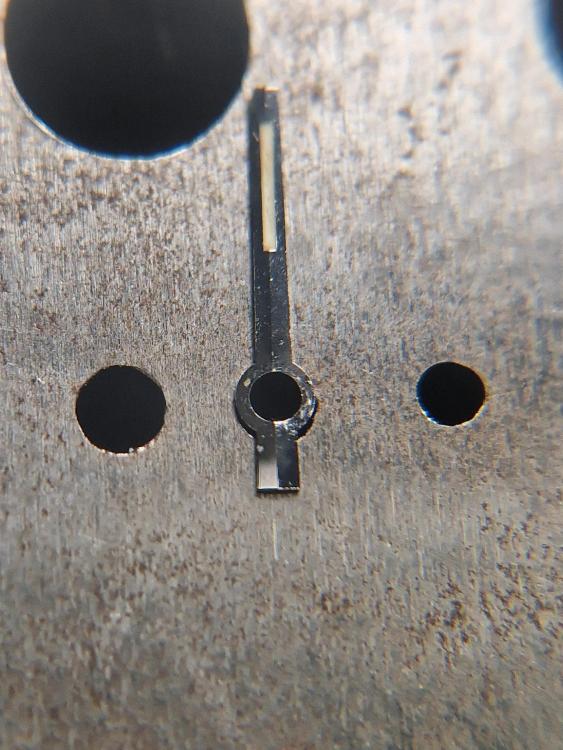

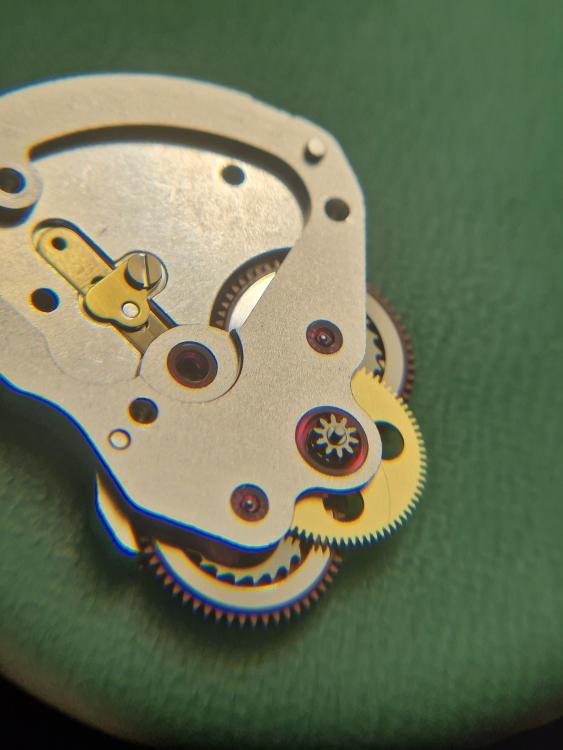

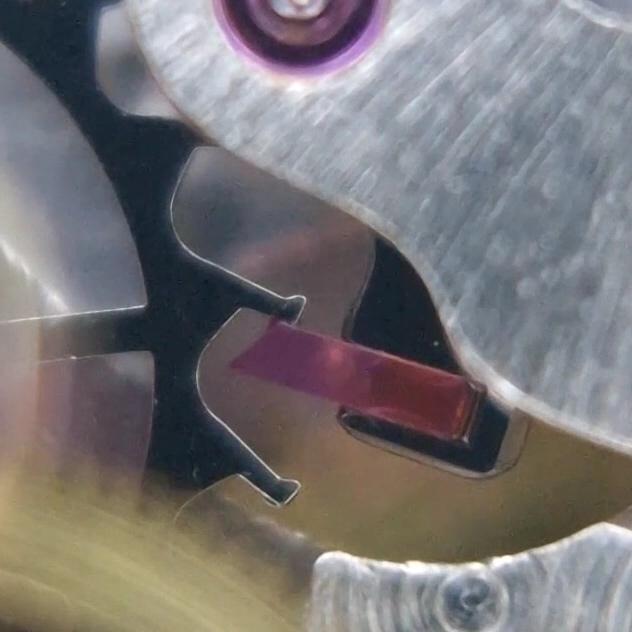

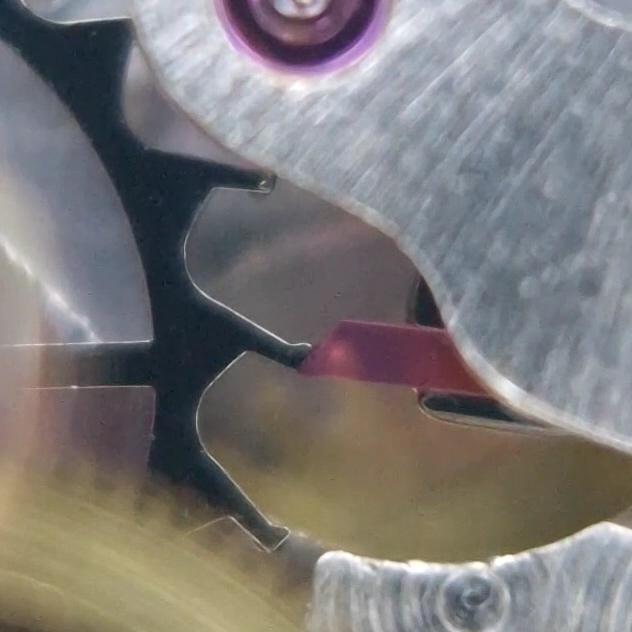

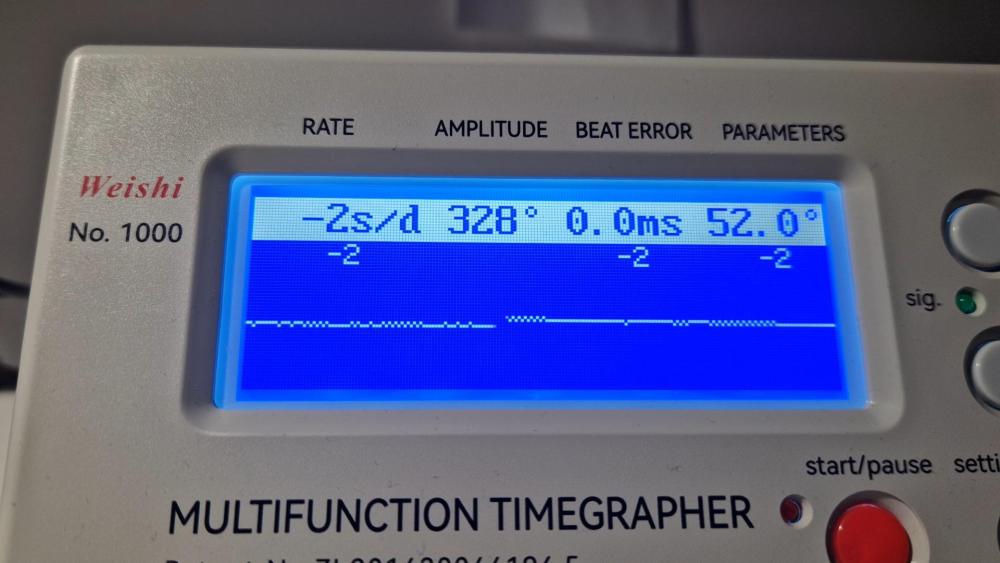

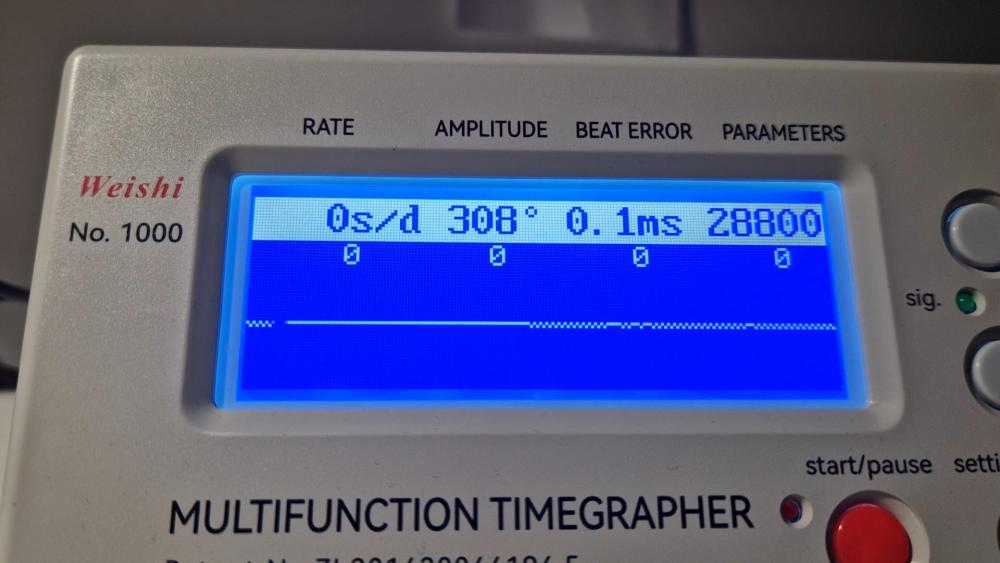

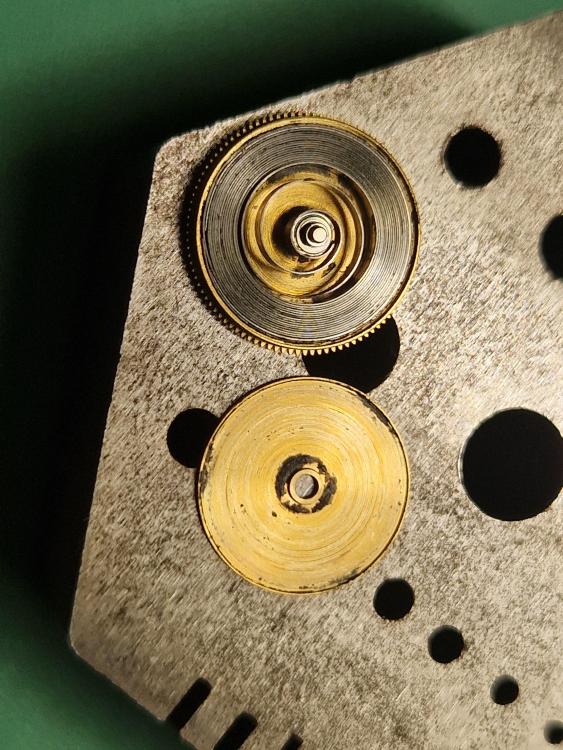

Hello all and merry Christmas (in advance)! I just finished a service on a Rolex 3135 in a lovely Datejust 16220. First, here are some overview pictures of the movement: The watch was in overall good condition, but it was running a bit fast and inconsistent (across positions) and amplitude did not reach 250 even fully wound and dial up. Upon disassembly, I did notice some a bit of dirt and some jewels/pivots had run almost dry. The barrels shocked me again (similar to the Rolex 2035 that I recently serviced): Thanks to @JohnR725, I had access to detailed oiling charts and service training guide: https://www.watchrepairtalk.com/topic/3626-rolex-3135-beat-error-adjustment/?do=findComment&comment=234180 After some good pre- and final cleaning, I assembled exactly as prescribed by the Rolex training guide that I followed the service guide in detail. For lubrication, I followed the Rolex oil chart, also posted in the link above. One particular issue is the Rolex lubricant "MR4". It seems to be somewhere between a very thick oil (like HP 1300) and a grease (like 9504). I used either HP 1300 or 9504 as a replacement and depending on the particular locations. My final "interpretation" of the oiling (with Moebious oils) is as in the pictures below. Regarding the pallet fork, the Rolex training guide seems to suggest a rather large quantity of 9415. Consequently, I put more than I usually would (but still less than the suggested amount by Rolex). See pictures below. What are your thoughts? For the automatic module, as show in the Rolex oiling chart, I treaded the reversers with Epliame and was VERY light on the lubrication of the "internal pivot" (see screenshot). As prescribed, I did not oil the internal ratchet/click mechanism of the reversers. Case: The previous watchmaker left me a present under the bezel. I noticed that it was not sitting perfectly even on the case. He (or she) must have removed the bezel in a way that damaged it a bit. I filed the damaged metal away with a diamond micro file. Bezel back on with my trusty Robur (with 3D printed adaptors for "standard" M4 dies). The dial and hands also got a bit of cleaning : Before: After: Casing: 1. align the case clamps on the movement with the matching groves in the case. That's how that looks. Turn everything around and slide the movement into position. Insert the stem. Done. At full wind/dial up. Vertical positions are running a bit faster (+8-10 seconds). I may look into regulating that further. I'll eventually post more results. To conclude, my usual "artwork": Merry Christmas to everyone!!!1 point

-

Hi Guys, My age has finally caught up me. I haven't been able to work on (read, break) any watches for the last couple weeks due to a herniated cervical disc. Lots of fun, NOT. As I recuperate I'm thinking about a work station that might be more user friendly for a painful neck. Maybe some of you older chaps have had to create a work-around to continue with the trade/hobby. I've thought about a much elevated desk where I could stand and work at eye or shoulder level. Right now I can't stand (or sit) at my desk computer for more than a few minutes, even though I put a box and plank of wood to elevate the keyboard and monitor; but maybe as I heal, working standing up might be a good option. With that, I am wondering if others have had to compensate for old age (especially back, neck, shoulder limitations), and what you came up with that helps. And perhaps, what made things worse. I hope that all who celebrate had a great Christmas, and a Happy New Year to all. Arron.1 point

-

Hello and welcome from Leeds, England. We're very patient on here, we are here to help. Ask away.1 point

-

Hi. Ca you give us a post of the complete back plate so as to confirm your identification. The kundo junior suspensions are all 0023” or .058mm lengh approx 90 mm measuring the old twisted spring is a no no as its length will be compromised by the twist. The recommended suspension is 5E in the Terwillers 400 day book. It also gives you the block positions , top and bottom when making up the suspension. These clocks look simple and in a way they are but and it’s a big but is they MUST be level and adjusting the beat without the correct tool is possible but not easy to achieve. There are also two styles of anchor post which have to be taken into consideration. Suspension units are available from Cousins UK, Esslingers, and Jules Borel, timesavers in the USA. I cropped springs to fit with no ill effect. The thickness is critical as the clock works by rotating / torsion with minimum friction. It has to be set up properly or it will not run The full height of the suspension including blocks is 94mm measurement taken from the book.1 point

-

Rolex_Movement_Calibre_3130_3185_5.pdfRolex 3135 parts (1).pdfThat's not bad for 7-8 years after the service! Congrats on a good job back then. But I guess it's time for a service indeed. It should be above 190-200° in VERTICAL positions after 24h. Don't wait too long. I recently serviced a Rolex 2035 had it's last service 10 years ago and both the reversing wheels and the rotor axle needed to be replaced. Cost of 350 EUR (for NOS, original parts))... and I'm pretty sure that this could have been avoided if it had come for service 2 years earlier. You'll find my thread about that service on the forum, too. Here is everything you could possibly find on the forum in one place. Except my "special notes" (sorry, only phone pictures of those). CALIBER-3135-3155-3175-3185-TECHNICAL-INFORMATION.pdfRolex oil chart 3135.PDFRolex 3135 parts (1).pdfRolex_Movement_Calibre_3130_3185_5.pdf Indeed. It seems to be irresistible to lubricate the centers and the clicks of the reversers...1 point

-

Just as a data point, I've placed five small orders with Cousins this year, all shipped via Royal Mail to Canada. No issues with any of the orders. And Cousins packs up my orders better than any other vendor I deal with. For example, small parts (say the size of a watch crystal or smaller) come in their own bag or envelope, which is then placed with other small parts in a small white ~10x5x0.5cm box, which is then placed in a large plastic bag with other small boxes and/or medium sized parts/tools, which is then placed in a Styrofoam-peanut filled shipping box. I do try to shop local (e.g., Perrin and Somal in Canada) when I can, but Cousins has the best online inventory I've found so far and often best price. Cousins price for shipping from UK to Canada via Royal Mail is comparable to what Canadian vendors charge for shipping across Canada.1 point

-

It's a nice look..to have, I would search to find a vintage rescue instead of the £1600 heritage...1 point

-

I have resistance to anything to do with training. Gym is a swear word to me. Hehe.1 point

-

The most skilled and successful people I have had the privilege to meet in my life were all also the most humble, curious, and inquisitive, and I think, no, I'm sure there's a strong connection between humble, curious, inquisitive, and success. I shall never forget my meeting with Mstislav Rostropovich in the early 1980s. I was a violin student and he was coming for a visit to our music school. We, the students, and the music world thought of him as a god. In my mind, I was picturing us, the students, bowing before him and thanking him for visiting our school, but when he arrived he shook hands with each student, introduced himself, and thanked us for the invitation. I will never forget it. And as I remember it he had more questions for us than we of him. It blew my mind.1 point

-

1 point

-

I don't like it, I like sub seconds, I like two tone dials but for some reason it doesn't work for me. Personal opinion of course.1 point

-

Second this…and I’ve purchased everywhere too but have only been ripped off from the good old USA1 point

-

Hi eccentric, WRT site forbids buy& sale in any form for financial gain, it does not forbid sharing links to good finds. I just suggest this idea , the decision to accept/ reject it is not mine to make. Finding a super earth must be easier than international shipping from my neck of the woods, anyway, but is business as usual globally. Rgds1 point

-

Some vintage tools can be a good deal over the cost of new. I have some nice vintage Dumont tweezers and some other vintage tools that were a good deal. Then there's some vintage tools that go for pretty insane prices. I'm still trying to understand why people would buy a JKA-Feintaster micrometer off of eBay for more than you can buy them new.1 point

-

Hi. A good dose of elbow grease and a new movement approx £10. To £12 and you have a decent time piece might not be the real thing but brought back to life, worth a bash in my opinion. Go for it.1 point

-

As far as I'm concerned that is fine. You answered my questions. As you know we have to be careful.1 point

-

1 point

-

Far be it for me to discourage a little treasure hunting. Last year paid a couple hundred gbp for an auction lot for ‘costume jewelry’ and a couple watches, one clearly a Bell & Ross or Bell & Ross fake. The wife wanted the baubles so I paid more than I should…though those pearls in there do look real, don’t they? Well the pearls are real- 3k worth and I have a lovely Bell & Ross fake with a Chinese movement that puts the timekeeping on my iPhone to shame . Happy hunting…1 point

-

1 point

-

I cant say i have a problem with it I always manage to work out what you are explaining, sometimes its just how you say it. We all talk differently especially me, because well I'm just wierd anyway.1 point

-

Good old Norm, he'll have forgotten more about watchmaking than I'll ever know. I wonder what it was like in his shop in the 30s when wristwatches were becoming ever popular taking over from pocket watches. I bet there wasn't a watch brand he hadn't handled, what a mentor to have for vintage repairing.1 point

-

Sorry to hear about the problems with your health. I have mentioned may times on here posture is so important. I had to pack it in due to poor posture which left me with spondylitis of the neck. I was diagnosed with it when I was around 40 the specialist said the wear in my neck was from someone who should be in there 70's. I googled what you have and it says over the counter meds and physical therapy can help. One thing that helped me was this Ergonomic Kneeling Chair they are so comfortable. I wish you all the best for the New Year. Let us know how you are getting on. Here is a link for the chair. https://www.amazon.co.uk/CASART-Kneeling-Ergonomic-Orthopaedic-Posture/dp/B07FVPBQRL/ref=asc_df_B07FVPBQRL/?tag=googshopuk-21&linkCode=df0&hvadid=345504571362&hvpos=&hvnetw=g&hvrand=18310946125231996355&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1006662&hvtargid=pla-734972430933&mcid=99af9cf8284a367c9ebbbef6e57a62ce&th=11 point

-

The spring bar removal tools you can buy are crap., even Bergeon ones. They will bend. They don't make them hard enough, as they want you to buy more. You need to make your own with tool steel, hardened and tempered, so it won't bend and will get the spring bar out after soaking in penetrating oil. Some spring bars can only be released from one side, so keep that in mind. Homemade tools are infinitely better than anything you can buy. If you are still having this problem, DM me and I'll send you a homemade tempered and hardened spring bar tool you can mount in a screwdriver fitting.1 point

-

I have made some changes to my DIY machine over time and thought that I should do an update of this thread. Outer wash basket has been redesigned with larger openings. Prints a bit faster and uses less filament. Also added a bottom impeller to encourage fluid flow through the basket layers. Added a basket layer that holds 4 of the mini mesh baskets. I still have one for holding 3 of those baskets. Drying shroud was made a bit larger. Less chance of the basket rubbing against the sides. Bottom jar baffles replaced with stainless steel mesh along the sides of the jars. The bottom baffles looked to be reacting with the wash and rinse chemicals. The stainless steel mesh has not had that issue. Testing with and without the baffles does show some reduction in the swirling of the fluid. https://www.amazon.com/gp/product/B0BMTY6KH4/ I extended the stirring rod for the basket. My 3D printed extension ended up breaking. I used a coupler and a length of stainless steel rod instead. I did grind some flats on the ends for the basket and the coupler to tighten to. https://www.amazon.com/gp/product/B07P5YZKY5/ The STL files have been updated for the 3D printed items. https://www.thingiverse.com/thing:59051661 point

-

So far, since 2015, CousinsUK has given me an excellent services, including returned items of low value when Royal Mail cocked up. In all those years that I've been ordering, not a single item was faulty. CousinsUK also gives the IOSS service (Import One Stop Shop) for Europe, which I can't find by HS Walsh or by Gleave & Co (?). Anyhow, thanks for the alternative addresses, but for these to have any value to me, they have to have IOSS1 point

-

I have a cut-off point of 335 amplitude. Anything below that is not going to knock. Anything that goes above that is usually going to start knocking. As this is an automatic it is generally going to be at full wind and full torque, but after a day or so it might settle down. It does seem quite a high amp for a 3155 to be honest. What spring did you fit? I find that at the total full wind for a 3135 it will be about 300 to 310. Did you put enough braking grease on the barrel walls? It might be slipping way too late.1 point

-

Thanks for responding! Funny you say "if you are really concerned about over oiling"... While I really wasn't concerned by it, I had this random/nagging feeling that I may have forgotten to lubricate the mainplate jewel for the mainspring barrel. Conveniently, it's possible to take out the barrel by only removing the automatic works, ratchet wheel and barrel bridge. The movement can even stay in the case. So I did that and, well, found that there was oil. So I didn't forget. However, I noticed that the upper jewel (in the bridge) was barely lubricated. Funny how my mind led me to that issue.. Anyway, so I lubricated the bridge jewel properly now and... amplitude is now through the roof! When I took it off my wrist after a few hours of wearing (and it was fully wound when I put it on), the timegrapher went up to 330°. Now I'm actually a bit concerned that I risk knocking. But it calms down after just 1-2 minutes and goes to 300-310°. So I think that the risk of knocking is low as you never really wear the watch in a perfectly horizontal position. Wound to the limit, straight off the wrist and onto the timegrapher (dial up): After just 1min:1 point

-

Somewhere between then and now I got a more complete kind of service guide. The original one just cover the 3135 whereas the manual itself is supposed to cover several calibers. So now we have the manual it more or less is complete. Then we get the parts list and somewhere in the universe I found a lubrication chart. CALIBER-3135-3155-3175-3185-TECHNICAL-INFORMATION.pdf Rolex oil chart 3135.PDF Rolex 3135 parts.pdf1 point

-

Hi Everyone, Longtime lurker on this site but I'd like to get more involved in this community as I've built up a couple years worth of knowledge as an amateur watchmaker. I love tools, which is one of the many reasons I'm attracted to watchmaking. I looked around at trying to purchase a L&R machine but was put off by the price. Last week I decided I could build something suitable for my needs. Previously I've been using a 3 step ultrasonic setup. I give you my Frankenstein! Total cost of the build was approximately $150 (not including L&R #566 and #3 Rinse) and includes a heated dryer function which works wonderfully. It took approximately four hours to design/assemble. I used an overhead stirrer and threaded the attached rod to attach to a tea strainer. And yes, those are indeed cones cut down to hold the mason jars :). Looking forward to participating in this community. Here are the parts: VONOYA Electric Overhead Stirrer w/ timer and speed controller Amazon Basics 500-Watt heater with tip sensor disabled (6x6) 6 inch HVAC connector 3 mason jars (thanks wifey) Soccer cones (thanks kids) Gladicier brand tea strainer w/ misc lock washer and nut from Hardware store BN-Link Indoor Countdown Timer (for heater so I don't burn the house down) Old shelving cut down (thanks house remodel)1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.f0fdcb904fb94600b8d08cf1e4ea5a6b.jpg)