Leaderboard

Popular Content

Showing content with the highest reputation on 12/01/22 in all areas

-

No that's definitely a bad attitude. Especially with American pocket watches the banking pins are movable and you should definitely move them leave them in some random place because you can what would be the consequences? Just to be technically correct that's not exactly a wostep handout. If you look carefully at the title which I think I changed after I downloaded it it's a combination of wostep and North Seattle community college As that's Where I down off their website. Which is why it's kind of a mixed up mess of things. But still it's good even if it is kind of a mess Then there's the problem with escapement terminology and time and wherever you're located or and a combination of all of us. If you look at various handouts on the escapement and I'll add in a couple more for you they have differing terminologies and they'll get obsessed with certain terminologies and stuff. The terminology becomes kinda Of amusing like so many things in watch repair there can be actually multiple names for the same part just depending upon where and when. But as you like handouts let's attach a few more. I usually think of the banking pins is there for Horn clearance only. But other people think of them as solutions to potential problems that they perceive they have or have not. Which is why typically on American pocket watches with movable banking pins they been moved. Then related to these so-called wostep handout is this lecture. Yes a perfect example of what happens when you film a lecture given at AWCI convention the audio sucks. But it's an extremely good lecture he's a very good teacher is well worth your time and effort to try to make it through it. Elgin watch company Escapement Terminology.PDF Escapement Detached Lever Escapement.PDF Escapement Elgin setting up the escapement.PDF4 points

-

Here's a copy of a Wostep handout regarding the escapement. It doesn't use the exact same terminology as @nickelsilver's steps, but I believe it covers the same territory. Escapement handout wostep nscc.pdf3 points

-

Are you rinsing it after cleaning in lighter fluid? If not there may be residue. Try rinsing with 99% Isopropyl alcohol, and dry it with gentle heat, with the parts in a basket you can use a hairdryer. A puffer works, too, if you have one. Fluid can get trapped between the coils and take forever to evaporate, but I'm not seeing that in your picture.2 points

-

For the most part it's hard to see this. Sometimes with a pocket watch and no hairspring you can see it. All you really need to see is the fork look at how much the fork moves in relationship to anything else you can see.2 points

-

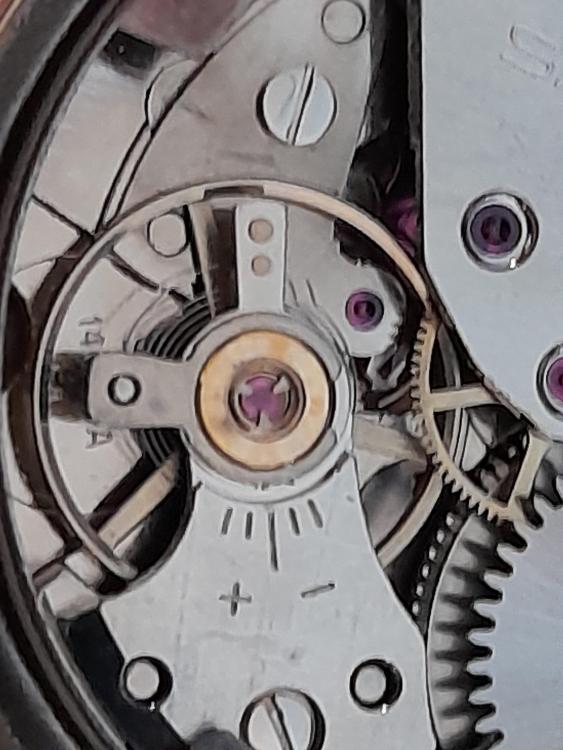

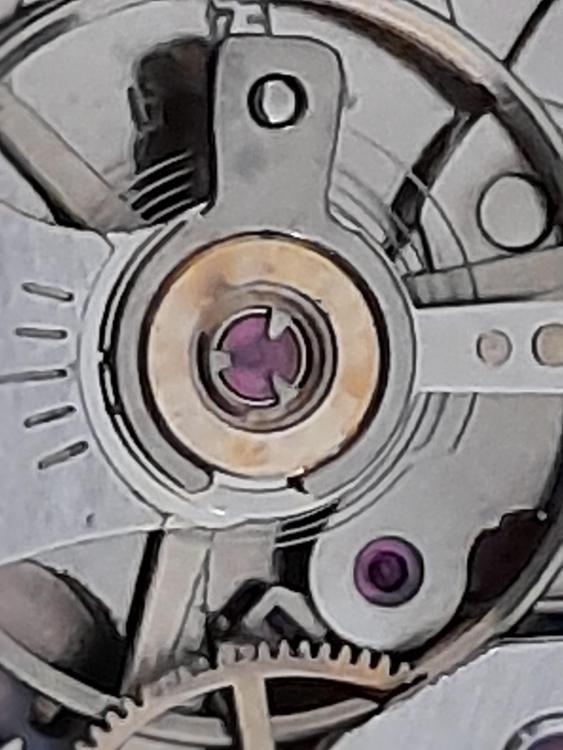

Now that I have the jewel issue sorted out, I'm having a new problem. I figured it'd make sense to keep the question in this thread instead of starting a new one in the repair forum. Hope that's okay. This is my first time working on a day/date mechanism, so please feel free to correct any of my assumptions here. So there's a jumper gear at the red arrow here: When the stem is pulled out to the center position, it moves left or right depending on how you turn the stem, presumably to set the date in one direction and the day in the other. When the stem is in the winding or hand setting positions, it's held to the right so it doesn't engage with that brass wheel. The problem is that jumper gear is extremely difficult to turn. Without that plate installed, the train runs free and there's power at the pallet fork. When I install that plate, the the train doesn't run at all. The pallet fork just hangs free between the escape wheel teeth. The part I'm confused by is how did it run before? Is there something about the day/date mechanism that I'm missing here? As far as I can tell, that jumper gear isn't removable, so I'm not sure how I would fix it, either. I feel like I'm missing some bit of knowledge here, and I'm hopeful this board has it. EDIT: Well friends, turns out today I am a ding-dong, but I'll leave all this here for anyone in the future. In the end, I was able to problem solve my way to the answer, so I guess it's not so bad. This small gear is upside down. The long part of its arbor interfaces with the nose of the stem, which lifts the gear up off the center one that's connected to the 3rd wheel. Flipping it over fixed the problem. The gear I was originally talking about is still stiff to turn, but it's only used when setting the calendar works, so I'm guessing it's supposed to be that way.2 points

-

I repaired one for a friend earlier this year. It belonged to his father, so I think it a genuine piece. The watch has an integral bracelet, which broke off at the weld many years ago. It was welded back by the agent in Hong Kong but was told that the movement was faulty and there were no spare parts. Really strange. I found that the centre wheel bush was worn and when I was testing it, it fell off the plate and disappeared. My heart missed a few beats! I spent hours searching for it to no avail. I bit the bullet and did a rebushing. Thank God I was able to solve the problem and restored it to working order. I even did a dial repair. Matching the paint color took a bit of trial and error but I managed to get it pretty close. I only failed to get a matte finish to match the original finish.2 points

-

For hole jewels, there are ones with straight sided holes and ones with olive holes as you have seen. Olive holes have curved hole walls, straight are self explanatory. Olive hole jewels reduce contact area and thus friction, and are generally used in areas that are most sensitive, like balance/ fork/ escape wheel. They also generally (not always) have a convex face opposite the oil sink. The convex face further reduces friction when used with a shouldered pivot, and when used with a cap jewel (oil sink facing the arbor/staff) promotes capillary attraction of the oil between the jewel face and the cap jewel. Many old high grade watches have convex faces on all the jewels. Some may also have olive hole jewels up to the escape wheel or further. If replacing a jewel, certainly go for olive hole with convex face for a balance, and it's a better choice for other places if the size is available.2 points

-

1 point

-

That sounds wrong mate, quite wrong1 point

-

I'm with David on this one. Last month working on an old sekonda, i was convinced the hs was magnetised as it looked visually clean but kept sticking. After demaging several times with no change, so i got in very close with a scope and with a little experiment when magnetising a hs i could see the coils pull together when they got close enough. Other contamination needs a closer contact to stick. A thorough clean by pulling out the spring, some agitation of the cleaner with a puffer and even got a very fine artists brush involved. No more sticking of the coils.1 point

-

Yes a better cleaning procedure I think is in order. Did you know you can actually order or at least it's listed Amazon will let you buy cleaning fluids from them with free shipping. As of you don't want to do business with the material houses in this country you can buy it from there. Then yes I know a gallon will last you well almost forever the cleaning fluid will probably go bad before you use it all up at least that's what happened to my first gallon. But the rinse will last basically forever. Then they actually do make as someone else pointed out above special cleaner for hairsprings. It's a horrible smelling substance but it does seem do a really nice job of removing sticky things from watch parts. So I use it for spot cleaning stuff and the hairspring then for detecting magnetic fields you can use the compass method but I'm not a big fan. Then there have been apps for your phone don't actually know how well they work they will pick up magnetic fields I just haven't tried them yet with the watch. Then the current recommendations from the Swiss can be found at the image below. Basically the recommending a tool it would detect if the watch has been magnetized and only then is it demagnetized and that I guess it verifies that it actually successfully did the job. But my real guess is that you have something sticky on the hairspring and lighter fluid really isn't's a good cleaning product for watches despite the fact that everyone on this group thinks it S getting something more appropriate would be better.1 point

-

I have said this somewhere else on this forum: working on radium is simply not a concern IMHO. I posted several government papers on the topic that support my view and I gave the anecdotal evidence that my father worked on radium watches from 1947 to about 1990 without taking any precautions that I am aware of. He died at 93 of issues unrelated to radium All that being said, don't eat it or ingest it through other body orifices. I have one of the inexpensive geiger counters...just for fun.1 point

-

Hi essence of renata, one dip, (or the new version) I think one dip is discontinued a quick look on the net will bring up a few alternatives.1 point

-

Hello MSB, I stumbled upon your post which looked familiar. I then remembered my Sandoz watch I put to one side a couple of years ago as I wasn't too sure about the shock setting. I was only just getting into the hobby and didn't have the confidence. Still learning mind. I've found nothing so far on the movement other than it's a Sandoz and under the balance it says "SGT 140-A E4". I'm pretty sure this one is a Swiss one rather than one originating in India. It's got a textured face and initials on the crown. Though I'm prepared to be told otherwise. I found it interesting that it was possibly a cost saving/disposable consideration way back then, who knows. Just thought I'd drop you a line to say thanks for asking the question, and share what appears to be another example. As it's given me some options when I get round to servicing it.1 point

-

on the card it gives me it says 5-50 cpm is considered normal for this counter. Again assuming because it detects Beta and Gamma. I'm in the states. Particularly NJ. It says 0.13 - .16 in Sv/h. I highly doubt this is because of working on a few radium watches. "Normal background radiation (as measured by the Leiger), is around 20-30 CPM (counts per minute, or about 0.14 uSv/hour)" https://reimaginingeducation.org/what-is-safe-cpm-radiation/ This quote is from the website link above ^1 point

-

Bruce Shawkey just did a nice post on Favre Leuba. http://brucesworldofwatches.blogspot.com/2022/11/favre-leuba-deep-roots-outside-us.html1 point

-

You may have caught the post before I finished it - see final photos showing now. If you zoom in on the finish it certainly doesn't look good but it looks nice to me on the wrist.1 point

-

How long is " a while" ? HOURS ? DAYS ? I use to face the same problem with pin pallet Oris, asked for advice, Nickelsilver pointed out that it is a lubricant issue, took me months to realize my Moebious oil must have been at least twenty years old when I boubht it, if not a fake oil to begin with. Do you oil fork jewels? Do you oil fork pallets or escape teeth? When it stops put some lighter fluid on above named jewels, also generously on balance cap stones, does it then run again? Rgds1 point

-

I'm still experimenting what would work and what not. Also on a pocket watch the parts are much bigger and I'm currently working without the hairspring. But one of my attempts is to transfer the position of the impulse jewel to the top of the balance wheel rim. I made a dot with a black marker on the top of the balance rim and, to the best of my abilities, transferred the center-line pivot/jewel to the rim. Made a small score in the ink ..... at least one has an idea where the impulse jewel is ..... whether it works needs to be seen1 point

-

Thanks for posting - a very useful document which contains the pictures needed to explain @nickelsilver's instructions. Just what I needed1 point

-

Did you ask the question on the group of how should I do this? On any type of special end Mainsprings and I words things that have protruding off the edges that need to go into holes or slots In the barrel there is an easy procedure. Yes I know it's another tool to purchase but watch repair is all about purchasing tools. You need a mainspring winder the mainspring into the winder you leave a little bit out you do not wind it all the way and like you would normal Swiss type spring. Click a little bit sticking out to stick that into the barrel with the rest of the winder which means it all has to fit you have to pick the right diameter you rotated around until your slot lines up with the protruding part of the mainspring. You then pushed that part of the mainspring in the slot hold it in place with like the back end of a tweezer or the biggest screwdriver you have any push the spring out. The very simple procedure if you understand what you need to do. Otherwise you can hand winding up in but that is generally frowned upon for a variety of reasons. That doesn't mean that it doesn't happen every single day right now someone on the plan is probably hand winding a mainspring it just can't have issues it's better if you could use a winder1 point

-

A forgotten part of a horological history is what you're quoting. I don't have an exact time frame but somewhere in the 60s through the 70s there were a variety of solutions that you could have. One of them was called miracle lube and there are a variety of other names for them. I finally saw material safety sheets for one of them and basically it was mineral oil dissolved in the rinse the final rinse your cleaning that is. So the oils in the rinse it gets everywhere in its stride Larry action pulls the lubrication in to all the cracks crannies and under the plates but it's worked. Ms. very popular in high volume watch shops where there are doing literally hundreds of watches per week and they're doing M at a very bargain price because typically was wholesale work and go the jewelry store and jewelry store didn't care as long as it was cheap enough. For the most part all of those products are gone except they still have the clock one available. So if you're really desperate you could use something like this you get lubrication literally everywhere that it would evaporate and leave the oil in all the cracks and crannies. I assume because are still making the clock version there must be people out there purchasing it.1 point

-

Hi Mike Have a look at this link http://www.abbeyclock.com/buk.html it has animated descriptions of escapements in action.1 point

-

1 point

-

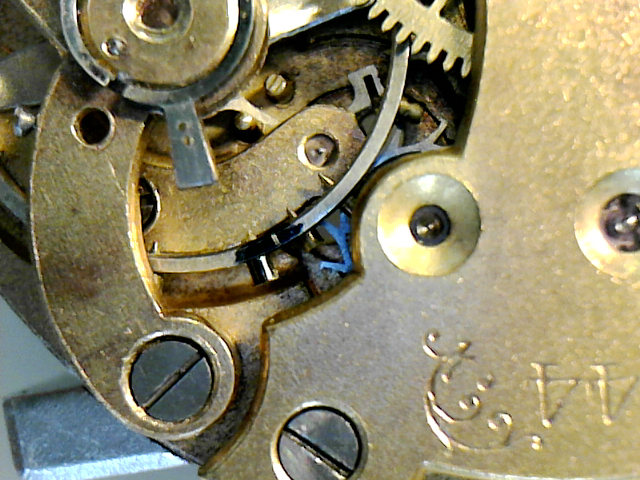

Hi fellas, I'm pretty sure you've both read this but it will take some mystery out of things. I know it's a chore without accompanying pics but if you do those checks you won't be bending stuff willy-nilly. Just had a "chronometer" (in name only haha) pocket watch in with both pins bent the same direction, did my checks and the escapement was . Why they were bent I don't know, but I would have spent some time un-doing had I just straightened them.1 point

-

Will do. Hes out of little offenders for auto theft today , he likes some tunes on so if you can leave your keys in the ignition for him that would be great. He said it depends on the market price of your car.1 point

-

Well I guess if quartz isn't your thing, then maybe a little bit of a Timex treat will brighten up your day. A 1977 Timex Marlin (26160 02477) joins the club following a couple of hydrocarbon baths and a lot of scrubbing and polishing. I also recently picked up a job lot of of NOS 1970s watch bands. Some were perhaps beyond saving, but there were a couple of denim straps that really ooze that 1970 vibe, so what better paring can you think of.1 point

-

Ah a little research has thrown this up Ed. The olive jewel has a curved inner surface that helps reduce friction compared to a straight hole. I imagine in a verical position this is more effective. I would think hard to tell the difference visually when choosing to replace. Probably used on higher end watches. Haha scratch that nickelsilver already answered1 point

-

Hi Ed. I think you are referring to the jewel shape to suit the type of pivot that it is for. Conical or straight pivot. S/S, C/C , S/C or C/S. Though this usually is the escape wheel and whether a cap jewel is used. What are the two choices Ed ?1 point

-

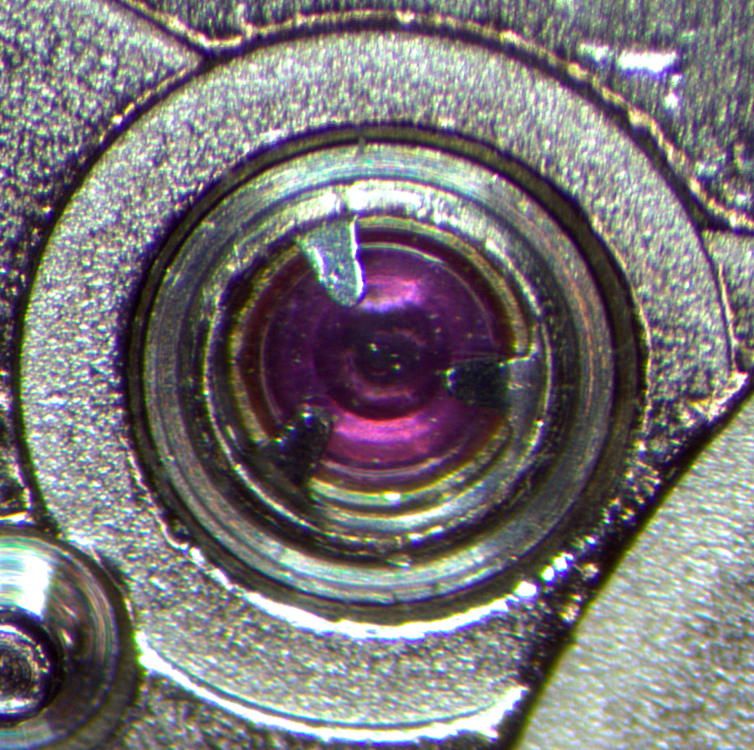

Thanks, everyone. Your feelings echo mine, and I really didn't want to take the cap jewel out, but there was so much gunk packed in from the other side there was no cleaning it out. Either way, here I am. What would you do if you were me? How were they installed in the first place? @Neverenoughwatches, here's a photo from that thread I linked. This is exactly what I'm looking at. Just got the replacement great wheel in. I wanted to get this Jurgensen off my bench before diving back into it. Here's a picture of mine in its current state. I tried sneaking an oiler under the ring to lift the edge, then pushing down on the prongs, but it's not enough.1 point

-

I don't find them very difficult at all, but I suppose it's because the majority of the movements I began learning on were Seiko's. Lots of 6309's, 6119's, 7006's, and 5606's. Speaking frankly, I'm a big Seiko fanboy! Value for money I think they are tough to beat, and some of their dials are simply stunning. They break down the keyless works into just a couple of parts. Their 'magic lever' system for the auto winding is so simple it's brilliant. I'm a fan. You can definitely tell they really thought it out and simplified it for mass production, but they are still capable of keeping excellent time.1 point

-

Good amplitude doesn't cut it for this group it has to be outstanding amplitude or else that's the problem. I know people that work at the Swatch group service center. For anything like this they automatically just replace all the escapement components they don't even try to troubleshoot slightest hint of anything infinite supply of parts new escapement components. Then as far as regulation goes despite having detailed specifications like for Omega they only sort of fall of this. The words there given a window the watch has to do between this and this and all they have to do is hit the window and move on they do not regulate for zero seconds. It out even try to get close to zero seconds they just regulate the window and they go on. So basically when you look at anything related the amplitude by the watch companies they're not concerned with a minimum amplitude or death they just don't what have too much amplitude and then they're concerned about amplitude at 24 hours but they're much more concerned about timekeeping. Of course if you have no amplitude are limited amplitude it 24 hours you usually have bad timekeeping is not ignoring the issue but that's not their obsession. That if you look at some of the modern specifications though basically say that the majority the watches will fall into this group a certain percentage will fall out which of the range so I'm guessing they only spot check a few of the watches and by percentages some watches will be farther out of range than the rest. I snipped out a image for you it comes from an internal Elgin watch company document dated about 1955 it's a nice book that explains how to give factory visits. It's divided into sections casual visitors versus jewelry store owners versus I think watchmakers in other words you get more and more technical stuff. There is a lot of overlap unfortunately no pictures it would've been nice to have pictures but no pictures just Words. Now why am I giving you this well let's read through amplitude specifications. They did have a timing machine that measured rate so they would look at the rate of the watch but notice on the amplitude they basically visually look at it and look at the turns that the balance wheels making. Then yes I always find turns confusing versus amplitude I'll let you figure out what a turn is. So you'll notice too much amplitude they put a weaker mainspring and. Then yes if you look in the Elgin parts book at one time they did have watch mainsprings that were weaker than the regular spring. Even Rolex had variations in mainsprings strength if they perceive there were issues. But notice what happens if they don't have enough amplitude somebody gets to look at the watch and possibly adjust the escapement.1 point

-

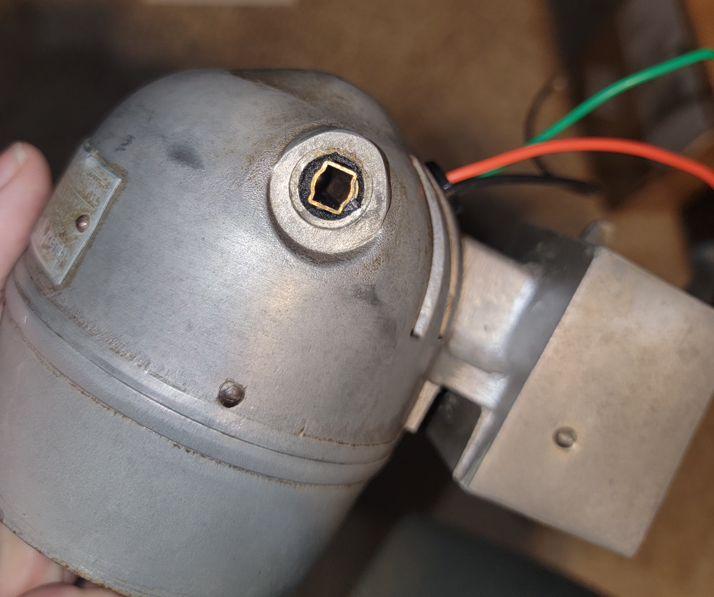

Recently there were several rants about the dreaded 3 pronged Russian shock spring. I have done quite a number of Russian movements but never had much problem with the shock springs until a couple of days ago. This Slava 2427 had the most uncooperative shock springs that I have ever come across. Just cleaning and oiling the two balance jewels took me almost an hour. I think it was a combination of a stiff shock spring and badly polished shock spring seats. I could get 2 prongs in but after that, the friction was so great that it became impossible to turn the last prong after it was pressed into the notch. It was then that I decided to make a tool to fit the shock spring in. My mentor described how to make this tool to me several years but I never made one as I never had much problems with shock springs before. It is rather simple. The tube was taken from an old spring bar and expanded slightly to fit the hole in the shock spring seat. Three shallow notches were made in the rim of the tube to catch the 3 prongs of the shock spring. The notches must be shallow, so that the tube can depress the prongs. It only took me 15 minutes to make the tool and using it to fit the shock spring is a real godsend. If any of our members have problems refitting these 3 pronged springs, I strongly advise making this tool.1 point

-

Digital microscopes are not as good as a binocular or trinocular real thing but, for those of us that for any reason cannot afford one of these, digital units are a valuable tool for inspection and other tasks. I'm reasonably happy with my little toy, that I use for after cleaning inspection, oiling the pallet stones (usually uninstalled) and working with diafix jewels just to name a few things. I hope the OP can take advantage of his until he has a better one.1 point

-

Hi IMO the beast way to increase amplitude other than replacing the spring is a clean barrel and lubricated spring. Polishing the inside of the barrel wont do any harm along with a dab of grease. A good clean of the train wheels bridges etc as they transfer the power to the balance. good luck it sounds like a special watch and worth taking care of for sentimental reasons cheers1 point

.gif.82dbf8a5f9893f64a093949d692557eb.gif)