Leaderboard

Popular Content

Showing content with the highest reputation on 07/21/22 in all areas

-

Another flea market find. Caught my eye. Only $1 US, and the band was an additional $1. It's a 1960s Elgin with an automatic 17 jewel 859 movement. Not very rare or valuable as I understand, but it was the only thing at that booth which I was interested in. All others were the kind of cheap quartz watches you could get in a crane game. It runs! Very well! And keeps time! I am growing attached to it.6 points

-

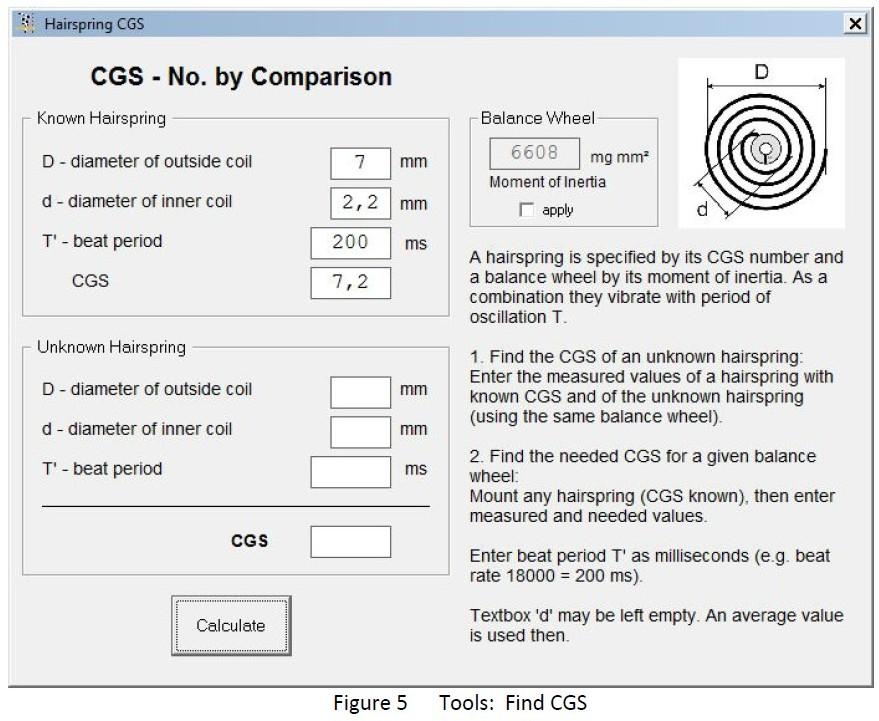

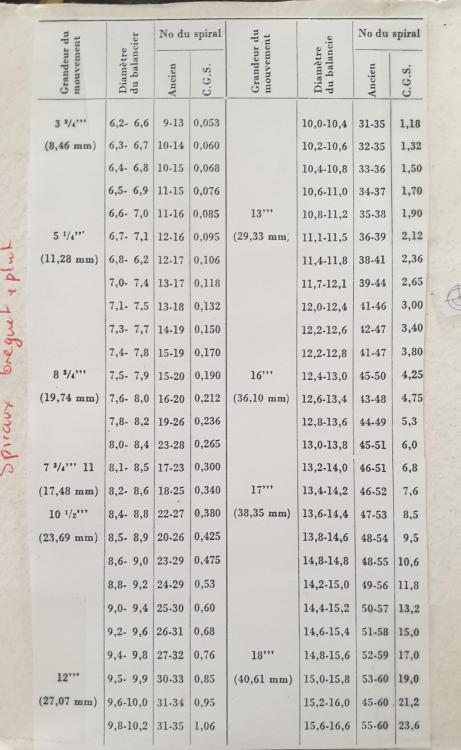

Happy owners of the electronic hairspring box for Luthys can use this tool in its evaluating program. Determines the CGS number of hairsprings (same what nickelsilver already described) and determines the moment of inertia of a balance wheel. The book that I know containing the theory is in German, sorry. Frank3 points

-

I think its pretty good Karl regardless of what you paid . But for 2 bucks can you even buy a coffee for that ? Here in the Uk we can't. So a great coffee price watch matey, we would only get the head or the bracelet Heres mine today. 50 pence. Or half a quid. A 1980's Swatch Pop watch with a jellyfish back. These things are becoming very popular with collectors, the watch is sealed apart from a battery compartment. The head fits into a surround ( hence the name) which has the strap attached. I think i prefer yours lol.2 points

-

Some previous discussions on CGS. https://www.watchrepairtalk.com/topic/20376-sourcing-hairspring/page/2/# And https://www.watchrepairtalk.com/topic/12492-hairspring-cgs-specifications/?do=findComment&comment=111751 Notice CGS N is by convention defined as springness per unit area. Regds Joe2 points

-

You may substitute flexural stiffness C by the often available CGS of the hairspring: C = CGS / (D^2 - d^2) D and d according my picture above Frank2 points

-

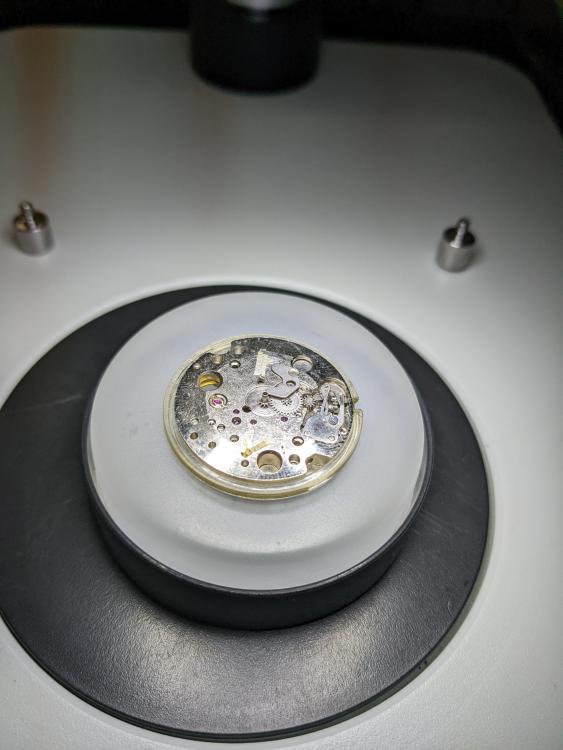

So being Cheap, I have been looking for ways to practice but not spend too much money on watches. I went down the route of looking for Watch lots from ebay where you get kilos of watches. I had also looked into getting watches from India where they seem unbelievably cheap. Eventually I found out that they sold vintage watches from China at stupid prices. This particular piece is one of 4 that I got from taobao. It comes from a place in the north of the country called Harbin. The brand is Beijiang? I believe it translates to Mighty river in the north. It has got 17 jewels and runs at a respectable 21600 and is part of the Chinese standard movement phase of their horological history. The kicker is I paid 150 RMB for this and it works out to be USD 22. This is the only one out of the 4 that had immediate issues. I took some photos and then promptly took it apart. The previous guy that has been in here used Dial dots? or double sided tape which I guess no longer works and so the dial moves. It is a mechanical and hand wind only. The bands were tough to take out, they seemed to be soldered in there so I snipped them off with a pair of pliers. I have an issue that I will have to sort out where part of the spring pin decided to stay in the hole and refuse to come out. Over all the movement is working and relatively clean as I am guessing it dates back to 70s, there were some stripped screws and holes to deal with and a lot of old oil and grease. This was exactly what this USD 20 bucks was for it learn how to take apart, examine, clean and put back together. After some close calls with incabloc jewels and the spring. I am happy to say it got put back together nicely. Amplitude went up, beat error is still crap but regulated it and I am happy with the final product. Not sure what to do with it understand to look at it and give myself an attaboy.2 points

-

update: after following a combination of the above suggestions the rotor played ball and aligned perfectly. The watch is no re-assembled and running. having said that is still stops randomly, I suspect a problem with the stem / hacking part. Thank you to all that replied it helped me enormously!!!1 point

-

If that is a glass crystal, then the crystal is probably "etched". A sticker or or something else that was slightly acidic was sitting against it for a long time, perhaps? The way to get rid of that on a glass crystal is to polish with cerium oxide, I've seen a suggestion of using a piece of dowel rod to hold the cerium oxide paste (at the end). Supposedly makes it easier to handle than using a cloth.1 point

-

Thank you SO much for all the feedback! I've ordered a couple more of the same movements so now I'm going to apply what I learned from those first ones to these new ones. Slow and steady and lots of pictures. I'm absolutely LOVING this "hobby" (I feel like its not really the right word for it because it feels like more then a hobby but until I think of a better word...) and I will definitely be coming back here with all my questions. Yesterday I took apart a lot of the springs and tiny pieces that go flying off for the first time and I was actually able to get them back in place. To me that felt HUGE! Thank you again and I look forward to learning from all of you in the future!!1 point

-

I use Simichrome which does a good job, just make sure the imperfection is on the outside, I spent ages the other day trying to polish out a blemish like yours only to find it was on the inside of the crystal, no idea how it got there though.1 point

-

Hi There are propriatry (polywatch)pastes for polishing watch crystals but I use Automotive chrome cleaner (Autosolvol) its mild enough and polishes ok takes a bit of elbo grease as does any polishing.1 point

-

1 point

-

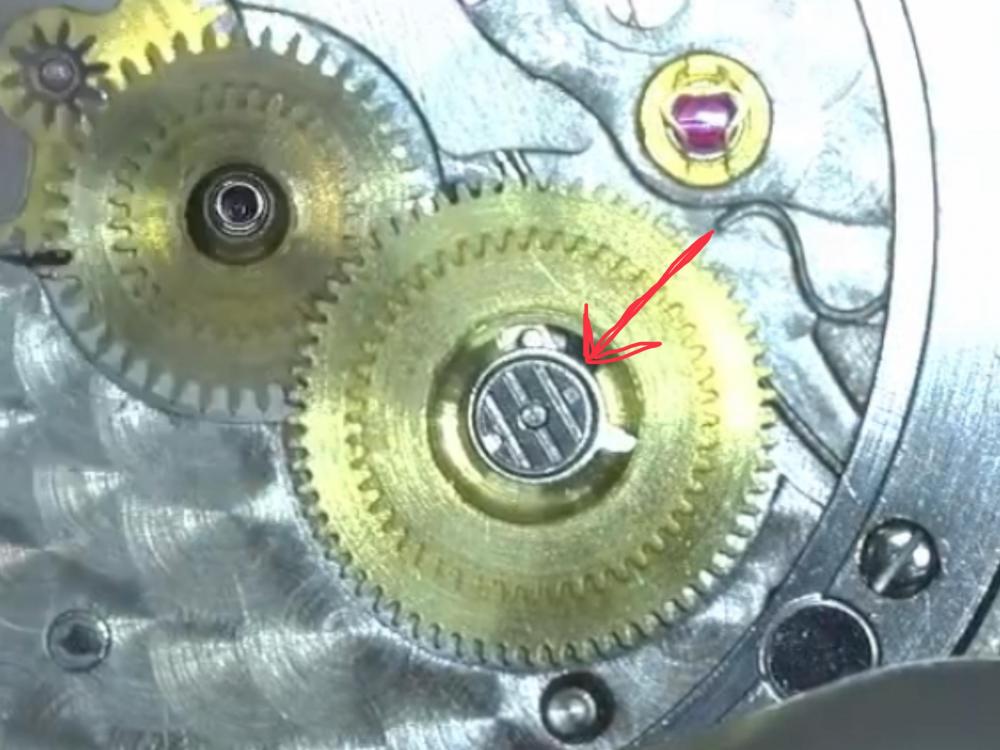

There is most likely a friction clutch between the pallet fork and the pendulum pivot. It serves as a automatic beat error corrector. If you don’t find any firmness in the extended pendulum positions the clutch might be to loose.1 point

-

It almost looks like it has been stained. It depends how deep this is. Some on here have had success in polishing out scratches. However I am not a patient person so unless imperfections are minor I just change the crystal.1 point

-

Hi guys, Ordered a stem for a fhf 1146 it has arrived and the watch is running perfectly. Thanks so much for all your help.1 point

-

I was working on a movement and had a similar issue with the balance wheel. It's probably not the issue you are having but I thought I'd throw it out there just in case maybe you have capstones on your escape wheel like a Seiko 66. When I placed the balance, I didn't put the capstone on the dial side first, so that when I put the balance bridge on, the balance wheel pivot was, as you say, just floating around and not engaged in the jewel. Of course, that was because the capstone wasn't in place on the dial side.1 point

-

Love that watch, and I'm a big fan of that style of numerals which I have a couple of my watches. Pretty good for $1!1 point

-

I like the method shown in this video; it works great and is cheap, so a win/win: You just get some 3M lapping film. I'm using: 100 Micron (120 Grit) 40 Micron (300 Grit) 30 Micron (600 Grit) Works great and the sheets are only about $2-$5 per sheet and you can get 4 or 5 strips off of each sheet. This store sells the setup seen in the video, but they are sold out and it's easy and cheaper to make your own.1 point

-

Sure. it is "Lexikon der Uhrentechnik" by Prof. Glaser. Horological science very very compressed. Frank1 point

-

1 point

-

This is my AHA! movement for the day! Not sure how/if this will happen in the shower. Thanks loads. OP, I feel your frustration.1 point

-

1 point

-

Well done one down three to go , definitly a retro look (seiko). worth the $20 for the experience.1 point

-

1 point

-

Eesh that's rough. I"m gonna be doing this at my computer desk and i'm going to take painters tape and some paper and make a little wall on the front of the desk so if anything tries to roll away it'll get stuck on the desk.1 point

-

Sorry a bit confused. What part are you trying yo remove. PS are you going to replace the balance or the balance staff.1 point

-

Hi Shane, When it comes to the theory and formulas, the book that I found that provides some of this is "The Theory of Horology". Chapter 7 in particular. AWCI has English copies of it on hand since it was out of stock for some time, but they are not cheap. Mathematical formula for a balance and hair spring T = 2 * pi * sqr root ( I / C) T = period, I = moment of inertia of balance around axis, C = spring stiffness. It goes on to provide formulas for hairspring CGS (same formula NickleSilver mentioned), stiffness, proportionality factor, variation of length, terminal curve ... This link has some information that might be useful as well (where he suggests getting a test spring with a known CGS and experimenting with it) https://www.watchprozine.com/watchtech/a-day-in-watch-school-part-six-hairsprings-/6112423/1223/ Cheers Terry1 point

-

As I am in the same stage as you, just started this as a hobbyist with great enthusiasm after watching hundreds of videos, I don't mind asking something obvious that tripped me on two of my first movement assemblies: If the pivots are indeed not broken, are you reinstalling it the right way up so its pinion is engaging with the third wheel or is it spinning freely in the wrong plane? A complete amateur's oversimplified observation is that sometimes the correct orientation of a wheels feels wrong, top-heavy, or upside-down. Take a photo at every stage of disassembly. In any case, this community is really helpful. I've been feeding them questions steadily for a couple of weeks and they've assisted me each time.1 point

-

That's all what matters. Now you know what kind of manual sensibility is needed when refitting the escape wheel, and that one cannot happyily tighten screws around. An asset gained when one starts taking things in his own hands as opposed to theoretical circles before starting, if ever. Everybody makes mistakes at the beginning and possibly even later on. Just avoid costly or unreplaceble pieces until you become 110% able.1 point

-

A very appreciative soul, thank you. That goes a long way towards you getting help. I think you have covered your bases with learning matey. Videos, books and being here. Besides having your own personal watchmaking teacher by your side ( here is the next best thing ) or going to watchmaking school. My beginners advice to you is take your time and do not try to move something that wont move freely. If its tight do not force it, sit back and rethink your approach. There will be an easier way to ease or release the part you are working on. Practise a gentle touch, here you are working on the most fragile components you will ever encounter. If you think you are not capable or not the right person to do this as a hobby then think again. I've been a joiner and builder for nearly 40 years, I've lifted heavy weights, strength trained and bodybuilt for 15 years. Its very, very rare that i break a watch part, ive learnt to manipulate hairsprings. So you definitely can do it, just with practise. So besides this approach, be methodical and engage logic when dealing with an issue. Think your procedure through first, have it in your head before you do it. As you progress with your learning the disassembly and reassembly will become second nature. Until then take plenty of pictures of the movement, stage by stage as you disassemble. These will help you put back together what you cant remember. And trust me you wont remember even after a short period of time. Then one last thing as a beginner, do not get frustrated as this will lead you down the path of damaging parts. If you feel it coming on, then take a break. Good watch guys are here to help you so dont be affraid to ask any questions at all.1 point

-

Hi By the look of it you have had a great list and advice on what and not to buy, pity the little glass jars are unavailable in the US ans they are realy handy in the U/s, My Grand daughter works in a Hotel so got plenty. also movement covers, in the UK we have scented candles that come in what looks like a whisky glass, when finished clean it out super glue a marble on top and hey presto a movement cover, paint pallets make good dismantling trays al though I have a ladies eyeshadow kit cleaned out of course, with several compartments and a lid, also for parts cleaning the ball type tea strainer makes a good basket. I have seen these advertised on ebay for in excess of a £5. I too am Scots but being brought up in Yorkshire look not to waste money. As N.E.W said antything with a watchmakers tag carries a price Bergeon being the "best" at removing money from your wallet. Good loups, good tweezers(Dumont) and screw drivers F*F, Horotec and of course Bergeon are the things to spend money on. My cleaning machine Cost a £10 with no basket the ultrasonic transducers were buggered but I stripped it down and it all works including the heater the U/s generator works but of course no sonics. Used mainlt for clocks. A cleaning solurtion I used to use was beaucare a spot cleaning soloution (Trichloroetheylene) now bannes I think it used to be used in the dry cleaning industry years ago. Now naptha and IPA.1 point

-

Here is my rough translation from French of the paper that explains what the C.G.S. number is. As far as I know, it's the only English translation that exits. My math is not strong, so I may have mangled some equations in my attempt at translation, if you find something that not right please let me know and I'll fix it. Cheers! 1934AFChr___4__233DTranslated.pdf1 point

-

I don't know of a resource that gives all the math to determine hairspring CGS to a given balance except for perhaps Theorie Generale de L'Horlogerie by Leopold Defossez, which I think is only found in French and rather expensive. The list below I've found is pretty good for getting in the ballpark to size a spring. If you get a spring of a specific CGS that's close, you can calculate the actual spring needed with the formula K=K' (D/D')² where K= CGS to find K'=CGS of test spring D= diameter of spring wanted D'= diameter of test spring at vibration point1 point

-

you might try George Daniel's book on watchmaking although I'm not sure it's going to have enough theory for you. You want some of the vintage books on watch design watchmaking. For instance there's a link below there is a book the first one that popped up where I did a search then you want to search there for a variety of figure out the keywords as a bunch of vintage books that might find helpful then you didn't give enough specifications. Over coil are flat hairspring for instance? Flat hairspring is typically vibrated to that specific balance wheel. We've had this discussion before on the group there are basically no more raw hairsprings so finding a hairspring to vibrate for your balance wheel will be challenging. Over a coil hairspring is easier as they were meant to be replaceable. But that manger balance wheel has to have screws on it because you'll have to match the balance wheel to the hairspring. Oh then there's the other minor thing for the hairspring just as a reminder in addition to timekeeping purposes the energy of the hairspring is used to unlock the escapement so they hairspring does have some other properties they have to be right they can't just visually look right https://archive.org/details/treatiseonclock00reidgoog1 point

-

Hi It has the look of 60s watch. The name on the dial is not nessesesary the manufacturer that witll be on the movement its self. When you get the watch remove the back and look ubnder the balance wheel, there should be a logo and a number this is the maker and caliber of the movement. If possible post pictures of the movement for further help. Cheers1 point

-

Hi Thats quite a comprehensive list and should be way adequate to do the work, the Seiko driver , well yes but you can find others that work equally as well. I have attached a recomended tool list drawn up by a member some time a go for a comparison guide. Hope you find it usefull. all the best 1612608791_ToolsfortheHobbyist (2) (1).pdf1 point

-

An interesting tour of the Vostok factory. The watches are assembled without gloves! When you get a brand new Vostok, you better do a thorough clean.1 point

-

Even the very small bottles of oil last for ages. I oil everything i work on even movements that are really poor quality that are causing me grief just to get a reasonable amplitude. Some of them i should just put in the bin, but i prefer to give every movement my best shot. Its the best practice you can get, can be a little disheartening with failing attempts but when i manage to get a poorly made watch running well its then a huge uplift. Ive been stuck on one for a few weeks now, going backwards and forwards with it inbeween other little repairs for people (its amazing once folk get to know what you're up to they start handing you watches to fix ). Which is ok as long as you make no promises, I've not had anyone not say dont worry you cant harm it, it doesnt work anyway. So far I've been lucky, and because they've not been around the block a few times on ebay they generally just need a service. If you still having tweezer ping Gary, you just need more practice. But there are other ways of carrying parts. I used rodico quite a lot for doing this in the beginning until i got to grips with my tweezer handling. Also try Ross's idea of fencing off your work area. Old tme watchmakers wore an apron that they pinned to the edge of the bench as well. Some light coloured lino cut in around your bench so you're not having to search through carpet and a good sized magnet is very handy for finding metal parts and a torch for jewel finding.1 point

-

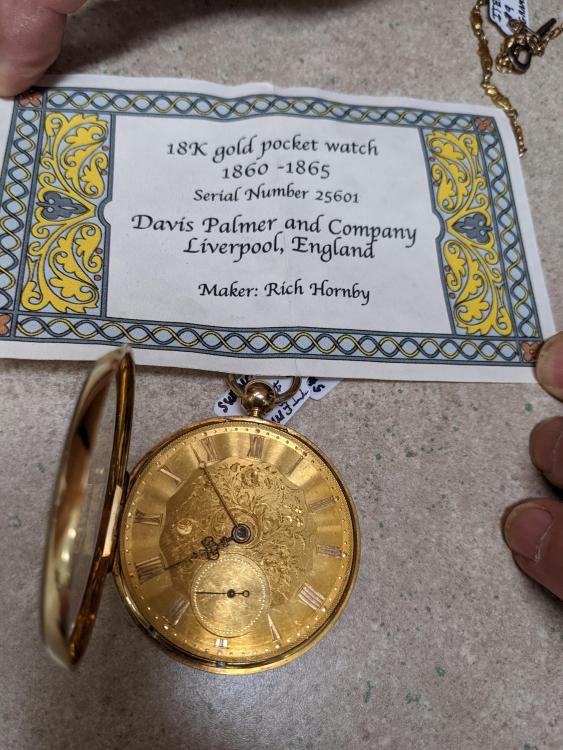

you're missing the minute wheel. Your options are to find an assortment and see if something will work that would be the easiest and cheapest probably. Otherwise you can make a new one or have someone else look through their assortment and/or make a new one. I don't suppose you have access to a time machine? If you can find somebody who stocks vintage movements for parts and other was a material house specializes in vintage watches may be. Otherwise know there were never spare parts stocked for this watch or basically any other watch in this time frame. It can only get spare parts if they're made in sufficient quantity and later in life. So some company was mass-producing a watch there might have been spare parts but these are almost not quite handmade more than likely hand finished. You probably need a mainspring when you get the old one out we can figure out what you might build put in the area probably have to modify the end may be depends on what they had on the end for the mainspring. If you're lucky the balance staff isn't broken otherwise it's going to be a lathe's project. Basically watches like this are restoration projects they're not your simple clean lubricate toss a few new parts in an offer and running plus the other problem of 100 years of your watchmakers or someone who thought this was a toy problems can happen from that alone.1 point

-

Yes I have seen that .Do you have the service manuals ,I think I was very fortunate the one i repaired , Accutron214ServiceManual.pdf accutron_service_manual_series_218.pdf1 point