Leaderboard

Popular Content

Showing content with the highest reputation on 10/03/19 in all areas

-

Adapting the Taig milling slide to gain 5mm travel on the bottom. That will allow milling bigger parts, like 50mm (wow) V-slot blocks for the vise and press drill. To hold it I had to drill and tap the faceplate, which was an easy job as it's made of mild steel. The single pass Chinese set worked well with the help of a micro tapping guide on the press drill. Then for a bit more facing work I beveled some 304 steel nuts. The lathe didn't made a fuss and I got to use the cute compound slide. I have a long list of projects all in line with the above, tools to make tools to make tools.4 points

-

3 points

-

Hi Gary Its a bit of a mess. Try soaking in wd40 for a time then using a staking block and fine punches drift the stem out. obviousy put the flat gear on the stake not the castle but be very careful.2 points

-

Changing the screw 99% sure won't do anything. It's where the screw seats that matters.2 points

-

1 point

-

I,d leave alum for the last resort. Soak longer, tap on the stem every few hours. If no luck, then use heat, device a soldering gun to touch the stem only, heat the stem and not the sliding nor winding pinon. Thermal expansion and contraction will break loose the rust bond between the stem and pinions. Best1 point

-

Honestly, don't bother with the spares/repair route, get a working one, there are loads at laughable list prices on eBay but they don't sell, even mint nos with contents. You might have to keep a look out but 20 to 30 is about the ballpark they actually sell for. Not really surprising considering that aside from the novelty factor and q branch thing, (which is admittedly why I wanted one), they're no more use than a basic LCD watch. Mobiles take such incredible photos now no one would realistically expect to use the camera beyond the 'I just took a photo with my watch, "Roger Moore eyebrow raise" how cool is that' thing.1 point

-

No problem here with replicas. I've had and still do a have a couple, watches I like but know I won't afford the real thing of. I will say however, it's highly unlikely it has a swiss movement at all, many replicas claimed they used ETA or similar but in reality all the ones I've ever seen, (a few), had either cheap Chinese movements or clones of swiss movements. To give an idea, if it didn't cost north of 500gbp the likelihood of a real ETA is slimmer than a supermodel during London fashion week. That said. Some of the Chinese movements are OK, the problem can be if parts are broken or damaged as replacements are nigh on impossible to source. Aside from generic things like mainsprings. Mainly because entire replacement movements are cheap. So it's a 6 of one, half dozen of the other situation. Odds are it will just need a service and if it ran for 4 years acceptably then it should be a decent movement. I'd take a look for you and be able to give you an idea if it's a straightforward service or not but I'm right the other end of the country in Scotland. Worst case scenario would be that you'd have to replace the movement and if it's something like a 2824 clone, one would cost 30 to 40 ish for a decent clone, less for a lower beat replica movement. I take it this has more of a sentimental value than anything to you?1 point

-

I've spotted a couple of those "spares or repair" but not had the courage to pull the trigger, if you will excuse the obvious James Bond pun.1 point

-

1 point

-

The top diagram I have posted on the main page of the forum, shows where impulse jewel should come to rest to be in beat. If you turn the balance wheel clock or anticlockwise, impulse jewel moves and gets out of the fork horn, so you would see the fork start to move. The balance wheel position where slight move to left or right causes the fork to move is where impulse jewel is in beat. So grab the wheel with tweezers, to turn it, while observing the fork from top view. Once you see where the fork interacts with the impulse, move the stud carrier to bring it( the impukse jewel) to rest within the horns of the fork, at such position the staff, fork arbor,escape arbor fall on a streight line and impulse should be in the midle of banking pins. Obviously if you check for the beat before cleaning you can just touch and turn the wheel with your fingers, More control. Once on timegrapher you can adjust more accurately. Best1 point

-

The "Kander 21 Jewel" got a little bit of TLC last night, so here it is in all its glory. It took a couple of thorough cleaning sessions before it would run well. Despite its 21 jewels, there a couple of obvious omissions. It is a pin palette for starters, and that 'aint no Incabloc. All that having been said, the thing is very eye catching, as indeed is the place it was made.1 point

-

Did the watch work before you serviced it? As you've tested everything what's the current consumption of the watch? One thing you might try is isolating the gear train from the rotor. In other words put only the rotor in and providing you can see it see if that moves when you apply power. That's a rather interesting rotor if it was demagnetized or didn't have its proper magnetic properties that would be a reason it wouldn't run. https://www.watchrepairtalk.com/topic/3913-omega-1337-quartz-movement-complete-service/1 point

-

For fitting the gear to the rotor, you don't really need a special tool, my staking set doesn't even have one so big! You can punch it out from outer side (which faces the inside of the caseback) by using a suitable blunt punch. Even a wooden dowel works.. For installing you can also use a suitable wooden dowel but relieve the inside first to clear the pivot. Just go slow and constantly check to make sure it goes in straight. Anilv1 point

-

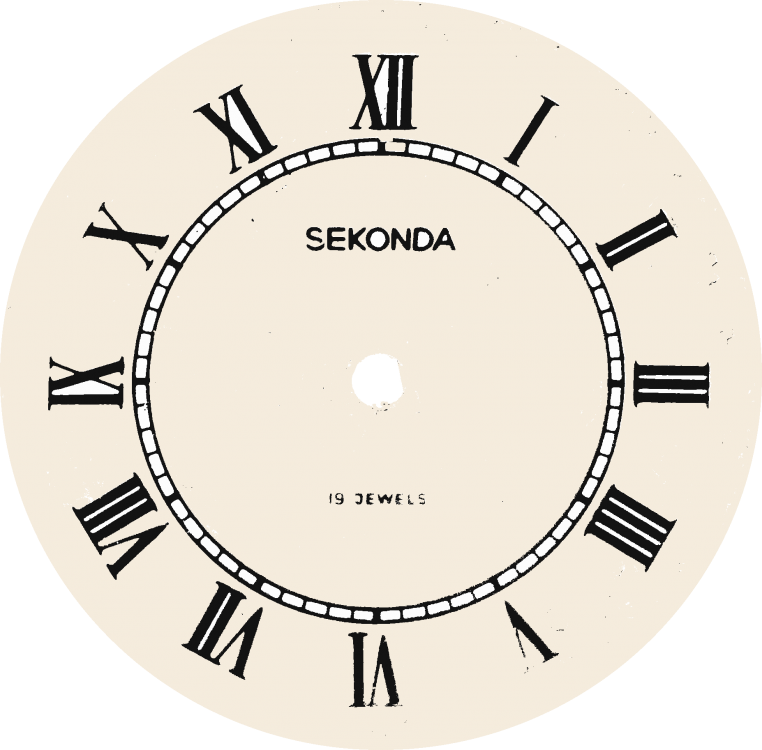

I grabbed a picture of the dial and did a little initial cleanup, in case I get a chance to repair it. I'll post it here in case anybody else is interested. I still need to tidy up the missing bits and sharpen it up. It is also not to any particular scale, so it would need to be sized before I attempt to print it. I may also add some registration marks, and possibly convert it to an svg if I can get a version that I am happy with.1 point

-

A machinist mentor told me it was a standard prank in the shop to ask to borrow the new guy's micrometer, then clamp up parts with a dummy mic (some old junk mic), holler to the guy that his "clamp" was hard to tighten- from across the room- then when he freaks toss it to him in a way he can never catch it. All that said I've seen some c-clamps that were so sorry they should have paid people to take them, and others that could probably serve as decent micrometers. I'm not anti China-cheap stuff, sometimes you find gems for practically free. But usually you get what you pay for.1 point

-

I think you will find the Chinese instruction manual specifically says, not suitable for use on cabinets. 不适合在任何地方使用1 point

-

In cases of hard to replace jewels, I prefered this method over no clean option. Remove balance complete, springs ..even regulating arm. Clean, even brush some parts. Spread a large sheet of white material on the floor. On which I work on balance bridge. Use bare hands and all it takes to instal the jewel assembly and springs back on, I do not worry about hand- parts contact at this stage. Rinse. Oil through chaton hole, oil pivots as well.instal. Meanwhile the balance complete is taking a bath in lighter fluid, shake the bottle very slowly. You have cleaned all, the jewel, beneath the arms. Rinsed , got a chance to see a full view of hairspring coils, endcurve, etc. I have no doubt you will find " not worrying about hand-parts contact, drastically eases working and improves your control over the task and enhances results.1 point

-

What I asked in your prevous thread " eta 2472 auto device disassembly" may be the cause of rotor slack. Refer to post 375 in your previous thread. A thin polymer washer may have been between the rotor screw and selfwinder module, very easy not to notice and loose it when disassembling.1 point

-

Have some Vetus tweezers .Good and inexpensive .But buy the stainless steel models . There only costing a £5 from cousinsuk .1 point