Leaderboard

Popular Content

Showing content with the highest reputation on 08/18/19 in all areas

-

I think the OP is just trying to decide if buying a MS winder and what are the common sizes he may encounter working on American pocket watches. Not fixing a watch at hand.2 points

-

Many thanks! Absolutely informative and beautifully photographed. I think the 238G is one of the few 23x I haven't got, but I'll know where to go if I ever need to tear one down. Regards.2 points

-

I don't have a link but I have a full set of both styles, I'll post some photos when I'm back in the workshop.2 points

-

Yes, certainly the problem is in that area. I think you're on the right path to fix it yourself, maybe hone your skills a little more before undertaking this repair and service. In the meanwhile you can watch videos by our Host Mark Lovick, and why not, enroll in the High Definition online course.2 points

-

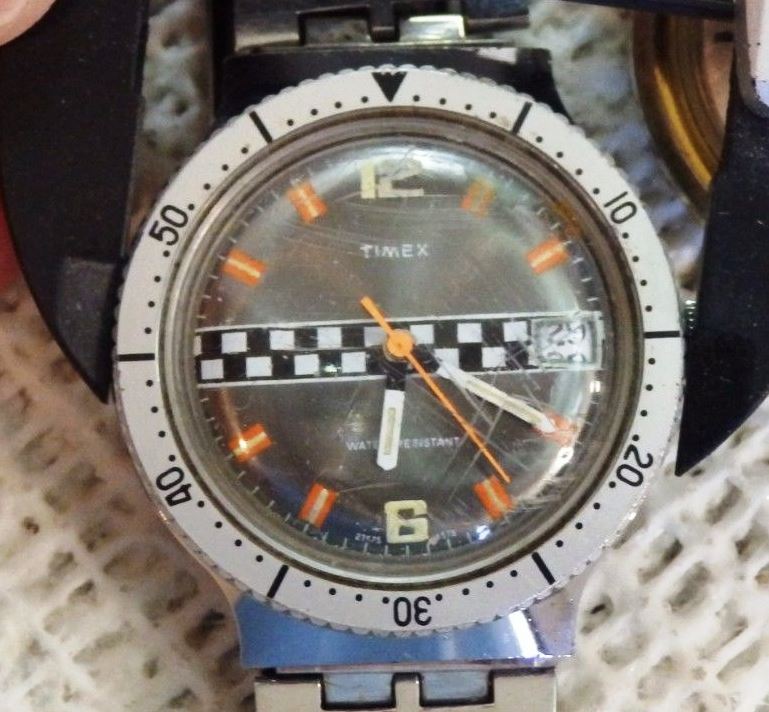

The former owner of this watch apparently test the "Water Resistant" print on the dial on this 1978 Timex. Yes, it failed the test and left behind a damage 106 movement. But, no worries because I had recently salvaged the movement from a 109 that I knew could be swapped in. that is once I add in the date assembly and date wheel detent spring. TIP: the 104, 105, 106, and 109 all have the same base movement inside. What makes them different is the date and or day date complication. by swapping a few bits you can interchange all of them. Okay you can even use them in a 116 and just have to nip the seconds pinon down about 2MM. ssshhhh keep this a secret! -edit: I forgot to mention the dial did suffer some damage as well but, I think it give some character to the watch now. Here are the before and after- I also gave it a good scrubbing, buffed out the crystal such.1 point

-

If you intend to work on PWs only, you will surely need no winders for ladies WW. You could get a coarse idea of the needed winder sizes if you take half of the movement diameter minus 20%. Frank1 point

-

Save your money, the tweezers in the hswalsh link is of little use. OH did a very good job finding this tool, but it is the smallest of the set, too small for gents- or pocketwatches. I suppose it is the remains of a long sold stock. My old Bergeon catalog shows them, but they were no more available when the catalog was issued. Frank1 point

-

That should work fine. If you do 2-3 rinses in distilled water a very quick rinse in isopropyl alcohol will have no effect on the shellac on the fork (like 30-60 seconds). The isopropyl will soak up the water and then dry quickly, with a warm air flow either from the cleaning machine, a separate dryer, or just a hair dryer. The warm air is a must to avoid condensation from the cooling effect of the evaporating alcohol.1 point

-

Won't be in the shop till Tuesday probably, but will say I've done a bunch of overcoil springs from scratch and only rarely use these specialized tweezers. There are other ways to raise the coil and I usually form the curve with two #5s. The special tweezers are useful when doing several or more of the same, you can set the coil raising ones up to repeat well, and find the curving ones that suit the form you're doing. I remember visiting Parmigiani back turn of the century and there was a lady doing a really small caliber overcoil, I think she took about 5 minutes to time it with an old school vibrating tool and like 30 seconds to raise and form the coil with the special tweezers. It'd be a half day work with the same equipment for a competent hairspring guy who didn't do them all day like she did.1 point

-

I was extremely lucky where I served my apprenticeship. The workshop was fully equipped with all sorts of watchmakers and clock tools. Besides back in the 70’s & 80’s tools were not as expensive as they are today. If you want to be able to reach being the best you have to make sacrifices.1 point

-

I'm afraid not. The springs are by movement size and caliber. You may find reference material to help you find interchangeable parts. I do have a very significant stock of NOS pocket watch parts. If you can tell me more I’d be happy to give you a spring or two to try. I have thousands of NOS mainsprings for movements from American 18s to 21/0. If that doesn’t make sense to you, post pics of what you have. The face, the movement and the barrel with measurements of each. Maybe we could narrow it down? Do you have the old spring?1 point

-

The trashed Gant "West Creek" got the finishing touches applied today. I picked this up on a whim, for 99p no other bidders, simply because the mechanism looked interesting. When it arrived, pretty much everything was wrong with it. The case was scratched to bits, the glass was smashed, the band was trash and the mechanism had obviously taken a knock, since the day indicator was off the scale. All of this has now been attended to. Fresh crystal, fresh leather swapped from a similar strap to preserve the branded clasp. I went for black as it matched the dial better in my opinion. The mechanism was partially stripped to fix what I guess could be termed the keyless work, or whatever the quartz equivalent is. One of the levers had jumped off, putting the whole day/date/time adjust into random mode. Here is a quick size comparison. 1950s ladies Smiths Empire, Gents 1930s Bulova, Gents 1980s Sekio and contemporary Gant "West Creek". It is well built with a stainless case and a VX46 quartz mechanism and it 'aint bad looking, but given its current RRP of £200 I think I'd rather add 50 new members to the 404 club for that money.1 point

-

Working on hairspring takes a lot of time. It is looking much better. Just be careful not to sneeze while working with it.1 point

-

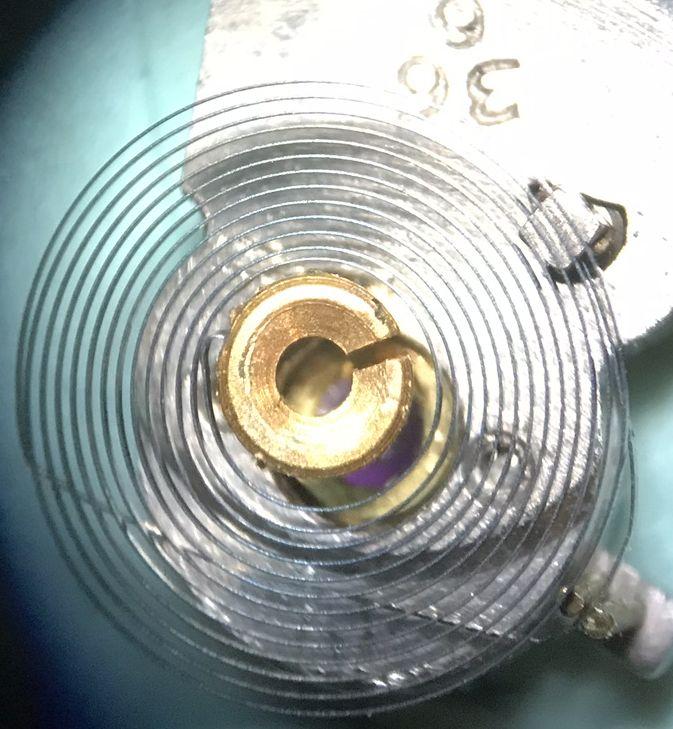

O.K. Thanks for all the responses. And yes, O.H. I know I need to correct the HS at the collet, just wanted to see if I could build the over curve before I did the easier part. Here's he current state. I won't lie and tell you it was easy. HS work is something I have to take in small bites. Clearly there is still work to be done, but I am getting closer to where I need to be. Thanks to all of you for your advice and counsel. And I too find the costs of some of these specialty tools absurd. RMD1 point

-

Mark uses Panasonic micro four thirds (as I do, but Olympus), and then switched to Canon full frame I think. My personal finding is that stands and lighting are far more important than camera and lenses. For the latest and better I suggest you browse dpreview.com1 point

-

Hi, I cannot imagine how the above hairspring could be formed without curve tweezers. Did all who give good advice ever make a Breguet coil? These tweezers were not available 30 years ago when I started, so I made my own curve tweezers from normal steel ones. A bit of work, but never regretted. Frank1 point

-

I could never get on with watch or P/watch winders. It is not bad practice. Just make sure you never take the spring out so it looks un-even, it should lay flat. Use finger cots to put the spring in.1 point

-

1 point

-

Thank you for your message! In terms of pocket watches, what would you say is the most common mainspring size? Any rules of thumb you’re aware of? Sent from my iPhone using Tapatalk1 point

-

Update I discovered the setting lever when crown is pulled all the way out does not engage because (see picture below) the post on my timing lever is gone so the lever was not secured at axis point which limited the range in which the lever could full extend. I ordered a new one should be here in a week. I will keep you updated, what I think happened is someone pushed the setting lever post to allow stem to insert or remove and they pushed it to hard and broke it.1 point

-

Hello Rexxus. i too started on pocket watches and started winding by hand. i understand most professionals, of which I am NOT one, consider it bad practice. However, what works, works! i stopped doing it by hand simply because it hurt my fingers to do so and I had been slapped in the face 137 times too often by particularly cheeky springs. I bought the model in you picture years ago and love it. There are two main drawbacks IMHO. 1. As nickelsilver suggests, the older ones tend to be work, particularly in the material that grips the spring in the center. Thus it can slip quite often. 2. This model nay has one arbor size. That means if you work on smaller movements with smaller springs, you may bend the center out of shape or even break it. In the case of wrist watches and smaller sprinted movements, it won’t fit at all. you can buy new winders one arbor at a time and build your set to your needs. They are a bit more expensive per arbor than a set, but if you don’t need a complete set, you save money and get the right tool. I must admit to coveting Marks Bergeon set in his videos even though I will NEVER need all those sizes. best of luck and do reach out with pocket watch questions and suggestions. I love to compare experiences.1 point

-

Ronsonol lighter fluid is way better then One Dip. I just got better results. The lighter fluid is so friendly to watch parts. You can leave the parts to be cleaned in it for days, just make sure you have a screw on lid for the jar as it evaporates very quick. After cleaning I would take out the part place it on clean tissue, hold with tweezers and use my blower to remove any residue.1 point

-

This is well made mov’t that wasn't running. No surprise, as both balance pivots were snapped, there is no shock-protection on this version. I'd classify this mov’t not the best for an absolute beginner, it's 11.5’’' size is fine but there are three flat wire springs not very friendly, many small screws all of different sizes, so to require a full set of screwdrivers. It is interesting to observe how many construction details that have evolved from this old design for reasons of optimization, cost and part count reduction. Let’s get started. To release the stem undo completely the setting lever screw,, then either pull it out, or be careful as it likely will drop as you turn the mov’t over. Dial screws are on the sides and best handled with a 0.70mm driver. Especially if you’re using an ultrasonic cleaner it’s a good practice to remove them to reduce the risk of dropping during work. Remove the dial washer and hour wheel, since the date ring spring holds on the other side of calendar plate I suggest that for caution you place the mov’t in a plastic bag after removing the three screws, and before lifting the plate. The day spring is tucked under the calendar plate, which I have turned up to show in the below picture You can put away the bag for now to remove the date ring, wheel, and finger, as well as the cannon pinion and the setting lever screw. Now lift the setting spring to reveal the joke and its spring, be cautious when removing the latter. Remove the joke, setting wheel and pinion, clutch wheel, sliding pinion, setting lever, as well the balance cap jewel, and we're done with this side of the mov’t. Strangely, the escape wheel cap jewel was missing. In reality the picture above has the setting lever still in place since I had not removed its screw yet. Now for the other side. Since I had removed the balance cock already, it’s now time to let down the mainspring with the usual pegwood braking technique. We can now remove pallet cock screw, pallet cock, pallet fork, escape wheel cap jewel, And crown wheel (left-handed). Also remove the crown wheel spacer pictured below. Remove the winding wheel screw and wheel, then be careful in removing the click spring, time to use the bag again perhaps. Finally remove the click screw and click. Having taken apart the complete winding system we can now remove the two train bridge screws and the bridge. Train is of the classic type, three wheels plus the escape one, which can now be removed. And finally two more screws for the barrel bridge, the bridge and the barrel. About the barrel and mainspring (sorry, not pictured) I opened the lid and found everything clean and in order. Since I was not to replace the mainspring I took no further action on moved to general cleaning. I did a couple washes in petroleum ether (refined naphtha) and isopropyl alcohol but some opacity remained on the plates, so I left these in ammonia-based cleaner for few hours, then rinsed in petroleum ether. Note that the latter (unlike lighter or engine fuel) contains no oils, fragrance or other additives, and leaves no residue at all. Much better, barrel and bridge already in place! About reassembly, I will not detail all the steps, but only highlights some important aspects. For lubrication I’ve only used three modern, fully synthetic products by Moebius: HP1300 for high-torque parts like winding and setting. 9010 fine oil for other pivots and jewels, it’s easy to apply from the outer side of the hole jewel. 9415 for pallet stones, only because I’ve just received it. Below from left to right, escape wheel cap screw, lower balance cap screw, balance upper cap screws, All have different sizes, so unless you photographed or otherwise set these apart you’ll have to use some logic to refit correctly. Same goes for all the other screws… they may look the same.. but they are not! Below the balance upper cap jewel. It also holds in place the regulator arm, for this purpose it’s slightly beveled. You will have to fit the setting lever on the dial side, and its screw from the other. Just use some rodico to keep the lever in place. The setting pinion goes with the bevel toward the sliding pinion. Ratchet and crown wheel screws have different head dia. length and thread direction. You may want to use the plastic bag to fit the click spring safely. Fit the click first, then the long leg of the spring under it, then the bent leg to sit firmly. The yoke and setting lever springs are also a bit tricky. All these pivots and sliding points are lubricated with HP1300, don't forget to test the working repeatedly before moving forward. I've found the date ring spring to be the most difficult, because it’s underneath the calendar plate as shown in the disassembly picture. After the spring is in the plate either fit it with a siding manoeuvre to place the spring against the date finger, or position the plate with the screws kept loose, then push the spring in place by the cut that is on the plate for the purpose. There is no date quick setting on this basic mov’t, that is done setting time back and forth across midnight. The finger on the date wheel is pivoting when moving backwards with the help of a really small spring. However doing that much setting counter-clockwise every other month does not damage the escapement, as sometimes is feared. The replacement balance complete came in the “a vis” version, which are there for poising, not rate adjusting. Actually I think the stubs are pressed not screwed. One last detail for the correct installation of the dial washer. Flat side faces and slides on the hour wheel, you can use HP1300 there. The edges somehow grab on the bottom of the dial. This veteran Swiss could have rewarded me a bit more on the instrument, but I hold no grudge to it and won’t try stunts as fixing beat error at the hairspring collet, adjusting for positions, or getting the missing cap jewel. And that is why I won’t, it would not make much sense for a desk clock! Now, who should own something like that? My friendly blacksmith, of course! I hope you have enjoyed my “no pretenses” article!1 point

-

1 point

-

I recently bought a watch cleaning machine from a retired watchmaker, when I collected the machine the jars already contained solution, the watchmaker told me the rinse jars contained isopropanol. I did ask him what effect on the shellac holding the pallet jewels would the isopropanol have, saying I would be worried that it would dissolve. He said he had used it since Benzine had been unavailable to use, and as long as I rinsed for no more than 15min in each wash there would not be a problem. He also said it was very quick to evaporate in the drying stage and left no residue. I have ordered new cleaning solution and rinse solution from Quadralene and intend to use these. I have though cleaned 4 watches last week in the solutions in the machine and have not had a problem. Today I decided to test and see how long it took to actually dissolve the shellac, The image above shows 3 Russian and one Swiss set of pallets and the shellac can clearly be seen. I have been using the solution for 15min each rinse and have not had a problem so I put the pallets in a isopropanol rinse for 1hr to see what effect it had On the Russian pallets it has greatly degraded the shellac and almost totally washed it away on one, but on the Swiss pallets it has not even touched the shellac on those. I will not use isopropanol again in a cleaning machine and intend to try a similar test with the Quadralene rinse to see how shellac friendly that is because the data sheet doesn't specify what ingredients are in it, but quadralene did tell me they have many watchmakers who buy their rinse and have not had any problems.1 point

-

I'm leaving the stain till the end. I have one of the drawer fronts that is trashed and another that has fallen apart and will need a few pieces replaced. I got my father-in-law's router for this but need to buy the correct bits for the recessed drawer pulls. Once I have those sorted I want to replicate the rails that would have originally be on the sides an back to hopefully catch pinging parts then move on with the stain.1 point

-

Thanks for the input Mark. I got the Etic for about $68 shipped. Assuming it's in stock, I'll have it tomorrow or the next day. I'll keep it away from books and I'll update this post when I get to use it. :D Blake, how's the bench? Did you re-stain it?1 point

-

If you can afford the Etic, then go for it - I melted mine by leaving it plugged in and mistakingly setting a book on top of it which pressed the button down :D I since purchased one of the Chinese ones to see what it was like and it works just fine. The Elma I have in my video is an electronic one and it is good but IMO seems to do no better than the cheap chinese one, it is just very convenient to use.1 point

-

Hiya, Thank you for the offer!!! I don’t have a specific spring I’m working on now. I’ve been buying the supplies and equipment I need and have picked up a few pocket watches to take apart, clean, and put together. Some are missing parts. Once i start taking them apart I’ll definitely be posting pics and reaching out Sent from my iPhone using Tapatalk0 points