Leaderboard

Popular Content

Showing content with the highest reputation on 10/29/18 in all areas

-

With Ronson lighter fluid, you could leave parts in a sealed jar for days. Just remove the parts, place them on some tissue paper, and use your blower. It evaporates very quickly. You do not need a rinse.1 point

-

Is the movement stuck in the case? or just the broken screw? If it is just the broken screw in the case try put in the ultrasound machine. I manage to take a few out just with the vibration of the washing machine.1 point

-

Unlike a capacitor microphone, a piezo doesn't need a power source. And a dynamic microphone is a power source.1 point

-

I always used this method. I do not think those tools were around in my time. The Bergeon was. https://wahawatches.com/how-to-remove-a-broken-screw-with-alum/1 point

-

You can sort of replicate what the Bergeon tool does with a staking set, get a stump and punch that will both fit in the threaded hole, and clamp the screw between them, then turn the entire mainplate around the screw. If the screw is really stuck it doesn't work so well, but generally once the head is broken off they have some freedom in the threads.1 point

-

The shaft is located between the hollow centre of the driving wheel and the shoulder of the pivot at the jacot end. The driving dog sits between the the spokes of the wheel to impart the driving force. Nothing is clamped in place.1 point

-

I agree that a clear bag is a very good idea. When I had to do this task the first time this video helped: https://m.youtube.com/watch?v=HiAh4TkN25s1 point

-

You are welcome Sir. Lets say the most to loose is a stem. The stem hole in the mainplate often gets worn due general use, especially if manual wind, so with this method if the diameter of the hole is worn down to non standard size, the watch can receive a fit stem yet. In some cases the hole is busted open, that where one pretty well is to mess with the mainplate. Don,t forget to grease the stem pivot upon assembly, lots of side friction there. The gold or chrome plating in the hole is the first to go upon use of the watch anyway. Regards joe1 point

-

1 point

-

As you say, there are two sets of numbers on the gauge. I'm sure the left hand set of numbers is the diameter of the pivot in Dousiemes, and the right hand set is the appropriate Jacot drum notch that you should use when working with that pivot. To check this, measure the gap of the gauge at the relavent numbers and see if it corresponds with the sizes I have given. Here is a conversion of Dousiems to Millimetres. 1 = 0.19 2 = 0.38 3 = 0.56 4 = 0.75 5 = 0.94 6 = 1.13 7 = 1.32 8 = 1.50 9 = 1.691 point

-

I'm curious about how you're holding the watch in the microphone? So I snipped out the way you're doing it and I have a sample of the way it's supposed to be done so is there some reason why you're doing it this way? Then I noticed the other way you're holding it where it appears to be your pushing on the crown? The jaws of the timing machine are quite strong pushing hard on your crown which is pushing on the stem isn't really a good thing to do. So many questions and so many problems. Then it's amazing how much power is lost through the gear train and escapement if it's not properly lubricated. Then totally wrong lubrication can be worse than no lubrication at all neither of which is desirable if you're trying to get your watch to run properly. The beat error? I'm attaching an image same timing machine different watch so you can see what 2.2 ms looks like. Your lines look like they're too far apart for the error they're producing? Then from the link below is references that later versions of this watch have a floating stud? If that's the case putting this watch in beat should be really really easy. Mainspring someday you'll have to put breaking grease on the barrel wall but that's not going to be an issue or problem right. Modern new mainspring are prelubricated it's an invisible lubrication unfortunately for the most part. But as you've cleaned the mainspring it now no longer is lubricated you probably should put some lubrication on it. From the list of lubricants you currently have you could use D5 on the mainspring. Then your description of it doesn't look too good? Everything you do to screw up the mainspring ripples down to the balance wheel. Besides the usual cone shape that you get from hand winding were there any kinks or bends in the mainspring? Then when timing more than one position is desirable. Your currently resting on the end of the balance pivot the least amount of friction so at least one pendant/crown position is desirable. A wristwatch crown down works fine. Cleaning fluids lighter fluid seems to be popular on this group. There are alternatives at the hardware store. It's important to remember no matter what you are using is it's not a one step process. This means that whatever you clean the watch in you now need to Rinse at least twice. Each rinse needs to be cleaner than the previous one. So the initial cleaning fluid whether it's commercial watch cleaner whatever puts things in the solution which is now coating everything in the watch. Then the next rinse reduces that concentration and the rinse after that will reduce the concentration. Then you don't have to go through a lot of cleaning fluid or rinse if you keep them in jars/Containers with tightfitting lids. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_24511 point

-

Sure! I’m not familiar with that solution but it’s formally a cleaning solution. Pegging is a good idea although it doesn’t come without a big discussion that can be found in other rooms... Now, that’s great for pivots and jewels but pinions and wheels may still retain some residue. Sent from my iPhone using Tapatalk1 point

-

Good job... that’s how one gets started. Obviously it’s not cost-effective but keep at it and it will eventually. My first observation is the cleaner used to wash the movement. There are multiple sources that show how using lighter fluid can really hurt you. Even if you don’t notice it, it may be leaving some residue, and if this is the case here and there, this could partly explain why your gear train has uneven resistance and thus the amplitude and rate vary so much. Add to that the out of poise mainspring, and the wild variations start to make more sense. Not oiling properly before timing is not a good idea but even then, I wouldn’t expect the significant variations you’re obtaining. Something to think about. It’s a good idea to let it run 24 hrs before doing more definitive timing measurements. The demag is a big deal. It should be the very first step before you even touch the movement. You should time the watch first thing, demag retime and then overhaul. Looking forwards following on your progress. Keep it up! Cheers! Sent from my iPhone using Tapatalk1 point

-

I'll point out that I work with a young-ish watchmaker who's probably in the top .01% and several times he's been banging his head against the wall on a prototype and gives it to me, I check and his balance pivots are dry as a bone. He never does it in a repair though. Anyway you're in good company- but do oil everything before checking (well, what gets oiled) and let it run for a good 24 hours.1 point

-

I doubt seriously if oiling helps identify the cause. The period of loose/gain you speak of, is reasonably indicative of possible fault in power train gears , it may corresponds to the period of the wheel exactly or subperiods thereof, caused by bad or unclean gear teeth and the like. In case the period inconsistancy notably change behaviour at different poistion as well, especially face up, down or oblique positins, other causes join in. Regards joe1 point

-

I have never used that type of gauge for pivots, so I don’t know about the measurements. I know you slide the pivot along on the inside until it stops and you read off the measurement. Here is a good video about how to set up a Jacot tool and use it. Working with such a tool takes a lot of practice. Do not start on something you wish to keep, wait until you have the skill. https://www.youtube.com/watch?v=f-8Vd2m-WBs1 point

-

1 point

-

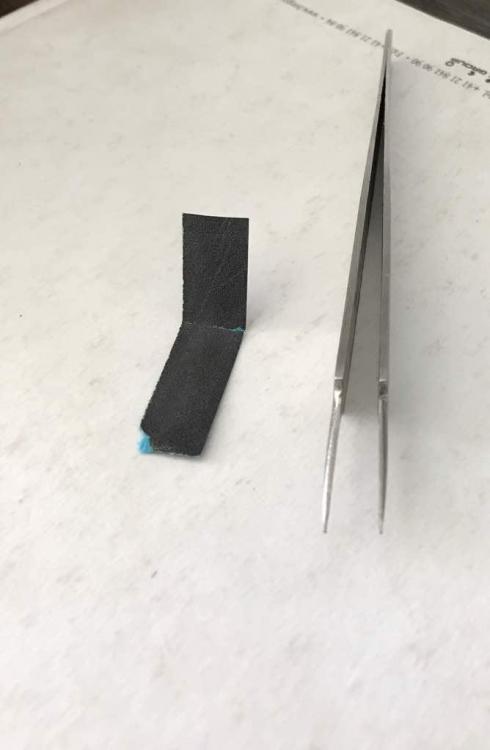

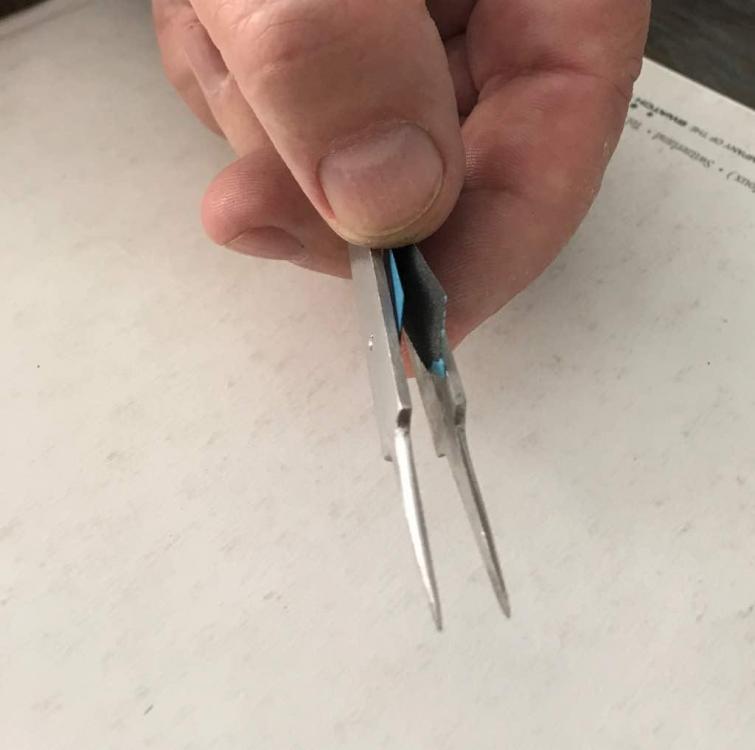

What is wrong with getting the right stem. Broaching the stem hole in the mainplate is destruction of mainplate, at best. If it came down to makiing alteration , all alterations are to be done on stem. 1. Cut a piece of sandpapre, shape it like V. Place the V in your tweezers. 2.install the stem in your stem holder. You can turn manually or turn stem holder with drill.1 point

-

Hi Andy thought I had a cheap watch collection. To me any watch or clock that does not work is a ornament and fixing it a challenge. Had a shufty at cousins uk where I get my parts. the pin pallet is £5.96. Escape wheel £6.55 then factor in vat and postage I guess that,s not too bad . I should have to wonder what sheared the pallet pins, If dropped the balance would have gone . one possibillity is one pin broke through wear and this caused the power surge which broke the other. The escape wheel teeth on pin lever watches are quite strong but I would check its running flat Poised. I have enclosed a PDF of the EB8800 (bettelach) an eubaches make . hope you find this useful. 2849_EB 8800etc.pdf1 point

-

I've attached the service notes with lubrication and a separate color lubrication guide. Seiko-Oil-5106A.PDF Seiko-5106A.PDF1 point