Leaderboard

Popular Content

Showing content with the highest reputation on 10/22/18 in all areas

-

Just finished making yet another balance staff. The big problem I had was that after I Jacot to pivots down to size, the balance itself was slightly warped causing the balance to rub against the palate fork plate. I managed to straighten it using caliber and fingers. Works well now. Fun day. Sent from my iPhone using Tapatalk Pro2 points

-

2 points

-

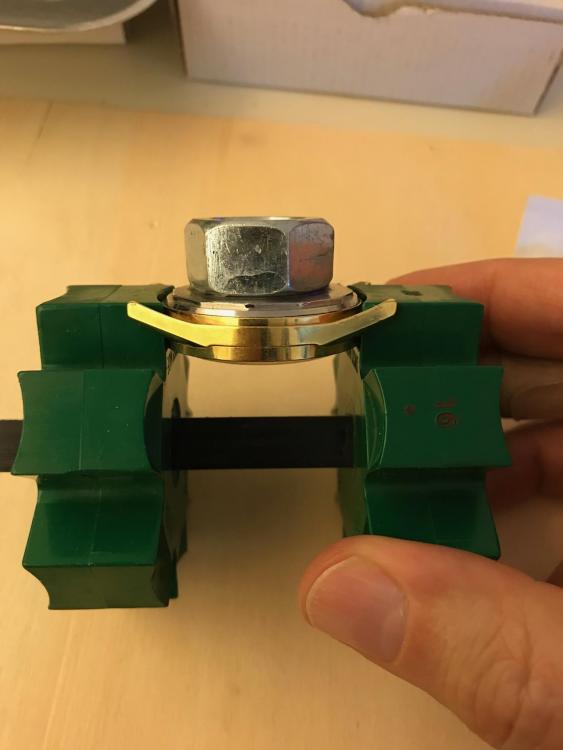

I bought a nice vintage chronograph watch with a 7733. Nothing fancy but the watch was just appealing to me and a good start in jumping into the topic of servicing a chronograph. So far I did only one, which was a Heuer pocket watch. So I wanted to open the case back with a very trusty old stainless steel opener called Vari-Matic. It did not open, when I tried to clamp the case into a vice and use force with both hands... the HANDLE of the steel opening tool was breaking away! Watch still closed ! I was desperate and after a while chatting with a friend working on cars he explained me that he was wielding nuts to cracked parts to use a ratchet..hmmm..ok wielding might not be feasible but i was trying it with superglue. I took a 23 sized nut sanded it flat an glued it on the back using superglue and let it sit for a couple of hours over night. This is how it looks like: Next i clamped everything in my large vise and used the ratchet: Voila it was open: And the best thing was that i did not even need massive heat to remove the superglue but dropped the nut and caseback into acetone for about 3 hours and it was gone. No residue just wiping of the back. See the pic below.....now i can service this watch. I hope this helps someone if he has no other option beside damaging the watch - give it a try - it worked perfectly. Am I nuts or are there others out there doing this?1 point

-

1 point

-

1 point

-

I concur on the timexes !you can buy buckets of old russian vostok and raketa movements for nil.Parts interchangeability is fair and they work the same way as their western counterparts. Out of a dozen you might get 3 or 4 to actually work,if not, not much lost.1 point

-

Hello, is there any way to get some info about the watch. For example movement name and number etc. Also after servicing what kind of readings are you getting on the timing machine? Thanks1 point

-

The pipe is missing from the case for the waterproof button to fit over. At present it is vulnerable to dirt and dust. I would say that type of design was popular around the late 80’s1 point

-

Looks to be superb work JD. thanks for taking the time to document it. Sent from my iPhone using Tapatalk1 point

-

1 point

-

Yes that is what I am saying. Assuming the spring you received are of larger width scratching the barrel from inside. In which case lubrication or serial number of grease wouldn,t help much. If my lidless idea do not appeal, test with one of the old springs. Regards joe1 point

-

I forgot to suggest, try installing the barrels without lid.1 point

-

I would give both watches full manual wind, let run at rest on bench if they run like30hrs, faulty winders is highly probable, Listen for sound of sudden power discharge inside the barrel while winding. If at full manual wind they run for six hours, the power source and thereon are to be suspected, either springs are weak or rub against the barrel on the inside , the barrel lid if not fit level can rub aginst the mainplate or barrel bridge. The free rotation of each wheel in the winder and power transfer to ratchet. Having said all this, I like all agree with you, both watches acting alike is most SUSPECIOS.wrong M/S or reversing wheels, Regards joe1 point

-

Its been years since I repaired one of these, so I hope I’ve got it right this time. Remove these parts, blue arrow and red arrow, the cam wheel is screwed on behind its face. I have marked the cam wheel showing the position it needs to be in. Put the minute hand on and move it to the 3 position. Now move the drum and watch the hammers, when they have gone down the scale, I would do this for at least 1 hour to make sure it is correct and all in line. If you are happy, put the cam wheel back on in the position that the minute hand is pointing to (I would pick the 3) and tighten up. Put the blue arrow part on, and test. Let me know how it works. The front plate is a split plate. It is possible to remove the springs without taking the whole movement apart. If you need to remove, a spring be sure to use a good mainspring winder, as these springs are very powerful.1 point

-

Physical copy. It’s not much though, about £10 or so iirc? Well worth it. Sent from my iPhone using Tapatalk1 point

-

1 point

-

No do not learn on Timex as their movements are very different and very difficult to put back together. Instead get a few 17 jewel movements to learn on. You will find the engineering of the parts to be much better and once apart they go together much easier. Pocket watches are another good learning movement because the parts are big.1 point

-

1 point

-

It seems that the Auto is not functioning correctly. I used to get this issue until I started using 8951, Fixodrop (Epilame) for the reversing wheels and auto parts. I also have a rotary watch tester that I run auto's on for 48 hours just to double check all is OK. I believe Eta recommend another solution for their reversing wheels but sorry can not remember it's name.1 point

-

There are small screws on the sides of the movement that press against two ‘feet’ that go into holes in the movement. Loosen the screws and wiggle the dial off. Sent from my iPad using Tapatalk Pro1 point

-

There is a seller on ebay who sells smaller volumes of moebius so it is more affordable if your just doing it as a hobby. She sells like 1ml and 2ml portions1 point

-

Thanks for the info. There is so much information on the web about watch oil, it can get very confusing.1 point

-

I actually talked my local watch shop into selling me small amounts of the oils. They said since I am a good customer they wouldn't mind me bringing my oil cups down for a small fee of $15! I guess it pays to be a loyal customer sometimes.1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point