Leaderboard

Popular Content

Showing content with the highest reputation on 01/27/18 in all areas

-

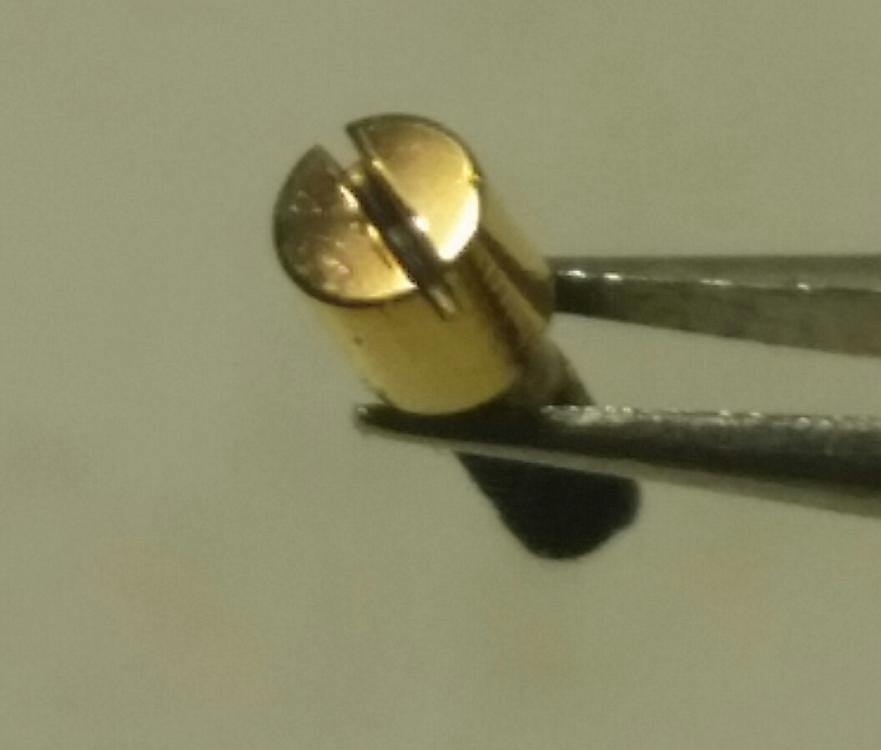

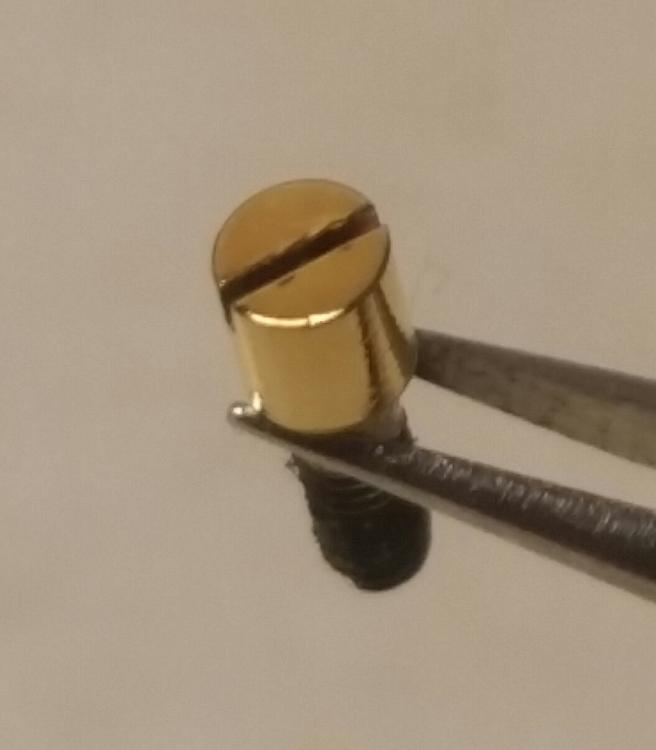

I just received another ebay gamble that seems to have paid off. An inexpensive ($50) gold plating setup, for restoring those pesky gold plated parts that some hack couldn't keep his bare fingers off of lol. Here's a couple pictures of an old screw I tried it out on. Polished with the dremel and felt wheel before plating, I didn't try to get all the nicks out of the slot. BTW, this was just a plain steel bridge screw, not previously plated. The electrical part is basically a 5v wall charger, a stainless anode and an alligator clip for the part. Plating took about 15-20 seconds.3 points

-

Cousins search function is funky. It returns a lot of bogus results. I just tried your search, and it certainly did come up with parts that were not AS1240. If I specified cap jewel, it came up with no results. My impression is that Cousins does not do returns unless the part is defective or was shipped incorrectly, being a wholesaler they expect you to know what you want :-) Learning how to navigate the minefield of watch parts purchasing is part of learning the repair game, and I don't think it's going to get any easier over time. Don't get discouraged, though, just don't make any assumptions, and verify what you are ordering before you pull the trigger! Cheers2 points

-

Hello all. In my search for knowledge and equipment on dial printing and hand making, I found this place. I have a degree in watchmaking, but our program was more centered on after sales service/support. Due to this I have been seeking other avenues to at least gain a rudimentary knowledge on topics not covered by my education. I have a tendency towards read more, post less on most forums and have been largely inactive the last several years on the watch fora of which i've been a longtime member. I look forward to getting to know the different personalities here, and hopefully adding to my knowledge base through the content. Thank you for having me. Have a good day.1 point

-

I found three stems but i could probably part with 2 if you can't find them elsewhere. Probably have some more ETA 2763 stems somewhere if i search harder.1 point

-

from another beginner......loupe, tweezers, screw drivers, case opener (knife and jaxa (wrench) type) hand levers and oilers would be the most basic and then collect from there. I would highly recommend buying the best quality Swiss stuff. Using low quality tools is a pita in the macro world but just unbearable in watch work. Over the last couple of years I bought out a few retired guys tools kits, just patience and watching the classifieds. It was a great way to get head start1 point

-

It is, I looked at others but Marks looked best suited to me Sent from my iPad using Tapatalk1 point

-

Yup dead straight on to the center of the stock. I learned that is very important when I was practicing on the brass. Sent from my iPad using Tapatalk1 point

-

bad carbide was probably a long shot....but it does happen and if all else has been tried.... You shouldn't try to heat treat HSS, there's no need, it comes hardened and ready for use. Its very difficulty hardening and tempering hss (like impossible) as the temps required need to be exact. Unlike carbon steel, its just not a DIY thing I'm afraid. Carbide afaik cannot be hardened or heat treated, its made by sintering and is what it is. If the tool is mounted, its dead on centre height? Sometimes easier said that done for very small diameters....and I know its pointing out the obvious but stranger things have happened1 point

-

Thanks khunter, I will advise my wife that you have approved my purchase... I have been looking for a decent set at a reasonable for a while, but keep buying other things instead :-)1 point

-

For some reason the dog has been avoiding me since I started experimenting I have a few Illinois movements with gold hardware that could definitely use some TLC, I'll have to keep reminding myself that "less is more" or I'll end up with a big gold lump lol.1 point

-

Thanks, I've been mulling over a microscope for quite some time, maybe some day I'll actually pull the trigger and get one :-)1 point

-

That turned out well....I'd be afraid of wanting to gold plate everything in site1 point

-

It doesn't look broken to me, at first sight but are you sure that you inserted it correctly ? Sometimes components inside the movement move around which won't allow you to properly put the stem back on. For mechanical movements and, perhaps, some quartzes, this means that you have to take it apart and put the parts back where they should be. Usually this doesn't happen on quartz watches and it shouldn't be hard to re-install the stem and crown. Have you tried gently rotating it a bit when it goes inside ? PS: I see a screw with an arrow pointing towards it. Usually this is the screw that you can loosen (not too much though) to remove the stem and when you put it back in you tighten the screw back.1 point

-

Very nice piece! Depending on the base metal you might need extra solutions, and it's all explained all over YouTube, etc, but it's super easy. The main thing is prep, the higher the polish before plating the better, and thoroughly clean of course. For the bits I'm working on that little 4oz jar of plating solution will last a LONG time, but they make larger quantities as well.1 point

-

that is the proper tool (for parting only). use it on annealed steel. as mentioned above, "drill rod" comes annealed, BUT, be sure to ask for the proper quench medium for hardening. ! drill rod will save time and aggravation. vin p.s. the stem must be hardened. cheers1 point

-

I think it's suggesting that the mainspring winders only worked one way back then. What I do is use the next smaller spring winder, then push it out in to the the correct sized winder, effectively inverting the spring so it's the right way round1 point

-

I realized only now this is simply about an impact that made the rotor fall off... nothing is defective. 2 pages of useless speculations.. including mine's Oh well.1 point

-

It's still taught in school. http://raulhorology.com/2012/11/the-mark-of-a-true-watchmaker-hairsprings-part-2-vibrating-the-spring-using-a-luthy-tool/ Maybe these laureate watchmakers will not use the skill in their career, but the knowledge is certainly not lost.1 point

-

Yeah I stripped down the auto mech again and spotted a gear round the wrong way. Seems to be ok now. I was going to start work on my Traser with a 2824 movement after this episode but I think i need a bit more practice. Thanks guys1 point

-

While 50 years may seem like a long time for just about everything getting serviced for a watch it's not. It's possible you might Be able to get a balance complete New. Then they used to be people who would Vibrate hair Springs for you I'm not sure if anybody still does that? The problem is the raw hairsprings are no longer available they haven't been made for years. Everything now is made for specific watches or the watch company sends their balances to hairspring company for them to do. So other than a novelty vibrating a hairspring is almost a thing of the past almost.1 point

-

The other problem with roller jewels is besides the already mentioned it has to be the right size is the shellac. There seems to be a quality difference which affects the melting temperature and how well it flows and just because it's in a little bottle labeled for watch repair doesn't mean it's going to be right. Then another option is the flake shellac used in woodwork except the flakes are quite right for use and the quantity is big enough for a whole bunch of people for their lifetime. Then if you going to send your balance wheel away to have someone see what they can do I would include the entire watch. You need the pallet fork to figure out the roller jewel size. Then you really want to test it out to make sure it's right and that everything fits if you start swapping things. For instance if the safety roller changes its size by very much you may have to readjust the escapement which is why changing the roller jewel is usually a nicer option if you can do it.1 point

-

If the stem is seized by rust (which it sounds like may be the case) then it would hopefully remain static. If the outer half of stem is still present, then try threading on another crown with a long enough tube, and perhaps a crown one size larger if the corrosion has caused the stem to bloat in size. If there is nothing to thread onto reliably, then machine a tube to slide inside the pendant tube and over the rusty stem; use two-part epoxy to adhere the sleeve to the outer half of the stem and then remove. Of course, even if the outer half of the stem is still there, it doesn’t necessarily mean that the inner half isn’t seized too!1 point

-

Why? If you think about it, on a rotor all the weight has to be one side, totally unbalanced to make it work. That makes so that any infinitesimal unbalance (it's even smaller being so close to the axis) introduce by deforming or gluing is irrelevant.1 point

-

That has been suggested above already: The things is, I'm not convinced that it's likely for as watch owner to posses the needed tools and dexterity.1 point

-

1 point

-

From scouseget posting "3). I watched a YouTube video yesterday from the AWCI, which stated that not only should a screwdriver be just the right width for the screw slot, it should never bottom out in the slot but rather sit just above it" Whilst I understand what is being said and why, good luck with that, especially the hollow ground enthusiasts. May get it to work on one screw in one watch but honestly! ? my test is a bit sort of simple but I found I was doing it without thinking. With the screwdriver of the right size in the slot vertically try to roll it back and forth between thumb and forefinger, if it moves at all "without the screw moving" the driver is not fit, dress or change the bit. Cheers, Vic1 point