Leaderboard

Popular Content

Showing content with the highest reputation on 07/16/24 in all areas

-

If none of the pros argue otherwise I'd go with Mobius 9010, although be extremely careful not to overoil. Do not cover more than 50 % of the cap jewel surface and redo if you fail. A standard 0.18mm super fine oiler may be too large, so maybe you'll need to improvise. I've said it before but I say it again. Amplitude almost killed my interest in watch repair until people like John said something about investigating how well the movement kept time, and that saved my interest and kept me going.5 points

-

My two blue-dialled examples, which don't appear to be duplicates of anything already posted on this thread. Both have mechanical movements, the first being my 'take it anywhere, do anything' watch which has been up mountains and diving (once). It is properly waterproof and the sapphire crystal is resistant to pretty much anything, although the bracelet is showing signs of wear after 17yrs of hard use. The other is a bit different. Alec3 points

-

3 points

-

I think it's more a case of viscosity dampening acceleration, not rate. Think of the fluid filled shock absorbers on a car. They allow the suspension to move steadily up and down at a steady rate, but dampen sudden accelerations. The train wheels are turning at a steady rate, so the oil should reduce friction and not have much dampening effect. The pallet is accelerating back and forth, so any oil would have more of a dampening effect.2 points

-

I would say our Joe here is having a funny moment, my guess is he's trying to steal my thunder. a couple of days of quiet from me and this happens2 points

-

I'm not sure where this is going? @Nucejoe, I can hide your post but I see no reason to do so. I'm saying this as a friend, not a moderator.2 points

-

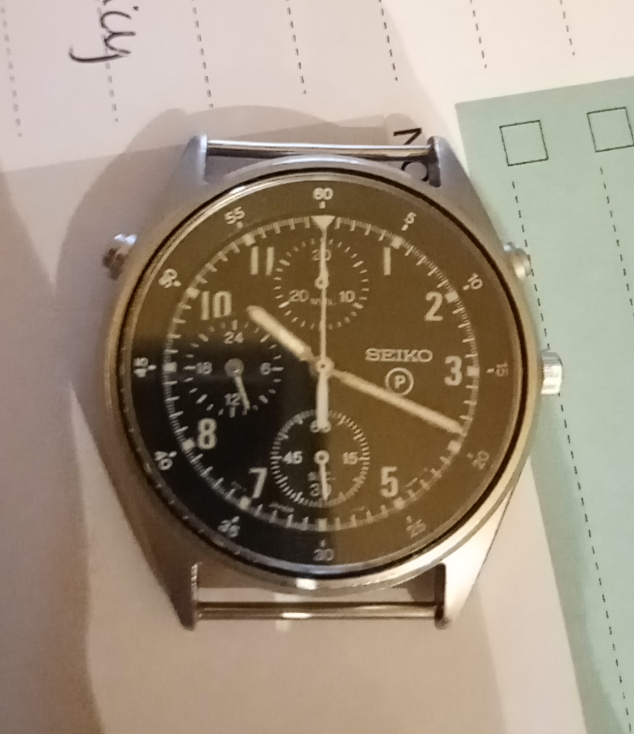

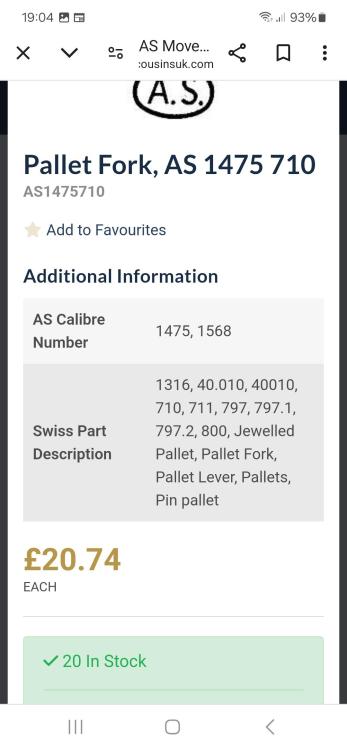

Thank you all, I’ve bought the one from AG Thomas, watch this space.2 points

-

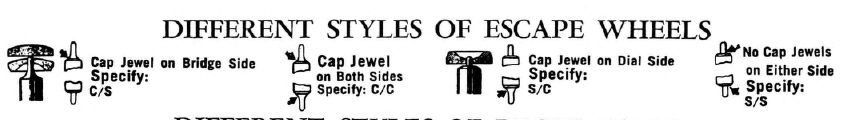

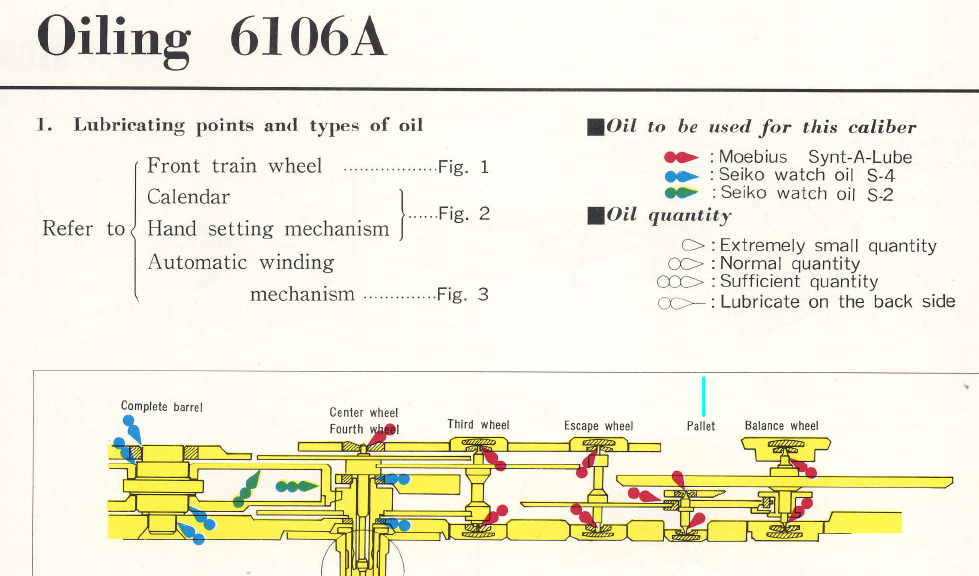

May be another picture out of the book I suppose it depends upon whose technical literature were looking at. So for instance if we were following Seiko's recommendation then yes we always oil the pivots because that's what Seiko recommends. Unless of course we don't follow what the manufacturer recommends then maybe we would do something different. But typically if you're anywhere in the universe and asked too many lubrication questions whoever is giving the lecture will always say follow the manufacturer's recommendation because after all the manufacturer should know what they're doing and typically you would not. Unless of course you decided that the manufacturers are all totally insane and you do whatever you feel like. Which works out fine for me because I'm working on vintage watches and there are no lubrication guides on that so I can do whatever I feel like. Strange I believe that's what my instructor in Switzerland said? Oh and you also forgot that all lubrication has a dampening effect. So in other words you want your pallet fork to swing really really really fast and classically putting lubrication on it prevents that from happening. Then a course if we go back early enough to organic lubricants as the lubrication disintegrates and gets typically sticky then this would be extremely bad. Fortunately today synthetic oils typically don't get sticky but still could have a dampening effect? What about using if you really must lubricate or about using an oil kinda designed for this? Quartz watches are interesting because when the stepping motor steps it steps typically really fast. Anything that slows it down or interferes bumps up the current consumption. Which is why originally when quartz watches came out they said no lubrication except then we had issues with that. Then the recommended lubrication but on some quartz watches I found that had issues. Then the Swiss came to the rescue with 9000 lubricants specifically designed for quartz watches which I find works exceedingly well. So if you're going to lubricate something that needs to move really really fast may be issued user oil designed for that well designed for quartz watches but still you can pretend it's a similar situation.2 points

-

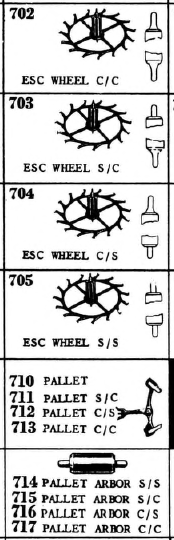

"S" is for straight (pivot), "c" is for conical. Conical would be used with a cap jewel.2 points

-

Have to agree. Become too political in his comments now. Shame. We are watchmakers. Long may we be so.2 points

-

The case is square but the back must be round to get to the watch. Can you post photos so we can see what you have.2 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot. I agree to me it is more likely the balance staff.2 points

-

Hi all - just joined as I’ve always been fascinated with watches of every ilk and just starting to enjoy purchasing a select few favourites. As I’m knocking on a bit I’m also thinking about being a bit more hands-on with watch repair/build as retirement hopefully beckons in the coming years. I’ll be having a good rummage around the site so I’m not asking old questions long since answered and hope to get to know some of you in due course.2 points

-

Hi all 40 year old guy from Norway here. I started getting interested in watches only about three or four years ago when I randomly stumbled upon a watch restoration video on YouTube. I had no idea what I was looking at, but I found it relaxing and therapeutic. I started using it as a sleeping aid late at night For the last few years I have been obsessing over watches in general. I am reading books, looking at youtube videos, reading forums and listening to podcasts. Buing and selling a lot of different seiko, citizen, and some others here and there. But now the last month or so I started to think I might want to try some restoration myself! That pushed me to buy an online course (that I got a big discount on, but wasn't too impressed by) and also watch every youtube video I could find about the subject. I also bought a few books, including "Watchmaker" by George Daniels. One of the first things I learned was that I didn't even really know how a mechanical watch really worked. I mean I thought I did, but I didn't. I still don't really understand how everything works, but Im learning every day. I have ordered SO much tools and equipment and built a small workspace in our basement. The tools range from premium swizz to temu When I find the time I want to start to practice on my own cheaper watches, before moving to some buy-to-restore projects. Hope to learn a lot from you all! -Kruttskjegg (which translates to gunpowder-beard or something1 point

-

1 point

-

Its rare that I'm ever stuck for words, but you got me with this Rich. I paid good money for this and thats the best we got is it ? Ken and Barbie's sausage slicer, cant wait to see it in Toys'R'Us , why do i even .......?1 point

-

1 point

-

Lets forget about improving my vocabulary, help hide my post from Mark.1 point

-

I had once suggested the group should try experiments. For instance lubricate the key less the mainspring but no other lubrication anywhere else and see what happens. I've only done extremely limited experimentation I found it quite interesting. Then what happens if you go the other extreme what if you oil the watch with HP 1300 for instance the entire gear train including the escape wheel of course not the balance I use 9020 on the balance. This should have a dramatically bad effect or does it? Now for you just figure out what I did with the charts I had of amplitude versus lubrication?1 point

-

1 point

-

Funny this thread's title says "a friend wants to sell me this Vostok" The reason he wants to sell his Vostok is, NOBODY HAS BEEN INTERESTED TO BUY IT. the only route to a deal remains, The owner has to look for and find someone to shove his Vostok up the buyer's ...... Hope Mark doesn't see this post.1 point

-

Well... it's only gone and started! Couldn't tell you what I did, came home late from work thing and decided to offer gentle persuasion... turned it around to get the movement out and noticed it ticking, result! Thanks all for the help, particularly you Andy - as a noob here it's been the nicest possible welcome to a forum I could hope for: so helpful! To the strap draw! Pleased with this one - as a fairly new convert to fixer uppers I've learned how to refurbish and relume (badly!) hands, I've switched the movement over including date wheel swap and rear plate, fitted the tiny hands for the first time and done my first non acrylic crystal swap. Here's how it arrived: Might have a play with diamond polish on the original crystal at some point... Need a rear gasket and strap too...1 point

-

Yes that's the correct one. At that price though he may be as ell getting it from France off eBay. https://www.ebay.com/itm/326179070044 Edit Or Bradford https://agthomasbradford.com/products/pallet-fork-710-as-14751 point

-

1 point

-

1 point

-

It would be difficult to heat up those screws. Try dripping some WD40 on the screws and leaving it to soak overnight. But before that, give the watch a good scrub with a wet toothbrush. Sometimes the dried up sweat and organic matter gets into the threads and jams up the screws. It's a good idea to dress your screwdriver to fit the slot of the screws snugly to avoid slipping and damaging the screws or caseback. I really love these torque multiplier sleeves for screwdrivers. They make taking out jammed screws so much easier.1 point

-

Hang on, are you guys not oiling the pallet fork pivots? Have I been somehow cranking out extra amplitude somewhere else?1 point

-

I have to agree with @mikepilk on this one. The roughly 11° of travel for the pallet fork makes any lubrication advantage questionable. In a typical non-capped pallet for pivot, end shake is determined by the position of the hole jewels and the pivot shoulder will be in contact with the upper or lower jewel dependent on position. In a capped setup, the position of the cap stone determines the end shake and the pivot point will contact the cap jewel. Since the pivot point is smaller than the shoulder, theoretically less surface contact = less friction. And, while lubrication might provide an added lowering of friction initially, it becomes problematic over time as the oil dries and/or attracts dirt. As for shock protection, is the mass of a pallet fork enough to warrant it?1 point

-

I have come across pallets with cap jewels, and wondered about whether to oil or not. In the end I decided not to oil, as the pivot is moving through a small angle, with very little load on it. If I did oil, I would use the tiniest drop of 9010.1 point

-

They sure can be sometimes changed without breaking the crown open. You have to cut the old o-ring to pieces with a screwdriver or something and then manage to get the pieces out. New (greased) o-ring can be poked in if it's not too big for the gap. Seiko 6105 divers cannot be done this way, the o-ring is way too big.1 point

-

As you're finding it really servicing technical sheets with complete lubrication for vintage watches for the most part doesn't even exist. Then even if it did exist it would give you lubrication choices that probably don't exist today.1 point

-

1 point

-

I'm not sure why photographing blue dialled watches seems to be that little bit more tricky than other dials. In reality this watch looks pretty much immaculate, but the moment the camera points at it, 1000 motes of dust land on it, and the camera (or perhaps the photographer) entirely fails to do it justice. There is a bit of a story to this watch, which I may share at a later date, and one of the other members of WRT will almost certainly recognise it. Suffice to say it hits the spot nicely in every way, but particularly when it comes to blue. My sincerest thanks to its previous owner for letting me have it, and I hope the beaver settles in to its new home comfortably. I'm also not quite sure why there seems to be a particular shared fondness for blue dials. Perhaps it has something to do with this.1 point

-

I recently serviced a Westclox 17-jewel vintage watch with a Seiko A201 movement. I don't know the exact year, but it's probably from the 1970s. Westclox dates back to the 1880s in the U.S. and built mostly clocks over the past century. The factory in Peru, Ill., burned down in 2012. I suspect the watches were something to fill their portfolio. The company had military contracts, and in the 1960s a watch similar to mine was sold with a "military" style. I bought my watch on eBay in March for $19 (including shipping) from a vendor who does not specialize in watches. The outward appearance was encouraging, although the case had hairline cracks, which I suspect were caused by aging shellac. The case was made in Hong Kong of inexpensive metals. I've been destroying watches for more than two years, learning from YouTube videos. This was the first jeweled watch I serviced and managed to get running. I've had a couple of failures. My first success was an economy Walden pin movement. I'm sharing lessons learned for this movement (sold on eBay). The reason I think the watch was never serviced is that all of the screws were frozen. Not rusted (the movement looked pristine), just stuck. I soaked them in small dabs of penetrating oil and a mix of transmission fluid and acetone, which finally loosened the screws. I found a couple of useful videos on YT for assembly/disassembly, but recorded my disassembly on an Andonstar microscope. Disassembly was straightforward once the screws were loosened. Removing the movement from the case was my first puzzle because I'd never seen such a huge retaining ring. It was just press fit, but I didn't know that. I pried it out once I realized it wasn't locked in place. The hands had small amounts of lume, completely deteriorated, but the dial lume was intact. The dial and hands were in great condition. I haven't sprung for a mainspring winder. My attempt to make a homemade winder using plexiglas as seen on YT failed miserably. I bought a new mainspring after a brief search on YT. I found mainspring documentation online, so I knew the size to order, $19.64 with tax and shipping. I fiddled with the arbor thanks to my lack of experience inserting it into the mainspring, but finally got it right. I closed the case making sure it was well aligned, but discovered later I had the barrel cover on upside down! I figured out my mistake when the click spring kept popping out. The barrel cover has an almost imperceptible raised section, which goes down, not up like I thought. The raised lip was just enough to keep the ratchet wheel from being flush over the barrel cover, which has a square-shaped hole. My biggest hassle was the train of wheels bridge. I fault the movement design to some extent. The first, second, and third wheels were easy, but the escape wheel was a problem. Its tall shaft with a small gear near the top engages with another wheel. I spent too much time trying again and again to seat the escape wheel. On top of that, the upper jewel of the escape wheel had a tiny, tiny y-shaped jewel spring that I never could put back in place. I had to use another jewel spring, a kludge job at that. By far the best jewel spring is the three-sided wavy shape (Novodiac or Kif) with three tabs that can be rotated effortlessly! I finally got aggressive when seating the escape wheel and it fell into place so I could screw down the bridge. Meanwhile, the pallet fork wasn't easy because it's buried in the movement. While I was making adjustments, for unknown reasons the mainspring unraveled, causing the wheels to spin out of control. Last time that happened, I ruined a keyless works sliding pinion with a broken tooth, I think. Anyway, the mainspring wasn't under full tension and I got lucky nothing broke. Along the way, I oiled as best I could, but this is an area where I need a lot more practice, especially with the jewels. They are tiny and prone to jumping away from you in the blink of an eye. This time I didn't lose any and I got some oil inside, but probably too much or too little. I got a little bit of oil onto the escape wheel, but this oiling task is way beyond my skill. The case looked rough, and I realized, after a light polish, it needs replating. The gold immediately came off. I have nickel-plated a watch case, with amateurish results. The metal has to be polished to a high luster for a professional look. I like the gold color, so I decided to do a light polish and keep the vintage vibe. I've documented my problems with the crown and stem, which can be reviewed here. The forum has been great for learning how watches work. There's no way I could have figured it out on my own. When I put in the final part, the balance wheel, for the moment of truth I got a big nothing. I wound the stem a few times and finally the balance wheel started turning on its own and looked to have good amplitude, but I don't own a timegrapher. The acrylic crystal needed some serious sanding. I used 400/600/1000/1500/2600/polywatch for a decent result. You get what you pay for. The movement is the strongpoint, but the case reduces the value greatly. Worst, the case back is one of those that needs a lot of pressure to press fit. Finally, it's about 2 minutes a day slow. I can live with that and I'm sure it can be improved with better oiling and beat error adjustment. But more tools are in order. Always more tools...1 point

-

If you look at horological literature that's available you will find very little on servicing like lubrication. This is because the literature when scanned into a PDF is primarily done for parts availability. Then it depended upon the particular watch company but a lot of them made the assumption that would know what you're supposed to be doing and they will give you a oiling chart for anything that you should already know how to oil it. Even give us the reference where is it covered? Then which lubrication are you going to use? Oh and there's a easy way to know if you're doing good or bad. The general consensus of a sizable percentage of the people on this group are properly serviced watch should do at least how many degrees of amplitude? If you think lubrication is controversy then minimum acceptable amplitude well if you do wrong you won't get your minimum amplitude and your life will be terminated. Yes the group does not tolerate amplitude failure.1 point

-

I have not really been into clocks Dell but I am enjoying your videos and have subscribed. Tom1 point

-

Hi and thank you all so much for the warm welcome! And thank you for your very helpful reply VWatchie, I really appreciate it. I have family from both Denmark and Sweden and have only positive feelings towards our fellow Scandinavians! I was planning on using the IPA last as a rinse, and its 99,9% Sorry for my terrible English at times. But I find it hard to buy something in Norway to use as a degreaser first. The only thing I have seen available is the Zippo Premium Lighter Fluid with one ingredient: Light Petroleum Distillate. I was hoping to find time to work on my movement this week so I was hoping to buy it from a store here in Norway. But thanks for some good recommendations that I can order from cousinsuk.com (England). That's where I ordered all of my oils, and I was very impressed by that webshop. I now found a Norwegian store that carries this product: https://www.lrultrasonics.com/solutions/111-ammoniated-waterless-watch-cleaning-solution-112 Would this cover all my needs (for now) together with IPA?1 point

-

1 point

-

Borkulating a hair spring is a rite of passage. We've all done it. Several times.1 point

-

1 point

-

Russian watches are junk, your friend must have discovered this fact.1 point

-

Disassembly sequence here (Please sort by name in ascending order) Assembly sequence here (Please sort by name in ascending order) The watch is an Enicar Star Jewels Ocean Pearl from the 1970s A bit of background I bought this watch on tradera.com (Swedish eBay) listed in the category "Klockor/Renoveringsobjekt" ("Watches / Renovation items"). It was listed as "working" despite lacking the winding stem. I bought it for three reasons. I wanted to try my hands on an inexpensive watch in visual need of renovation. I was curious of the Enicar brand and their in-house movements, and I thought the blue dial with its applied indices had potential. It was clear that the watch needed a new winding stem, crown, and armoured crystal. I found an original stem on eBay from Spain for less than €10 including shipping (a bit of a bargain I think). I bought a bunch of inexpensive waterproof crowns from CousinsUK.com so that I could select the most comfortable and at least somewhat nice looking. I also bought a couple of inexpensive Sternkreutz armoured glasses from CousinsUK.com Overall the movement looked pretty OK except for a third wheel pivot that was rusty. Removing the rust (using vinegar essence) the pivot became Coca Cola bottle shaped so I burnished it and in the process had to remove approx. 2 to 3/100 mm. This in turn created too much side-shake so I replaced the jewel as well. The mainspring looked pretty OK too so I kept it. The cannon pinion also needed a bit of tightening. I guess the friction between the centre wheel arbor and the cannon pinion really can't last forever when a watch is being used for many, many years, perhaps even for decades (looking at the case back of this watch it has seen massive use). Anyway, to tighten the cannon pinion I first tried with my Seitz jewelling pusher and stake for lanterning cannon pinions, but it feels like the edges of the pusher and stake are somehow too blunt or perhaps not designed for wrist watch movements?! So, I resorted to my cannon pinion tightening tool (Bergeon 4733) which is really a bit scary to use but works very well once you've destroyed your first two or three cannon pinions learning how to use it. The trick is not to alter the position of the screw (unscrew it) once it reaches the inside of the handle. As soon as the screw touches the inside of the handle it's time to press. That will usually tighten the cannon pinion the required 1-3/100 mm (I would guess). To give back some of the luster to the dial and hands I simply used a Dial & Hand Cleaning Pen from CousinsUK.com. It worked better than I had expected. The old lume was partly missing and what was left was completely crusty so I simply scratched the remains off and didn't bother to replace it (the blue colour shining through the hands looked pretty great and I don't care much for lume anyway) Despite throwing everything in my arsenal of collected knowledge and experience on the this watch I couldn't get it to run perfectly. The amplitude (as well as the rate) in the horizontal positions fluctuates between 260 and 280 degrees but mostly stays around 260 degrees. I did adjust the curb pin as the hairspring was pinched between the boot and the curb pin and made sure it bounced evenly between the two, but the effect was only marginal. I suspect that the hairspring touches the lower part of the boot. Anyway, I decided to wait with further investigations, put it together, wear it and enjoy it. Despite this shortcoming it performs very well as a daily wearer, only varying in rate between about +1 and -1 seconds per day.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)