Leaderboard

Popular Content

Showing content with the highest reputation on 06/07/23 in all areas

-

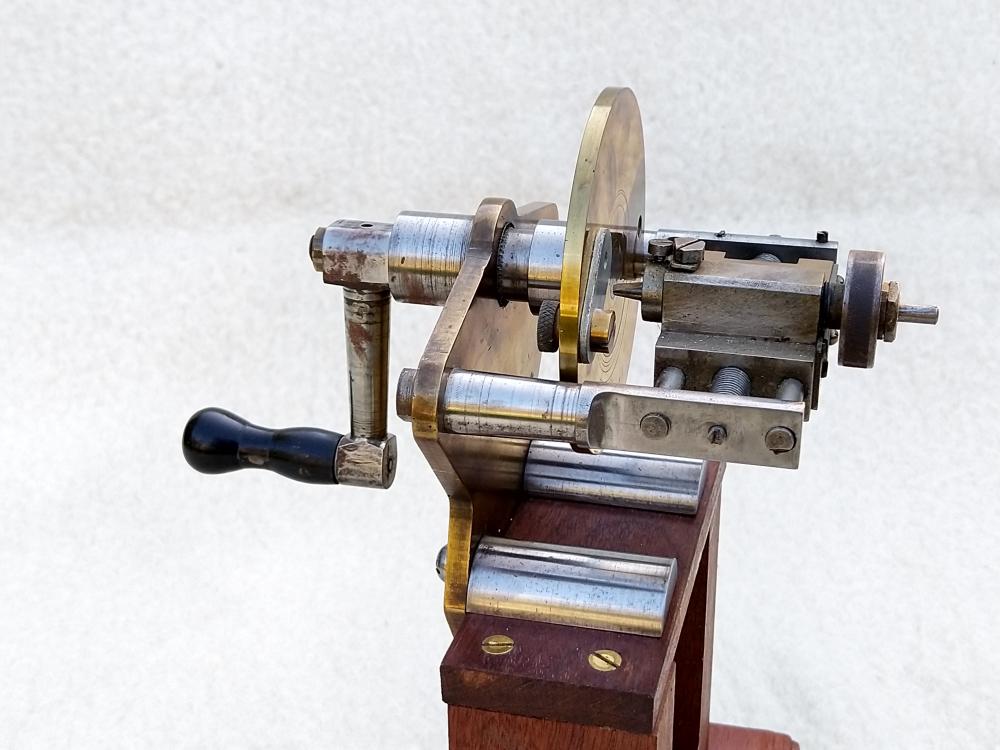

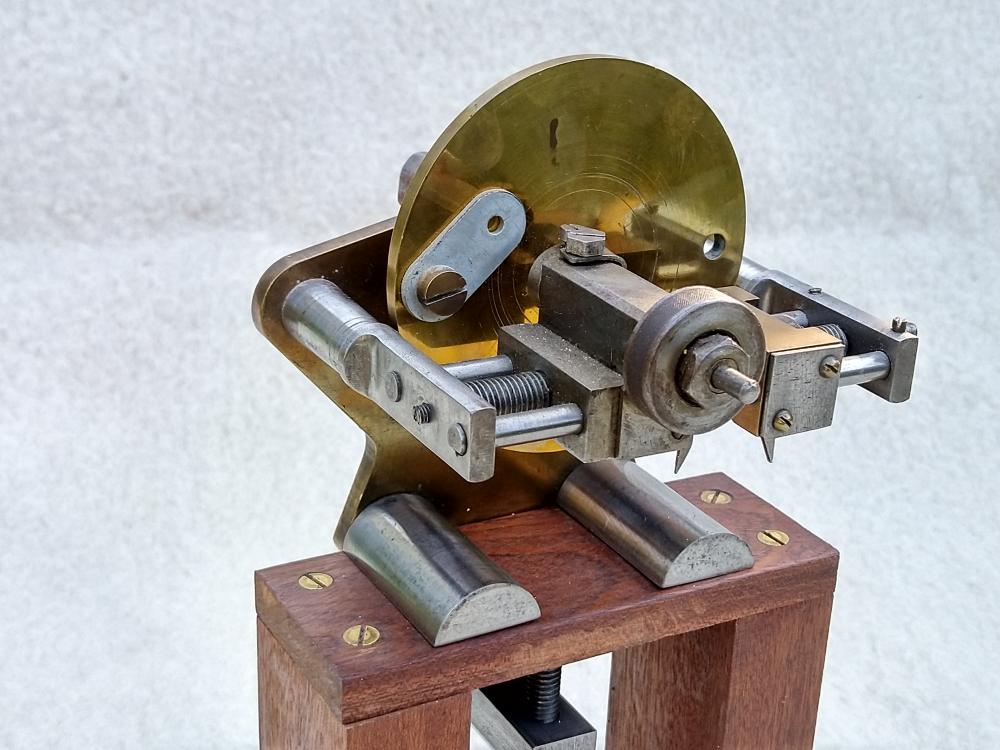

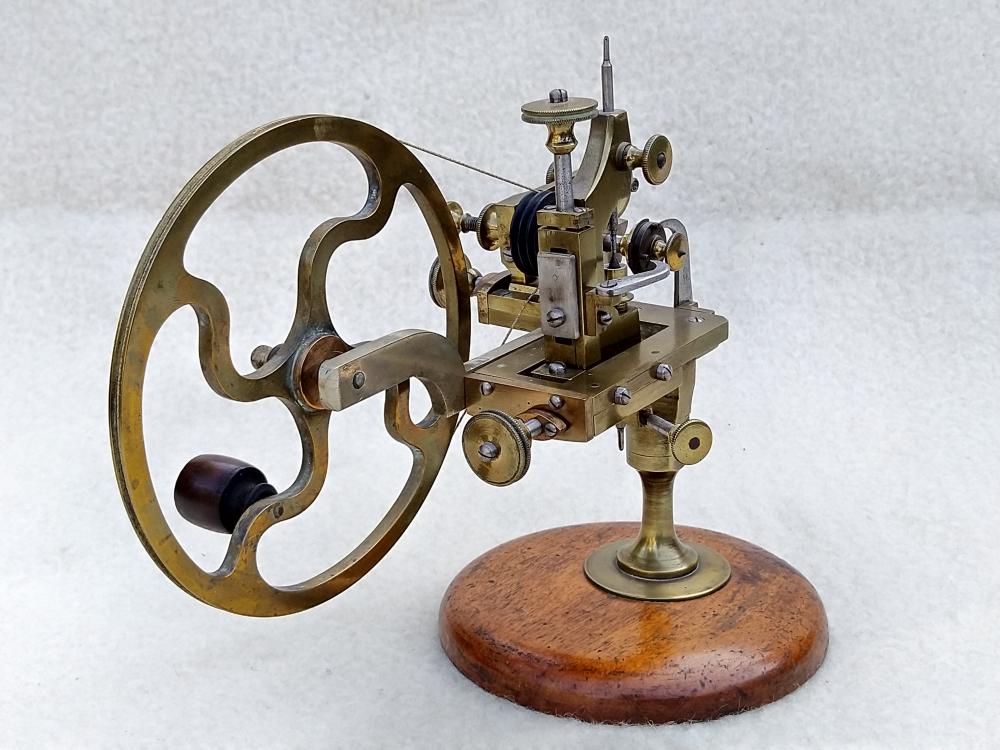

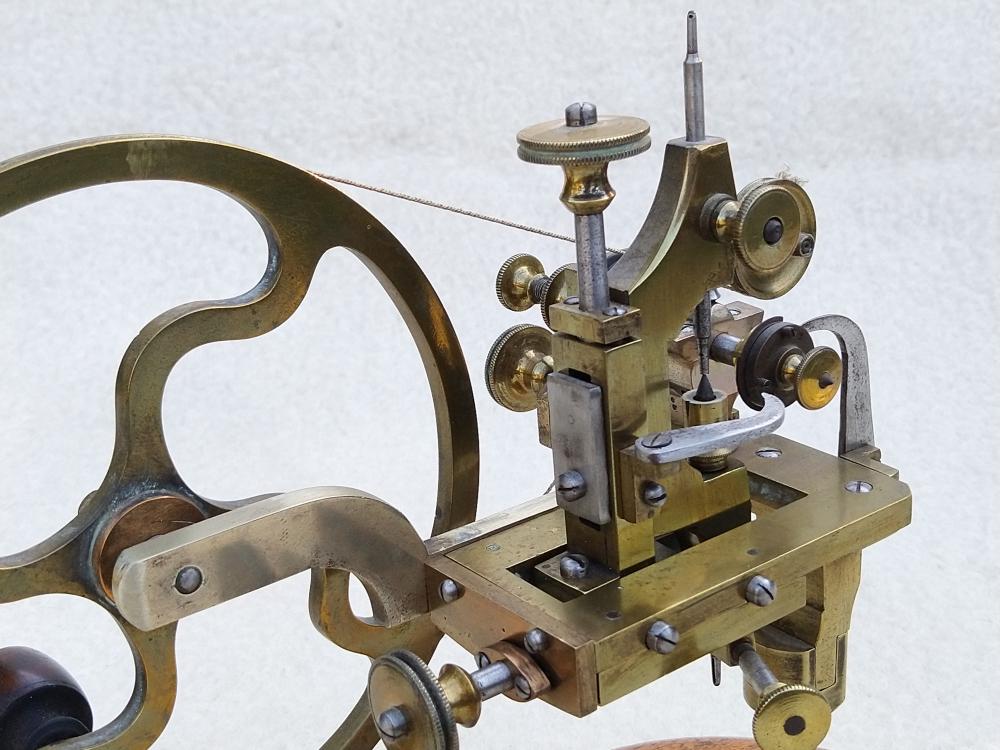

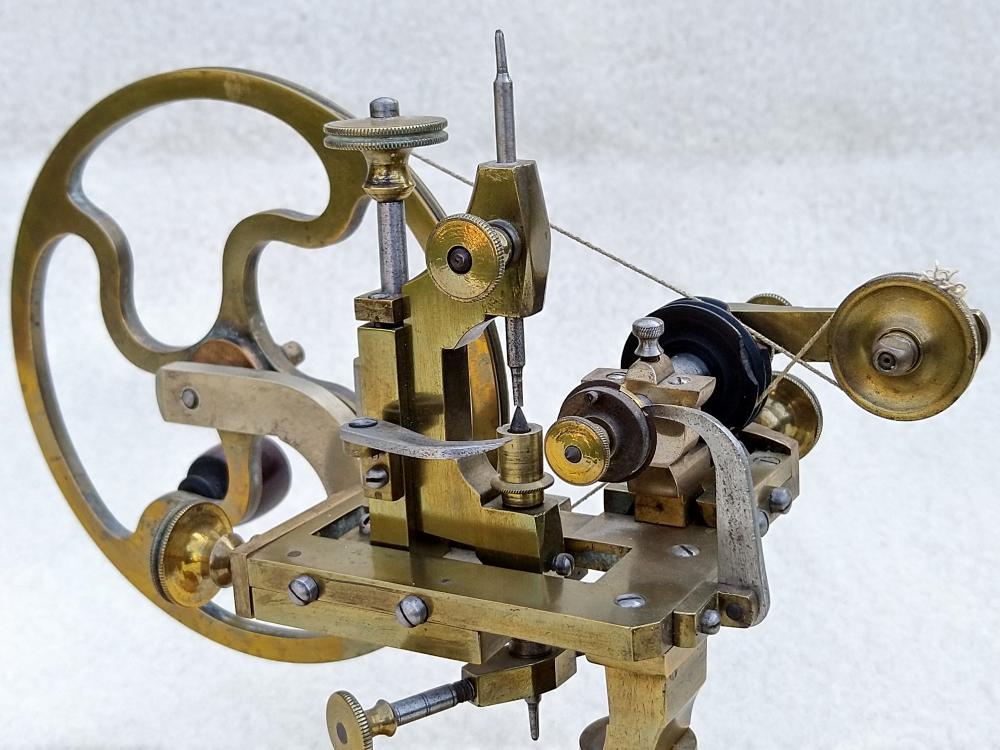

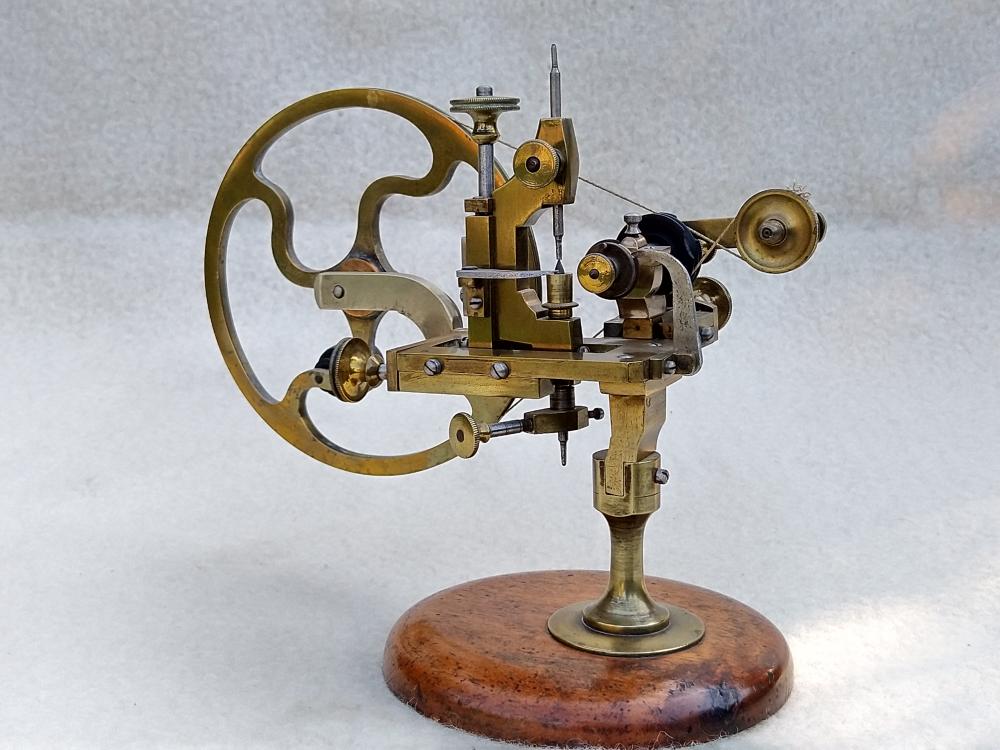

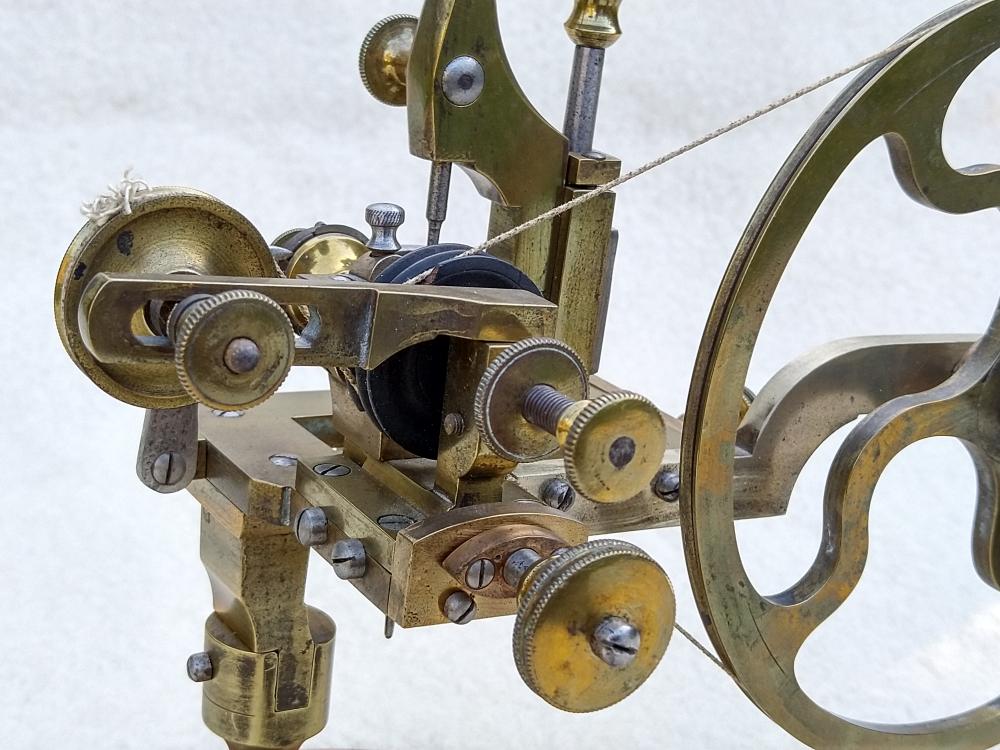

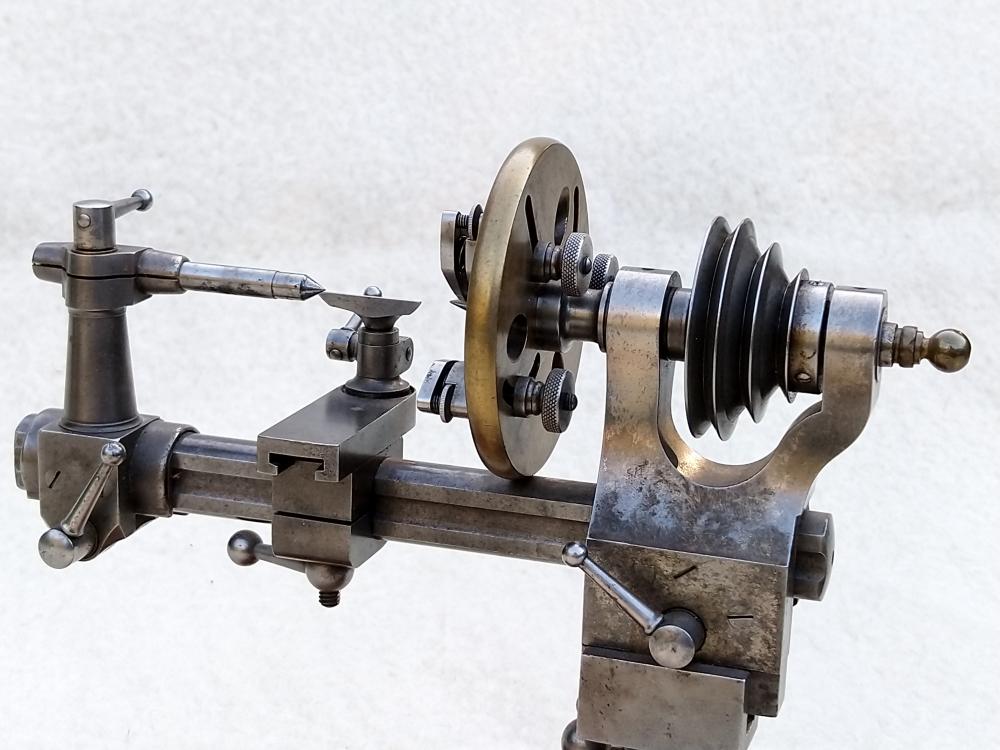

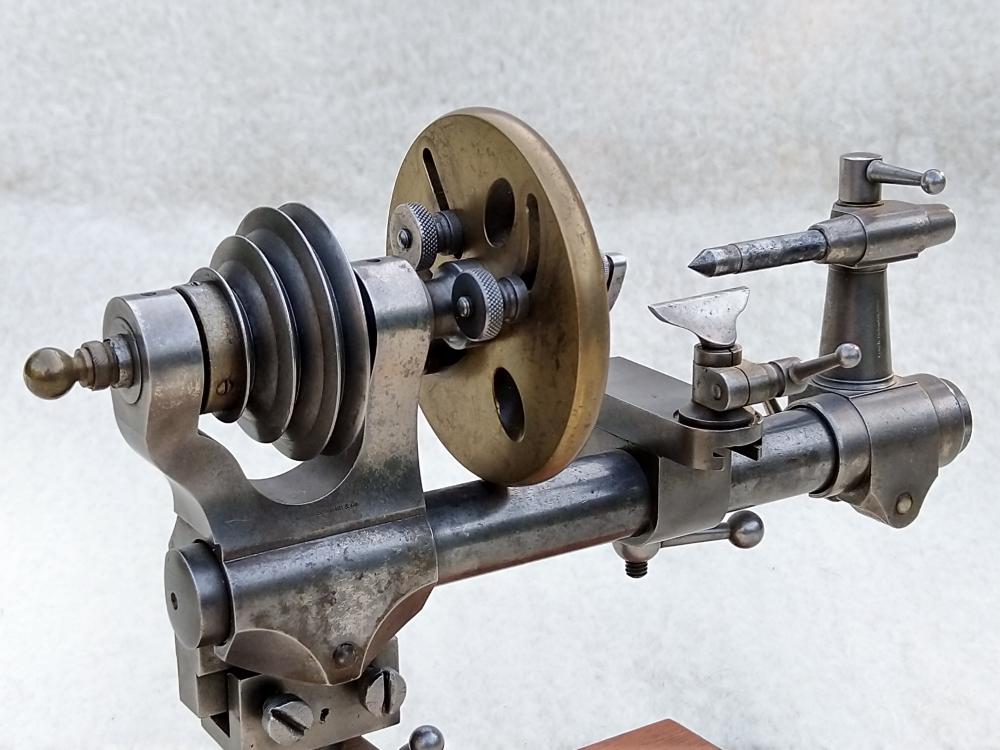

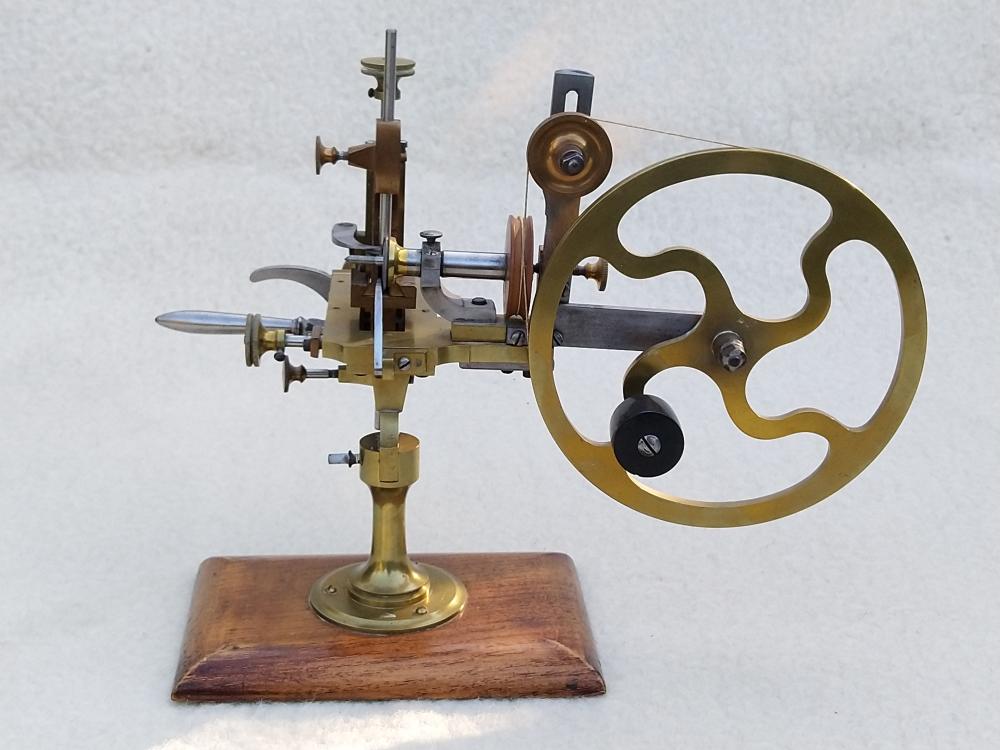

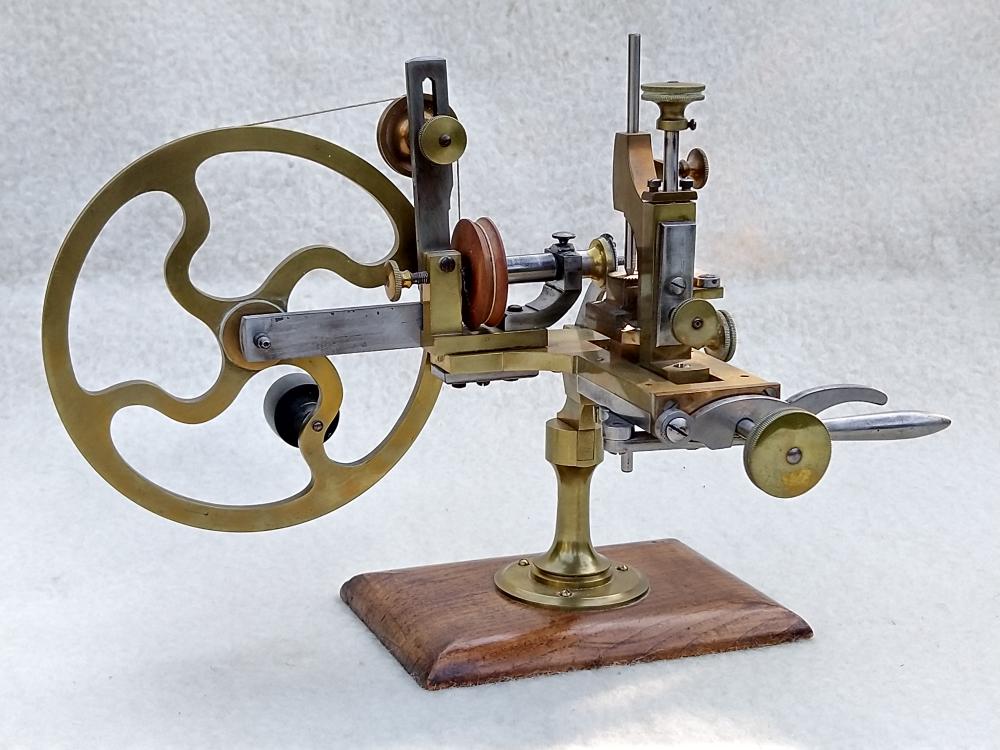

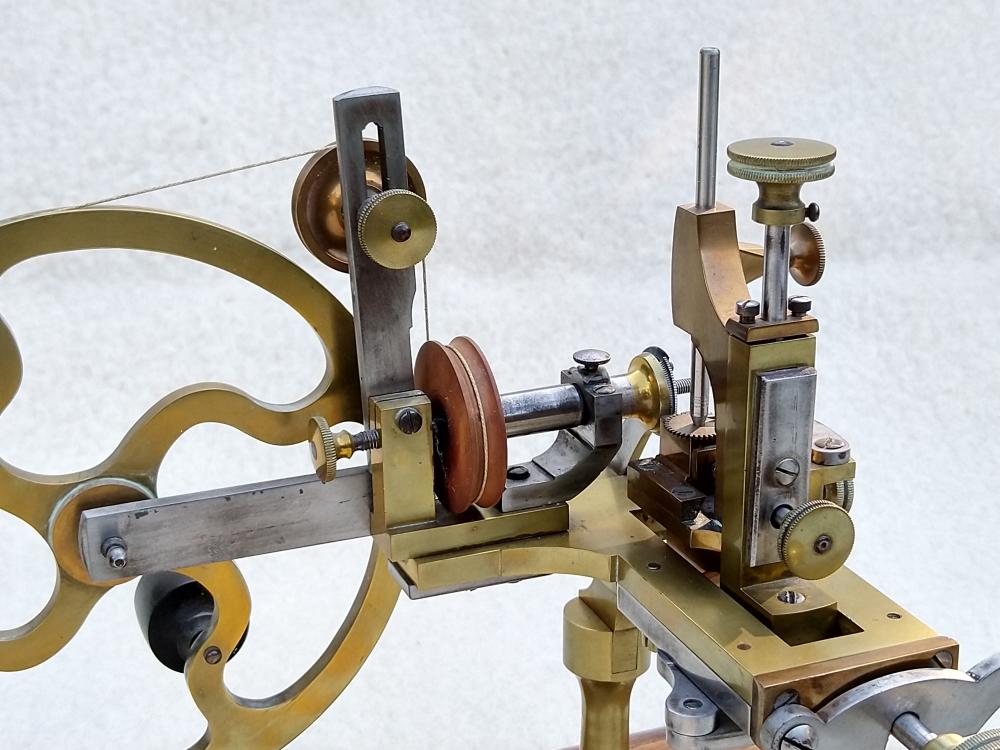

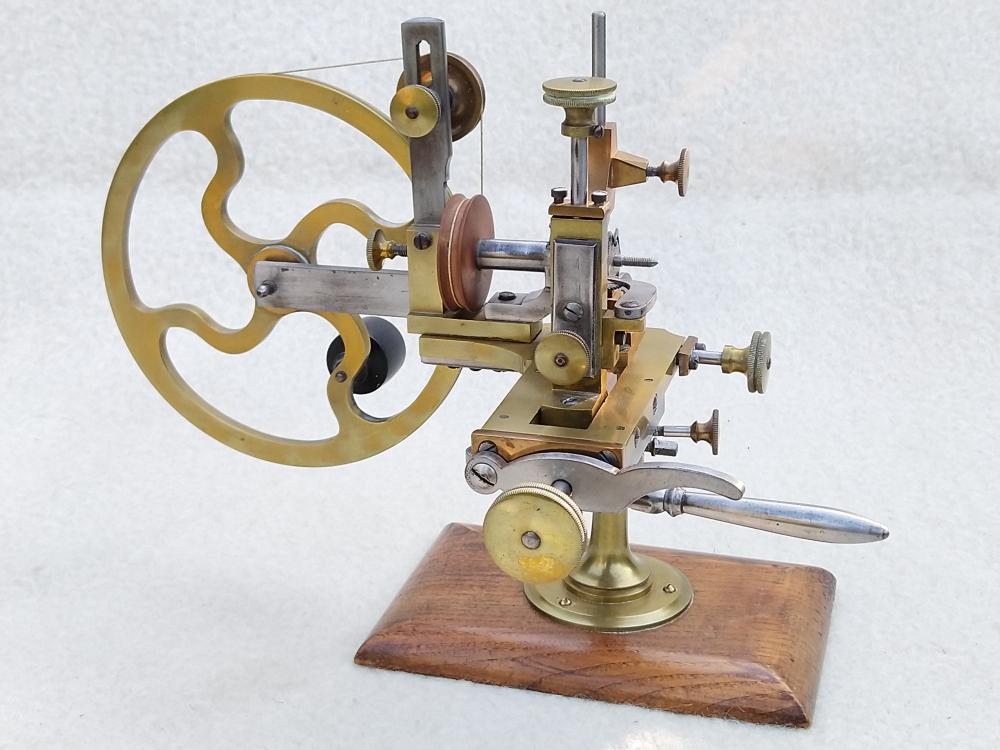

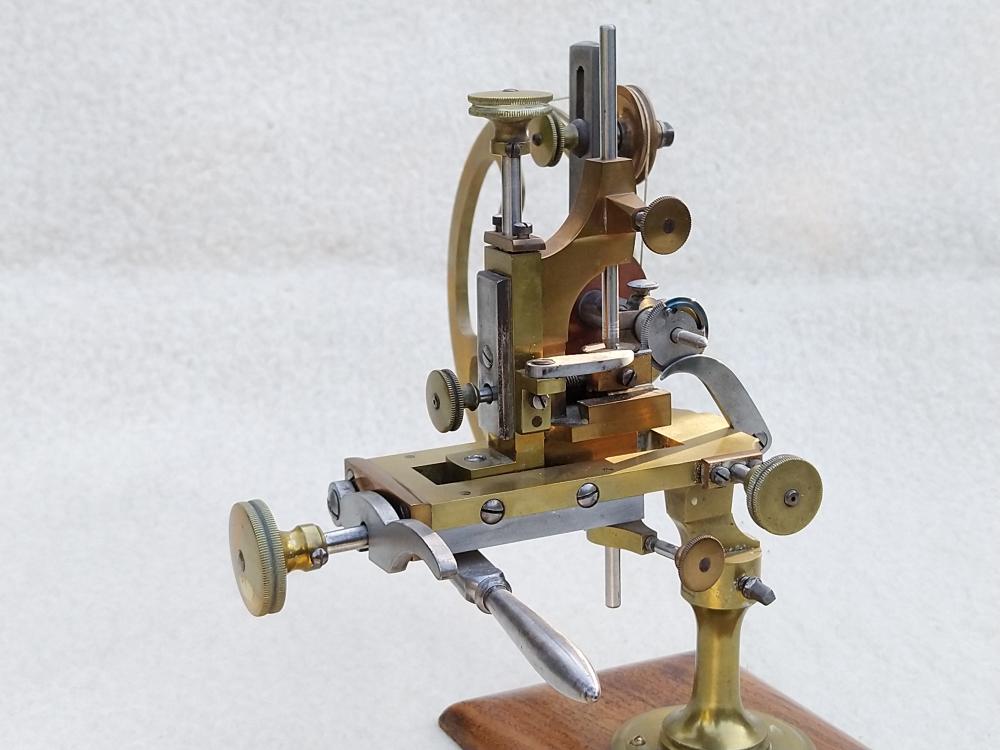

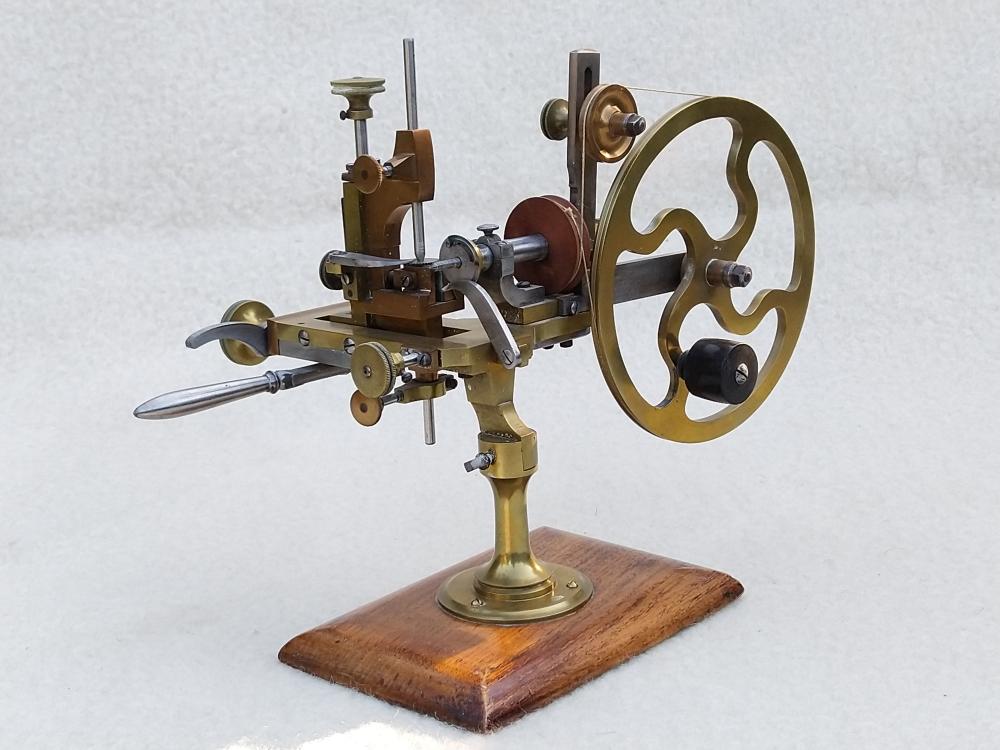

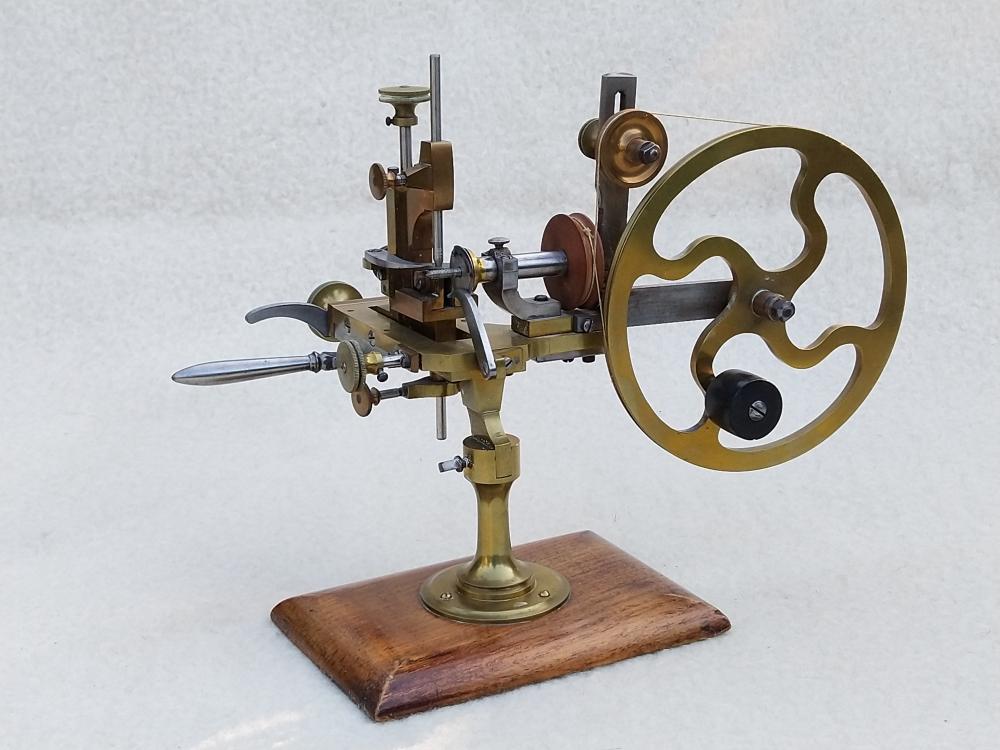

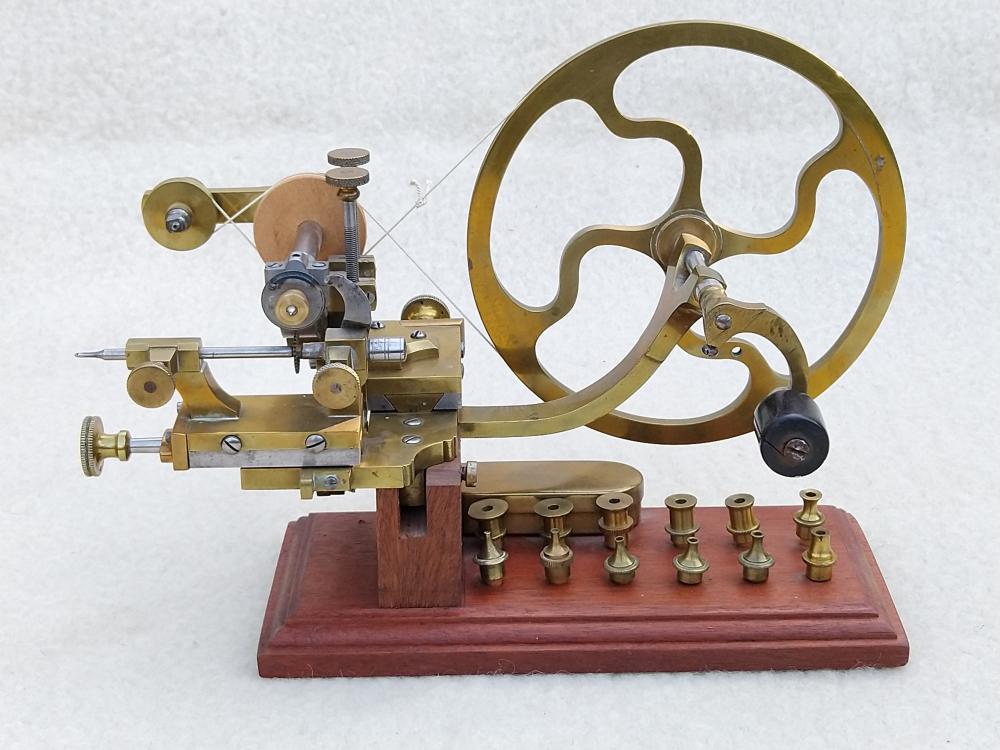

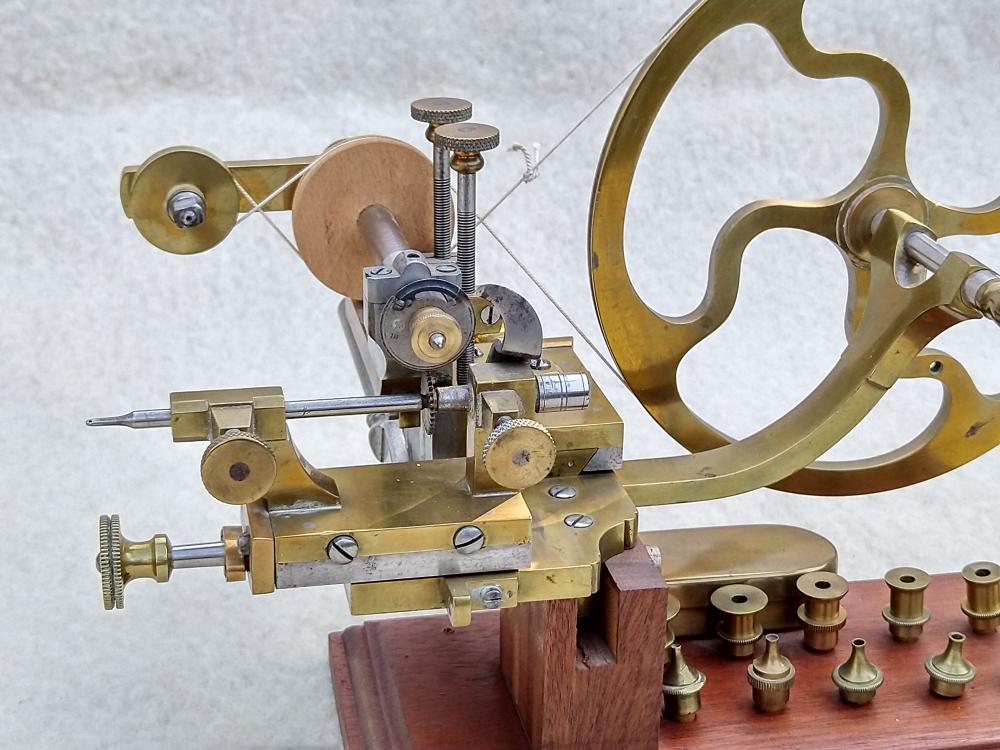

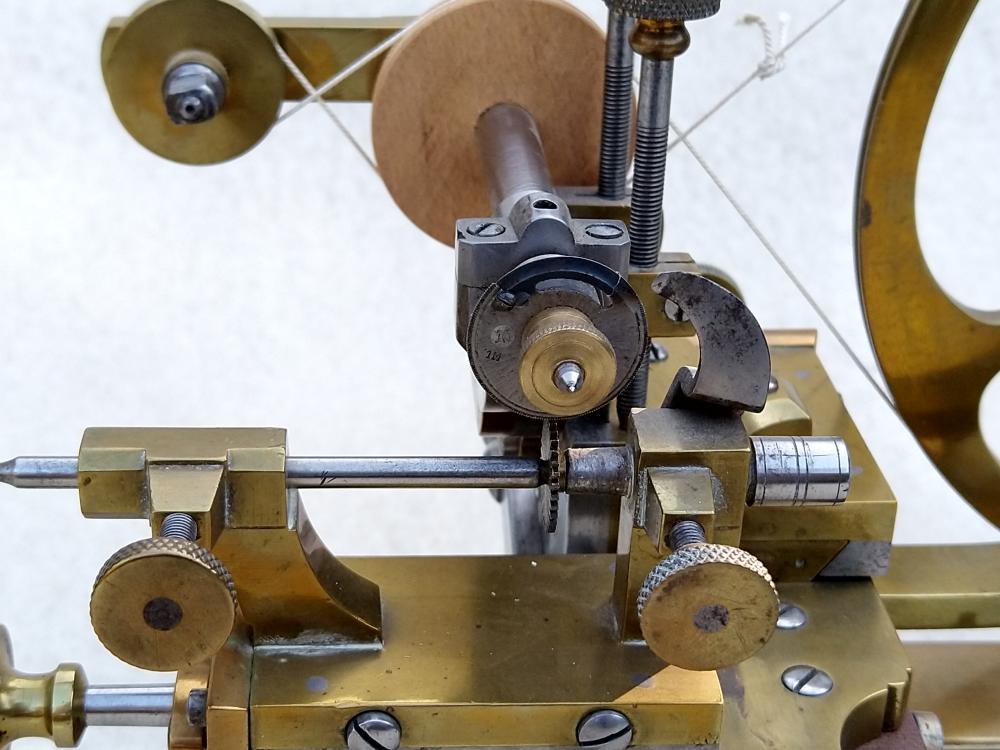

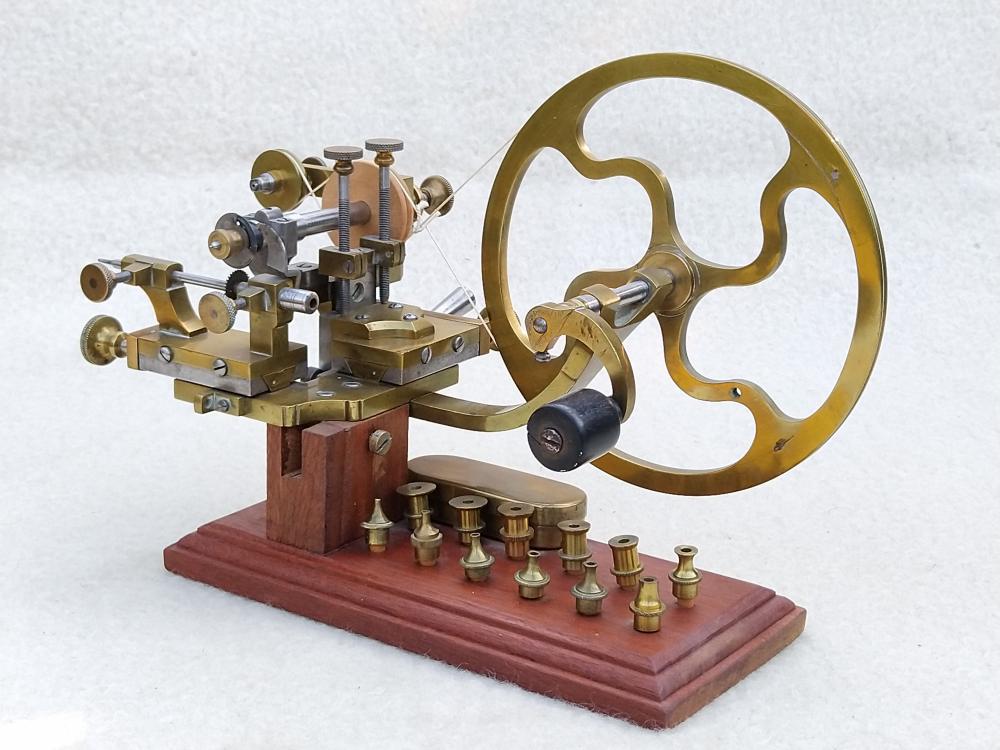

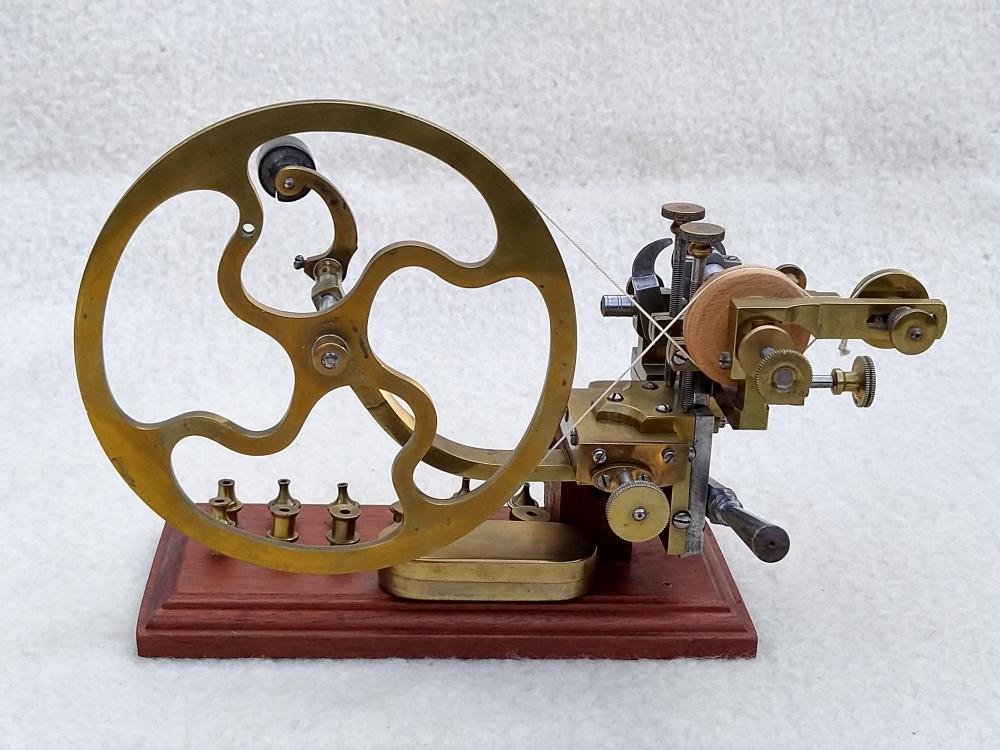

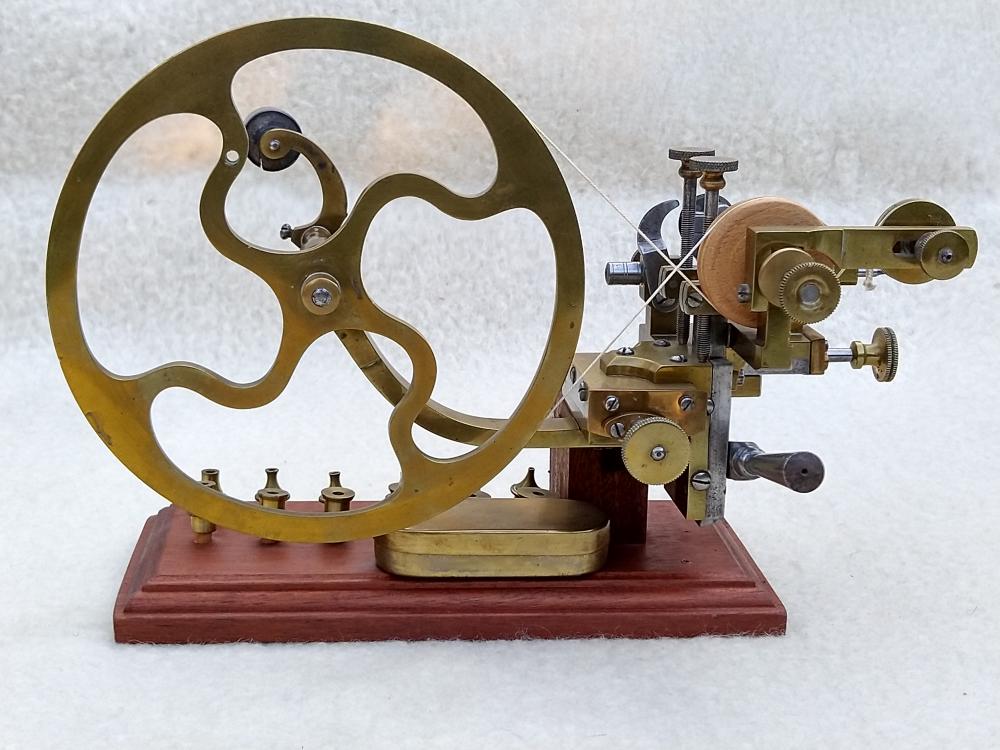

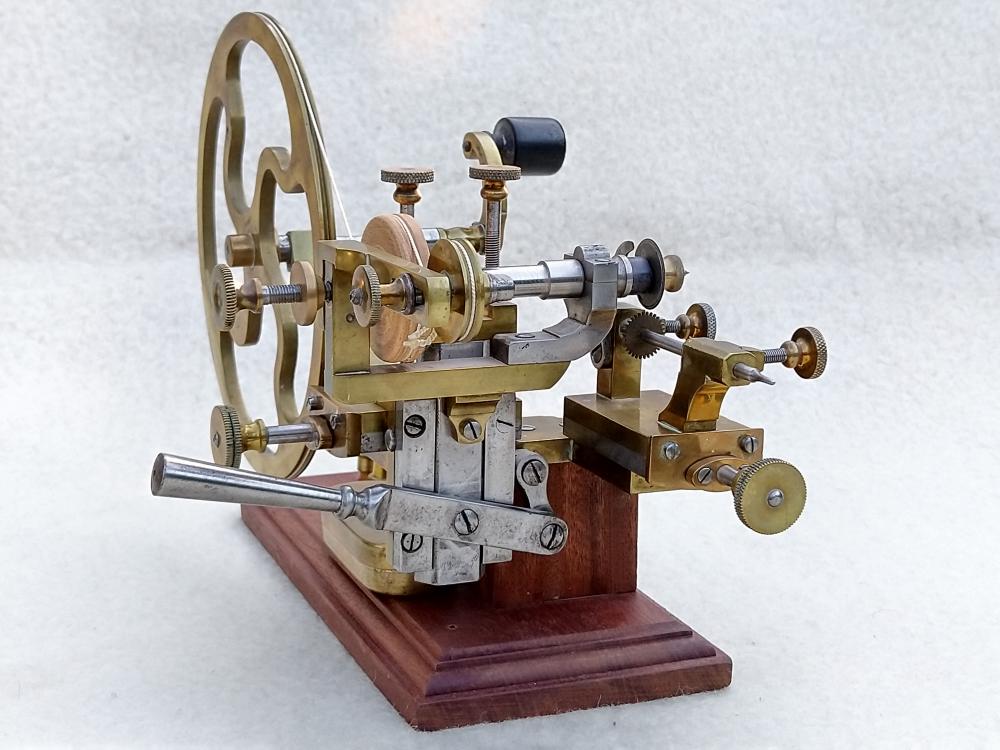

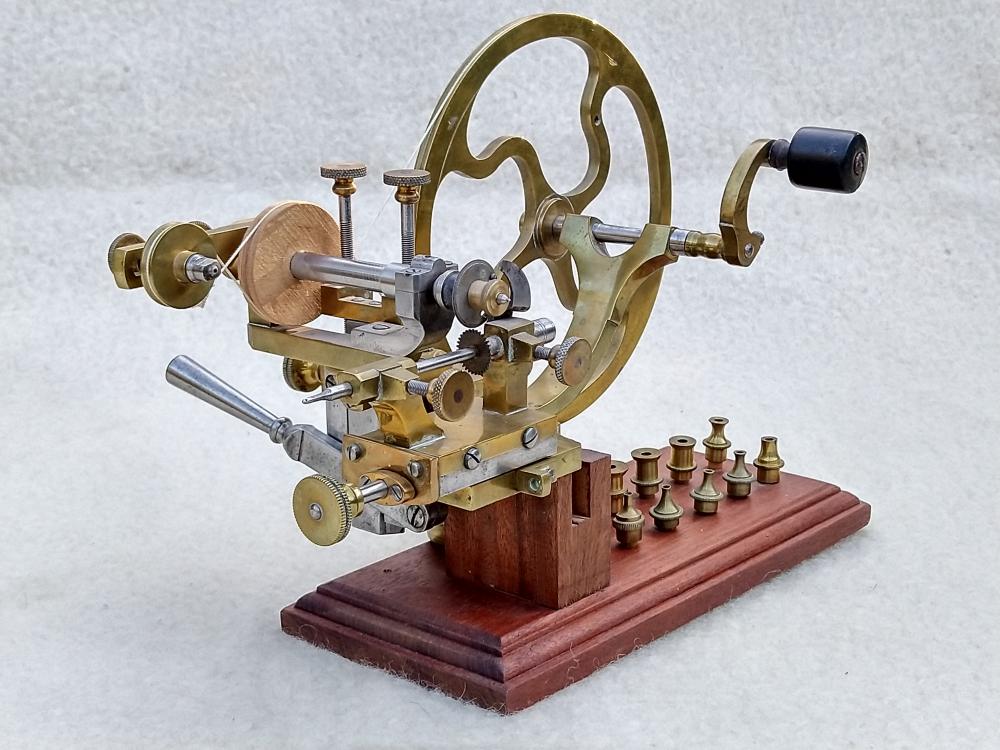

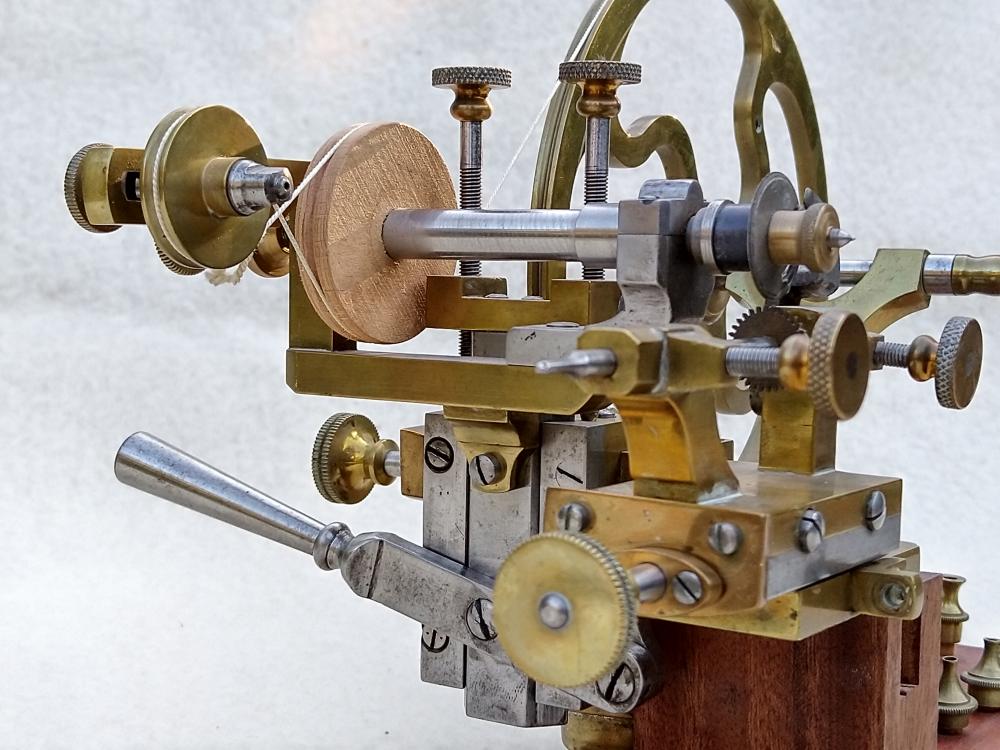

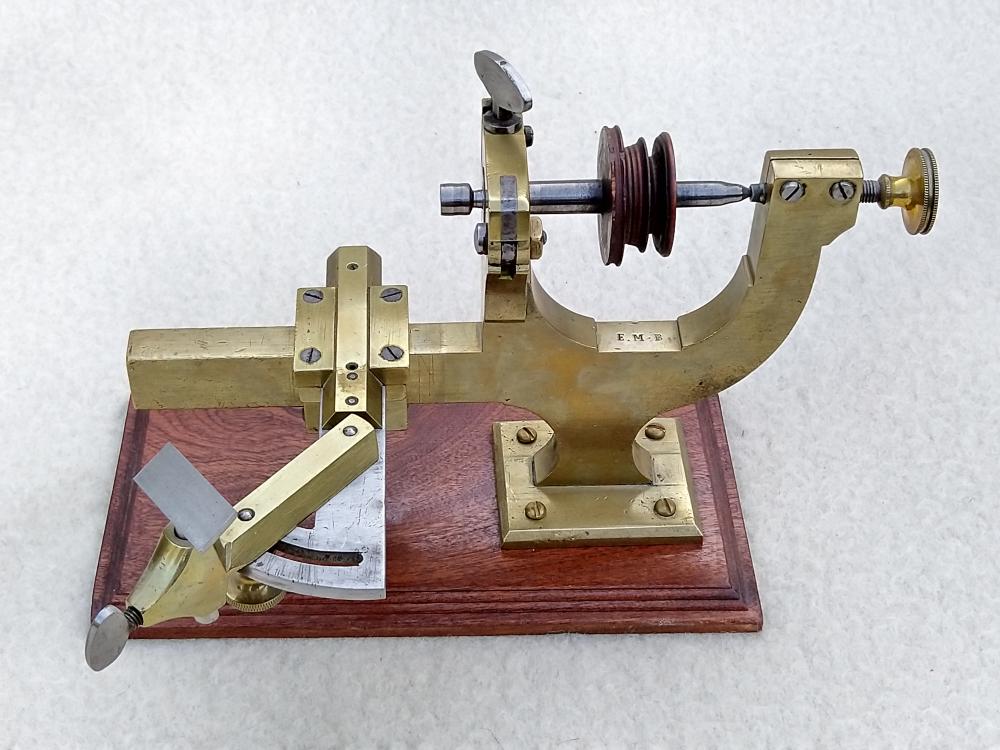

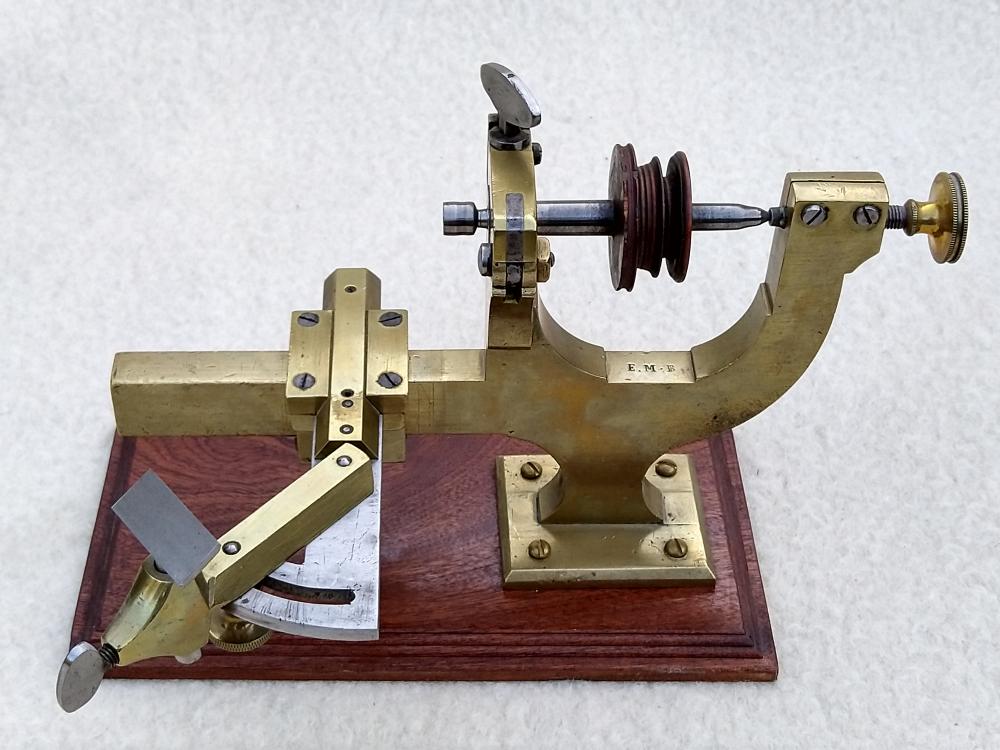

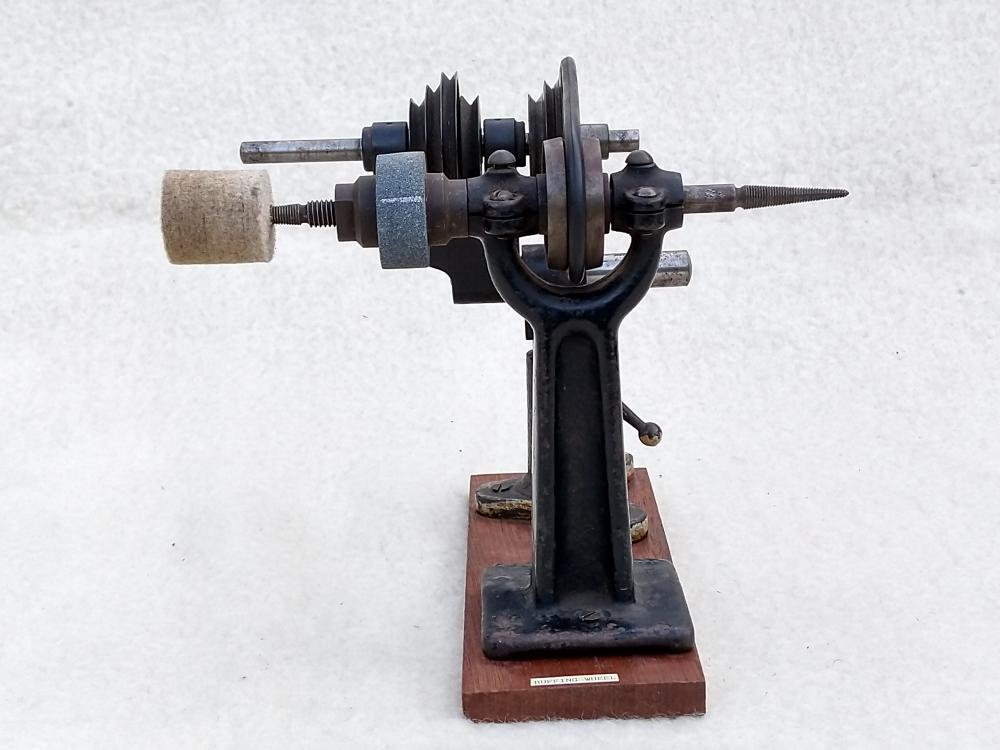

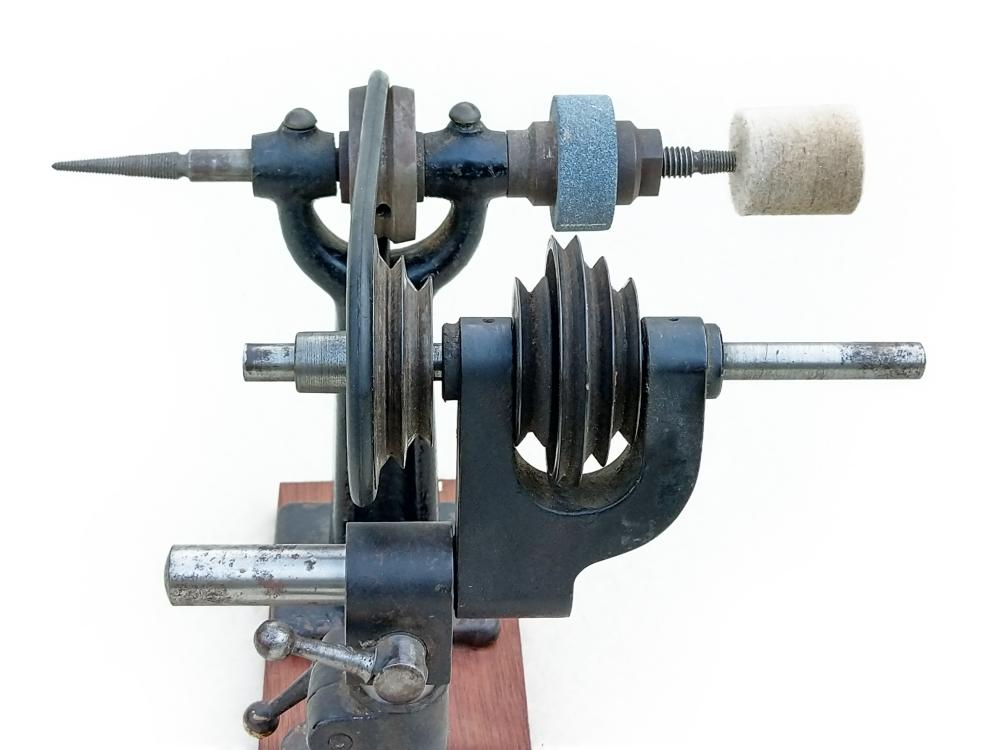

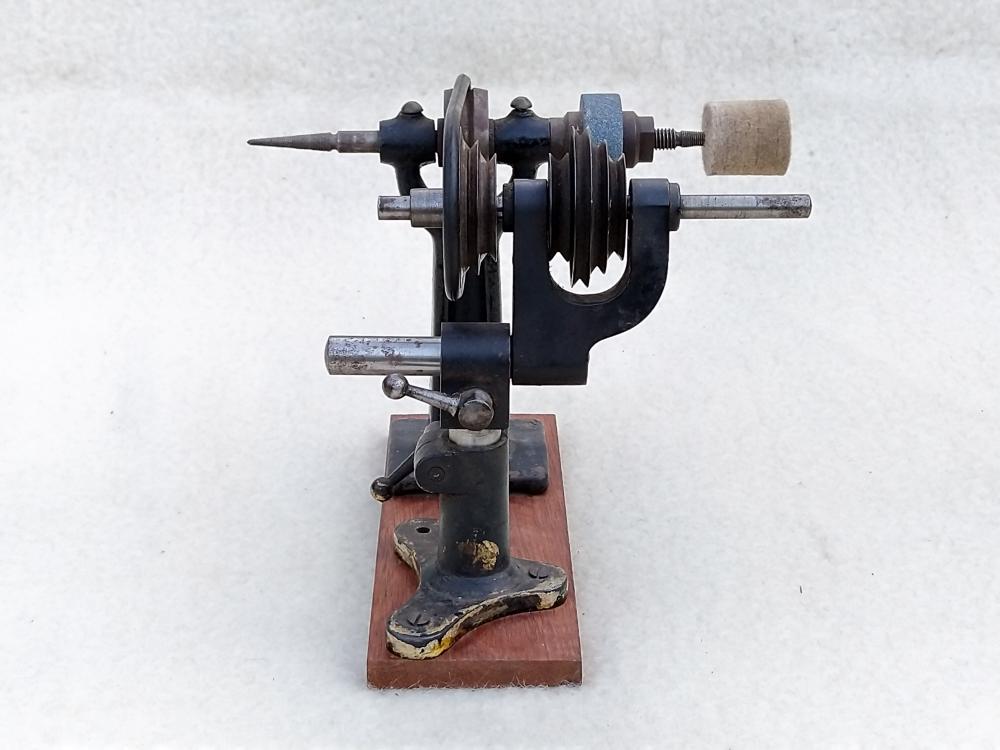

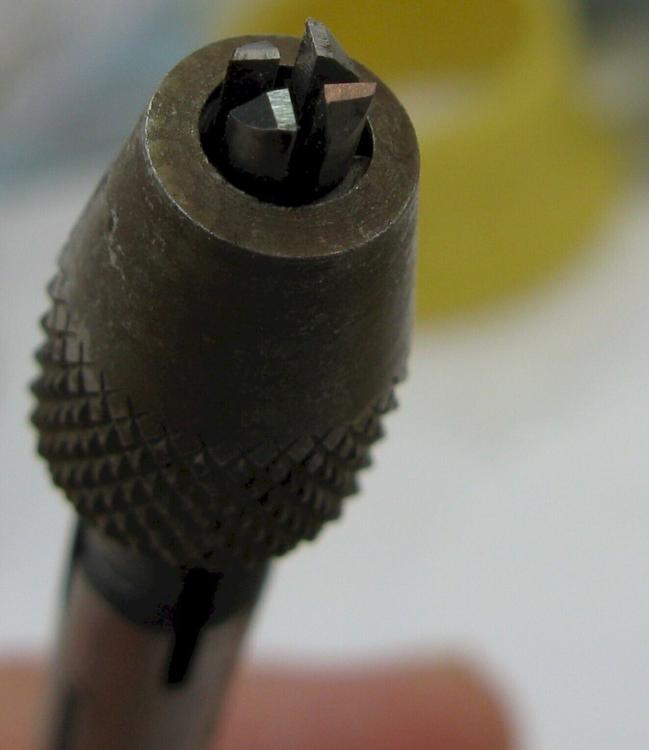

Here's some pics of my scope. It's a simple setup with a B8 shank that fits the tailstock. Ideally it would be adjustable in one axis, so the cross hair can be brought over to the hole edge, but as long as the hole fits the field of view it works. I rarely use that one though. When I do faceplate work (which is frequently) I have a dedicated Schaublin 102 short bed lathe that takes a removeable spindle in the headstock. The spindle also fits the table holder of a Hauser M1 jig boring machine (gotta love the Swiss!); so, part goes in faceplate on the Hauser, which has a scope that interchanges with the live spindle in its head, scope is used to center the part, then the whole faceplate spindle goes to the Schaublin. Sounds like a lot of steps, but it's really really fast and really really accurate. It's much more convenient tapping the part in center with the spindle vertical. Then, if needed I have another scope that fits the tailstock of the Schaublin 102 (it can be fitted with a taper to fit their 70 too). It's adjustable and has built in illumination, very nice scope. But it too hasn't been used in years, just too easy to use the other setup. But bottom line, any scope with at least one cross hair can be used, and it doesn't have to fit the tailstock, you could set it on a wooden block on the lathe bed. All that matters is that you can see the hole, and reference it to some line in the scope's optics. A magnification of 35x will allow you to center up within microns very easily. You will need to hold the part down on the table of the jeweling tool and prevent it from turning, but as you turn the reamer, if it wants to move the part radially you should let it move- just not spin, or lift up from the table.4 points

-

2 points

-

That's why I try to get to the source. Once the basic principle is understood, the rest is a logical consequence. If the theory is correct, than Indeed, the amount of wobble will be the thickness of the shaving = amount of asymmetric. The logical consequence would be that the to be reamed hole has to have the freedom to float by the amount of asymmetrically and can not be clamped fixed in relation to the reamer. It's a bit difficult to explain in a non-native language, but I do hope that you get the drift of what I'm trying to explain2 points

-

Neither made from gold, nor baked bean cans, it showed up today and is a very attractive, high quality, very well made, Peseux 320 based stainless steel cased little watch. As the "least expensive Catorex on the web", it was certainly worth the gamble. I would guess it is from the sixties or early seventies, as it has a fixed stud, rather than the later moveable one. I'll post pictured once I have it cleaned and serviced. Here are a couple of teasers just in case I forget to post the finished result.2 points

-

2 points

-

Ironically I read that the other day, but I had already cleaned the parts at that point. I found that my ultrasonic solution of water, simple green, and bit of dish soap did the trick, as it generally does on almost everything. I wasn't going to take a chance of contaminating my cleaning fluids with whatever that gunk was on the stem. There were a few stubborn bits of it in the crown tube, so I removed the tube and got it all cleaned out with a smoothing broach and then pushing some Rodico through it. I'll try some olive oil the next time I run across one of those.2 points

-

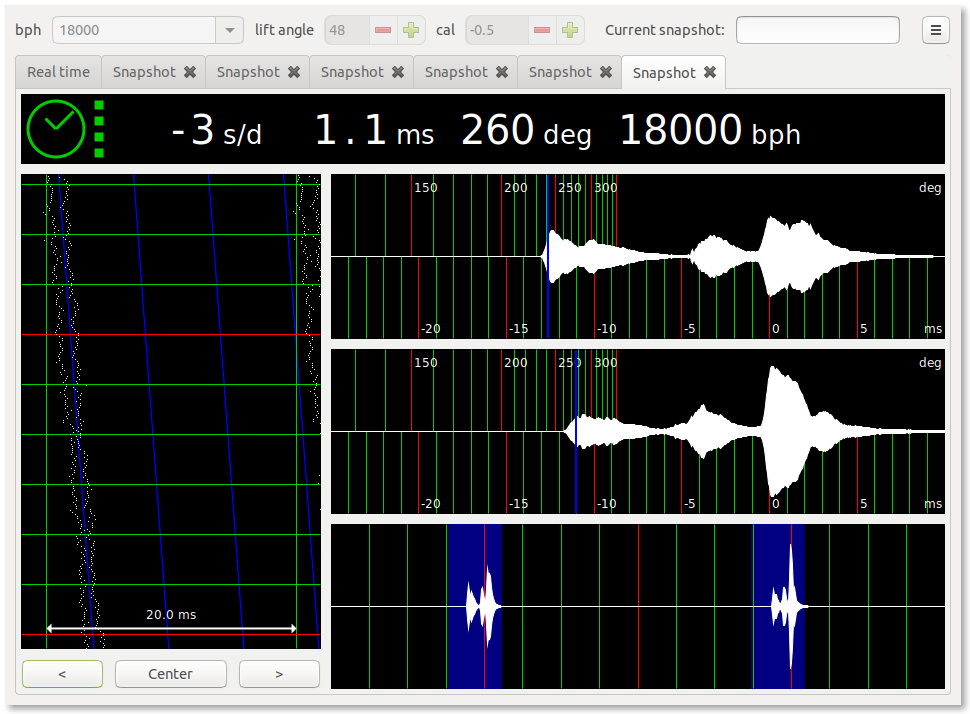

Usually when I find them they are brittle and disintegrate into tiny pieces. This one was exactly like you described, a black tar substance, and the first one I've come across. I suppose it is due to whatever material they originally made it from. I eventually got it all cleaned up though and got the timekeeping side of the movement assembled tonight. I'm thankful that's it's running at all after I lost a screw for about 20 minutes. Right after I found it I turned around and pinged the click spring into another dimension. I ended up having to make a replacement spring, but it was a simple shape and worked out in the end. It's running healthy. Initial readings were great, and I'll dial it in further over the next few days. It was my first 36000bph movement on my bench, and that timegrapher was moving quick!2 points

-

Are you sure you have used the correct length screw in its right place.2 points

-

That's what I was going to recommend start small and gradually go up in size do not try to go to the finished hole. Then despite somebody insisting that their precision we made and that you can go all the way to smooth particle be absolute perfect oftentimes I find the whole is now too big. So I finally get almost to the end and I try the jewel but be careful not the forced the jewel they will break. The whole really does have to be the right size to avoid complications.2 points

-

You might have lost shellac off pallets during the clean. Are you set up to take a vid of escape wheel when running? It will reveal if pallets miss the escape teeth, misaligned pallets, pallet having moved back in fork slots are most probable. Rgds2 points

-

Every time I see the name it has a instantaneous visual effect of me remembering. I was giving a talk at a nawcc national meeting so every time Henry Walked past me he stopped and we talked and he told me to get the book his book because it have all the answers. Unfortunately the book does not have all the answers. But still a very interesting person kinda regarded as the father of American watchmaker in a way but arbitrary rules like this are incorrect there is a procedure that's more or less a starting point and I'm pretty sure the depth is too great. What you normally want to do is you check your worn and guard pin clearance to make sure their right. Fortunately on a watch like this unless you change the pallet fork we can assume even though I hate assuming they're probably right. Not like an American pocket watch with movable banking pins that mysteriously move under their own force overtime. So once you verify your clearances are cracked and then you can worry about the pallet stones then it also depends upon who is hand out and/or book you look at. Every single one of my have slightly different terminology and as somebody pointed out up above the clearances are different depending upon whose literature you're looking at. So the first thing you a check which is not a problem here you would check by moving the pallet fork to make sure that the escapement does actually function and that the escape wheel can clear the stones. If they get out too far then the you Stop the escape wheel permanently. So overly simplistic where should the pallet stones be? Rotate the balance wheel hold it in place pretend you're checking the guard pin clearance. Wiggle the fork but this time look at your pallet stone how close are you to the impulse plane? There has to be a little bit of safety here you can't fall off and hit the impulse plane so basically as close as you can to the impulse play is the absolute minimum you can have. The maximum of course is a Be out so far that you stopped escape wheel from rotating. Then the farther out they are the worst the amplitude will be. This is because when the roller jewel hits the fork and it's pushing on the fork it's unlocking the problem is your unlocking for a wall on the time so by the time it unlocks your only go to get a tiny bit of push and your amplitude is going to crash and burn like we have now. So whatever I'm looking at now says 1/5. I see up above 1/6 But I'm looking at a handout that I think I'll attach I found it online somewhere once. Some of it came from a lecture anyway there are the handouts lectures somebody's added to it they have slightly different. So rather than an arbitrary number I would reduce it as much as you can and yet still have safeties so it doesn't land on the impulse plane rather than a arbitrary one third which is way greater than anything else I'm looking. So handouts attached the light reading move the stones in a little bit and things will look better. Make sure you put some lubrication on the stones it's an amazing what lubrication of the escapement will do it's more important than anything else in the watch. Escapement handout wostep nscc.pdf2 points

-

2 points

-

I think: yes. It may wobble by the thickness of the shavings. Never spent thoughts about it, but wondered how a Swiss tool can be so out of round… Frank1 point

-

It may just be the pic, but are the hairspring coils evenly spaced, and not sticking ?1 point

-

1 point

-

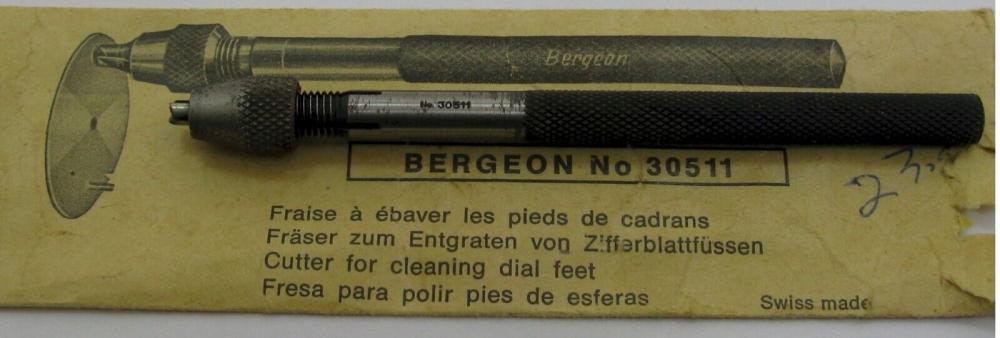

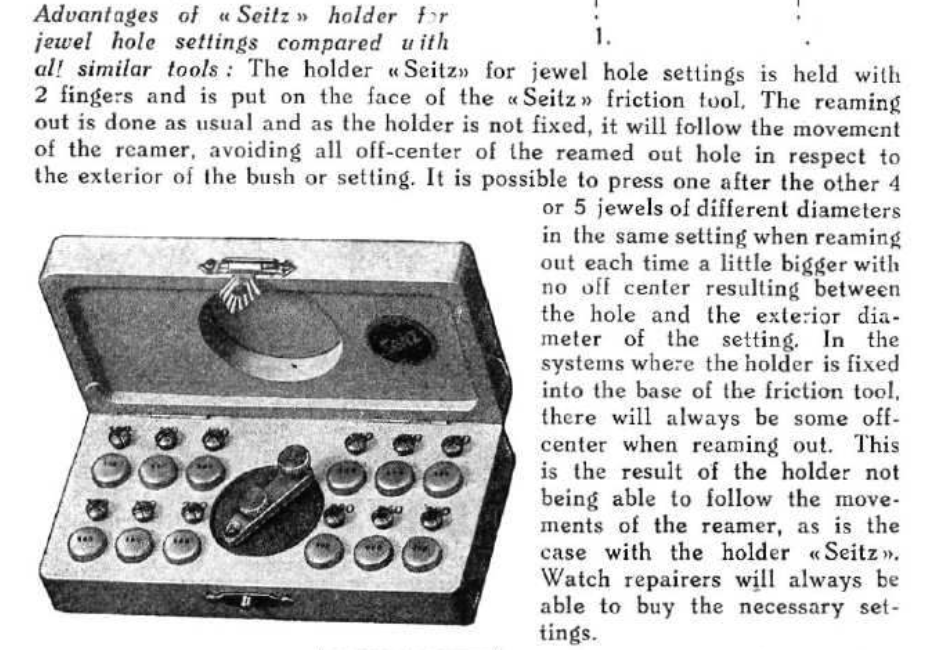

This is one of those interesting things in life not just watch repair. Everyone has different experiences everyone hopefully remembers their bad experiences and tries not to do that again. But everyone still can have different methods of doing the same thing their method works fine for them and your method doesn't and they won't even try it. Then didn't see that anyone posted the users manual for the tool yet. So I've attached that maybe that will offer is some insight in the using the tool Seitz book.pdf1 point

-

Eyup watchie tbh i was under the assumption that the part would need to be held rigid but also in conjunction with no side tolerance of the tooling. So something like a slow moving version of a lathe. But thinking about what frank and Nicklesilver have said it kinda makes sense not to fight against where the reamer wants to ream,( well kinda makes sense and will probably make more sense when i actually have a go myself ). As regards to the floating, i think the part still needs to be held ( by hand if large enough ) but only enough to allow the cutting to take place so not clamped in position. Floating as on water but still able to bob around and have some movement . This sounds like it only applies to a hole that has ovalated (as opposed to holes in respect to ovulated, which is completely different to anything watch related ) otherwise that would make the Seitz clamping accessory pointless.1 point

-

No, it's not, hence my question. If you read my initial question, it is stated that I hand-held the plate to prevent rotation of the plate, but I couldn't prevent the small radial movement of the plate while turning the reamer. It took me a while and having read all the answers, I think (I "think"!) that I understand now what's going on. The reamer is ridged and stays in the center-line of the ridged Seitz jeweling tool (ignoring the play of the shaft in the jeweling tool). Since the reamer cuts only in the direction of ration, it cuts an asymmetrical hole while the reamer itself stays in the central-line (symmetrical). You can't have both, so something has to "give", in our case the plate. This asymmetrical cutting action continues until the very end (the top) of the reamer, where the cutting edge goes over into the cylindrical part of the reamer. If you have a close look at one of the Seitz reamers, the cutting edge "tapers off" toward the cylindrical part, therefor the cutting action become less and less asymmetrical towards the end. This, as I understand it now from @praezis, where he mention other examples, should give a cylindrical hole. That's also the reason why you should continue to ream until the reamer is fully down, including the cylindrical part of the reamer. This in my current understanding of how it works. Please correct me if I'm wrong1 point

-

I think the issue is with the plasticisers in certain types of synthetic (urethane?) rubber . You will see the same phenomenon happening with old drive belts in equipment like tape decks, VCRs, record decks and such like stuff. If you encounter any more like this, try using olive oil to clean up the black goop. It works remarkably well.1 point

-

Hi. If you are sure all the wheels are intact, no broken/missing teeth and the pivots are good, the wheels run ok when installed then check the pallets as Joe advised fir loose stones or bent pivot .1 point

-

What I would do is to dismantle the watch again and it install the keyless work and the barrel then verify that it all works as it should do if not investigate if ok contine th build. Parts to check, setting lever, setting lever spring, crown wheel, sliding pinion, stem locking piece A parts/ tech sheet c be found at cousins document downloads for the FE 4611. On the Cousins uk site.1 point

-

The ESAQuartz 1501 - (ESA 9183 quartz mechanism) - "Verity" arrived and got a quick tear down and inspection. Its a pretty substantial watch. Some might say robust. The case is multipart, and the outer case snugs into the inner one using a rubber gasket, which had turned into the kind of black tarry liquid that is often the fate of gaskets from that period. The actual case back was secured with another gasket, which had turned rock hard and broke when removed, and the battery cover had a third gasket, which seems to be fine. There may be an O ring in the crown tube, but I didn't get that far. Much cleaning later... just for the record, black tarry liquefied gaskets are removable with olive oil, and I felt it was safe to handle without my biohazard suit. The mechanism is completely frozen, and the crown wont move, so a full strip down is in order. Not tonight though. I'll save that for another day. Here you can see it next to a modern quartz mechanism for comparison, and also next to my current daily "beater" watch. which rather ironically is actually larger than the "Verity". All that effort and research to make smaller and smaller quartz mechanisms and fashions dictate that watches got bigger, not smaller. Its a strange world we live in. I must say, the ESAQuartz 1501, and indeed the whole watch is fantastically over engineered, and probably cost a small fortune when new. If you would like to see a good tear-down of the ESAQuartz 1501 /ESA 9183 @Marcdid a good write up about it here. https://watchmender.wordpress.com/2019/03/04/smiths-astral-quartz-esa-9183/1 point

-

For us unless we have finances for scale measuring with a scope then just training the eye . High beat movements require less lock , i seem to remember reading 1/6 of the impulse face. There are other escapement checks besides the depth of lock. I dont have enough experience here to fully explain it but i think it begins with pallet lever horn clearance. There is a good explanation by Nicklesilver buried somewhere in the forum threads, try a search for it.1 point

-

1 point

-

I've no idea where an old Fortis with a Venus 180 are going for, but for $40 I thought it would a nice little project. The movement look pretty undisturbed and I've seen a new balance staff, if that's the problem, for a tenner1 point

-

Not working usually means better price. This allows us that can fix watches to pick up things cheaply or hopefully cheaply.1 point

-

What no pictures the movement? Yes Seiko has all sorts of interesting movements I was looking at the vintage manual wind. Then as a little late to post my pictures here because it was supposed to come Wednesday so would've been in the mail when I'm posting but it showed up yesterday on the porch. DHL from Japan definitely faster than US mail which is probably why had arrived early. Then I did pay attention to the case and dial but I really wanted a manual wind movement. Specifically a specific type of manual wind movement like this 23 jewels. If you look at a lot of the grand Seiko's there at the very top of the food chain but this watch is just a little ways down not is nicely finished missing to jewels different regulator but very similar. So in other words my cheap version of a grand Seiko not quite as grand but still nice. Then since it arrived it appears to be in the mainspring is broken pushing on the center wheel it takes often run sell if I'm lucky that's all I'm going to need. The only other minor troubling thing that bothered me was the picture of the back shows it to look blank? But was looking up other watches like this the pictures showed writing. Then in real life looking at it the writing is there but it is extremely faint as there's a heck of a lot of scratches. Makes me wonder how long somebody wore this watch. Then the second watch didn't save any individual pictures I just snipped out the overall images so not the best. There is more of an afterthought because shipping is per package and it seems a bit high for one watch and this was on sale so I just thought it made things look better if I'm getting two watches. Then yes the dial looks a bit not the best in several locations and the crystal should be changed. Then it is wound up nice and tight. Because as far as I got fixed I haven't figured out how the back comes off yet doesn't appear to be in a place to pry it up but the image is very clearly show that it does come off even though it looks like a frontloading watch?1 point

-

Two facts were confused here, I am afraid: - a hole not staying/getting round - a hole wandering out of center, though round. It will get/ stay round, not oval, if you ream fully to the end (and was smaller before reaming). But it can wander from its true center - if it was oval, sidewards worn before - if you press more to one direction while reaming. You will produce bigger shavings in that direction and move the center then. One cutting edge is is used for canon drills, too, to produce long, accurate holes. The item moving with the reamer is normal, due to tolerances of the tool combination. It will do no harm if you let it move. Clamping the item would throw the produced hole out of size. Frank PS written before 2 new posts above1 point

-

I tend to agree with Jon that the only real way to know your hole is on location and round is to use a faceplate in the lathe. But, many, many watchmakers have reamed holes for jewels with their Seitz or Chatons SA or Favorite or Horia etc. tools successfully as well. It's one thing if you're opening up a hole 0.10mm, another if you're opening say a hole for a barrel arbor pivot a full mm to fit a bushing. As has been observed, the reamers don't necessarily turn concentrically with the spindle of the tool; this can lead to the reamer cutting oversize if the part being reamed is held rigidly. If the part is allowed to float, as Endeavor did, the reamer will probably follow the original hole and cut to size. The reamer will make a round hole, and should be run right up to the cylindrical part (and some oil used). But if working on an oval hole, the location will almost certainly be an average of the original hole center and the new center of the oval. This will be an improvement of the prior state, but not ideal. To add to all the confusion, there are different types of reamers used by different manufacturers. Favorite uses 5 sided tapered reamers, look like short little cutting broaches, that end at a cylinder of the correct size. Seitz and Chatons SA use single lip reamers. Horia offers both, calling the 5 sided ones cutting broaches and the single lip ones smoothing broaches. I've used them all, and found that the single lip ones from Chatons SA cut the best, and run quite true in the spindle. I still let the part float so the reamer follows the hole as well as it can. But most of the time, I do the work in the lathe. I have a rather large (for watchmakers) lathe set up permanently for faceplate work, and use optical centering like Jon mentions. It really takes just a moment to center up and open up a hole! And I bore it right to size, but I have plug gages that make checking very simple.1 point

-

1 point

-

I don't usually fancy the yellow crystals but it seems to work with that dial... ...and you can't set fire to it unless you share video. I speak for all of us...1 point

-

For the last couple of evenings, I've been working on an Amida 15 Jewel based on the Amida 500 movement from sometime around 1950. This is a slightly odd mechanism, as it has the initial appearance of a jewelled lever arrangement, but is in fact a pin lever. The movement is well made, and pretty easy to work on. After a little swithering, I did change the crystal. It looked original, and I would probably have left it alone, but it had yellowed somewhat, but the thing that sealed its fate was the crazing that became evident if the light struck it from just the right direction. As you can see, it made a marked difference to its appearance, although some might argue that the yellowing gave it a warmer look. I'm in two minds also regarding the hands. I suspect they might polish nicely, but the nagging voice in my head is saying, they might also end up looking uneven. It does run reasonably well all things considered. It doesn't quite qualify for the 404 club, as it came in at a rather too hefty price tag of £4.99 GBP. but since I've made a few other exceptions to the rules recently, it may just get an honorary membership. There are a couple of other issue I need to address. The first is the fixed pins and rather small lug width, which measures at a rather odd 15.3mm. I'll either need to source a strap, or perhaps use this an opportunity to make a custom sized strap for it. The second issue is.. do I dare set fire to the old crystal, just to see if it is made of nitrocellulose? If you hear a loud bang and detect the smell of singed eyebrows, then you will know the answer.1 point

-

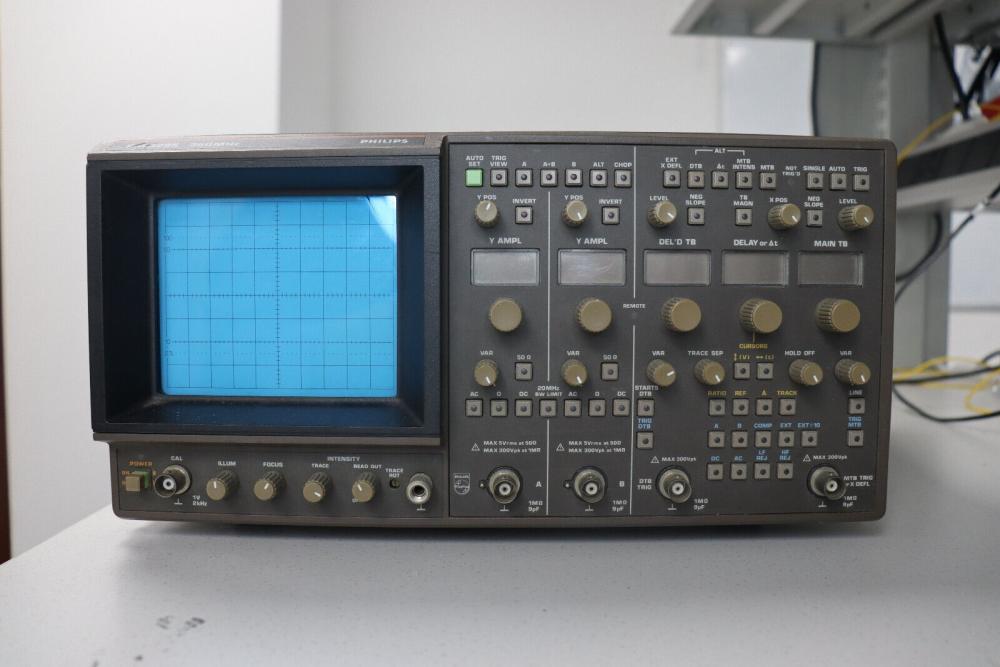

I should really be more careful when I go hunting round ebay. All sorts of junk tends to follow me home. This time it was a Philips (Fluke) PM3295 350 MHz Oscilloscope. I don't really need another oscilloscope of course (can you have too many oscilloscopes I wonder), but it only cost... (drumroll) 0.01p (plus shipping). My current 'scope is Metrix 803B 40MHz which I picked up about 10 years back and repaired, so if I can get this running it will be a bit of an upgrade. I can almost guarantee that the power supply will need some work (although it does have a safety stamp from 2020), but other than that I have to admit, that even when you factor in twenty quid for shipping, it does look like the best bargain I've picked up in a long time. A 350Mhz oscilloscope is obviously overkill for fixing watches, but great for any other electronics projects that come along.1 point