Leaderboard

Popular Content

Showing content with the highest reputation on 06/05/23 in all areas

-

For something with big pivots, not holes like the sweep wheel, I have truing calipers that will take them (dozen or so different, some with replaceable nibs so they can be made as needed), but for instances where those are too small like center wheels on a pocket watch, I use a depthing tool, or put the wheel up between centers in a dead center lathe. Depthing tools in watch sizes are plentiful and cheap, don't count on them for depthing, but for truing a wheel they're great! Clock size depthing tools on the other hand... expensive! My 8th grade English teacher would literally kill me for the first paragraph.3 points

-

I was waiting for an answer from somebody before I came back to the group. If you look at tools and material supplies over the years you'll see a trend of their just not available anymore. The Swiss appear to see that there is no longer in need to supply things for repairs. Like for instance balance staff for modern watches. If balance staffs are not being supplied is no longer a need for a tool. One of the things interesting about Seattle is we used to have an AWCI chapter. This met with have regular meetings with lectures at some point in time we parted ways with AWCI but we still have meetings with lectures. The benefit of this is continuous learning and upgrading and interesting people to give lectures. So Jeff worked his way up to the head watchmaker of a chain of jewelry stores I think they have about used to have about 30 watchmakers including a service center. That matter is they had watchmaker he went to all the various company trainings all over the place and he would bring that knowledge back to us. Like how to change a particular Rolex balance staff. But for this discussion when I was curious about was what about all the rest of the balance staffs and it turns out the method was the same for all of them. They use a Horia tool With special pushers to just push the staff out. Push isn't technically the correct term in a way. Rolex, Elgin and Hamilton possibly others all have stabs designed to break the rivet. In the case of the Rolex staff when it breaks it makes a satisfying popping sound as Jeff once gave a lecture at doing that. The rivet broke free and a beautiful circle and that is still the method that Rolex was recommending as of 2019 when he retires. So apparently some professionals are still changing balance staffs when they're available they're just not using the tool of this discussion. Then I found different documentation for the tool it looks like even sizes of the holes2 points

-

See if you can find some disassembly photos of a marine chronometer. Maintaining power is only needed on movements with barrel and fusee (or weights); when you wind (the fusee) the moment that you are winding you are effectively cutting power to the train. On a normal watch or clock with going barrel, when winding you are actually increasing the power (a bit) to the train. On a precision clock that power cut could affect the timing, and something like a marine chronometer it could spell total disaster if suddenly the escape wheel was free-floating and the balance swinging at full amplitude. But the actual function is just about identical between a weight driven clock and spring driven piece with fusee. The maintaining power is in the fusee. Also- back to marine chronometers- forgetting to let down the maintaining power (if possible) or blocking the train (if not) before removing the balance is an easy way to learn how to make spring detents, escape wheels, and locking stones .2 points

-

I hold the wheel in a lever type jeweling tool, between a pusher and a stump on the wheel hub. You can turn it by finger and see where it's high/low, then adjust with stout brass or nickel tweezers gently bending until it turns flat. If it's flat in the tool, it should be flat in the watch, unless the hub has gotten tweeked in the wheel (rare), or if the extended pivot it fits to is bent (common).2 points

-

That sort of tool was around way back when those horrid battery movements started to take off they were free The usefulness would be to anyone starting out repairing those movements replacing batteries not being able to keep a vast stock because it will be expensive, not being able or not aware of tec sheets or helping with the ID of a battery for a odd movement providing the old battery is still available, some batteries have no I D on them.2 points

-

Okay friends, thank you again for the encouragement and help. I went back with a fresh head tonight and the bridge fell into place in just a few minutes. WHEW! Now it's time to phase. The scary part!2 points

-

Common wrong approach even by pros is how you proceeded detaching cock-balance assembly. Best to loosen cock screw , not entirely and not remove it, then pry the cock to loosen/ disengage it from the locating pins. Under the remarks subtitle, Dr ranfft list many calibers which practicaly are the same as AS324, the balance complete of any fits your watch. Good luck pal.2 points

-

Thats exactly how I started my attempt but keeping track of the bend was difficult, putting in a horia worked really well. The depthing tool sounds better.1 point

-

Nice tip! I tend to put it on a staking block with the hub inside a hole and judge what is high and what is low then transfer the wheel onto a piece of soft wood or even thick leather with a small hole in to accommodate the hub and push down on the high spots whilst keeping the wheel flat, but I think I'll try your way next time.1 point

-

Great vid. Straight to the point. Nice! I would put a slight flat on the side of the punches near the tips after annealing the tips, then drill through the side so they look like your last pic with holes in the sides. You'll need a V block and clamps to hold the work still and a precision bench press drill with some decent tungsten carbide drill bits. Then you'll find removing the broken off staffs maybe a little easier. You'll then need to harden and temper the tips again afterwards. Jobs a good 'un then. Or, you could turn some replacements on your lathe (if you have one) from some tool steel and harden and temper them with holes in the sides. I always have a supply of tool steel to make new stakes/punches and various tools. Here's some hand levers made to BHI specs... https://www.instagram.com/p/CpTjbxujGrP/1 point

-

1 point

-

I've just assembled an ETA 2879 which had a wobbly sweep second wheel. As the pivots are small I managed to use my truing calipers. It's not easy to get the such a thin wheel perfectly flat - it runs close to other wheels/bridge in this movement. In the end I bought one from Cousins as they're only £7. I hadn't thought of using the jewelling tool - great idea. What about wheels with larger pivots - I guess you could hold them between two concave punches on a staking set?1 point

-

i know that feeling i broke the pivot on one 18 months ago, I'm pleased to say i learnt my lesson and this one is not my doing. No its not of any value really, something I've been back and forwards on harvesting parts for a few weeks in beween organising stock space in my watchroom. Its had a fair few issues this is just another to add to the list. Also looks like a bit of a design flaw, the pinion of the second hand sweep sits quite low in the bridge, should have had a bit more depth to it to engage better with the drive wheel. Just wondering if it has been pushed lower by a heavy handed second hand setter.1 point

-

Longcase regulator clocks. High quality clocks with a fusee normally what are called bracket clocks Vienna regulator clocks. Some good quality fusee pocket watches to name a few. I have in the past restored a James McCabe English carriage clock which had maintaining power as you can guess it also was a fusee movement worth back in the 70's then around £10 thousand, to day about £80 thousand.1 point

-

One of my friends used to service Marine clocks including a lot of chronometers including Hamilton. If you listen to him basically a chronometers an accident waiting to happen. He once gave a lecture at a nawcc regional meeting on chronometers but went off into the horrors of what happens if. I was waiting to see if all the people trying to sell their chronometers started looking for rope to hang him because it sounds like the best thing to do with their chronometers lock the balance wheel and put away safe and never touch it ever again. Then one of the chronometers I acquired was one that had a total disaster. Escape wheel and balance staff pivots gone. I think just about all the tools associated with the escapement of course gone. Plus of course the escape wheel teeth were all bent over. A very interesting design of the escapement where works nice when it's working but if there's an issue it would be very bad.1 point

-

This video actually gave a better view than the others I've looked at, thanks a lot! Comparing mine to the video it seems the yoke is too worn so the setting lever can't move it far enough to engage the setting wheel. Time to order a new yoke it seems!1 point

-

That’s an astonishing presentation. Clear, concise and complete. I doubt I shall ever be in you league, but I’m only 3 months into the hobby!1 point

-

The index wheels all seem to have a strangely large amount of runout. As long as the teeth are intact they just seem to work though. When phasing, I do as in the quote above, but I don't want to see any hesitation- smooth running only. That's a shame they skip the actual phasing part in the vid! Henry was actually a guest instructor when I was in school to teach us Accutron work- interesting guy and he really did know his stuff. You could check with AWCI, the American Watchmakers and Clockmakers Institute, who made the video; if you are a member you can check out books and videos from their library.1 point

-

bob on Nucejoe. The watch you are working on somebody may have used or you may wish to use Maxcell, Energizer, Rayovac, JCB, Duracell, Varta, Citizen, Seiko, Timex, AG, IEC, Panasonic, Eveready, Toshiba, Sony etc, etc. Although some use the same codes. Charts are available and a pair of insulated calipers to double check the size, but a beginner might want something simple and convenient , whats more convenient than this ?1 point

-

Only £4.99 on ebay, could be worse, if it was Bergeon it would be £499.1 point

-

You see that little round hole on the top? That's for you to hang it. You could use it to make earrings, wind chime, mobiles, bird scarer.... You could hang it 100 yards away and use it for target practice. It can keep your cat amused for hours so that you can work undisturbed. Maybe it'll work on the grandkids too. It's really useful.1 point

-

Just when you thought they couldn't get any more scruffy, I present the latest ebay horological detritus. That was the only picture in the listing, so I have no clue what (if anything) is in it. I'm not into this for much, though, just 0.99p plus shipping, so its not a major issue if it turns out to be scrap metal. The second find of the day has a little more chance of actually working when it arrives. It also looks considerably less scruffy. A USSR era Raketa 2609 HA based pocket watch with a missing bow.1 point

-

Apologies I did not read through all of this thread. Looking at the issue of removing a broken pivot from a Platax punch would be very difficult indeed. I did break the tip of a punch ( Don’t know how!,) . So I annealed the tip of the punch re- shaped the tip with my lathe to remove the broken part and re drilled and hardened the tip. So as a follow on I would have thought the same method would work to remove the broken pivot.1 point

-

1 point

-

You need to take off the screw at the end of the shaft as well. There’s one that goes into the rod.1 point

-

Need more info. I've got a small batch imperial stout I'm about to bottle!1 point

-

I'm sure that these settings are able to be taken apart, but I've never done it. I think you would press out the pair cap/hole jewel, then they are two separate pieces, each jewel in its setting. I have a 218 here for service but it's my mom's and don't really want to experiment on it... haha. But maybe I'll give it a go. Edit- it's one setting, you push the hole jewel and it pushes out the cap.1 point

-

the marvels of modern cinema? Unless they're actually doing a live stream they get to practice. I know someone who does a YouTube channel and for the limited time of the video you see they did a whole bunch of background filming. Then of course because they don't want to have a disappointing video not going to show, oh dear the roller jewels on the wrong side of the fork never to see that.1 point

-

I did order THE THEORY OF HOROLOGY directly from: https://www.booksimonin.ch/fr/9493-english-the-theory-of-horology.php#corps and it ended up costing me $197 USD where the book itself was only $150 USD (136 CHF) so it cost me another 47 bucks to get it here. It was a PITA. They wouldn't directly take a CC # as I recall I had to do a money transfer using PayPal. The people there that I dealt with were great!1 point

-

Don't know if this is something you want to take on and learn, but silver and gold plating is quite straightforward and the machines needed are inexpensive (the solutions can fluctuate in price). If you have any scrap cases/bezels you could easy do a few and see how they come out. You just have to look up what binds to the base metal, and if you can't plate directly on (you can't with brass) you use an intermediate metal. For example, with brass I know you have to plate with nickel first, then gold to get a gold plate.1 point

-

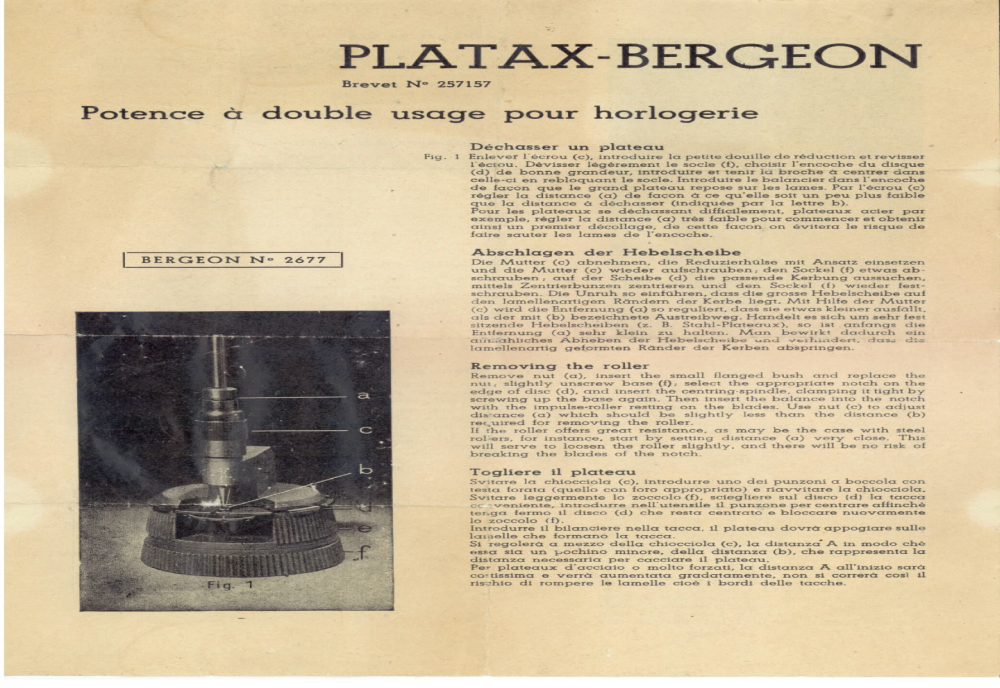

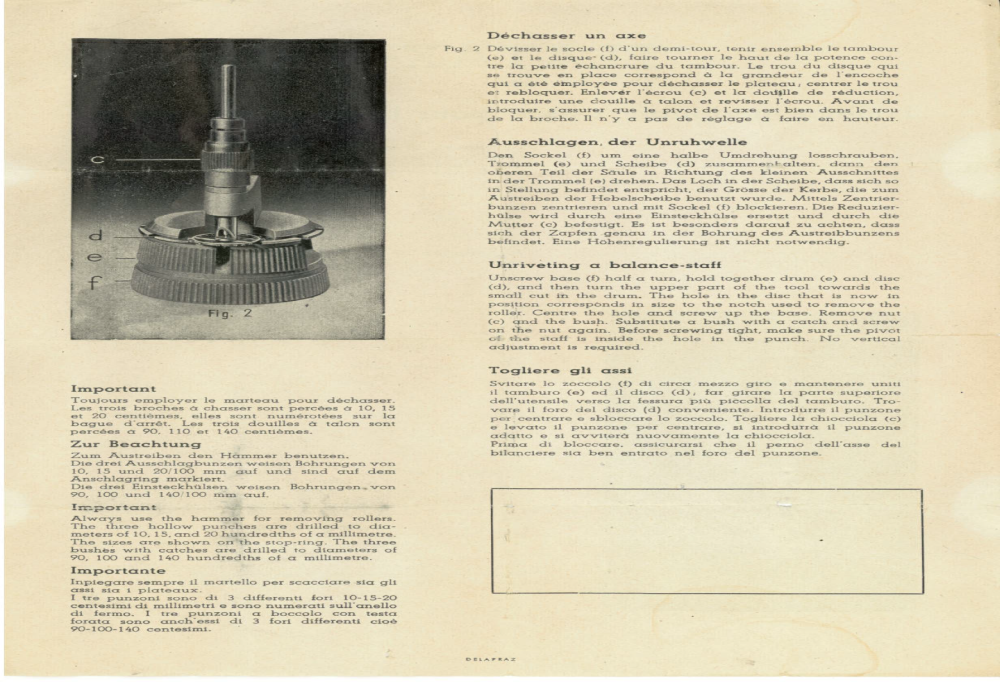

For anyone interested I made a PDF how-to guide for the Platax tool. If you read it and find anything missing or incorrect, pleas let me know so that I can update the PDF. Thanks!1 point

-

There's always a risk of opening the hole in the balance when punching out a staff. On a hard steel balance (bimetallic) or a Glucydur there's a smaller risk of enlarging it too much, with softer nickel balances it's pretty sure the new staff will be quite loose. Supposing you manage to get the new staff riveted, there's no assurance that the staff is centered in the enlarged hole, so you'll have to spend more time poising- which on many balances means removing metal with no means of adding. The K&D staff removing accessory for staking tools and the Platax do ensure that the balance isn't distorted when punching out a staff. The Platax is particularly useful for dismantling assemblies where you need support between two parts. But I'm with Frank on removing the hub. Or, if the balance is Glucydur or nickel you can soak it in alum for a few hours.1 point

-

I own a Platax tool and when used I only apply the lightest taps to remove, if it shows no sign of removing then I cut the majority of the balance rim away with my lathe before finally tapping out with the platax. Some Staffs seem to be made of real strong metal and I type with experience these vintage staffs if punched out it widens or distorts the hole. The key is what ever method is used the balance must not be distorted in any way.1 point

-

Has to be a joke there about p#ss and losing wood....0 points