Leaderboard

Popular Content

Showing content with the highest reputation on 06/02/23 in all areas

-

3 points

-

3 points

-

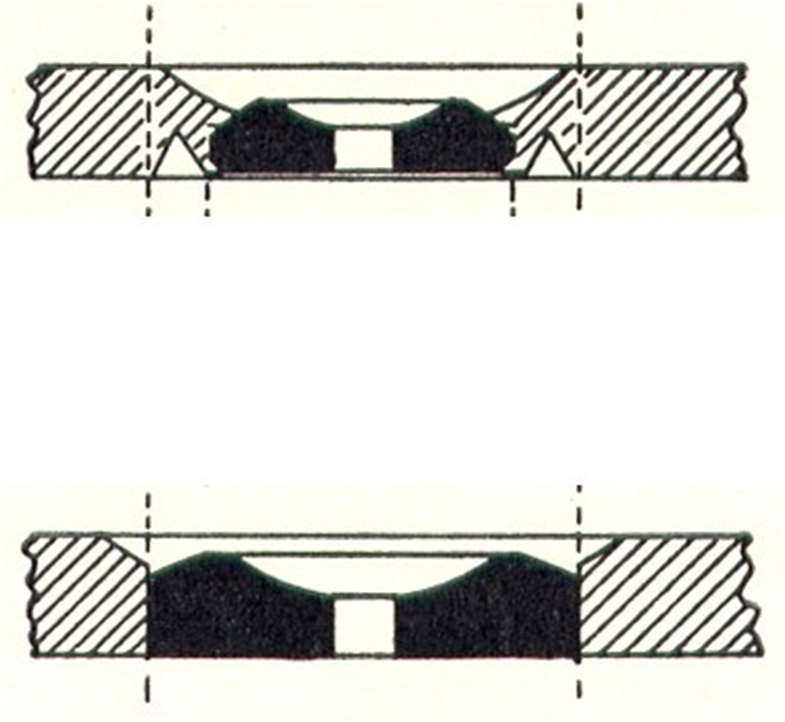

Wishful thinking if they're the same thing the most definitely not the same thing unfortunately. Looks like this will be a simple answer for make as I don't have to answer the question now you're going to put the watch a way problem solved for all of us. But while were here just for the future. Let's look at what the difference is an procedural things for replacing jewels. Plus I've attached a PDF for you you might find it helpful and a link that talks about your watch If were going to look up parts. Let's start off with jewels the upper one is burnished in. In other words is held in by friction ring metal in this case on the bottom of the image against the jewel itself. The burnished in jewel ideally needs to be a special shape in other words it has to have rounded edges. Sometimes people will burnished in the normal jewel but it's really not the best thing to do. Then the second picture On the bottom is a friction in jewel. The notice the size the jewel are square and flat smooth and its cable bill being pushed in this is why attached the PDF this is the tool you need to do this. The problem today is the fine jewels for burnishing in although there is a way of modifying existing modern jewels but that requires a lathe which you don't have either so we won't worry about that. https://pocketwatchdatabase.com/search/result/elgin/29781224 Seitz book.pdf2 points

-

The extra metal next to the jaws is just there as added protection for the fragile ruby. The screw thread would be to stroke your tweezers over to induce some vibration and help the balance settle into position.2 points

-

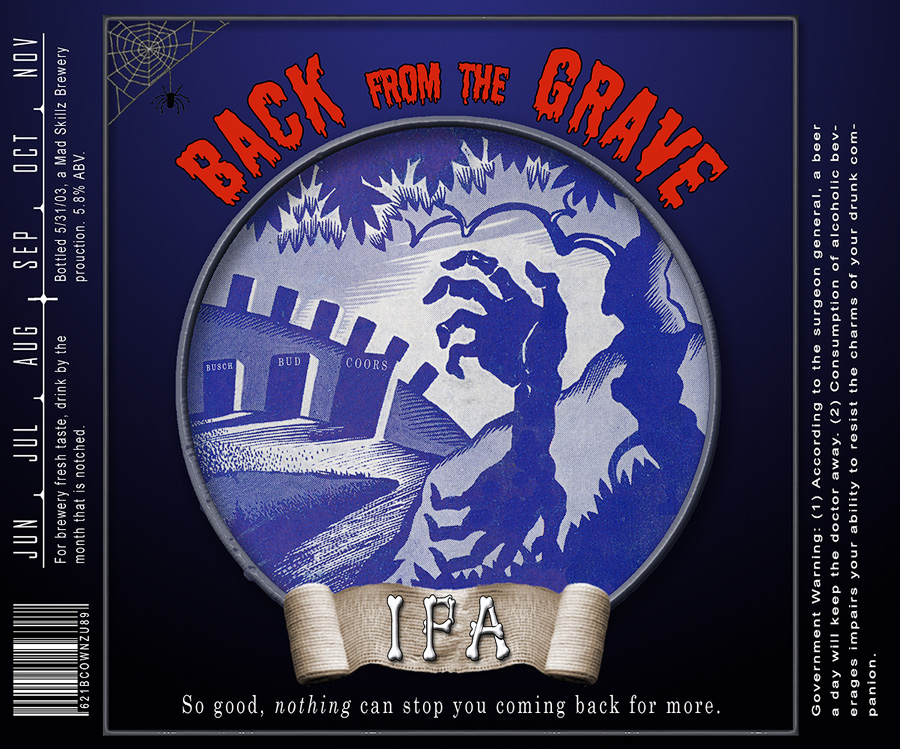

I got into homebrewing about 25 years ago. Started with extract and after a few years went to full grain. Over time added a Morebeer sculpture and a heated/cooled SS conical fermentor. I converted a chest freezer into a kegerator as bottling was such a PIA that kegging the beer made more sense. The compressor died after a few years so we got a commercial 8 tap keggerator. This one has been going now for about 9 years. And in a bit of a crossover with watchmaking, I had a logo made for our home brewery and had it turned into a clock Living in the SF Bay Area we are spoiled with amazing breweries and beers (and Hetch Hetchy water for home brewing!). The grocery stores here have extensive selections that are different week to week. Because it's so easy to get amazing beer we have slowed down our home brewing but usually still manage to have something on tap. I spent a few weeks hiking the Cotswold trail with my wife about 10 years ago. There was a definite difference in IPA's in the areas we visited compared to the US. The beers here tend to be much more aggressively hopped with a higher ABV. I was surprised to see beers, like the Greene King IPA, labelled as IPA's with a 3.7% ABV. Stylistically I would consider those more of a session Pale Ale than an IPA. But I did enjoy that one. And speaking of IPA's, I made this label for one of our IPA's and it won a prize in the BYO magazine label contest.2 points

-

2 points

-

@ManSkirtBrew I started brewing... 14 years ago maybe? with an extract kit my siblings got me for xmas one year. I like really dark beers, and the only kits I could find topped out with brown ale level SRM. Also, I'm not a huge drinker, and 5 gallons takes me FOREVER to get through. I pretty much lost interest. I moved to Colorado near dozens of really top notch breweries (helps when the water is so good!), and had a lot of fun exploring different styles, but really honing in on what I like (big, giant, thick stouts). It was really all grain or nothing, and my understanding of all grain at the time was that it took $$$ in equipment and lots of space, and I just didn't have that much interest. During the pandemic, I discovered the brew in a bag method that had come up in the last decade or so. Much easier and lower investment for all grain, plus I can make much smaller batches much easier. I've made the same stout recipe over and over and over now in 1.5 gallon batches solely to fine tune my process. I'm getting mid-80% brewhouse efficiency, and with this last brew upped the grain bill by 50% as my first real deviation. My efficiency didn't drop, so assuming the beer itself tastes as good as I expect it to, the next batch will be 200%, and I'll keep going that way until I top out (not sure I want to do a double mash). Once I figure out my upper limit for extraction within a reasonable efficiency range, I'll start playing with other malts. It's been a ton of fun, WAY easier and cheaper than I thought it would be, and the beer has been far better than it should be. As objective as I can be, I can honestly say my very first round, mistakes and all, tasted better than all the other beers I had in the fridge, and it's only gotten better since!1 point

-

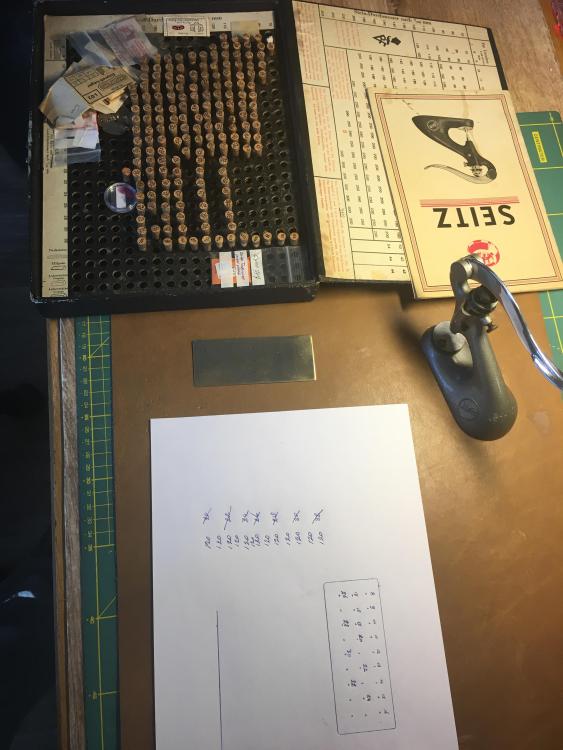

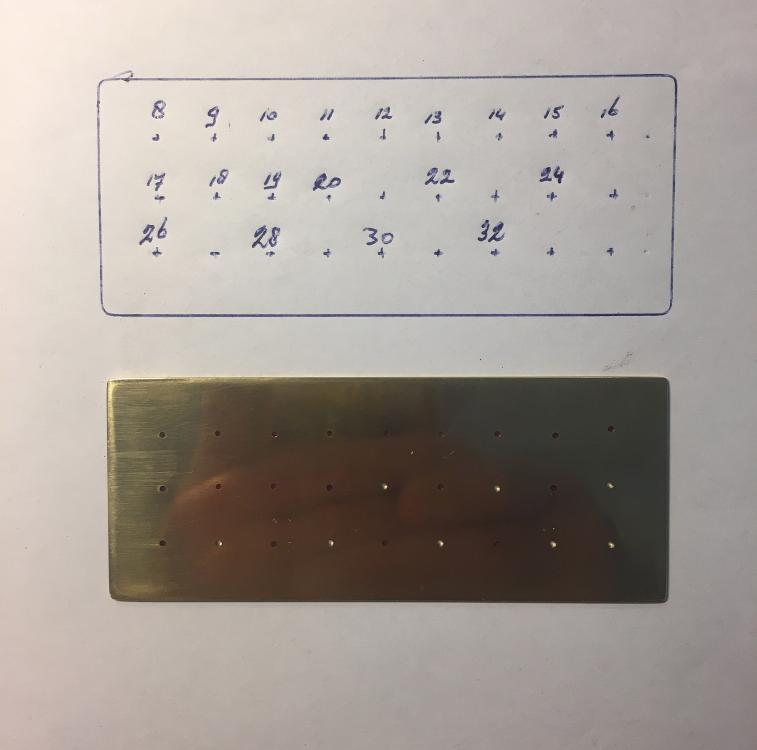

In order to start learning my Jacot tool and select the right size bed, I wished for a Seitz jeweled pivot gauge. Sadly, the prices asked for these gauges are astronomical. Currently on eBay from €350 and way upwards to over €500 !! Wild West prices In my Seitz jewel-box I had a "complete" range of jewels 8,9,10,11,12,13,14,15,16,17,18 & 19 in the OD size of 110 and 20,22,24,26,28, 30 & 32 in the OD size of 120. Marked 27x spots (1x1cm distance) on 10cmx10cm, 1mm thick copper-sheet and drilled them out with a 1mm drill. The holes for the jewel sizes 8-19 were reamed to 109 and the other holes reamed to 119. Cut the "to be jewel-gauge" at the size of 10x4cm, polished it and inserted the jewels; Left the holes open for the "missing" jewels; 21, 23, 25, 27, 29 & 31 and there are two more slots empty for 33 & 34; Whether I'll ever need these bigger sizes? They weren't in the Seitz jewel-box, perhaps for a reason? If I ever stumble over these sizes, I can insert them, the holes are already there. Those "missing" bigger sizes are also easy & safely to measure with a micrometer or gauge-caliper. For now, I have a jeweled pivot-gauge with a full range from 8/100 to 20/100 and from 22/100 to 32/100 in steps of 2/100, I think enough for making a start on my Jacot-tool Next, to finish this project off, is to find some small metal-stamps to number the jewel sizes.......1 point

-

I think that might be it. I have that diagram but didn't pay attention enough to it I guess. As to your question about dial position, it didn't seem to make much difference. Lower than normal amplitude, but just completely stops with the last 1/4 or 1/2 turn of the screw. (And I actually already tried using a shorter screw to see if that did anything). Thanks for the tip on the lighting--I couldn't tell that one side was curved just looking at it. When I have the light reflect on it, I can tell one side is flat. I'll assemble soon and update.1 point

-

1 point

-

I don't know that I'm an actual authority, but I can tell you my version of history. As for the actual timelines, I'm not entirely sure, but I'll share things as I learned about them. Back in the late 1900s (oh god) we started seeing craft beer just start to emerge here. I remember the first big craft breweries coming out of the west coast, like Stone Brewing. Their tagline at the time was "You're Not Worthy." Their Arrogant **BLEEP** IPA was aggressively hopped, big, malty, and in your face. The west coast IPA craze was on. Dogfish Head in Delaware on the east coast came out with their iconic 60/90/120 minute IPAs, which indicated how long they were continuously hopped during the boil process by their hopinator machine. They also pioneered the "Randall", which was basically a reverse water filter that ran beer through fresh hops en route to the faucet. There were also more reasonable examples, like Sierra Nevada Pale Ale, Dale's Pale Ale. Not IPAs in name, but definitely in hops and flavor. The American craft palate was all in for the hops. But then maybe 10 years ago, a backlash of sorts started. Breweries like The Alchemist started making beers like Heady Toppper, a hazy "New England" style IPA, and the NEIPA was born. It was hazy, juicy, fruity, generally lower alcohol than the big west coast styles, like the 9-18% ABV Dogfish Head offerings. It almost immediately became the new definition of craft beer. I actually got a review of one of my IPAs with the comment, "It's a great beer, but too bad it isn't hazy." And now there's something of a backlash against NEIPAs. In classic American fashion, brewers took them to the extreme, adding lactose and tons of fruit to make them more accessible to the masses, watering down the style in the process--milkshake IPAs are a thing here. Now I'm a big believer in people enjoying whatever they enjoy. There's no shame in it. The thing is, these hyper sweet, thick, fruity NEIPAs are not reminiscent of beer in almost any way. So the craft beer pendulum is swinging back towards clean, beer flavored beer. Lots of lagers are starting to show up. 5 years ago I won an award for "Most Unusual" at a beer festival with a super classic, clean, light Mexcian style lager, because it was the only one at the event. This year there were dozens of the same beer. It's fascinating. And apologies for unexpectedly jumping up on my soapbox!1 point

-

Didn't use to be but they produce some very good ones now. Not sure when it started, maybe @ManSkirtBrewcan enlighten us.1 point

-

1 point

-

Lack of end shake on balance staff. Check the jewel setting on mainplate. Normal causes, flipped over end stone, moved setting housing, crimped chaton, worn jewel hole and bent staff pivot. Good luck pal1 point

-

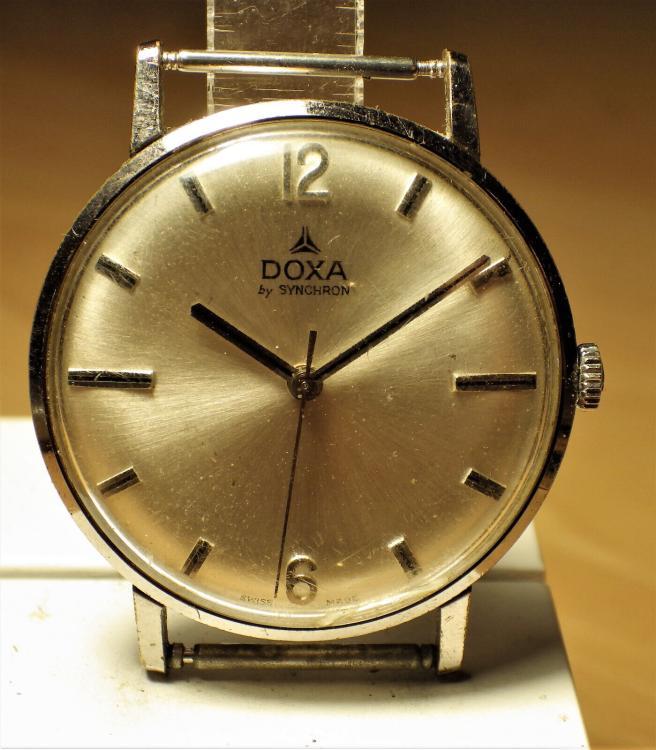

Hi, I've been dabbling in watch repair for about 15 years. I'll get into it, get obsessed for a while, and then stop when I get a couple of restored watches. I'm back on now. I've only done seikos because they're cheap and easy to find. And if I screw something up, no big deal. I currently have a box 'o watches in various states of repair. I found a couple of cool old dials in my collection that I'm going to try to get going again. Latest one pictured below.1 point

-

Well done! However the gauge jewels have smaller hole tolerance than the public available ones, afaik. Frank1 point

-

You need to take off the screw at the end of the shaft as well. There’s one that goes into the rod.1 point

-

Here's hoping I don't have to do that again. Thanks, @nickelsilverfor testing the theory out. When I can get away with it, but usually just at work Well, this is the most frustrating gear train I've ever tried to install. I just spent an hour trying to get all 4 pivots to line up and I'm no closer to it than I was an hour ago. I had to give up before firing the thing out a window. I genuinely have no idea how I'll be able to do this. EDIT: Guess who just figured out he also has pegwood stuck in the bottom jewels in the mainplate? BIG SIGH1 point

-

1 point

-

Do-Hicky = Whatcha McCallit On a serious note ....ish. Being away for a short time, and it being my 75th today, means that I have a few pence left. I have purchased my last ebay items for the foreseeable future . An eye loupe, so I can use the microscope better. A 3 oiler pot that has closing lids, sick of hairs. 2 watches which I made silly offers on and amazingly they were accepted (I'll post photos when they arrive) 1. Vintage Angel 15 Rubis Antimagnetic Molla Infrangibile. 2. RARE DOXA wristwatch with Synchron cal. 41 (ETA cal. 2750) from 1960’s. Time to get serious with the hobby me-thinks. Ross1 point

-

I'm sure that these settings are able to be taken apart, but I've never done it. I think you would press out the pair cap/hole jewel, then they are two separate pieces, each jewel in its setting. I have a 218 here for service but it's my mom's and don't really want to experiment on it... haha. But maybe I'll give it a go. Edit- it's one setting, you push the hole jewel and it pushes out the cap.1 point

-

That's correct! That was my conclusion as well which I wished to have confirmed by a professional, which I now have. Thanks! Well put!-1 point

-

Okay so if I interpret the question correctly if we look at the mainspring barrel only can we tell which direction to put in the mainspring? Then they want to make this more fun it has to be an automatic watch otherwise On a nonautomatic there would be a hook some form that would be the same giveaway as the armor. Then the answer would be no you can't tell. Because you have no reference at all. Then because barrels come in all different shapes sizes and gear placements in other words they could have their teeth in the middle or on the top or the bottom depending upon the watch that's not very helpful. It's a Seiko watch you don't even have a stem the wind the watch sometimes. The easiest way then would be to place the barrel in the watch and look at how it drives the center wheel. Unless we have a backwards running watch the center wheel goes in one direction.1 point

-

Thanks for the tips and i'm heartened to know that it's not always as easy as the YTers make it look.1 point

-

I try to lift and hold the balance wheel in place and manipulate the movement around it- tilt, turn and rotate. It feels less fiddly than moving around with the dangling balance wheel…1 point

-

it's a shame I don't have pretty pictures like up above. Usually what I want to do is I usually put it towards the movement. Then when I come in with the balance wheel I have the roller jewel much farther away from the fork but on that side that I rotate the balance bridge in place and drop it in place. Then the balance wheel can oscillate towards the fork and if you're lucky it takes often runs. so looking at the pretty pictures I'm guessing it's my dyslexia I do the exact opposite. It doesn't really matter though I think matters is that you get the roller jewel on the same side that the fork is and to put the roller jewel like 45° away from it in not trying to get the roller jewel into the fork yield do that all by itself you just don't want the roller jewel on the other side of fork because that is an irritation. But sometimes ill just do that all by itself especially if you bump into the pallet fork1 point

-

1 point

-

Hi All Couldn't find a forum called "proud moments" but this is as good as any . New 6497 movement (Seagull ST36), stripped, cleaned, lubricated and reassembled. then regulated - quite well too! Sourced a case, dial, hands and strap and built my own watch. I'm sure many have done it but feels good to have something I created! Strap was delivered today but I wasn't home so it's at the post office! To be worn tomorrow! Simple, smart and cheap! Very satisfying.1 point

-

I have an MKS (Meikosha Manufacturing Co. Ltd.) set which does indeed have a curved glass (not perspex) lid very similar to the set pictured, I believe that Mark Lovick also has one. Mine is not an inverto style like this one though so it's difficult to make a direct comparison. If it is from MKS under a different name then the quality is excellent. The stakes are all the standard 4.7mm diameter too so compatible with the majority of other sets that you're likely to come across.1 point

-

1 point

-

A special lubricant is recommended for the Seiko 7546 quartz movement to ensure optimum performance. The main lubricants required for this movement are Mobius 9010 for the barrel and gear train, Mobius 9415 for the escape wheel and escapement fork and Mobius 9501 for the keyless movement. These lubricants provide the necessary protection and minimize friction to keep movements running smoothly and precisely. To ensure the longevity and reliability of your Seiko 7546 quartz watch, it is important to follow the manufacturer's recommendations and guidelines when applying these lubricants.0 points

.thumb.jpg.334efff2e136a28a6a01353fd041979e.jpg)