Leaderboard

Popular Content

Showing content with the highest reputation on 05/09/23 in all areas

-

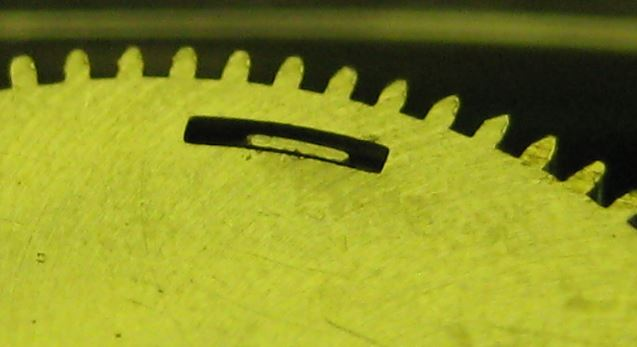

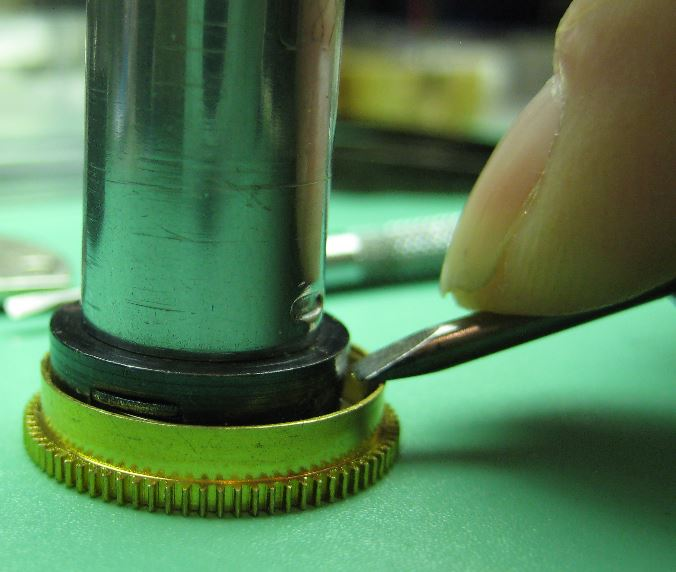

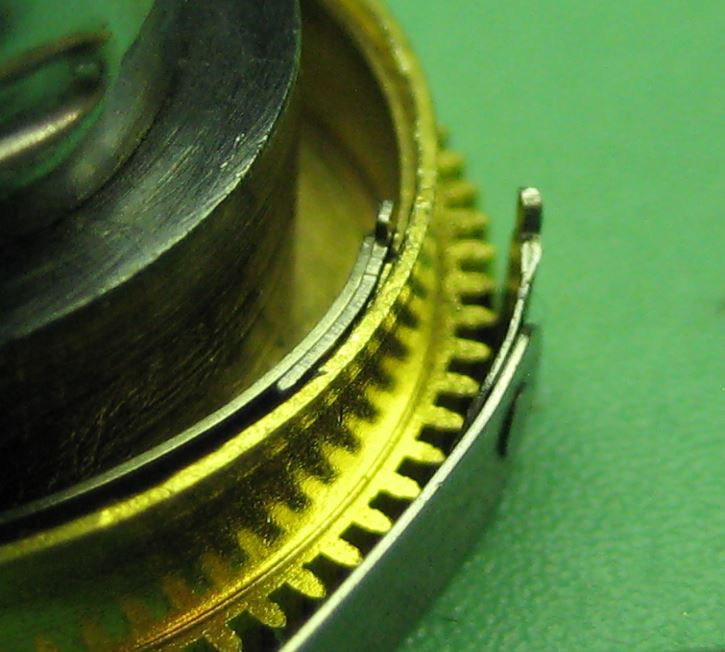

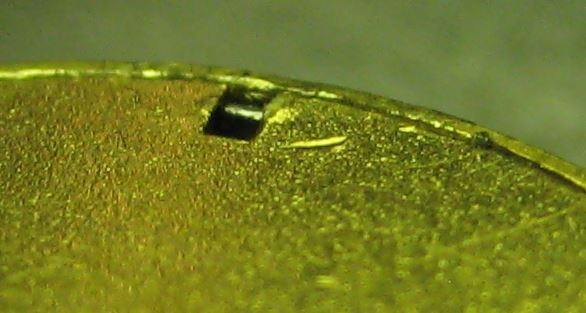

what's interesting in watch repair is there's more than one way of doing things. I think there's a better way to do this. Because pushing the spring in after the fact does require really strong fingers can scratch up the inside of the barrel and sometimes it just doesn't work. So maybe there's a better way just a little modification to his procedure and everything would be fine. before we get to the modification of the procedure just to see the problem. In this particular example we have an Elgin spring. It has a protruding T and a square hole and the brace part that holds the whole thing in place. the modification to the procedure is not to wind the entire spring into the wonder leave a little bit sticking out. in need to leave enough to work with this might have been a little on the short side. You don't want to leave the lot out because it becomes much harder to get it into the barrel. also pay attention to diameter the winder it has to be small enough to go in and still accommodate the mainspring that sticking out. now comes the interesting problem of video would've been better as I don't really have enough hands to properly show this but I'll try to describe the procedure. I usually hold the barrel in my left hand and the winder in my right hand. They start by inserting the end of the spring and angle into the barrel followed by the winder itself. Once you grasp what you're doing it's really easy to do this I think it took less than five minutes to put the Elgin spring into the barrel from out of the package. It just seems confusing with the wording perhaps now for those eagle eyed people you'll notice that doesn't quite look right? This is because I photographed three separate T type mainspring insertions and by the time I got to the Elgin I didn't photograph everything so this happens to be a Hamilton. So basically inserted in don't worry about where it goes just get the whole thing into the barrel. Then you can rotate the handle of your winder until the tea part is over the hole or slot. then I usually use my largest screwdriver push the mainspring down verifying that it is in the slot in this case. Do not assume that it's in the whole and/or slot you have to visually verify which is why you have to pick it up and look and see yes it's where it's supposed to be. so the key here is with a little bit a spring sticking out your rotate the winder until it's over the whole/slot then you push it in and look at the other side to make sure you see something like this. In other words the Elgin has its protruding part into the slot exactly where it's supposed to be but we can't quite push it out yet we just need to verify it is where it's supposed to be. now we get to one of the most important steps you can't just push the spring out and hope that's going to stay Where it currently is it will probably jump out. This is where the back end of your tweezers would work or I usually use my largest screwdriver. basically going to put pressure on the protruding part that sticking up and hold it in place. Now you can push the spring out when you're holding it in place and it will stay where it is. then of course once the spring is out you do want to make sure that it actually did stay word supposed to be I don't recall ever having it jump out so but still you want to check. Also into putting the lid on of course make sure that you align it with the part that sticking up.4 points

-

Lost of bad experiences with Cousins in this thread, so I though I'd share my positive experience with their customer support team! I purchased a set of Bergeon screwdrivers with the rotating base, and noticed that the base was very "crunchy" and didn't rotate properly. Sounds like the bearing had taken a good beating. I told them this and they sent a new one. They didn't even want the old one back. Maybe it depends on whether the support rep is having a bad day or not?3 points

-

It should indeed come back up after a day or so, but maybe not all the way. I know certain LeCoultre movements, the really tiny ones, don't like 9415. Similarly to your Omega, often running quite well with the escapement dry, then big drop in amplitude with 9415 and not a full recovery. A very, very small amount of 9010 works great. These are smaller than your Omega, but certain movements are just really sensitive.2 points

-

2 points

-

I don't ever recall having that problem.that it hasn't happened perhaps. But you do want to make sure that the mainspring is identical to the one you're replacing and that it actually does fit the whole/slot. When I was photographing the three main Springs I was doing the original Hamilton I struggled for quite a long time just because the T didn't want to go into the hole at all. There is no way as going to push it out until it would actually go into the hole. often times with T ends the replacement may be bigger or shaped a little different than the original. Or like in the Hamilton with the picture below the riveted tea party is on the wrong side of the mainspring. So basically is not a drop in place because a whole isn't in the right place for the replacement mainspring. Then the tea party didn't stick up high enough so I had to hold it a little differently I wasn't happy with that. The other two mainsprings the Elgin which I have pictured above was textbook perfect but they Hamilton was a nightmare which was also probably because I had to basically identical springs to do and they both did the same thing replacement not identical to the original which is currently on the outside and the replacement is on the inside. alternative way of holding the spring in place. I suspect that the replacement spring is slightly narrower in addition to the end not being quite right which is why I can't use my normal method of holding it in place. Instead is even CM pushing almost straight down with the flat part of the screwdriver which did work. here you can see an example of I don't think it was as tall as it should've been the T part should definitely be higher up. Almost was invisible on the other side. then unfortunately this is watch repair it be really nice to say that only one method is perfect and it works every single time and no it doesn't. Which is why we have alternative methods of doing things but for the most part I don't have a problem inserting mainsprings this way at least if I can get it into the winder. Which is why we have multiple of different sets of winders at work and they occasionally it still has to be hand wound in.2 points

-

that is the way it is supposed to be, i..e, the spring has a notch. Regarding the giddy up problem, I've experienced the same condition on a 10BPAC. In that case, I had a very slightly loose sweep second hand that was losing contact with the pinion. You have to work your way back in the chain from the sweep second hand then the pinion etc to find the problem. Have you tried another sweep second hand? Have you checked the pinion to make sure it is true and not bent? Does it always do it in the same spot? Check a full rotation between the wheel and the pinion and watch to see where the hesitation happens at that level. Does it do this in multiple positions? Have you observed that the sweep second hand driver wheel and pinion are close to level and meshing with no wobble? And so forth down the chain.2 points

-

Doodad, thingymajig, billy do, oooohjah, whatsit, wangdoodle. There seems to be a whole new language I need to master before I can take the pebbles from your hands2 points

-

https://www.cousinsuk.com/product/double-ended-pin-vices It doesn't say it's brass, but that's what I got.2 points

-

Perhaps try increasing the tension that the sweep seconds tension spring is providing on the sweep second pinion. I've never personally seen "backlash" that the tension spring is supposed to control, but what I've read makes it sound like this. EDIT: was the tension spring broken? It looks like it in the movement photo but in the parts tray it doesn't2 points

-

When you say removed, did you remove it from the balance cock and then take it off the balance staff? If you did that, could you post some photos?2 points

-

Watching Leo Vidals video about how to blue hands, at one stage he uses copper / brass shavings to distribute the heat equally to the hands. Most of the materials, or kinda equivalents thereof, used in this video I already have. Missing were fine copper / brass shavings. I guess for the most of us, not too expensive to get. But if you live in one of the Nordic countries, where the national sport seems to be to make everything as expensive as possible, a small 500gr bag of mixed sizes copper / brass shavings on eBay, including postage, sits around $20, of which the postage takes the biggest part. As mentioned in the video, one has to take care of the possible impurities in those shavings and the finer shavings are better. Thinking about how to get copper / brass shavings cheaper, the idea came to me to chop up the fine copper-strands inside an electrical lead. You can cut them as fine/short as you like, as many as you like and they are clean, no factory sweep One meter yields more than needed; I do assume that these will work just as well and that they can be re-used .......1 point

-

To make sure you have the correct amount of tension on the sweep second pinion, run the watch without the sweep second pinion or brake spring in place and note the amplitude after at least 48 hours after lubricating. Let's say it is 300 degrees amplitude. Then fit the sweep second pinion and brake spring and set the tension so it is just enough to stop the flutter/backlash of the second hand, but not so much tension to reduce the amplitude by more than 10 to 15 degrees amplitude. That is the Goldilocks point. No flutter, but not a ridiculous drop in amplitude. If the spring is dented or damaged, that will decrease the amplitude radically, making you think it is something else, so make sure that isn't the case. Any bigger drop than 20 degrees using this method, then you need to backtrack the problem, such as a bent sweep second pinion, bad lubrication, over lubrication, dirty pinion leaves, too much side shake, etc... Also, I always advise to fit a new mainspring, so you can rule out any power output problems because you aren't using an old spring.1 point

-

I did make sure of this when I reassembled, and it seems to be behaving well now. I just ordered a new center wheel, but at least it was only $14. If there's a significant difference in the fit of the seconds pinion shaft, I'll swap it out. But for now I might just put it together and wear it for a bit1 point

-

1 point

-

Can you try attaching the subdial second hand without the dial on. You might be able to see what's happening under the dial. If it runs then add the hour and minute hand and see if that also runs. This might draw your attention to dial fouling.1 point

-

one of the things you're seeing is specifically the stopping. If you set a watch and depending upon the particular watch and how tight the Canon pinion is you can stop the watch. Basically if you can rotate and cancel out the force the mainspring the watch.. The same as if you turn in the other direction carefully you can kick the amplitude up a little bit it's not really an issue because you're setting the watch the problem would be as the amount of play between the gear driving the pinion. That's why the spring is there. Gear trains tend to produce pull stations up our that you normally wouldn't see you look at how that gear meshes with opinion you'll see that it might actually be a position where it's not actually touching at all and in that moment the secondhand can move back and forth as why the spring is there to just make sure it doesn't flop around in the in between positions. It's a common problem for that style of design which is why they have Springs. Also in manufacturing if the gear and pinion were sized properly. also if the poster gear rides on is bent conceivably it may go in and out of meshing properly and you may see it worse in some positions Alan I think I might have mentioned it up above but if I didn't make sure that there is no lubrication on the spring. As it's supposed to be holding something in place and lubrication would make it more slippery and then your hand flop around a little bit.1 point

-

Hi @JohnR725, I tried the "leaving the tail outside method" and I just couldn't get the T into the slot. Must be the same problem as the Hamilton. Then I tried Alex's method of pushing the T with a brass tool. And I was shocked by how easily the entire coil of mainspring was able to turn inside the barrel. It went in with no problem. I'll keep both methods in mind. You'll never know which method would work better on a different watch.1 point

-

Hi Karl. A man to look up David La Bounty. AWCI OR NAWCC. He seems to be well versed in the Ansonia clock world, I have read and used his advice. Setting up the J levers and count wires. I three clocks using that type of movement.. as Old Hippy said strike wheel and spring missing, I have a scrap movement should you find the hard to find. They were a common clock used in many. “ Gingerbread” kitchen clocks. You will also need a set of mainspring clamps or what I do is wind up the spring and wire it before separating the plates.1 point

-

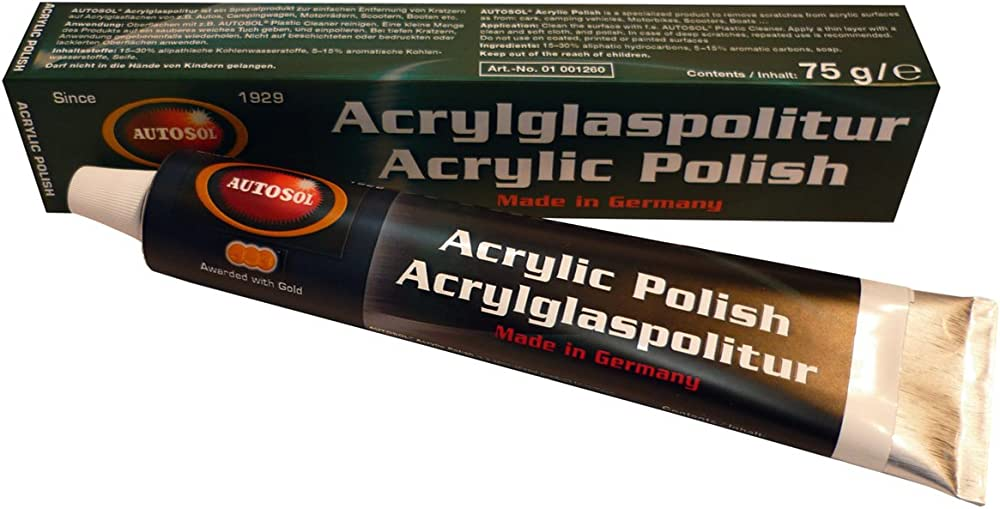

Residue on the bezel/case and not the acrylic crystal, right? Because I'm fairly certain acetone will melt acrylic.1 point

-

No, it's just the lighting in the picture. There is definitely good tension on the pinion (thank you for putting the right word to it for me!). Much of the keyless works were rusted, but since I have two movements I used the parts from the not-rusted one. I just took the nicer-looking dial, which happened to be from the rusty movement. I can, and it looks very worn to me, but since both movements look the same I didn't want to assume it was incorrect right away. I will take the second hand pinion spring off and check it for tension again, but I did notice something else this morning that's probably important. When I pull the crown out to setting position and turn it to set the time, the balance stops spinning--but only when I turn the crown clockwise. If I turn it counterclockwise, the balance continues running. Also when I turn the crown clockwise, I see the seconds hand rotate counter-clockwise a few degrees. I've never seen that before, so I assume it's significant to our diagnosis here. I have, and it looks the same. After you suggested it, yes, and it looks dead straight. Yes, after removing and re-seating the driver wheel. It did seem to be worst around 4-6 o'clock, but after removing the pinion and reseating things it seems to be running smoothly. The problem with the balance stopping when I set the time persists, though, so I'm not ready to button it up yet.1 point

-

Looks like you are missing the complete wheel for the strike side and the spring. You should be able to find a replacement. You need to measure the going side one including the arbor size that is where the key fits on, teeth count (how many) the size of both holes and the complete length of the arbor from end to end. Ansonia movement are very popular even here in England. From your photos I can't see any more so it looks as if the rest is all there.1 point

-

rust typically comes from somewhere a combination of alloys of iron, oxygen and water. Do you know what was rusting in the watch? Then rust can make a really nice grinding compound. can you see the bushing? Oftentimes the bashing can wear out especially if there was rust on the shaft. So you may have to replace one or both of those usually when you're driving a sweep second pinion usually is a spring. This is because there is play in the gear teeth and without the spring you'll see the play exactly is what you're seeing. Possibly made it worse with the amount of play the shaft has in the center tube. So somewhere there is usually a spring and is not supposed to lubricate the spring. Where is it supposed to provide friction so that as the secondhand is being driven it's not free to flop around. So not a lot of friction just enough friction to keep the pinion from flopping around.1 point

-

What bad practice. The reason you use watch mainspring winders is so you do not distort the spring and so your fingers do not contaminate the spring because of the oils in your skin. He is touching the spring all the time. I suggest if you go down this road wear finger cots.1 point

-

Currently working on my newly acquired Seiko Lord Matic 5206A, but it's being a real pain! I had it back together and all seemed well, but then I noticed that the date disc would not turn using the manual change, but would if I wound on the time 24 hours. I was scratching my head trying to figure it out, then I noticed that the balance had stopped, and would then only start for 30 seconds before dwindling to nothing and stopping . I decided to put it down and watch some TV before it earned some free air-miles! . Thinking I should just strip down and troubleshoot along the way and repeat the entire service. So near and yet so far!1 point

-

I only know because i made that same mistake of doing it that way round when i started using the jacot. Round first if the pivot requires it then polish out the sides. There is always the argument that badly scuffed sides of a pivot could damage the insides of the lantern hole. Maybe that going a bit far and I'm not sure if the runners are a any more harder material than the lanerns. I've subscribed to his channel, definitely worth watching more of his videos. I agree always pracice on something much less important. I'm holding back on swapping out a balance staff on my Record DD. I want a lot more staff replacements under my belt first as the balance complete for it is over £250.1 point

-

This one is new to me, better than some out there. Just watched his video on using the jacot tool. As you say he takes his time to explain things. His order of polishing and then rounding a pivot did seem backward though. Rounding last the side of the pivot can pick up score marks from the lantern that you would want to polish out afterwards. Thats just my experience and thought worth mentioning.1 point

-

Not skilled like an experienced pro !?? He seems to me There is a huge difference in knowing your stuff and teaching. For teaching you really need to know your stuff. Even though I've the equipment, I've never done jeweling of worn holes. I've seen a few video's how its done, but he has given me another incentive to give it a try. Great video, great commentary (I like his accent a lot) and for sure educative1 point

-

1 point

-

1 point

-

Here is my watch of today - I made it myself from all new parts, I think I may switch out the hands to ones with white lume as the plain silver doesn't show up very well at night (see below and tell me what you think), ie the black polish on the hands is black most of the time (see minute hand below) unless it catches the light and turns white (see hour hand in picture below) which is the only time you can see it on the busy backdrop of the dark skeleton movement. It's a Seiko NH72A skeleton movement and an 'Ali Express special' strap/case, here are the hands I am thinking of switching to with white lume and red seconds hand.....opinions:1 point

-

somewhere in the group we were having a discussion of how to put the T end Springs in most the people were doing it by hand but I keep saying you can use your winder. So I asked if they would be interested and they indicated they would so somewhere lurking in the computer is about 10 the 15 pictures on exactly how to insert with the mainspring winder I is need to get around to doing it. I would like to say that it's super super easy but in my example photos the first Hamilton it was a real pain in the ass even with the winder. The other two wed in in less than five minutes basically as fast as you can wind it in and shove it in you are in but not the Hamilton's and if you would hand wound you would have the same problem. So someday I'll get around to posting pictures. usually as long as the arbor? Like the mainspring winders the arbor has to be the right size for the mainspring that you have or specifically you have to have the right mainspring for this watch. So as long as the arbor goes in with a reasonable amount of pain in the ass to get it in it should look. But you could grab a with your pin vice and gently twist just to make sure it actually is hoped if you're dealing with American pocket watches those sometimes you'll find arbor come which we dropped right through if it's out of the watch and in the watch it isn't necessarily any better so yes it probably is good to make sure that its rights because it is a pain to get the watch altogether only to find that it makes a nice slipping sound that's not really very nice. Oh but just remember initially the very first time it might slip until everything catches it just shouldn't make the slipping sound continuously. Not that any of us would have any knowledge of that sort of thing.1 point

-

Not necessarily , better to make sure the arbor is hooked onto the mainspring and all is good before fitting the lid. Some swearing would ensue if you have to disassemble to solve an issue inside the barrel.1 point

-

1 point

-

1 point

-

The "Montine of Switzerland" slim GP 17 Jewel dress watch got a few cosmetic touches last night. The hands were straightened out, repainted and re-lumed, and the case back was re-finished, and of course the crystal and strap are also new. Ignore the slight grubby marks round edge of the new crystal in these pictures. They are caused by the polish I was using, and I did remove them later. The new lume is actually surprisingly bright, even with a small amount of pigment added to tone down its overly new looking yellow colour. Much more so than the original tritium pips on the dial, which have pretty much lost their luminosity. This is what I started with.1 point

-

what is your definition of vintage? then you won't find what you're looking for. The group will be impressed though but Omega would not be impressed at all. This group you've achieved 300° amplitude outstanding. Silly watch companies like Omega or Rolex they're more concerned with whether the watch keeps time. That's because the silly customers want their watches to be on time and customers typically don't have timing machines to see if there amplitude is within proper specifications. the only time you Rolex Omega are concerned about amplitude is if he gets too high that could be an issue but on any of the timing specifications all they're concerned about is at 24 hours typically in a specific position like one of the crown/pendant positions does it have a minimum amplitude. then without a specification of what vintage is the end are working instruction number 28 they have timing specifications for hundreds of watches but anything that they don't have timing specifications for falls into the category in the image below. although this isn't even entirely complete because you'll depend upon the grade of your watch a chronometer grade watch should keep better time keeping them a generic watch and with each of the increases in a quality of timing the increase the number of positions for timekeeping. So a chronometer grade watch the time and six positions and a standard grade they were usually time and three positions.1 point

-

And, he has some really nice tools in great condition, and I'm a sucker for nice tools! Also, clean, orderly and structured. I like that a lot! Well, not skilled like an experienced pro, but his way of learning is skilful! I especially enjoyed the following video:1 point

-

Quick question... when I get a replacement spring... if I have a left handed movement but they send it with the red washer, does it matter? I would assume I have to flip the washer upside down so the red is facing down or will locusts swarm my house because I am breaking some sort of rule?1 point

-

Hi, I don't know worn jewel holes, just damaged ones. But I knew many worn pivots. Usual sizes are: pivot under 0.2mm: jewel hole = pivot plus 1/100 mm pivot 0.2mm and more: jewel hole = pivot plus 2/100 mm Frank1 point

-

I know it's the obsession of this group but is amplitude really that important more important than keeping good time? What sort of amplitude are you aiming for for instance there is the timing specs from Omega what sort of timing amplitude are they expecting? Notice there only concerned about the amplitude at the end of 24 hours 170°. They are in real life concerned about timekeeping not amplitude. another problem conceivably could run into is something this tiny is lubrication will be critical. I remember when I was in school the instructor is using an organic oil for the super tiny ladies watches. From the lubrication specifications I've seen usually organic oils do have better properties for reducing friction but consider the worse it everything else. then yes I went back and looked at your video I think it looks better than the Rolex video that someone gave me as it was flopping around considerably more than this. Oh and then there is the other little problem jewel wearing out or pivot wearing out?1 point

-

There you go. 1st book. Free to anyone. Been downloaded over 50,000 times now. No_Man_Has_The_Right.pdf1 point

-

1 point

.thumb.jpg.80d166adeeb3ca46adc6e63cf014f236.jpg)