Leaderboard

Popular Content

Showing content with the highest reputation on 05/08/23 in Posts

-

My mentor just seals the part with a slip of paper with the description in a plastic bag. He has a sealer that seals and cuts at the same time. Then puts the little bag in small plastic boxes. Everything is labelled and organized. While me, I keep turning the house upside down looking for things that I know I have, and end up finding things that I don't remember having. Then I get distracted and forget what I was looking for. Anyone else like me, raise your hand.7 points

-

4 points

-

I acquired an L&R Master off eBay months back. It was dated 1954. It looked tired and after receiving it ran really poorly. So, I embarked on a rebuilding project. I am writing this because I found some sources for parts and services that may be useful to others, and it had taken me a long time (I’m talking many months) to find them all and get the work done. Link to pictures of before and after are attached at the end. Thanks to all on the forums and other sites for info, diagrams, and pics that helped me along the way. I cant recall where I got everything so a general thanks! The process was as follows (to help those taking this on): · Took the whole thing apart and stripped the paint down to the bare aluminum. I ground off some bad casting bumps while it was stripped. · I tried to crinkle paint it myself with VHT Wrinkle Paint but just couldn’t get it right, so I stripped it again and decided to send it out to have the body (including the motor housing) powder coated. So, the motor had to be completely disassembled before sending for powder coating. · All parts I was reusing were cleaned and polished where needed. So, you really need to have abrasives and both a workshop polishing wheel and Dremel. · The rheostat was not smooth and would cause the motor to jump speeds. But turned out it was just dirty with hard carbon build up so a good cleaning and some gentle scraping of the contacts and it was fine with smooth resistance all the way through the range. I also hit it with some very fine sandpaper (1200+ grit) lightly then cleaned with acetone. · Trying to get the rheostat knob off it crumbled into small pieces, but I found a good one on eBay. The knob as well as the motor brush housings are made of Bakelite on these old machines, and it doesn’t polish well nor necessarily hold up after about 70 years. · The heating resistor was good. Resistance was tested and was as marked. So cleaned it up. · The light bulb socket was good so just cleaning needed. Bad bulb but I found bulbs to fit on the internet and bought a box of #41 2.5V E10 base. · Then there was the motor. OMG. It ran but rattled, buzzed, and didn’t always turn. Bearings, wiring (I am lucky I didn’t fry myself when I turned it on after receiving it), and some burnt out armature winding wires on the rotor itself would cause it to not always start. Also cracked wire going into the stators. Finally, I decided to try to have it rebuilt. Very hard to find a company that rebuilds these Fractional Horsepower Motors. After searching for what seemed months, I found a company in California that would rebuild the armature and stator. · The brushes themselves were good and easy to replace if necessary. But one of the brush holders was cracked. I found a company that made brush holders that almost fit (larger by just about 1/32” with some slight enlarging of the motor housing brush holder hole. Drilled it out to 1/2” they fit perfectly. · I added a fuse and an IEC plug to the back. There is very little room on the back so finding an IEC outlet that fit was an effort. When getting new switches, I decided to get an On-Off-On switch for the motor Forward-Reverse. It’s normally an On-On switch. I didn’t want to rely on the rheostat to stop the motor. So I can leave it on a setting and switch the motor off. I also use a switched power line. I just never liked the fact you cant fully turn off all power to the entire unit given there are liquids and electricity in close vicinity of each other. · Grounded the whole unit of course. · The jars are original but had no covers so purchased on eBay both screw on and lay on replacements from someone that makes them via 3D printing. They are not as nice as the originals but work well and are lower cost and new. · The impeller had a crack, but I was able to repair it by brazing the crack and filing it smooth. You can easily braze aluminum carefully using an aluminum brazing rod and propane torch. · I did all the wiring and soldering myself. Those courses in collage in electronics helped Fitting the wires into the motor housing is a real challenge if you don’t have an original pic of the inside. Someone had already been inside the motor and the wiring was a real mess. Thanks to others on this and other web sites where I found wiring diagrams and wiring photos of the underside of the unit. · I used rubber coated wire between the motor top and the main tube because it just seemed softer and more flexible compared to some vinyl or PVC coated wires and that moves when moving the motor to the jars. The one thing I didn’t do is try to renew the motor and control panel labels. I have seen some others that look like they were able to do it but for me with the lettering and all it is just too detailed to paint by hand, so I just cleaned them and gave them a clear coat to protect them. Note that I did find a company www.dyna-graphics.com that could create duplicate overlays with all the L&R lettering, etc. (industrial decals) that could be applied to the control panel. Normally used for electronic control panels. But they had a minimum purchase, and I didn’t want to spend the money. Bottomline it was a long process and the motor rebuild was expensive. But with all spent its about what you might pay for one online that has been rebuilt like new and normally you don’t get a like new motor. Here is a list of companies that I used for parts and repair: · Gundy Powder Coating - Bayshore New York · Eurton Electric - Whittier, California. They rebuilt the rotor, armature, and stator (I put it back together myself and pushed on new bearings and fit the brush holders). · Motor Bearings - MiMotion https://www.motion.com/ Brand: MRC (SKF) Size MFR#: R6ZZ. The existing bearings were marked making it easier to replace. · Brush Holders - Phoenix Electric Manufacturing Co. (the bad part is they have a minimum order size. They come as a set, and you must buy 10 sets minimum. Each set includes the following parts: Part #1520-BC-660-895 (the holder), Part #AE-51-TP (the screw cap). · Switches – Gaynor Toggle Switches got them on eBay. Any good toggles should work ok. · Heater Light Bulbs - #41 2.5V Miniature Light Bulbs with E10 Base (purchased from Bulbtown.com but available multiple places). · Jar Covers – eBay sellers, 3D Printed. Link to Photos: https://1drv.ms/f/s!ArzY7G4e4SiEhe5TWmrNvCMc7vV9AA?e=TsAh9E Thanks bob3 points

-

In that picture, regulated is just another word for vibrated. With stud at the right place: „regulated“. Without stud: unregulated. It has nothing to do with chronometer grade or quality. The Swiss often had issues with their translating. Frank3 points

-

The "Montine of Switzerland" slim GP 17 Jewel dress watch got a few cosmetic touches last night. The hands were straightened out, repainted and re-lumed, and the case back was re-finished, and of course the crystal and strap are also new. Ignore the slight grubby marks round edge of the new crystal in these pictures. They are caused by the polish I was using, and I did remove them later. The new lume is actually surprisingly bright, even with a small amount of pigment added to tone down its overly new looking yellow colour. Much more so than the original tritium pips on the dial, which have pretty much lost their luminosity. This is what I started with.3 points

-

I am not exactly sure if this qualifies for the 404 club. I bought this off the bay for US$8.09 (£6.47) with tax and shipping. Knew it was a Winton from pictures of the movement and import code, but all dial lettering long gone. This is filthy and has very worn case. But it is an AS 1287/94 with incabloc shock springs. Not worth the time of day for a professional but for an amateur this seems like a great project. It runs and so we have some numbers to work off of, no complications, and everything is present. The scalloped bezel is kind of cool. It ran for several days, and the mainspring seems intact but now it stops after a few minutes. Anyways here it is...3 points

-

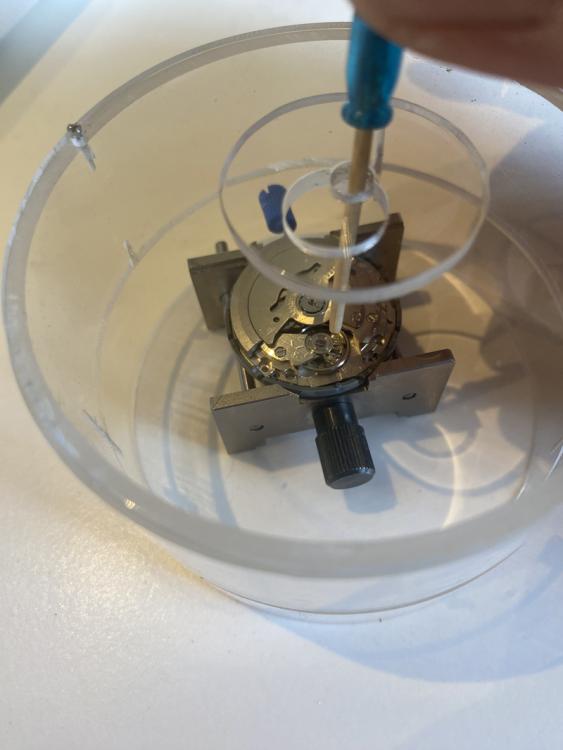

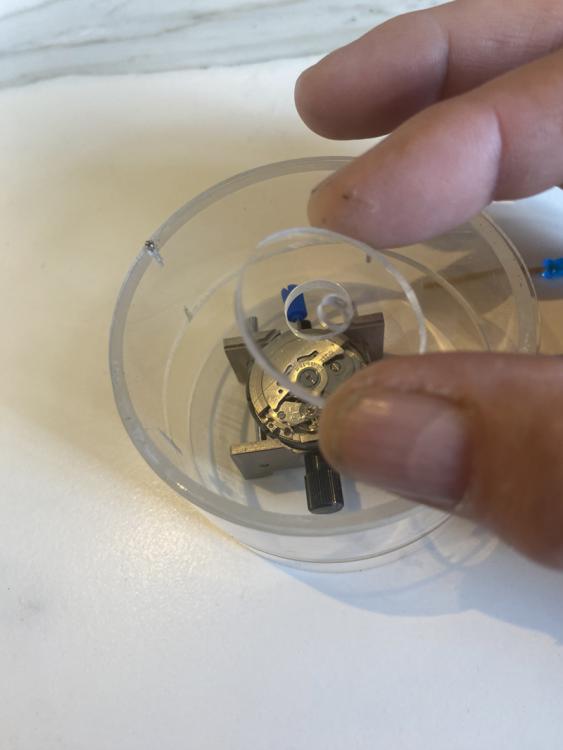

Hello everyone, I came across this tutorial while looking on the net for parts for an NH36. I'm just an amateur and rather a beginner (and French. Forgive me my English) but my level today allows me to disassemble / reassemble a movement, clean it, oil it, and finally adjust it. I mainly work on NH36, ETA 2836 and Miyota 8200 (watch mod). My first attempts with these small parts were catastrophic, losing them most of the time! Also not having tons of money to buy tons of expensive tools, I make them as much as possible. Specifically for these parts, I made a small box out of plexigass to avoid losing them if they jump out and a small tool which makes the operation incredibly easy in few secondes without loosing spring. If it can help newbies like me, I would appreciate it. . If3 points

-

2 points

-

I know that there are 4 grades of ETA movements, Standard, Elabore, Top and Chronometer. And, as @JohnR725's pic above, shows, the top 2 grades use Glucydur balances - which you can tell as they have curved arms. The nickel plated wheels have straight arms. I always look for the curved balance arms when buying.2 points

-

If you check the pivots, and they look fine, then during installation I would investigate whether the stud needs to be deeper into its hole in the carrier, or if the spring has been deformed. I'm with Neverenoughwatches on that one. I just got done working on an old Illinois 18s which, when I first opened it, looked like the stud projected rather far up and out of the balance cock. More than most. When I reassembled after cleaning, it would not run right until I had pressed the stud all the way in, right up to the base of the hairspring. Once the stud was sticking up out of the top, she ran like a dream! The hairspring was not twisted on this watch, but I think it may have been fitted with a stud which was meant for a thicker balance cock. I see weird things on some of these antique watches. You never can tell sometimes. The watch wants what it wants. On most, the stud needs to be level with the surface; on some the stud is so short that it comes up just below the surface; and on still a few others it is best if it sticks up like a stubby periscope. If the pivots and balance and its jewels are all good, I'd look hard at how the stud is mounted, as well as the rest of the hairspring to see if it has been twisted.2 points

-

Are you sure both pivots are present, to me the wheel also looks to be not level. With both jewels removed can you see both pivots through the jewel hole ? I would go with one of the pivots is missing2 points

-

Replace it that is a horrid repair. You need to make sure the two holes are as near to the original to have a good fit you can always enlarge if needed. here are some that can help the first link is best. You cold look on ebay. https://www.cousinsuk.com/product/v-shape-by-size https://www.cousinsuk.com/product/click-springs-assorted2 points

-

1 point

-

1 point

-

1 point

-

What sort of spring is it? If it's a standard end, it's fairly simple to just push them in. Make sure it's the correct way up, and the spring is sitting within the barrel. The way I do it : I push it down on the spring with the flat end of some brass tweezers until the spring is flat with the washer, but still held in the washer. Then using the pointy end of the tweezers, I start working around the outer coils, making sure I push the spring end in first. If it's a T-end, good luck . There's a way to do it shown in the video (from 35m)1 point

-

I have more images out of the PDF. That would explain what you're asking for by the way he isn't the first to come up with a list others have done up before him. But I'm guessing because he lists every single caliber is a separate in the lists sometimes consolidate them probably what a split them apart is when the problem occurred. Which means it must be more like this you should build go through the list and look for numbers that are slightly increasing Watch Brand, Caliber, Size, VPH and Lift Angle.pdf1 point

-

Most were bought already labelled. The stems and staffs i have that are unknown i measure them with a bench micrometer and check them with staff and stem lists. Balancestaff.com have a huge database of staffs and stems. After much practice it now takes around a minute to measure them and can take up to 5 minutes to find a calibre match on the data base. The stems require taking 6 dimensions and the staffs 5. The unknowns are like treasure hunting, interesting when i find something high end. Have recently pulled out VC, Blancpain, omega, Patek. My reason for aquiring large amounts of staff stock as most watches i was buying needed a replacement. I didnt want to be in a position of searching buying and waitng separately.1 point

-

1 point

-

I would just keep an eye open on eBay it exists in a generic form it should exist sooner or later on eBay. Then I don't know if all the other US material houses charge the same shipping maybe somebody else. Then of course some of the other material houses in the UK perhaps may have it. Cousins isn't the only mature louse in the UK1 point

-

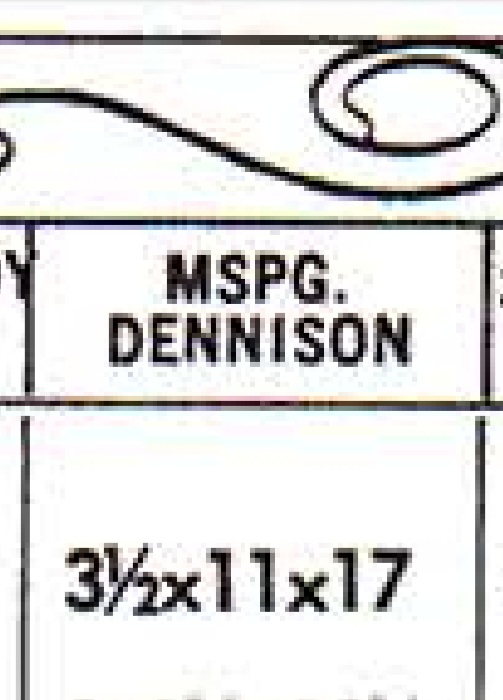

The Dennison width is the metric height ( ignore where it says metric width as in modern mainspring sizing it is known height )The Dennison strength is the metric thickness. In the old sizes the third measurement was given in inched this we can easily convert to mm. The last modern size is the barrel inside diameter in mm, not really needed. Do their size specs look like this ? The last size is the length in inches here we can be a little flexible in mm. The fourth size in Uk is barrel inside diameter in millimetres that size is not used in Dennison sizing of the mainspring. I guess the reason to use Dennison for very small dimensions is ease of quotation compared to 0.00xx" America still use imperial measurements far more than we do.1 point

-

Thanks for asking and reminding me to return to this thread! What I found was a decent movement (although somewhat rusty around the keyless works) in dire need of a service. The Hamilton brand name was to be found nowhere on the movement when I took it apart. The inside of the case back was stamped "Made in Hong Kong" but the back of the dial was stamped "Swiss-made". It's difficult to tell whether it is an official Hamilton or some sort of Franken. Everything feels like it's good quality and the case even has drilled lugs, but I haven't seen any other Hamilton Khaki housing an ETA 2892-A2 movement. If you want to get close and personal with the movement in this watch you can check out my service walkthrough of it.1 point

-

1 point

-

Looking for information on how to use a screw-head polishing-tool and a Jacot-tool, this Grumpy (but with fine humor) guy takes his time to explain & record it very well. I haven't seen any of his watch repair video's jet, but if they are of the same quality, it may be worth to check him out; https://www.youtube.com/@grumpyswatchrestorations/videos1 point

-

As paul quite rightly says the problem looks more to do with the balance wheel not installed correctly or a broken pivot.1 point

-

Usually a twist somewhere on the spring. If the spring look flat when unassembled then the likely cause is at one end of the spring . The spring is held fixed at two points the collet and the stud, so a twist at either end can make the hairspring raise up like this. In my experience its almost always at the stud end unless someone has been faffying around with the collet. Mostly due to the balance assembly being removed a few times. The weight of the balance wheel tucking down where the hairspring is pinned at the stud. If handled roughly and stretched this is where the twist can happen.1 point

-

Cousins do all types of click spring and i am sure they do that type, the only thing is you have postage and packaging on top if you live in the UK someone might have a spare one they can send you, i will have a look later today to see if i have one and get back to you if i do.1 point

-

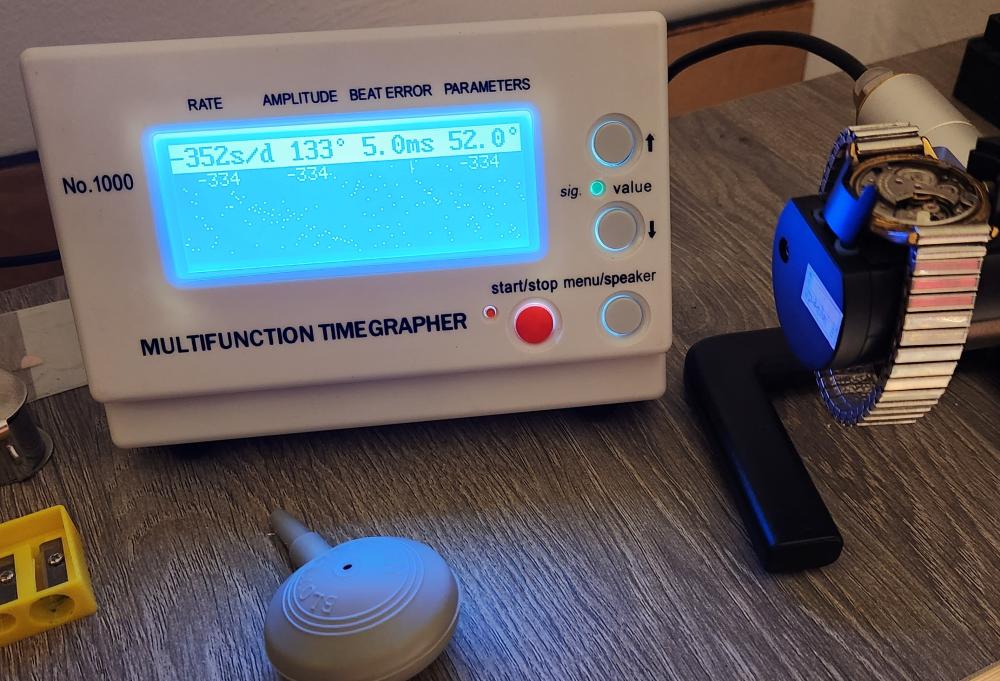

what is your definition of vintage? then you won't find what you're looking for. The group will be impressed though but Omega would not be impressed at all. This group you've achieved 300° amplitude outstanding. Silly watch companies like Omega or Rolex they're more concerned with whether the watch keeps time. That's because the silly customers want their watches to be on time and customers typically don't have timing machines to see if there amplitude is within proper specifications. the only time you Rolex Omega are concerned about amplitude is if he gets too high that could be an issue but on any of the timing specifications all they're concerned about is at 24 hours typically in a specific position like one of the crown/pendant positions does it have a minimum amplitude. then without a specification of what vintage is the end are working instruction number 28 they have timing specifications for hundreds of watches but anything that they don't have timing specifications for falls into the category in the image below. although this isn't even entirely complete because you'll depend upon the grade of your watch a chronometer grade watch should keep better time keeping them a generic watch and with each of the increases in a quality of timing the increase the number of positions for timekeeping. So a chronometer grade watch the time and six positions and a standard grade they were usually time and three positions.1 point

-

how about a question for you we have a picture it says regulated. Now find the picture where it says unregulated see if you can do that. In the meantime here's a picture out of the bestfit book for the balance wheels. There is the hairspring that is flat there is the over coil no mention of regulation I wonder if that's an issue? Oh look there is the balance wheel for a cylinder and its regulated which is a joke because cylinders keep really crappy time anyway. So if that says regulated does that mean the others are not regulated? all the number refers to is a type of balance wheel with a flat hairspring. It doesn't give any specifications beyond that other than because you know there's a stud that should've been vibrated reasonably close depending upon the watch so that when you put it in slight move the regulator it should keep time. The part number in no way refers to quality difference unless? okay am attaching another image as far as I know on Seiko watches if you have a number I have Seiko this watch number there aren't any variations for that watch unless they change the letter on the end that can change things but only if the parts list of the technical documents says that it changes things wishful thinking cannot convert a plain Jane Seiko to a chronometer grade because you feel it should be that way the Swiss a little bit different so for instance the Swiss 7750 at least on the manufacturing guide that I have here three different grades if you want to use that term. So what is the difference well on the higher ends the mainspring is slightly different slightly longer running time little different physical characteristics probably made to produce a more even source of power over 24 hours.then you get the balance wheel and hairspring both of them are different on the higher end better temperature and better just stability. so found the parts list they don't seem to list the chronometer grade balance wheel as expected then they don't even list the other balance wheel but. I think when you're looking at the various descriptions up part number 721 balance complete you see the rewards regulated timed just a mean to complete balance you don't have to vibrate the hairspring for instance. I doubt you're going to find a part number 721 that says DIY you must regulate this yourself. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_77501 point

-

I saw the video on YouTube last week but I thought the acrylic sheet would get chewed up pretty quickly. Aluminium would probably be sturdier. I use a brass jawed pin vise from Cousins for inserting stubborn arbors. It holds the arbor very securely and so far has not scratched or damaged any arbors yet. Great idea. I've always wondered why nobody manufactures a winder like the types for clock mainsprings, which uses the original arbor and steel containment rings. Can you imagine if clockmakers had to buy a different winder for every movement they worked on? ($$$$$$)1 point

-

1 point

-

I've attached the parts list in case you need that. the parts list is interesting because it looks like the barrel says that sealed but the arbors available the mainspring was available separately so obviously it's not really a sealed barrel it was meant to come apart. then I will parts listing you can see when things are compatible with whatever but it does look like the barrel was actually meant to come apart because their separate components. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=LON_280 1559_Longines 280.pdf1 point

-

Can the rivet be drilled out or filed off? But you'll have to be very careful not to mar the brass plate.1 point

-

did you look at the link I had above? If you did you would find CROWN, WHITE 35M10NS1 Discontinued - Use J-35M10W oh dear is discontinued that's the problem that page you'll have to make one because oh wait are they suggesting a replacement. We probably don't want even waste our time on the replacement because we did it would take you to a link like this. It also confirms what I suspected it's a style of crown found on Seiko or other Japanese watches the part number is indication of what it is 3.5 mm for the diameter 10. Looks like it's available. http://www.julesborel.com/s.nl/it.A/id.7208/.f1 point

-

The bezel popped right off only because it was poorly glued on for some unknown reason , the facet spring still around the rim. The bezel insert is in fact identical to my Smiths diver also is the watch case, the crystal and the bezel apart from the bezel is possibly aluminium its extremely light and the Smiths is brass. The insert is resin filled as we thought, i now have to figure out if they can both be removed and swapped as i prefer the smiths brass bezel ho keep original.1 point

-

I think we need to redefine what question you really trying to ask. The chronometer grade balance will be different than a balance complete unless it's a balance complete for a chronometer grade watch. Chronometer grade balance wheels will be made to very exacting specifications with very exacting materials. You can't just take an ordinary Seiko balance wheel and make it up balance complete for a chronometer it has to be the right balance complete in the first place. So yes you get a Seiko balance complete to keep chronometer time but that would be in a Seiko or any watch for that you could probably regulated to keep perfect time on the timing machine but it won't be temperature compensated temperatures will screw it up all kinds of the things the screw it up. As far as a Intel Seiko part numbers are for the balance wheel for your watch if you do not have a chronometer grade watch you do not have a chronometer grade balance wheel so we need to redefine what the question who trying to ask is? now if you really want a chronometer grade balance wheel for Seiko you really need to get the Seiko watch that goes with it as far as I know I think only the grand Seiko's are chronometer grade. https://www.theseikoguy.com/grand-seiko-vintage/#google_vignette1 point

-

Dr ranfft lists one spring for entire L280 family, thats 281/1 & 284 and 285, then he gives the spring's dimention, so barrel complete or parts of any of above calibs interchanges.1 point

-

it's basically just showing that that balance wheel goes in either of those watches so both watches as far as timekeeping should be identical. the answer would be no/sort of yes but actually no. If you place a chronometer grade watch on a timing machine like the one we have at work and we time it in six positions you will find that the timing is all really really close the poise is practically perfect and the watch is really really close to zero and everything looks really nice but does that mean it's a chronometer grade watch no for instance come to where I work and my boss a modern or a Seiko for that matter or almost any watch and he will regulate it for you. Then he gets really excited that he's regulated to chronometer specification. So what does that mean dissenters they hairspring he regulates it's the beat is really tightly so fresh oil on and in multiple positions it looks really really impressive does that make it a chronometer no but he gets a printout enhances the customer and everyone's really happy their Seiko is now keeping time with the second a day except is it really? The chronometer specifications are timing over high not instantaneous on the timing machine. Although in order to time perfectly over time it still has to look pretty darn perfect on the timing machine but grammar specification is timekeeping over several days maintaining some very exacting specifications. https://mizeni.com/movements here is an interesting page on the website it lists the balance wheels in which watch they go in https://mizeni.com/parts/seiko-balance1 point

-

1 point

-

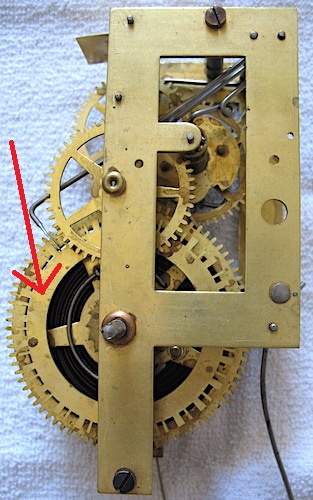

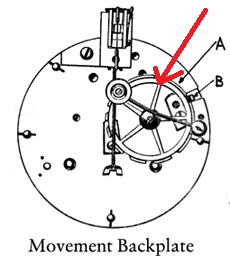

Can you show me the movement. The count wheel is normally the wheel on the strike side it is the wheel that is used to determine the number of strikes the clock makes. Here are two photos showing count wheel striking the first is from an American movement the second is from a French movement with the French movement the count wheel is on the outside of the back plate, the American one is on the inside of the plate. I have marked both with a red arrow.1 point

-

I picked up the Ansonia today. And while it is a strike, instead of a nice musical chime, you get a more musica............<doonk> noise. I also put the pendulum on it and gave it a nudge, ticking away but that is not right either. Tick, tock then a longer pause before the next tick, tock. So there are things for me to look for. The hammer doesn't strike the number of times as indicated by the hour. The hammer stays in contact with the gong after it strikes. And the tick,tock,,,,,,,tick,tock reason needs to be found. Some tools arrived today. One of them being a set of C ring spring retainers. Have got to get my mate up the road to laser cut the wooden parts to make a Joe Collins mainspring winder. Have got everything I need, so then I'll be able to do a bit more than look at them. I also have the Enfield coming from Darwin. My wife said after I picked up the Ansonia today, "Let's make this the last clock until you move some along". I'm going to be in strife when the Enfield gets here.1 point

-

No @oldhippy. It will sit with my ever-growing collection while I do more reading and educating myself. Getting c-clamps, punches and other things. Oils etc. I have to bite the bullet at some point and get myself some simple clocks as you suggested to me many months back. I have got myself some nice clocks now and the last thing I want to do is bugger them up. I have a bunch of brass so I won't need to worry about buying anything if I need some. Have mucked around a bit on the little Unimat which has been enjoyable. Fortunately, I do have a second Hettich which has the same movement as my grandmothers clock that I am restoring. So at least I have something simple that has the little intricacy of the light copper hairspring which powers the movement when the weight gets lifted by the solenoid. I have already reshaped the hairspring on the second movement as it was al bit out of shape. Have had to do a fair bit around the house lately and have not had a lot of time to myself. I do have one question if anyone knows? Is it normal for these bezels to be attached to the case using what looks like a couple of wood screws through the brass? I have an idea to fix this. Will say more once I get a chance to look at it.1 point

-

1 point

-

I'm so glad this topic popped back up. I'm new here and hadn't seen it. Blue is probably my favorite dial color, in contention with champagne. Even so, looking through my collection I appear to only have 4 watches with blue dials. Then again, my collection seems like it's probably puny compared to some of you here. In order of acquisition: Seiko SNKK45 ("Seikonaut"): Seiko SNZH53: Grand Seiko SBGA375 (it's hard to coax the blue out of this one - it looks black most of the time - had to get in bright sunlight for this picture): Bulova Precisionist 96B257:1 point

-

1 point

.thumb.jpg.80d166adeeb3ca46adc6e63cf014f236.jpg)

.jpg.183c04e02542d727b31bfc38e20b8ef6.jpg)