Leaderboard

Popular Content

Showing content with the highest reputation on 04/06/23 in all areas

-

Ok my pro watchmaker friends from another group gave me the go ahead to finally....finally close this thing up. They said the only thing they could think of i could still do is tweak teh regulator pins to fix the crown down deviation but taht it's so risky with these old type pins that they told me not to do it. 2 days on the wrist and it's gained 15 seconds and i haven't even done my final regulation so i'm confident it's finally done. Today the sun finally came out so i could get some proper beauty shots of it. I'm just in love with this dial. The blue is just stunning.6 points

-

Hi All, I just wanted to post something about my first try at temperature compensation adjustment. Basically I have been working on my first pocket watch from 1935 that turned out to have a cal 19.71 movement. I had got this running very well with amplitude DU/DD of 310 degrees at full wind and 285 degrees after 24 hours. I did have to change the balance staff as that was terribly worn. I did notice that there was a variation in rate due to temperature. Normal +3 SPD Hot -2 SPD Cold +9 SPD It appeared that the split balance was under compensating. I read the books that I had on the subject (De Carle and Fried) that suggested that If I could move weight to the free end of the balance arms then that would give more correction at temperature. The books even gave a guide on which screws to move to achieve different levels of compensation. I proceeded with caution and moved the screws indicated. I was then thoroughly amazed at what this 90 year old watch was achieving: Normal +3 SPD Hot +1 SPD Cold +1 SPD I have noticed that the poise is just a little out now (as it was before) but I should be able to adjust that with considered adjustment of the 4 meantime screws as that is where the heavy spots appear to be. That's a job for another day as I am still in shock. Steve.2 points

-

2 points

-

Fine emery grip paper double sided taped on to lollipop sticks, come in handy for allsorts of jobs like this. All done under a scope i would add to get the best fit possible.2 points

-

Probably better more experienced folks than me can answer. However if the instructions say to file it down I would first remove any flash on there. After that I would gently use high grit sticks to get it to the point it would just push in and hold. Lots of skill there to not screw it up just take it a tiny bit at a time when you get to the adjustment stage, maybe one stroke each side with something like 2000 grit. Tom2 points

-

Maybe its like the chinese destructions you get for flat pack furniture. Everybody ignores them and makes up the assembly as they go along. Personally i would have a reasonably tight fit but still have some glue on there as a back up. Can you be fully sure that the crystal is tight enough not to be affected by temperature changes ? Is there much of a bevel on the case front to hold it in place ? Are you able to bend and manipulate the crystal enough to fully utilise the bevel edge ? Plus you have to file the crystal's bevel accurately. I would say a touch of glue.2 points

-

2 points

-

Ultrasonics are fine for cleaning - the professional cleaning machines all use it. Also, IPA is fine for a quick final rinse for ALL parts - again, the pro machines recommend it.2 points

-

About a week ago I had a watch on the timegrapher. I wasn't thinking and put some case parts into the ultrasonic machine, which is about 15 feet away from the timegrapher. As soon as I turned it on the timegrapher readings went nuts, looking like a snowstorm. Turning off the ultrasonic cleaned up the signal on the machine. It's pretty interesting to see how much it affected the machine, still being quite a good distance away from it.2 points

-

Hi years ago when working in the computer industry we uses Rs232 transmission with Norton line drivers to boost signal loss over distance . In an electrical storm induced current in the lines used to fry th Sn 75110 driver chips, we put them on rafts for easy changing.2 points

-

I would assume that the EMF is overcoming the shielding on the wire from the microphone to the unit. The microphone turns noise into electrical signals and the EMP is interfering with that.2 points

-

Tell us about the time you used it to pick up a cap jewel2 points

-

This is my first time trying to restore and fix up a mystery watch from ebay. If anybody who's worked on these old 70's seikos wants to follow this thread your wisdom would be appreciated! Picked up this guy for a song on ebay specifically because it's one of the nicest condition ones i've seen with an original dial. THe hands are a little patina'd but the dial seems perfect other than two missing lume pips. I love this dial. THere's no real deep scratches or gouges in the case just a MESS of desk dive scratches that should polish out real easy. It's non running, the date and day roll over with the hands but the day does not roll over if you use the second crown position. The crystal would polish up nicely but there is sadly a small crack at 12 oclock so that will have to be replaced. Opening it up the movement looks pretty good. The balance will move with some pretty strong blows from the bellows but things seemed pretty gummed up and there is what looks like either really old solidified grease or oil or maybe glue under the reduction/ratchet wheel screw. Not sure what is up with that. I'm unsure what is going on with the hairspring as i dont' know what a good one in this movement should look like but it looks a little strange inbetween the stud and the regulator arm. I hope it's not shot but if it is i got a parts movement that does barely run so if i have to scavenge one then hopefully that one works well. The movement looks pretty clean other than some light powder rust. Guess i'll pick up some evaporust unless other people have a better method for de-rusting. Under the caseback is what looks like the signature of a watchmaker and v-9-24-87 Amazing to think this thing hasn't been serviced in almost 40 years. Here's hoping that's all it needs now! I'll be diving into this next weekend probably. Real excited to give this boy some new life as i just love this funky 70's design on it.1 point

-

ideally the mean time screws should all be even unlike two of yours that are very grossly out of adjustment. and yes it's amazing what a railroad grade pocket watch will do if it was properly adjusted at the factory and hasn't been played with by inexperienced people which typically is what happens to watches over time. That includes things like Rolex watches that come in that are out of poise because people adjusted the weights inappropriately.1 point

-

Looks like a good collection. Do I spy some Gridfinity bins? I like that parts tray in the tin.1 point

-

I've added some other things to the collection. Redesigned the tweezers stand to make some other tools handy. On my workstation there was a keyboard tray that was doing me no good. Then I discovered the Gridfinity storage system. This seemed like a great solution to use that space to keep certain tools and supplies handy. I printed up all sorts of bins and customized holders to fit into the base grid. As my needs change, I can rearrange, add, and remove bins.1 point

-

The Date lines up at 3 and 3.8. The Day needs a specific wheel for each orientation. Seiko slightly change the orientation from true 4 in order to reduce the parts count. The degrees of change are the same so it will line up in either position. With the stem in for orientation purposes, you will see the alignment of the Date wheel at 3 looks correct. If the Day wheel doesn't look right, it is probably a 3.8. Rotate the stem to about 3.8 and check if the Day and Date are aligned at about the 3 position. You can use a paper straight edge to help you visualize the alignment. Once you have seen it a couple of times, it is easy to spot. The inexpensive ebay movements are almost always 3 o'clock Day/ Date and use the grey spacer. If modding a real Seiko case, you will need the black spacer. Most of the Aliexpress cases work correctly with the grey spacer.1 point

-

1 point

-

Define "tell the time". It knits a scarf, one stitch per half hour, so it tells the time about as accurately as a sundial, so long as you are prepared to count stitches.. On the plus side, if you wait a year, it will have knitted you a 2m scarf. Besides, if you want to know the time, you ask a police man.1 point

-

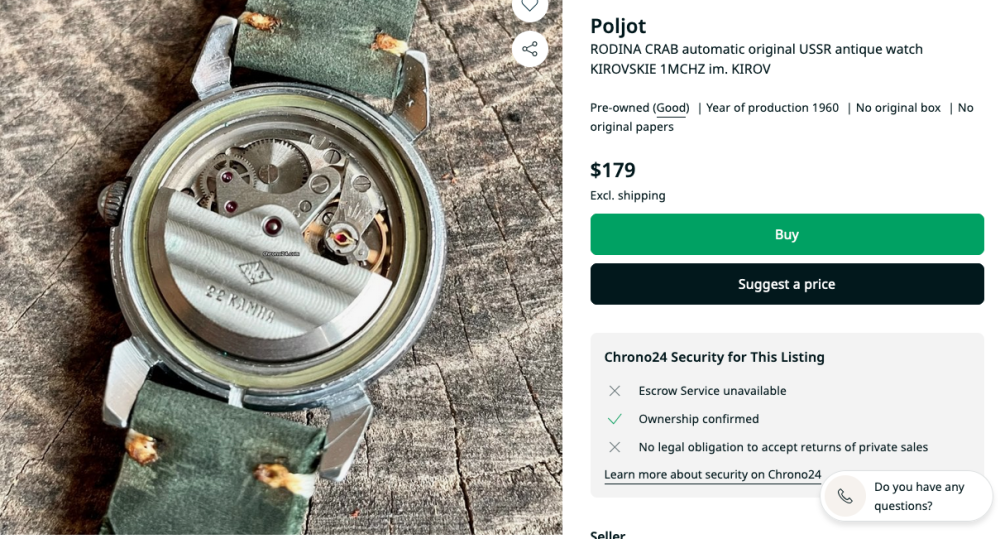

That's it, and it explains the extra holes and jewels too. It's a Poljot 2415A (Rodina) which is missing the entire auto-wind module. Not to be confused with the Poljot 2415 (Orbita) which has a fully integrated autowind rather than a bolt on module. I should have twigged looking at the case back which is designed to accommodate the autowind.1 point

-

Electronics might as well be magic to me so i have no idea how any of that works but that sounds real plausible haha. Probably why i like mechanical watches so much and not quartz.1 point

-

Oh yeah and cuz i forgot to do so. Thanks to everybody here who helped me out on this one. this was a real learning experience. I appreciate all of ya! Since i posted my timing i've checked it a few more times. ALL the numbers and signal have improved a lot since it's been running for a few days. Still got that deviation in crown down rate but all my lines are straight with no fuzz or missed ticks. This thing is running SO amazingly well now.1 point

-

See the picture Endeavor posted. A pivot ( of the gear in auto winder's module, goes through the cut out to reach a brass/ jewel hole ). This must have been a popular watch for it's rugged self winder.1 point

-

1 point

-

The inner threads are opposite threaded compared to the outer threads. Remove the limit stop in the back. Unthread the handle up all the way on the big outer threads. Then pull as you turn the opposite direction. That should get the handle to unthread fully. Clean things up and apply some grease to all of the threads.1 point

-

It's still a works in progress. It was my parent's room and it still has some of their old stuff and junk accumulated over the years.1 point

-

1 point

-

Superglue is not really very good in tension, designed more for shear applications. Best product I have used in similar situations is Devcon Steel. This is an epoxy with steel granules. It is easy to apply with a needle or pegwood and has a tendency to flow into a nice fillet. Can be filed afterwards if required. I normally leave it a few days in a warm place to fully harden. I think Devcon did other metals as well. Not sure if they are still trading though.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If it is a complete unit you don't need to open it. It will have the correct lubrication all done at the factory.1 point

-

I'll have you know smoots are still a relevant unit of measure. When I lived in Boston I regularly ran across the Harvard Bridge which has the smoot gradients labeled on the sidewalk. My watch was set to measure the pace of my runs in smoots per fortnight. My wife says she still loves me anyway. I'm lucky that way...1 point

-

1 point

-

If you think this is confusing what about this lubrication at the link below Let me highlight the important things from the link below. It comes in a larger bottle such much cheaper than the normal oil we use. The viscosity is 110 is makes it more fluid than 9010. So this is a extremely light oil but look at its description it's good for "Synthetic oil especially developed for alarm clocks & pendulum clocks. Can also be used for watch escapements" So apparently oil Lighter than 9010 is ideal for clocks or watch escapement's? Then while you're there you can get the spec sheet.So the definition of synthetic is neat's foot oil which is not synthetic that I'm aware of. I believe that would be an organic components. Then the rest of it is paraffin oil which I suppose could be synthetic. I'm also attaching the lubrication chart test specifications.. Specifications and you'll notice all the lubricants are superthin and the chart really doesn't make a lot of sense at all. Which is the typical problem with descriptions of horological lubrication's of basically descriptions in the technical specs suck. Normally were stuck with the viscosity but even here the viscosities are way too light and yet the light oils can be used for clocks so viscosity apparently flies out the window for making decisions. On the other hand the oil below is a lot cheaper. So it isn't entirely sympathetic like it says on the website. https://www.cousinsuk.com/product/novostar-type-r Oh and then 9021 of my watchmaking friends said 9020 was obsolete. Because of you look at a lot of modern tech sheets it's no longer shown as a lubricant. It's basically 9010 and HP oils. Oh and there was something bothering me about 9024? Notice at the link below if you go to the top of the page it's in the category of lubrication for Synthetic Oils for Polymers? Then those pesky words again because look at the description that cousins hasWhere the oil is good for high temperatures we don't really care about that.But it's back to the reference of is used for plastics? So it looks nice on the spec sheet where it doesn't really bring up the plastics aspect. Okay I got oh improve my reading skills if you go to the PDF for 9024 and read the wonderful words it says at the end of the paragraph is says for plastics. But the technical features in addition to the word plastics they do have the word metal. https://www.cousinsuk.com/product/moebius-9024-syntaviscolube?code=O1073 So if you want to go insane read all the technical descriptions on the cousins website of everything related the horological oil and see if you can figure out what would be a suitable one to use for anything? Oh maybe a book would be helpful? Yes it's a little out of date synthetics didn't exist but still it's of interest. https://archive.org/details/frictionlubricat00lewi1 point

-

Yes, absolutely. Here is how I keep track. Once I take a picture, I know which screw goes with associated plate...and... Hearty AMEN! Since the screws remain in their compartment and the picture associates the plate, there is never confusion. My bin is printed with my 3D printer. Never seen a commercial solution that I much cared for. Amen: We are brothers from a different mother!1 point

-

Red Dot Diver is a nickname and this is actually a Marlin. Based on the hands I'd say it was second generation and from 1984. Yes, you will need to lift the bezel and the crystal to remove the movement. I don't see anything wrong with the crystal that a good buff and polish won't fix. What is wrong with the movement? BTW - you know one diver leads to another...like this The diver upper right was the latest addition.1 point

.thumb.jpg.6610b6556afa25062bcb95a61aa7e1ba.jpg)