Leaderboard

Popular Content

Showing content with the highest reputation on 04/01/23 in all areas

-

Today, more fun with junk. In this case, its a reverse quartz conversion. I picked up the little quartz pocket watch for 99p because I thought the fake mechanical movement was was worth a few pictures. I mean these things are a cheap as chips anyway, so why make a fake skeleton mechanical version of what is pretty much the cheapest mechanical watch still in production. However, someone, somewhere felt it worth the effort, so fake cheap quartz ersatz skeleton mechanical watches are a thing. I guess you could argue that they are more accurate and reliable than the real thing, but then so is a Casio F91W, so if you want accurate then perhaps it might make more sense to buy a "proper" quartz watch. Anyway, I digress. When it arrived, I noticed that the movement insert appeared to be "convertible" to a real.. cheap Chinese skeletonized mechanical movement, and since I have a couple of those lying about, I decided to give it a try. What more can I say. Five minutes with a scalpel and some sandpaper and the movement holder was converted. The stem from the original mechanism fitted the extended crown tube from the quartz version perfectly, so there wasn't even any faffing about. It just worked. So now I have another skeletonized Chinese movement mechanical watch for 99p plus whatever the donor cost (probably also 99p). Its interesting to see that these things are so "boiler plate" in their construction that you can do this. It winds, sets, runs, and the button on the crown operates the front cover perfectly.4 points

-

I suspect that the central shaft which clamps the table is seized, preventing the locking cam from doing anything. You might be able to free that up with a sharp tap from above using a brass drift so that you don't mark anything, and that should sort it out although if it were mine I would strip the frame down completely, clean it up and re-lube it.3 points

-

...that I bought but not the first I completed. It's an EBay rescue non-runner- the first one I intended to get working. Well today it finally happened... Fortunately the Ebay-ers couldn't drop a quart of oil in it because they couldn't get the case back off. I had to run it though the freezer a few times but it eventually popped right off but I had to remove the bezel to take the movement out the front. The movement was dried up but otherwise unmolested. Cleaned up nice. New lume, two new springs and a Sternkreuz from Cousins, then a few days with the movement under the dome. I spent the morning with the tg, pad and pen getting it closed in- so far so good... (disclosure: some lizards were harmed in the making of this watch strap..)2 points

-

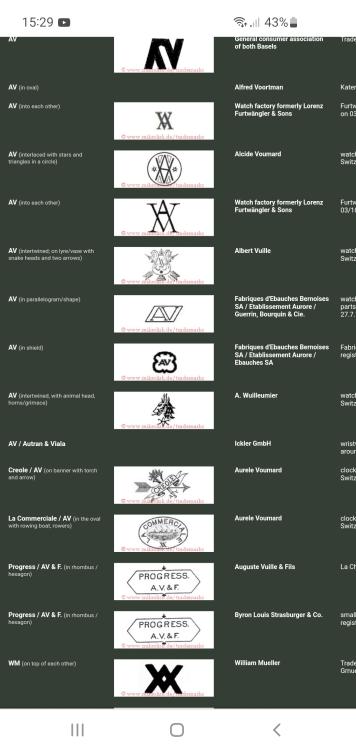

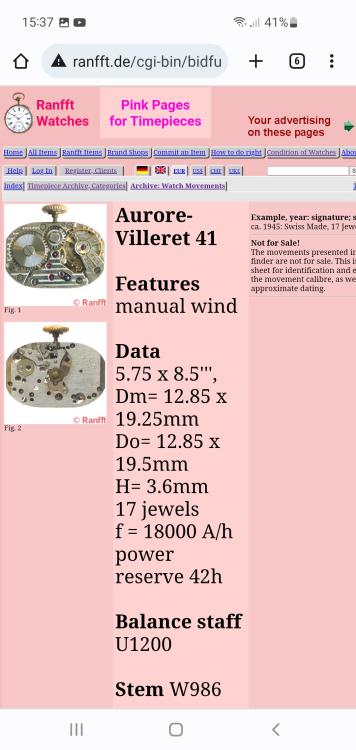

Go on to Dr ranffts database, to see the entire family of Tissot 781, Enter the keywords ; TISSOT 781 RANFFT the minute wheel off of at least some of the manual winds should enterchange with the variant you have. Next go to Julesborel site to find the minute wheels they have listed to readily have available for sale. Expensive You should find out what caused the teeth to shear off, if such fault remains it might damage the new wheel too. Possible causes generally are; Loose or worn locating axle/ pin for the minute wheel or adjacent one. Issues in between the minute wheel and canon pinion side. Good luck pal2 points

-

If the locking knob is moving I would think the cam is ok, it is pretty sturdy. I would think that it would be more likely that the axle in the centre of the table is seized. The screw that is stuck will be what is keeping the locking mechanism in the stand, I would look at getting that out so your earlier thought about getting penetrating oil is a good one. Once that screw is out you should be able to just pull out the locking cam and locking knob easily. Tom2 points

-

I sent in photos of the issue to AliExpress and requested a refund. I already have a resolution. They provided a full refund and I don't need to send the tool back. I would have been happy with a partial refund since I was able to fix the press. I put in a proper sized grub screw. It took a minor bit of sanding the bottom of the screw, to make sure the collar would clear the screw head. Secured it with a dab of loctite. Cleaned up the gouges in the shaft keyway. Loctited the rest of the screws and greased up the inside and outside of the shaft. The press cycles smoothly now. There's no issues with alignment of the top to the bottom. I won't be making a habit of ordering via AliExpress, but I can see doing so on a select basis. Looks like we were posting at the same time.2 points

-

I did point out to read my comments first. It was the only one I could find that was how to take part a Smiths Enfield Strike.2 points

-

There are probably different systems to lock the table. I had for a short while a Helios staking set and that one had a different system. For whatever it is worth, I took a picture of my Boley set locking system. The big knob pushes a tapered pin forwards. The taper pulls the center-pin down, locking the table. Hope that may help?2 points

-

1 point

-

Hi find attached sheets for thr tissot 781-1 Hope they are useful for you. 2790_Tissot 781.1,782.1,783.1,784.1.pdf1 point

-

1 point

-

The Wittnauer 11ABC is actually an AS1395, try looking for documentation for that.1 point

-

1 point

-

Hi after much goofing around on the net I found out its most likley an A Schild cal so far underermined, inported to the UK by Geroge stockwell Stockwell and co. Old Hippy was right it tapped out. Under a normal loupe it looked solid but under hi magnification one could discern the join so with a bit of gentle persuasion it came out ok. so cheers Old hippy. In all the years I have been at this game thats the first tapout I have had. Its now in bits being cleaned ready for the re assembly.1 point

-

No, but I bet you said this one tool is outside my budget but this other tool is within budget and it will do the job. As a hobbyist, I don't need an entire pro level set of tools, and frankly, I don't have the budget for that if I was so inclined. I have my share of top quality name brand tools, but on others, I did look at less expensive options to stay within my budget. I do also have to maintain some domestic peace and not go too far overboard.1 point

-

1 point

-

I have never said this tool is too good I should have bought the cheaper one.1 point

-

It is missing a few key components.. like perhaps a case, half a strap, a winder and crown, but it does have a crystal.. of some sort.1 point

-

Ok having no choice and bearing in mind its made of wood so easily repaired, I broke it open through the top. And low and behold it has a tin vibration plate that connects to the tin disk, or did until I broke the solder join. So Hector you are right it's a form of amplifier intended to amplify the sound of movements. What an interesting peice of kit, now I will put it all back together and have a play.1 point

-

1 point

-

That it turns through an arc suggests an eccentric for sure. On many things that use an eccentric to clamp there is an adjustment; typically the part with the radial hole can either turn in relation to the piece getting clamped (the table here), screwing in or out, or, there will be a screw in the end of the shaft that the eccentric actually works on that can be screwed in or out. Once you get it apart it should be evident. This is the eccentric clamp from my big lathe, with a screw for adjusting. The second pic is from my small lathe, the "t" section is threaded and can screw closer or further from the hole, and is locked with an axial set screw. These are eccentrics from lathes but the concept is the same. Not all eccentric setups have adjustment though; there you have to get creative...1 point

-

1 point

-

Ok thanks for allying my concerns. I have such bad luck with ebay. I'll report back.1 point

-

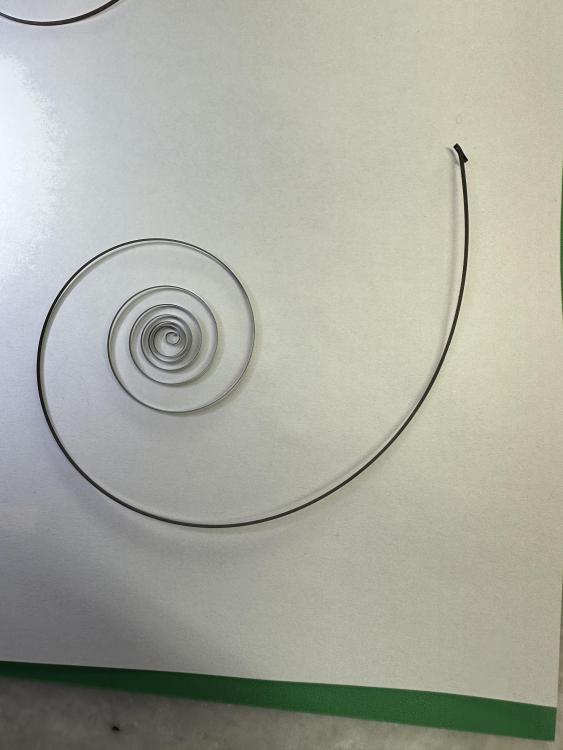

I rather think that you will find it is supposed to be twisted. ETA used a similarly helical stem on the 2783, there is a discussion about it here. I don't think that yours has become twisted through abuse, the amount of torque required to do this would almost certainly have caused the stem to have sheared, probably in the threaded section.1 point

-

I was thinking the same; it's study stuff and won't break that easy, by hand that is. I would have been more worried if the knob could turn 360 degrees. Since the knob can turn only 180 degrees means that there is resistance, therefor I'd assume too that the shaft & cam are okay. The center-shaft is a precise fit and with some debris or rust in between, it could easily seize up.1 point

-

that's an interesting country you live in. I heard a rumor that they might manufacturer watches their in fact rumor has it they been doing it for a very long time. That means conceivably tools materials supplies can be found in shops. Unless of course it's all going to eBay now but I'm guessing at one time you could find nifty stuff in shops. Perhaps as nickelsilver appears to live in the same country could enlighten us as to whether there still shops selling used tools and supplies? unless of course they've embraced eBay and it all disappears the eBay.1 point

-

The dial has to go out through the front. There is a metal bezel holding the acrylic crystal in. You can try using a razor to wedge under the bezel and lift it off. Look for a cutout around the bezel to wedge the blade in. Slip the blade into the notch and slowly rock it to create a crack, the work your way all around the bezel until it pops off.1 point

-

Yes, the Helios-set had a different system. I never took specific pictures of the locking mechanism, however on one of my pictures you can just see the knob with pin. As you may be able to see, the end of the pin was off-center moving the center-pin up & down. It may well be that your center-pin is stuck?1 point

-

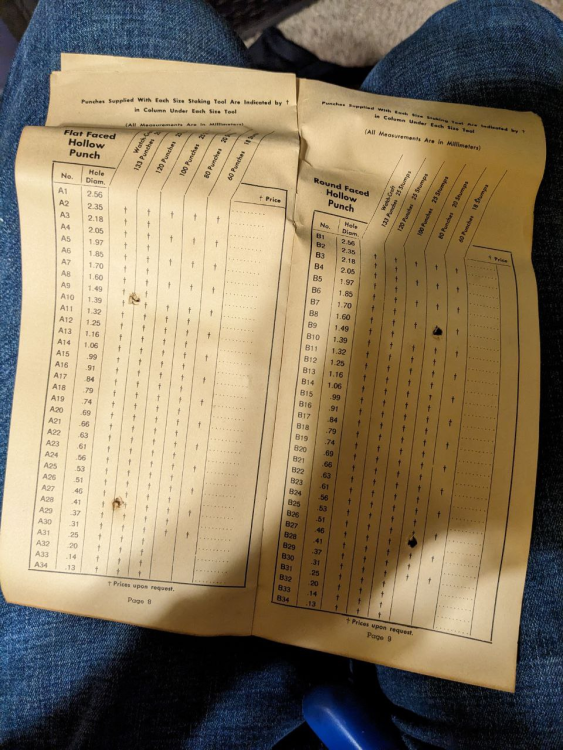

Heya So the staking set arrived. The punches short of not having a full set and the thing itself appear to be in great condition and just need a bit of derusting. My concern however is that there's a good bit of play in the table on the thing yet the knob on the back does nothing and rotates a little less than 180 degrees. I have a feeling this thing is so old there's probably stuff rusted and seized up on it and it just needs to be taken apart and derusted and oiled up in a few spots. Here's a vid of the wobble on the table. https://www.dropbox.com/s/7k86sh2mcv0vdfo/PXL_20230401_024922606.mp4?dl=0 Turning the knob doesn't seem to do much of anything. People more familiar with this, your input would be appreciated as i gotta leave this guy feedback or decide whether there's soemthing wrong with the thing. I assume it's an old tool that needs a little TLC. There's these two screws on the bottom, I assume i need to adjust these to deal with the table play and disassembly. I tried the larger one and it is totally and uttelry seized up. Guess i'll have to get some penetrating oil. One neat little detail is that this came with the original booklet! It has a list of all the punches and the punches are all labeled so it should be real easy to complete this set and keep an eye out for deals on ebay. Ok this is wild. It came packaged with crumpled up newspaper, really old from chicago. Look at the headline on the day this paper was printed. Not watch related but very interesting.1 point

-

1 point

-

maybe I'm having a dyslexia moment and reading this backwards? On vintage watches a lot of times it's just a pin sticking out the same as a lot of mainspring winders have a pin in which case you can wind in either direction. But typically arbors have a shape so they can only grab the spring in one direction. so if somehow the spring goes in backwards it won't catch and it would just slip forever making that familiar clicking sound which is good versus destruction if you could actually wind it backwards.1 point

-

0000 wirewool and a little oil, then i use autosol to give a final polish to them.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

Hi welcome to the forum. Pictures with the questions help a lot and slow members to see the offending watch. Cheers1 point

-

1 point