Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/22 in all areas

-

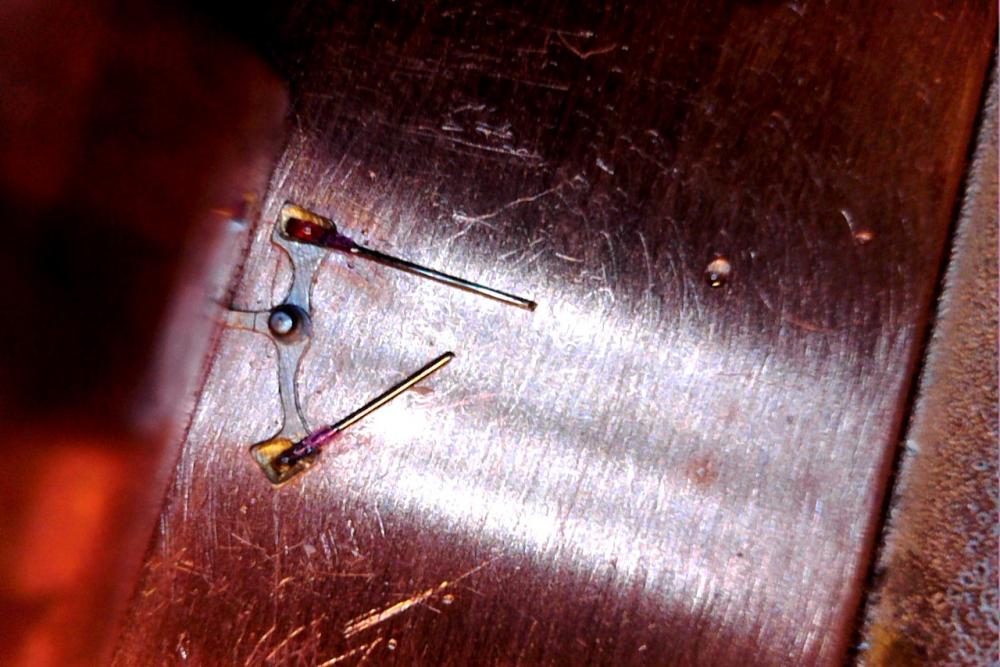

Just an update on how I got on with the pallet-jewels of CousinsUK, or rather Bergeon. As described above, since the escape-wheel was running on the low side of the fork-jewels, it would have been nice to get jewels with the correct fork-slot size and higher than the thickness of the fork. The jewels would than "stick-out" underneath the fork when installed, covering the escape-wheel teeth fully. I didn't get the desired jewels, so some improvisation had to be done. In order mount the jewels higher (or lower if you wish, with the fork in the correct position) a 0.2mm SS-wire was used as a temporary "filler" underneath the jewels. This worked very well. Not having the jewels with the desired height, it was a total pain having to use these "filler-wires" each time the setting depth of the jewels had to be adjusted. Not having the proper equipment either, it took me many, many times to install the fork, check the setting depth, taking the fork out, place it on the pallet-warmer, insert the 'filler-wires, heat everything up and adjust one jewel at the time. Initially the comment @nickelsilver wrote (https://www.watchrepairtalk.com/topic/23176-1975-omega-861-amplitude-after-24hrs/#comment-196690) was above my head. But now, after having played for days with these jewels until I finally got them right, I fully understand what he, and @JohnR725 said. Drop-lock, draw (run to banking), total lock, horn clearance, safety-pin clearance and very important: moving one jewels effects the other, have become fully clear to me. A very important lesson learned and I realize now that adjusting the jewels on the 1975 Omega 861 isn't going to be as easy as I initially though. The Omega has a shallow total lock on the exit and a heavy total lock on the entry jewel. Pushing the entry jewel in means extending the exit-jewel. Anyhow, the new Bergeon jewels are installed at exactly the correct height, or low, so the escape wheel teeth do run fully on the impulse planes. Now I can concentrate on the balance timing screws So, thanks to all for your excellent help and wishing you already a very prosperous 2023 !!7 points

-

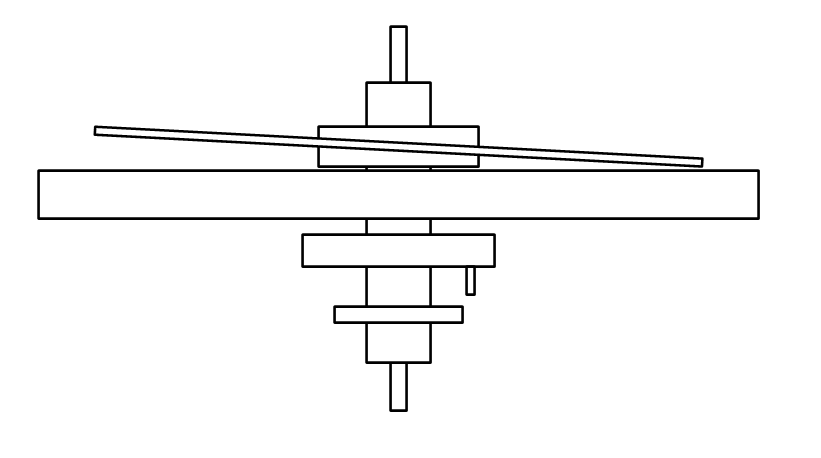

Yesterday I was working on an Elgin with poor amplitude. I looked at under the microscope and could see some vertical wobbling of the hairspring but really could not tell if the hairspring was hitting the balance arm. Given my limited experience, I was hesitant to mess with the hairspring because, other than this slight wobbling, it looked good. Nevertheless I removed the balance and observed it outside of the watch and determined that there was a slight bend that was likely causing the hairspring to hit the balance. I would say it looked like this drawing I show here. Here is the amplitude I observed. I made a number of micro adjustments with my hairspring tweezers until I got it pretty level. This took me about 30 minutes being EVER so careful. Here is the amplitude after making the adjustment. Next I have to regulate it. Once I got the better amplitude, I stopped for the day!!3 points

-

Hello and thanks for accepting me, I have been collecting Soviet/Russian watches since approx. 2019. At that time I had quite a vague (actually almost none at all) picture of the fundamental functions of a mechanical movement. Inspired by another comrade on this community I decided to give amateur watchmaking a chance and have since then started diving into this endless world. Well, let's say I am still snorkling, starting with Vostok 24xx movements. Still learning I am looking forward to take part of the experience of comrades in the WRT forum. My goal is to continue lerning more about serviceing and fixing mechanical watches, mostly concentrating on Vostok, Raketa and possibly, at some point, be able to service some of the Poljot 3133 based chronographs in my collection. One thing I have learned is to let the process of amateur watchmaking take its time. Best regards and CU / Johan3 points

-

3 points

-

Hello Johan and welcome to the forum. I have added a document that you might find useful. TZIllustratedGlossary.pdf2 points

-

Update: The calendar is still changing reliably 3 weeks after bending that detent spring to reduce its tension so I am going to call this success.2 points

-

2 points

-

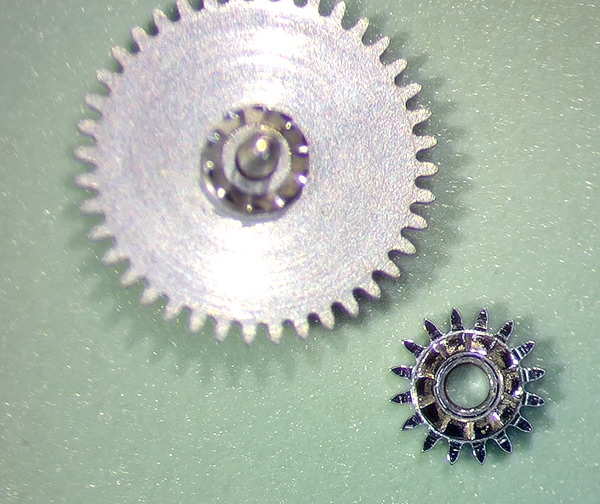

One of my favorite 1970's Bulova with that red crosshair accent on the dial. This was my first service of an automatic with Bulova's 11ANACB own spin on the reversing wheel design, similar to how the winding and sliding pinions interface so that when the wheel turns in one direction it locks but slips when turning in the opposite direction. It only needed a cleaning and a new setting lever spring.2 points

-

Thought I would start a new thread rather than tag on to my last one about a broken motor. This is my second L&R restoration project. Harder than the first because of the bad wiring and broken brush housing. As noted in the earlier thread, I 3D printed the housing fix, and performed a complete rewiring of the motor. This thing was hacked by some previous owners--not unusual for this old stuff. The lamp was replaced with a neon one. The heater appeared to be taken from a coffee machine!!! Geez! What a mess it was. All of that is removed and I have ordered the correct lamp. This model L&R used a 220 ohm 50 watt resistor as the heating element. Impossible to find so far, so I may opt for a PTC heater (ordered one from China). No final decision on that. The cleaning basket interface is not shown in this picture, but I do have it. What I do not have is the three-tine spring that interfaces between the spinner and the basket. I stole it from this unit for the earlier one I restored. These are impossible to find--at least so far. I think this was originally black, but not sure. Should I paint it???? Anyway, it is at a stopping point until I get the needed parts...maybe finish next year.1 point

-

1 point

-

This really has me confused. Have you now been able to determine that this is by design by Omega? In my (limited) experience the locking depth should be the same on both the entry and exit jewel, no?1 point

-

Hi NEW. Get stuck in plenty to learn and at 55 plenty of time, you are never too old to learn. All the best1 point

-

Hi as an old git nearing eighty, diabetic,arthritic hands worse when cold, eyesight not too good but do ok. I am still working mainly on clocks but doing the odd watch also as mentioned good light even breathing and patience and knowing when to walk away and calm down, Doing the job it just takes longer at my age there is no rush. That’s why it’s important when answering queries be mindful that not all of the posters are fit young men in their prime with full faculties and be considerate.1 point

-

"Cheap Timex" and "Hard to service"? Them's figthin words partner! I may have worked on one or two or 5000 vintage Timex and will say with 100% confidence that from the factory no glue used on crystals. The red dot diver has a very low profile crystal and it requires the use of a crystal wrench to lift off. Or you can use the internal air pressure method. I'll let you research that one. Before adding some additional tips for the red dot.1 point

-

Hi LWS. In addition to a dial washer I have also found a divot in the plate for the same reason, increasing the endshake. Don’t be tempted to polish them out .1 point

-

From my experience doing other things that are very much about precision and it works for me in the little watch repair I have managed so far. 1. Breathing, keep a steady relaxed breathing regime. 2. If using a loupe always keep bothe eyes open. It can take a lot of practice but not doing this creates an imbalance between the eyes which will cause problems. 3. Use the minimum amount of muscle tension to perform the task. This extends to the rest of your body, not just your hands. you can do it, it just takes a bit of effort working a way that so few people are used to. good luck and I hope this helps in some way. Happy for you to DM me for more information. Tom1 point

-

Outstanding! Really neat to see you accomplish this, it's an inspiration. Cheers!1 point

-

I keep thinking about this imaginary conversation as I apply for watch school - "Yes! I want to repair watches!" "How are your eyes and fine motor skills?" "Well, my eyesight is crap. I have age related macular degeneration, and get poked in the eye once a month with a needle to keep it from getting worse. My hands shake like a leaf in a gale, hard to keep things steady." "Go away" Like you, I use magnification (microscope) and tons of light to compensate for the vision problems, so far so good. Tremors are a little harder. If I try and pick up a part with tweezers and hold it in mid-air, I can't keep it still. So, I've learned techniques to help with that, basically always brace the arm and hand. I had a bit of trouble putting a balance in a pair of calipers yesterday, so I changed the way I was doing it so that everything was braced against the bench surface, then no problem. I've even mostly given up caffeine, anything I can think of to keep steady I try. Even paying attention to how tense I'm getting can make a difference, if I find myself concentrating and tensing up, I stretch, take some deep slow breaths, and try to get Zen . It helps. Unless something drastic happens, I think I can keep this up for quite a while. I've read about some positively ancient watchmakers who are still at it, so I know it is possible. Cheers!1 point

-

Welcome to the forum. I have a few Russian watches - Vostok 2414, Poljot 2409 and 3133 ('Blue Angels', the first chrono I serviced). From my experience of Russian watches - The quality isn't bad, mine all run well. The watches and parts are often cheap, so good watches to learn on. The only differences I found from Swiss movements - you will often find spacers under the balance cock and the mainsprings can be a bit harder to source - 'T' ends seem common. Good luck1 point

-

Hi Depending on the movement fitted to the watch a 2 sec jump or a 4 sec jump is idictative of the battery getting towards the end of life and needs replacing. never leaave a dead battery in a watch as they degrade and leak and corrode the metal contacts and in a worst case the entire watch.1 point

-

This is a sweet looking watch, all those red accents really work. I just wish they had left off the Westclox emblem or made the wordmark a lot smaller. It's the same symptom that usually puts me off of Orient's offerings; too much logo.1 point

-

1 point

-

Hello Johan, welcome to the WRT forum and good luck with your forey into horology.1 point

-

A few weeks ago I purchased an L&R Special cleaning machine from a member of this forum. Well wouldn't you know it, a few days ago I was asked by a local hobbyist watchmaker whom I've gotten to know if I'd be interested in purchasing his Elmasolvex SE machine he recently acquired. I'm not sure if he just needed money quickly (I didn't ask), but I was offered it at a very steep discount over it's normal selling price. Even though I now had a freshly rebuilt L&R Special, I decided to move forward with this purchase. I knew I wouldn't come across this opportunity again, and I can sell it on eBay for a decent profit if I choose to. I made the purchase this morning. I was told this unit was only used a couple of times. If I didn't know any better I'd think that this was brand new. There isn't a mark or scratch to be found on the unit. The jars are perfectly clean, the seals look perfect, etc. I even got the original shipping box and packing materials. I'm pretty happy I was able to pick this up. I'm going to give it a try in the next few days. It is honestly overkill for my needs, but it was too nice of a machine to pass up for the price I was offered.1 point

-

I saw one of these for sale a month or two ago for around $1,000 with free shipping from, I think, South or Central America. I wonder if this was that one? I would have bought it at that price but I had already paid the sticker price for a new one shortly before that. Let us know how you like it. I almost called their tech support when I first started using it as I could not get the basket to insert into the holder no matter how much force I used. I had to stop trying to mount the basket as it was hurting my hands. It took a good 4 or 5 watches before it "settled in" and now the basket just goes in easy peasy.1 point

-

1 point

-

1 point

-

\ That spectacular Girard Perregaux Gyromatic and the diminutive Suizo above reminded me a somewhat of this ETA 1080 based 1950s Linaso Candido, so I dug it out and gave it some fresh air too. I'm fascinated by the elegance of these smaller 1950s watches. So much more refined in my opinion than the majority of recent designs.1 point

-

Another potential candidate on its way for the 404 club. Judging by the case and case-back style and similar watches on the web, this is probably a Poljot 2414 and possibly from the mid to late seventies. Described as "overound" it may be suffering from rusty keyless works, which are a common issue, or just generally gummed up with old USSR era tractor oil.1 point

-

I love the blue dial on this Westclox. The FE 140-1B was a joy to work on. All bridge screws, including the pallet bridge, and even the setting lever screws, were the same screws. Even the dial feet screws took the same size screwdriver as the bridge screws. I love that the calendar guard plate has a cutout for the date jumper spring so you can place the spring after first securing the guard plate. I wish every movement had that.1 point

-

Yes, it's the size of the fork slot. You don't get to specify the height, or length, it's just a "standard" size Seitz determined is sort of universal. You also have to accept the angle on the jewel face, which is for most older watches noticeably different from entry to exit, but a replacement jewel might not have exactly the same angle as the original (there are many many geometrical variations of the lever escapement). But, most of the time a Seitz jewel works just fine.1 point