Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/22 in all areas

-

4 points

-

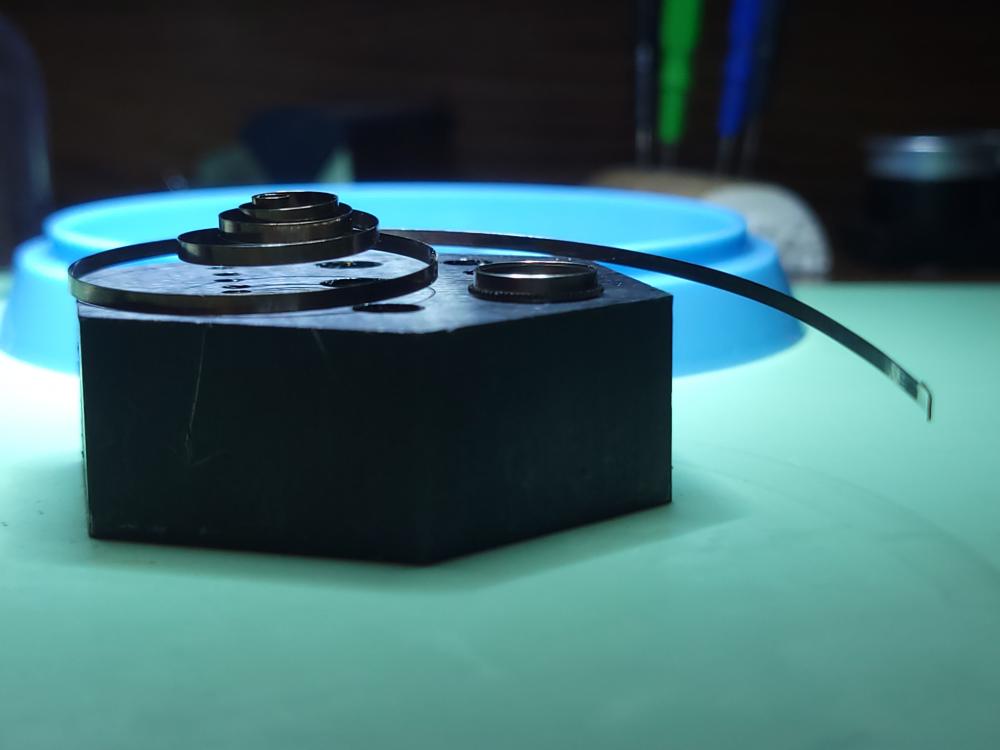

Yeah, pretty clever what you did there. I don't know exactly what you did, but I could hear a clicking (relay?) which certainly gives it a kind of Rube Goldberg character to it that you get to experience every time you use it. That's cool. Importantly, it appears to work very well and I am impressed. The bulky part of what I did was the motor and power supply. I don't know what power/motor the Janta uses, but since the working machine has existing power & motor, if you could just insert a little micro and H-bridge driver board it could probably fit. But your solution is great too and doesn't require any programming and all that. Possibly more long-term reliable as well. I've been inspired by you guys to spend some time back at my 3D printers (after about a year hiatus) and have whipped out a couple simple watchmaking tools. I'm currently researching a bit to figure out what filament and even resin might be useful to withstand some chemicals and higher temps. I haven't decided which one yet, and not even certain what temps my printer is capable of reaching, but I'll figure it out soon. I at least do have an all-metal hot end, so at least I'm not starting from the bottom. But the summary is that I hope to leverage the 3D printer and maybe come up with some useful thing or things. Thanks for the inspiration.2 points

-

Corrosion doesn't seem too extensive. Other than the outer half of the stem, the keyless works look pretty good. There's some on the center wheel arbor, which may need replacing. Someone scratched "8020" into the back of the dial. Lots of side shake in the barrel bridge. Going to have to close that hole up. Definitely going to need a mainspring. Overall though, could be worse. I don't see any cracked jewels or anything alarming. Yet.2 points

-

I have always wherever possible supported UK supply houses. However for the first time I ventured to “AliExpress” a Chinese based company. As a tester I ordered a lubrication oil stand what looked visually the same as I recently purchased from Cousins UK. See pics below. The top one is purchased from Cousins the lower is the one purchased from “ AliExpress” I can report both are identical in build apart from the “ AliExpress” has different coloured lids. The difference is price. Cousins including postage £28.94 AliExpress including tax and import tax £17.94 I do not know what the answer is but these savings for an amateur are worth considering. However the down sides are: It was 4 weeks + before delivery. Be aware Chinese tools have been reviewed many times and reported in the BHI mag and there is a difference. The biggest difference is the quality of metals used by the Chinese. Also their horological tools are just not built as precisely as the Swiss tools. But for a keen amateur well worth a punt IMO.1 point

-

A few weeks ago I purchased an L&R Special cleaning machine from a member of this forum. Well wouldn't you know it, a few days ago I was asked by a local hobbyist watchmaker whom I've gotten to know if I'd be interested in purchasing his Elmasolvex SE machine he recently acquired. I'm not sure if he just needed money quickly (I didn't ask), but I was offered it at a very steep discount over it's normal selling price. Even though I now had a freshly rebuilt L&R Special, I decided to move forward with this purchase. I knew I wouldn't come across this opportunity again, and I can sell it on eBay for a decent profit if I choose to. I made the purchase this morning. I was told this unit was only used a couple of times. If I didn't know any better I'd think that this was brand new. There isn't a mark or scratch to be found on the unit. The jars are perfectly clean, the seals look perfect, etc. I even got the original shipping box and packing materials. I'm pretty happy I was able to pick this up. I'm going to give it a try in the next few days. It is honestly overkill for my needs, but it was too nice of a machine to pass up for the price I was offered.1 point

-

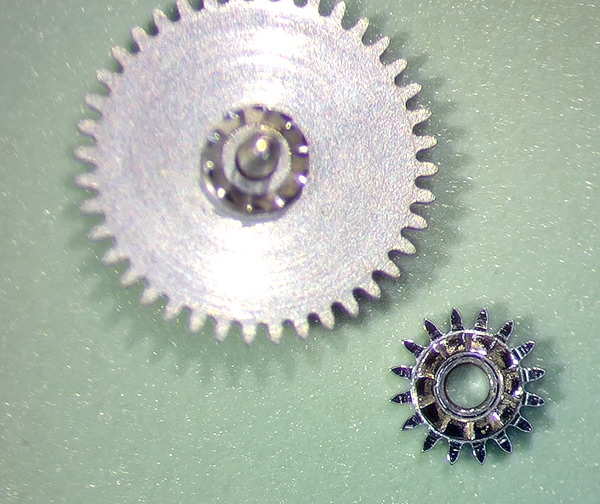

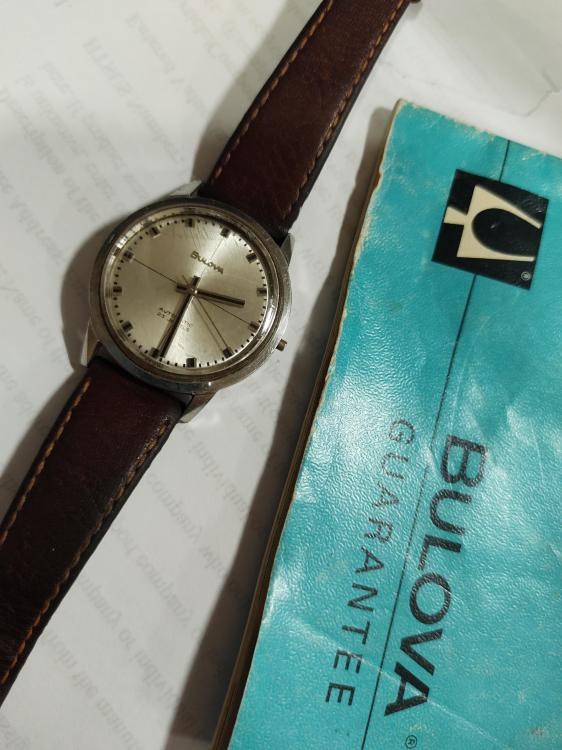

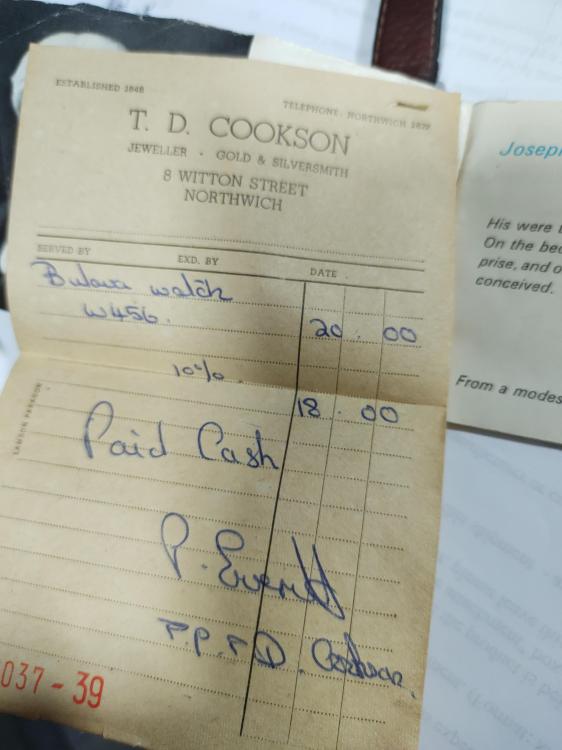

One of my favorite 1970's Bulova with that red crosshair accent on the dial. This was my first service of an automatic with Bulova's 11ANACB own spin on the reversing wheel design, similar to how the winding and sliding pinions interface so that when the wheel turns in one direction it locks but slips when turning in the opposite direction. It only needed a cleaning and a new setting lever spring.1 point

-

My rather simple experiment indicated that PLA does not react with the L&R cleaning/rinsing solutions. HOWEVER, PLA has a low melting temperature, so the heater step will compromise a PLA basket. I have ordered some ABS and will see how well it responds to both chemicals and heat.1 point

-

I hope the perplxr videos are restored, they are very high quality, much better than the majority of "watch repair" videos on Youtube.1 point

-

1 point

-

Yes this is exactly what I did. So far from the chemical compatibility charts I've been looking at it seems like ABS, HIPS, or Nylon will hold up good enough to the common cleaning agents in most solutions. But there are always so many solutions everyone has to test against their own products.1 point

-

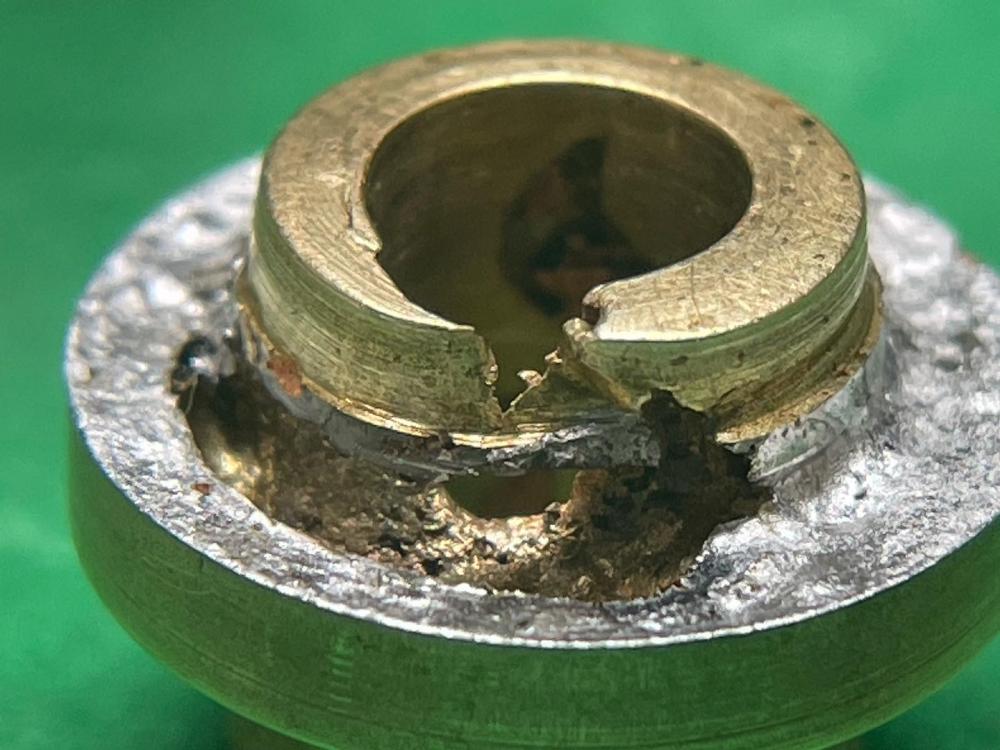

I hope people pay attention to what I have been saying for ages about ultrasonic cleaners and what can happen to parts. Just imagine if this was a wheel from a very expensive antique clock. I thank you for posting that photo.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I've got my own topic about the finishing to make my own dial, funnily enough, based on a Hamilton too. One of the videos I've found is: Unfortunately it doesn't really cover the lacquer. I think there's an industry-standard lacquer for watch dials, but I can't remember where I saw it, or what it was called (hence my own topic for that and another question). Did you eventually restore your dial?1 point

-

Hello and welcome to the forum If you intend to work on the Omega I should get some practice in on some cheap watches first (running ones) that way if they dont work afterwards you know you made the problem. Once your skill levels are up to it then do the omega. The watch.fix site do some selfpaced courses run by our administrator Mark Lovick which have proved popular and informative.1 point

-

1 point

-

A FEW HOURS LATER I made a spreadsheet to compare the part numbers for both 7009A and 7019A movements, and it looks like these are the parts that don't match. Now I just gotta dig those bags out and try and find the odd ones out. Intermediate Date Wheel Barrel and Train Wheel Bridge Pallet Cock Screws Bridge Screw Third Wheel and Pinion Escape Wheel Hopefully the differences are noticeable enough under magnification, the screws have me worried though. A SHORT WHILE LATER Welp, I'm pretty sure now that only the main plate was different. I got all the parts under the microscope and did A/B comparisons and couldn't find any differences at all. I did manage to uncover a third wheel and an escape with missing pivots, so that's nice. They're out of rotation now. Next step, curate a full set of the best looking parts and clean them.1 point

-

You were right first time msb lol. Funny though, maybe worth remembering for dislodged component teeth. If its keeping time and lasting somewhere around the reserve, i would wear it.1 point

-

hah I'm pretty sure it's due to the sounds of pin-pallets being different from a Swiss lever. I feel like there was some talk recently of a forum user here who'd made software that was more accurate for different styles of movement like this. I'll have to check my bookmarks.1 point

-

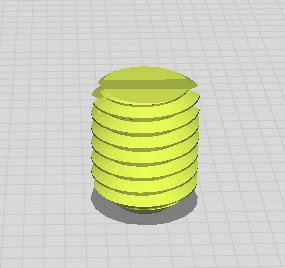

More progress on some custom 3D printed baskets. These are half baskets and the dividers can be customized however I'd like. Seems like the 3D printer is more than capable of making a nice mesh. These baskets are for medium-large size parts so the side hole sizes don't matter that much.1 point

-

I buy big watch Lots ( scrap or in need of repair) , so actually have living evidences to learn from of mistakes made by previous watch destroyers attempts to glue or shellac jewels& end stones in place. Even if it does work, it just isn't proper watch repair practice. Rgds1 point

-

This piece is, as you guessed, kind of cap jewels. The piece is called "Lower end piece for third escape wheel", and is part of the 7019 movement. Be aware that some parts of the 7019 movement are not compatible with the equivalent 7009 part, for example the 2nd, 3rd, 4th and escape wheels are not compatible.1 point

-

Hi folks. I'm new to both this forum and myself personally working on watches, but in a way not new to the watchmaking trade. What I mean is, I'm pretty old but my brother, now deceased, was a master watchmaker so I was exposed to the field since the '70s. I had a kind of "stick it to The Man" resentment of living by the clock so I stupidly never took advantage of talking much shop with my brother while I had the chance. This is especially stupid since it's not like I just don't have the temperament or personality for it - I am a machinist and toolmaker by trade! In my defense, my brother always lived pretty far away in all but about 2 years of my life, but still... we always got along great so there simply wasn't any good reason why we didn't spend a bunch of time talking shop both directions other than the standard problem of all of us being so dang busy to have time to step ouside ourselves. I am not exactly a stranger to working on small scale stuff and my brother did hand some tools down to me over the years, i.e. tweezers, loupes, etc. Even an old Boley lathe & some collets. Anyway, I'm kinda getting into it a little bit lately, so hoping to glean some info of you veterans and maybe having a little something to offer now and then. Vinito1 point

-

I snagged this Hamilton Beach mixer motor off ebay for a good price...for a backup if needed for future cleaner repairs. It was missing the brushes that are round. I could not find any, but I did find square ones where the dimension of the side was equal to the diameter I needed, so I bought four sets for cheap. Then I turned them on the lathe. I was surprised at how well they turned out. I do not have the cap screws, but I assembled the motor anyway (had to rewire it) and held the brushes in with rodico. The motor works. Now to solve the cap screw issue.1 point

-

By "resistor", do you mean a specific resistive heating element or will a wire-wound power resistor do? If the latter, an ebay search for 50W resistor showed these two on the first page. Not 220Ω, but close enough? https://www.ebay.com/itm/224936453056 https://www.ebay.com/itm/163673519584 And these on any given day: https://www.ebay.com/itm/144468074390 I doubt this is helping, but I'm trying.1 point

-

I used an ESP32, but I'm pretty sure something like a Pro Mini would be fine and less overkill. I just started this project so the micro board might change. Basically the cheapest you could find should control a watch cleaning machine I think. Just need PWM and probably 4 or so high/low GPIO Here's a video link showing what I got it to do as of last night. Short video, and still too long: https://youtu.be/gA0I5p6n5yo hmm. I just took a cursory look and evidently the Arduino stuff has gone the way of the Raspberry Pi. Probably the cheap way to go is an ESP of some kind - they are still relatively cheap... so far I guess. The way things are going, next month they might be extinct too I suppose. Remember the good old days?1 point

-

@muddttI like your DIY stuff. I've done enough 3D printing that I know why you made teardrop-shaped holes in the sides. @jimzzillaGood on you too for the reversing. I just yesterday did a microcontroller version of something similar. It might apply to a whole different cleaner project thing someday. Some great ideas flowing here.1 point

-

1 point

-

The Generale Ressorts book shows a 13"' (ligne) Smiths movement, which this one is, as using a spring 1.60 x 0.135 x 660 in a ring 14.5mm diameter. 0.17 seems really thick for a 13"' movement, but it is a pin lever (and not a very tall spring), and GR does have some errors in the book. It's not uncommon to find springs far off the original size that have been used in the past to get the watch going, which might explain the height difference. For a spring that should work according to your measurements Cousins has GR ref 3398 1.30 x 0.17 x 520 x15, which should be fine (and cheap at 7 pounds).1 point

-

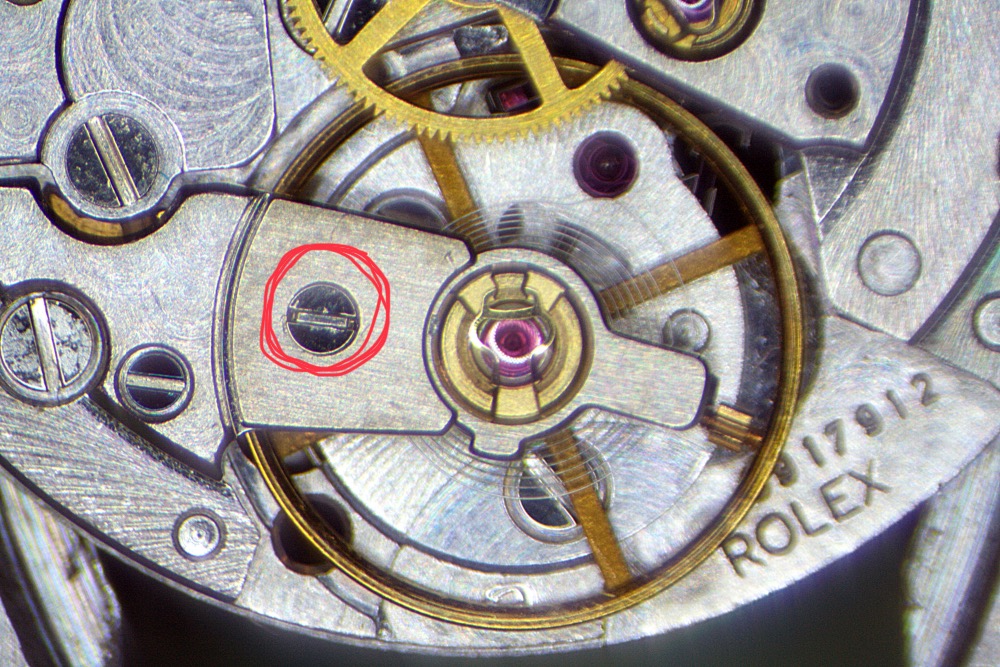

this is my amusement on the collectors discussions. They like to complain about the high cost of watch repair. The greedy watchmakers and brag about how they have a watch running perfectly and I haven't had its serviced in a very very long time. Then of course at some point time they're upset with the greedy watchmaker because their watch has a problem. that's where you start finding all the issues of things worn out broken destroyed. Plus on authorized Rolex service they automatically replace a lot of components that we can't even get. So even Rolex knows a time limit between servicing where things have to be replaced The other aspect of this that would also cause your problem is the gaskets will all disintegrate at some point in time and if you can get moisture into the case you can end up with a little rusty even surface rust which is actually a really nice grinding compound. It's one of the sad realities of synthetic lubricants rather than becoming sticky and stopping the watch like in the old days and saving the watch synthetic lubricants just disappear everything is dry and then the watch grinds itself to death. this becomes very common on early automatic watches that don't have jeweled bearings for the automatic mechanism. genuine versus other has changed with time. I was once working on a Rolex that I had and it was at a time when the material houses still could sell Rolex parts. Seattle used to have anything at one time we had for material houses you could walk into and do business which was really nice. My favorite one run by Dan attempted to convince me to buy a best fit rotor rather than Rolex because it was $25 versus 75. But all the rest the parts I had purchased were genuine in the original packages. I was unhappy but. All the years I done business with that particular material house and than he had never steered me wrong and everything that he said was good was definitely good so we ordered it. It looked identical I could not tell at all. Years later I get an answer to that question. Somebody going to school in Switzerland visited the best fit factory. At that time when Rolex would sell parts to us common folk they also sold parts to bestfit soda Omega. So when he was there they were packaging up Omega parts in the morning in the original mega packaging. But in the afternoon bestfit parts the same part but just under the bestfit number. So sometimes at least the past generic wasn't generic.1 point

-

Trying. Been 3 hours on the floor now with both of those things. Tore apart my desk, checked my clothes, checked all of my drawers. Ready to give up on the whole damn thing. You have got to be kidding me. I think I'm more angry at where I found it than losing it in the first place.1 point

-

A quality of life upgrade for the machine. 3D printed a handle for the knob cause my knob HURTS! Just snaps on and makes it easier to tighten and loosen the knob without ripping my hand. Part file below. https://www.thingiverse.com/thing:55486701 point

-

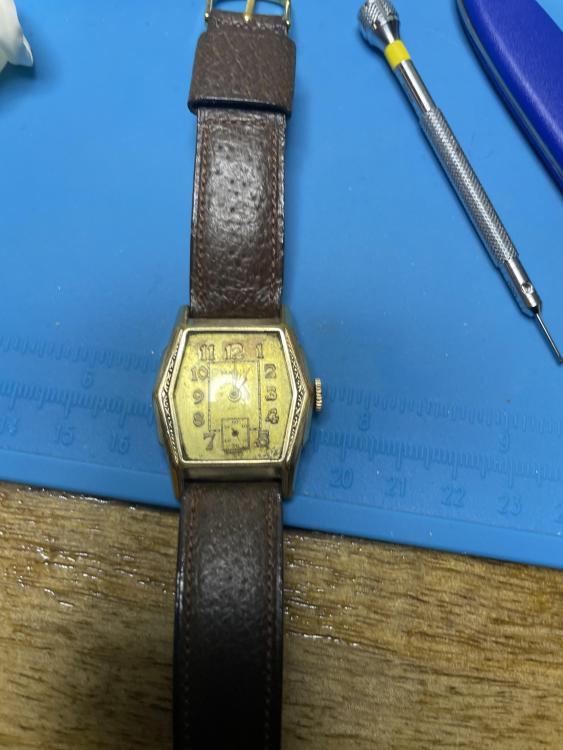

By chance do you have a link? Not sure I have seen it if he achieves any color other than flat white. i love original patina, but when a dial is just something I’m not happy wearing, or completely illegible, I restore it. So I’m not in either camp - I just want it to be something I want to wear. Here are a couple photos of examples - these however are not my watches, they are watches someone asked me to restore. They chose the colors. They are happy, so I’m happy. I am not familiar with them. Do they achieve the look I’m after? it’s a matter of preference. Some watches I leave as is. This Hamilton, though, I won’t be happy wearing unless I restore it .1 point

-

1 point

-

Thanks again Rob. I've taken some photos of the brushes. I don't know how long they need to be, but they are spring loaded and seem to be in contact with the motor. Hopefully you'll be able to see from the photos if this is the cast and they are ok. It was hard to get a good shot. It'll also give an indication of the dirt inside the motor housing. Other images to follow... I'm having an upload issue!1 point

-

0 points