Leaderboard

Popular Content

Showing content with the highest reputation on 10/12/22 in all areas

-

Just thought some of you may be interested in an old Italian watchmakers shop and workshop. He was very shy ( bless him ) spoke no English at all, but was happy for me to take a few photos. Some may not be great as I was using an old crappy phone. I would have bought something but his clocks were around 3 grand, I think he mostly customer repaired and was working on a huge fusee pocket watch wearing a loupe, a pair of tweezers in one hand and the watch in the other hand. I couldn't see a microscope anywhere in his workshop, but then didn't see any wristwatches either. But he did have a multi watch winder so maybe repaired but didn't sell them. He had loads of old tools on display, here are a few.4 points

-

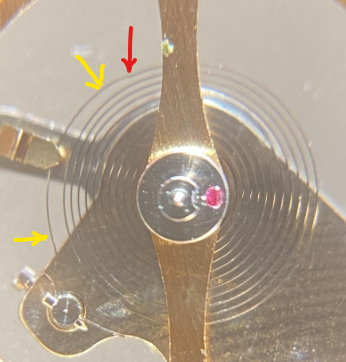

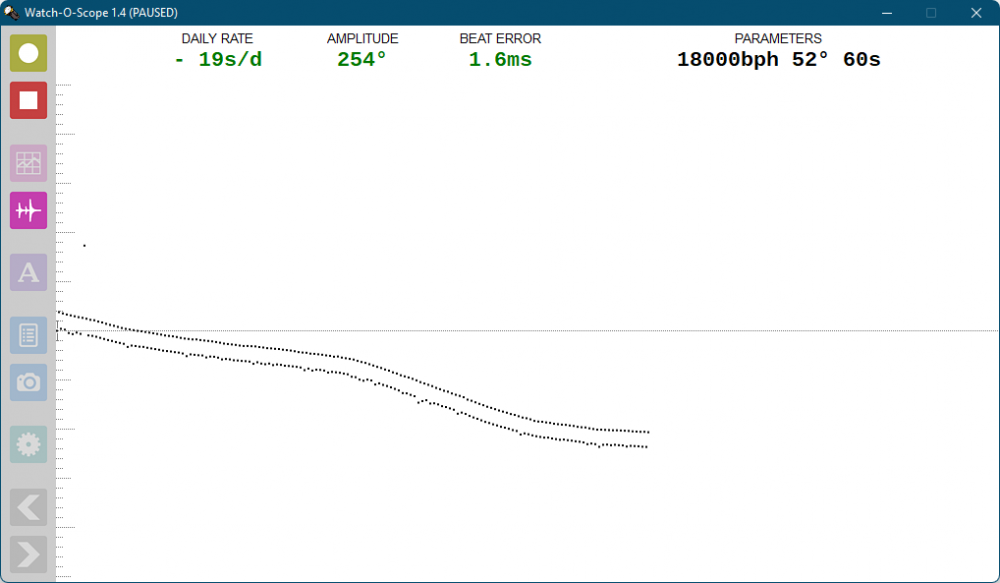

Picked this guy up from a local jeweler who said he didn't deal in used watches, but had this lying around. For $30, I had to take it home. Non-runner, turns out the upper escape wheel hole jewel was badly cracked and destroyed the pivot. New escape wheel, mainspring, jewel. I also bought the mainspring sliding attachement, not realizing it came with the mainspring. As well as the ratchet wheel, when I meant to buy the crown wheel. It's a learning process Getting the new jewel in the right place was quite the test of patience, but in the end I think I won. The timegrapher reading is right after I got it back together, just to get an idea of where I'm at. I know the amplitude is a little low, but I'm hoping an overnight run to let everything settle in will help. I'm also waiting on an Elma antimag from Cousins to demagnetize the movement. But overall I'm really pleased with the results and kinda proud of myself, and thought I'd share, maybe to inspire other newbies like myself. I'll post up once I get the case cleaned and all back together!3 points

-

but they're really saying is they do limited testing and they just say replace the module. Because of they do detailed testing it takes a lot of time and effort and they would have to charge you for that. So not breaking down what's causing the battery to be discharged too fast. This means defective circuits that's not working right. Or if moisture's gotten into the watch and gets on the circuit board that would be a problem. Usually have to gear train is blocked it will cause an increase drain the watch will run and that could be what's going on. They just evaluated and said basically it's not running replace the watch you going to take the watch apart into a proper evaluation rather than guessing what it is. Unfortunately with electronic watches it does require test equipment beyond normal watch repair. This is why if they can they would just swap the movement and be done with2 points

-

Here is an update on this machine. I have cleaned it and repainted it, cleaned up the motor and oiled it. As you can see, there is an Edison socket for the heater. Not sure what was done before, but I found a 60W ceramic heater that might work fine. Next up...rheostat. I ordered a 500 ohm 50W one and was not happy with the size nor quality. Since I had a 125 ohm 25W (rated at max current of 0.447 A), I investigated whether that would work. I measured the motor current driving it with 50 volts (that is all I have in my lab), but noted that the current is pretty much constant under no load conditions at around 30-50 volts. Not sure if that holds at 110 V. In testing, I found the motor just ran too fast with 125 ohms so I needed more resistance. I looked around the lab and could not find any suitable power resistors (hey...I am an IC designer dealing in micro watts, why do I need power resistors), so I had this crazy (and perhaps dumb) idea, just run the whole circuit in series--motor, switch, rheostat, heater. The heater gives me some IR drop and also provides heat (not the 60W that I wanted). Anyway, for now, I am going to leave it at that because I am going to replace the switch with one having a smaller footprint. In the mean time, I will look for a power resistor. Update: I just pulled the rheostat from the other L&R machine. It appears to be a factory unit. It is 750 ohms.2 points

-

yes that's always the challenge with eBay. Sometimes you can tell from the reviews like lots of negative reviews are not a good sign that you're getting a great deal. I do find sometimes you have to read the reviews because I ordered some hardware not for a watch and pondering why it's not arriving is looking at the review in somebody complained took extremely long shipping time but it's amazing what happens if you place a question on eBay because it has to be resolved within a certain length of time or else. But that still doesn't help with poor descriptions of what the item is like the condition of the watch. but still with all its problems lots of marvelous things come from eBay and I spend far too much money there.2 points

-

Yes. Sounds like it's a loose cannon pinion problem. Does the crown feel very loose when adjusting the time? Cousins has stock for two different heights of the cannon pinion. You'll need to measure the height of the original cannon pinion. Most cannon pinions can be tightened. Can you post some photos of yours, so that we can advise you further.2 points

-

Look up your mark at "mikrolisk.de". Most times you will be lucky. Frank2 points

-

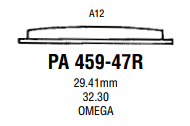

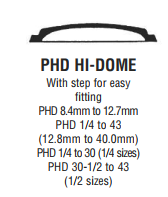

Hello everyone, I would like to present to you my latest project, a Vulcain Cricket (yes, another Cricket), model S2315A. I always wanted a Cricket, and it looks to me that Vulcain has made a lot of different variations of dials, watches etc. Cannot really find much info on the one I have. Initial condition overall: is running, but definitely needs servicing. It has a lot of DNA allover the place. Also, the watch came with its original bracelet (I wonder how that will turn out). Movement: looks to be a cal.120. Not 100% sure as googling for this caliber brings different results. What do you think? Also had tested it on the timegrapher, results on the picture. Crystal: needs a new one, as the original is cracked and has oxidation on the tension ring. Dial: looks pretty clean. Case: gold plating has some ware. Honestly not sure what to do as I have no setup of my own yet. Is it worth sending for replating? I am a newbie in the trade so any thoughts or suggestions are super welcome! Thank you!1 point

-

Before - and - After 107 Timex Automatic. This model orginated with a 31 automatic and was later made with the update 107. This watch insored designer Todd Synder to create a monern version. Actually quite a nice homage but saddly only a quartz https://www.toddsnyder.com/pages/the-military-watch-by-todd-snyder-timex1 point

-

Here is a project that is been going for several months. It came from my box-o-watches. It had a broken staff and a rusty stem and no crown. I cleaned and staffed it--got it running fine. Later on, I noticed there was a problem with the mainspring. It was slipping. I could not tell what was going on. I found a NOS mainspring on Ebay and installed it. Still had issues. Finally discovered that the issue was me. Not gonna air out my noob mistakes, but once I decided to focus and use my problem solving skills, I figured it out. The final thing to resolve was the stem and crown. I could never figure out if this case needed a case tube. I decided to put one on. I had some case tubes in the watch bench, but none fit perfectly, so I put one that was close on the lathe and turned it down to size. Found a crown among the watch graveyard that would work with the stem and the case tube. Oh, long time back, I found a crystal in my stuff--perfect fit. Today it is all together. I am a little concerned about the tube. I may need to put a dab of superglue on it. The hands and dial have radium. I wash my hands after working on it and frankly not worried. Nevertheless, I found an identical NOS dial and have ordered it. Maybe I will swap it out...maybe not. That is TBD. Pictures below.1 point

-

1 point

-

1 point

-

1 point

-

Allowing you to photograph his workshop, he must have been an absolute gentleman, try that in the UK you would have had the police round.1 point

-

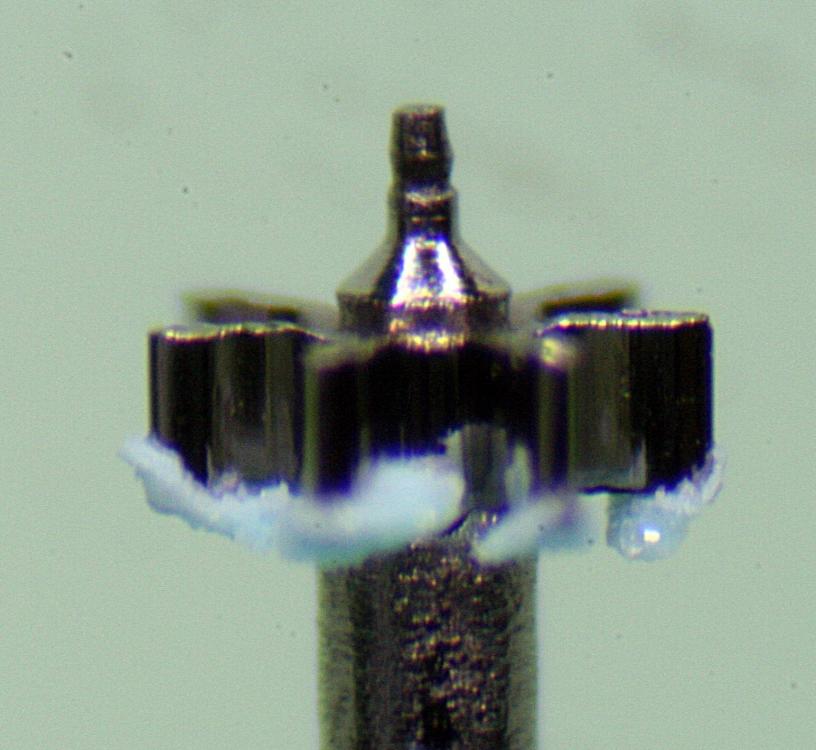

Good evening guy’s here a small updat about the 5M42-0e39 with a battery problem. The seiko repair center wanted it to replace the clockwork because it was draining the battery. Watchweasol on this forum wrote me dirt could be the problem and so it was. A member on a Dutch forum afford me to have a look. He noticed that the watch was not being openend for quiet some time so how did seiko manage to know what was the problem. Strange!!! This member saw that there was oxidation on the stem and parts of this oxidation attracted to magnetic parts inside the clockwork. Cleaned it replaced a part changed the battery and bingo. I show you 2 pictures the first picture you see metal and the second picture you see 2 circles lowest circle oxidation part he replaced highest circle the oxidation stem. Special thanks to watchweasol1 point

-

Ah, so apparently their consensus is that it is a basic, functional, cheap watch. About what I expected. Well, it's in fairly good shape and keeps excellent time, but considering how much time is involved and how many fees I'd have to pay, it'd be a waste of money to try to sell it. I think I will just ask around among my friends and see if anyone wants a watch. It isn't my style, so if anyone here would like it and feels like reimbursing on shipping, you can PM me. Otherwise, I will scout about.1 point

-

Apparently it's a Chinese brand. Bit of discussion here : https://www.thewatchforum.co.uk/index.php?/topic/13756-apogaumapogam/1 point

-

1 point

-

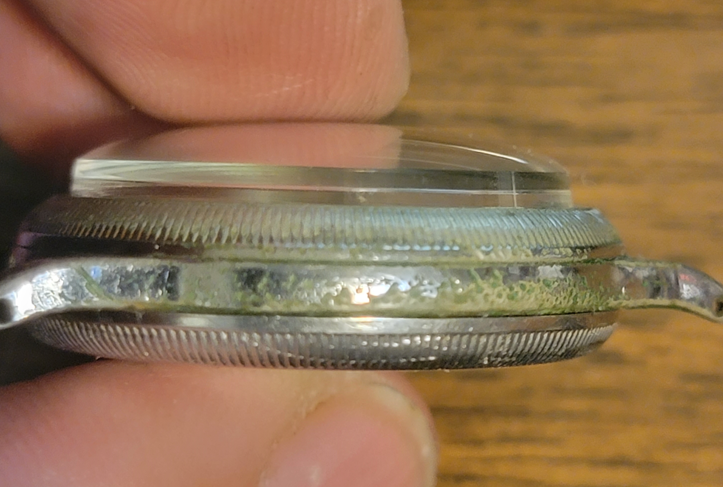

You've got a rival @JohnR725 It looks like the terminal curve is wrong, with different gaps at the start and end - yellow arrows. I would suggest it needs more of a kink at the red arrow. In your pic it looks like the hairspring is bunched a little tighter on the regulator side. With an uneven gap, and the spring sat on a pin, moving the regulator left or right moves the hairspring different amounts, putting different side loads on the pivots. Before trying to reshape the terminal curve, what I'd try to start with, is bend the spring outwards slightly near the bottom yellow arrow, so that it sits in the middle of the pins, then look at the timegrapher plots.1 point

-

I'm attaching the parts list so you can see what the parts look like it looks like from the parts list it's not the third wheel 201/1 which is labeled large driving wheel. then it's part number 240 which I'll let you read its own peculiar name. So yes their separate components we should build a separate and possibly there is a way of typing them because they are separate components. I've expanded the image of the parts list and snipped it out so you can see the parts better 939_AS 1906, 1916.pdf1 point

-

What I did and I had many back opening tools. A pair of old pliers and file the nose of the pliers to fit, make sure it is a good fit as you do not want to damage the back Hold the case in a vice if the have the Jaxa vice that will work fine. Open the pliers so the pliers fit in the slots and turn.1 point

-

I am wearing one now...my first one that I brought back from the dead. Have saved another one and have bought a running one. I have three. But I only wear the one. They are straightforward to service overall.1 point

-

1 point

-

I suggest that you get an old hairspring, then try out adjusting it on various different surfaces - rubber, plastic, glass, card etc and find what works for you. I find glass too hard, and prefer something with a little 'give', like card or vinyl. Just because Bergeon make a tool, doesn't mean it's the right, or best, way to do it.1 point

-

Hi with the power off the movement does the balance spring sit evenly in the center of the regulator pins, I may be as you are moving the regulator, its bearing against the springs outer or inner edge. Worth a check before delving further1 point

-

Update. The markers are trivial to remove. Unfortunately, the distance between the holes is slightly different, and there is a notch in the marker on the donor dial--used to put lume. So...I am now attempting to make replacement markers. I won't put a post on them because that seems a bit hard. Will glue them on. Stay tuned! Update OK, so here is my first marker. Not perfect, but to the naked eye, I think it will work. I thing good enough1 point

-

Hi The usual reason for the high drain is dirt and or congealed oil, In some cases the oil used is synthetic but again it picks up minute dirt particles and as such places more strain on the watch and it has to use more energy to overcome the obstruction. So to be sure the watch needs to be cleaned and tested.1 point

-

I am very honored as a non watchmaker to be accepted here on this forum I just a person who realize how magnificent and fascinating it is how a watch could be made and be developed. A lot of people only look at there wrist to see what time it is and that’s it. As I already mentioned it started with my fathers watch a seiko 5m42-0e69 with a broken strap bought donor watches just for the strap. Than gave these watches a second change and sober he fever started. Like to show you my collection.1 point

-

1 point

-

Yes you can. Just make sure you have the spring sitting the correct way round to go in the barrel and set the barell down on a hard surface, place the mainspring inside the barrel still in its holder and find something that is just smaller than the surround to gently push it out. If its an automatic watch make sure to apply breaking grease to the barrel first.1 point

.thumb.jpeg.cd6d20f3fd1f21747a43456b96dd785d.jpeg)