Leaderboard

Popular Content

Showing content with the highest reputation on 08/11/22 in all areas

-

3 points

-

In the watch collecting community, the concerns about non-original parts are heightened and rather than just calling something out as a "frankenwatch" they may call it a "fake" even if it contains authentic manufacturer's parts. However, in the watch repair community I think there is an appreciation of interchangeability and the utility of cobbling things together from donor movements as needed, so fake is more often reserved for 3rd party copies or cloned parts that never originated from the OEM, often with a poor fit and finish, that are being passed off as something they aren't. In those cases they aren't concerned with using manufacturer's names under false pretenses, so if the rotor you are concerned about was a true fake trying to pass itself off as a Seiko part, they probably would have forged the makers mark! But if this is for a first project watch, then even if it would be a cloned part, the proper function and contribution to power reserve may be more important than whether or not is is signed.3 points

-

I always preferred nickel tweezers to brass; much stronger, but with similar "grippiness" when handling small parts, which is their main advantage over steel in my opinion. They come in #11 and #12, which I can't really tell apart, but they are similar to #3 steel tweezers in size and shape. When new they are quite fine. After some time they become more and more blunt with redressing- I have some 20+ years old that have lost a good 2 cm of length and are useful when some real force is needed. They are more expensive than brass but worth it in my opinion.3 points

-

I think the Montaine should look good with a little TLC and a fresh crystal. The Timex probably will clean up nicely. The two ladies watches probably just work, although servicing that tiny tittle Regency might be a bit of a challenge. At an average of £1.24 each I can't really complain regardless of the outcome.3 points

-

You must have missed the web site link above https://violatweezers.com/1 point

-

all done! thanks for the help guys. John I went ahead and gave the pegging thing a try but no luck. so heres what I did: First of all, under closer magnification I found out they weren't burrs, but stake marks. 3 of them spaced around the diameter. Have you ever seen that before? staking the bore on a balance wheel? I have a jeweler's countersink in my staking kit that, along with a jewel reamer I gently teased the stake marks from the bore. riveted the new staff in and it worked great. again, thanks.1 point

-

1 point

-

1 point

-

Hiya Frankie. Check under the balance assembly mate, quite often therexwill be a manufacturer name and calibre. If not then the keyworks needs a looksee at. Whip it out mate ( the balance assembly that is ) look for manufacturing logos, shields, badges etc. The bestfit books and downloads will show you most of them.1 point

-

I have taken it to a shop they said to pick it up next week, they estimated the cost to be 10 euros so I figured might aswell before I break something, I appreciate all the help you guys have provided I will be sure to post an update once I get he watch back1 point

-

It's not the movements that were faked as such, but rather poorly rebuilt from random parts that were made to fit. Also it's the cosmetics on the watches that had liberal sprinklings of AM or otherwise poor quality fake parts fitted. I use AM parts on many of the stuff I play with if I don't otherwise have a choice, but then that should be disclosed when the piece is sold on again.1 point

-

No mention or make I did notice on a site it must be virgin olive oil but sure if it was just a tongue in cheek comment.1 point

-

The bezel can be very tight and almost impossible to remove in safe, undamaged way without a special tool. However to refit an hand all you need is to remove the crystal. Air is pressed into the only tube that is one the case, where stem goes troughtout. Trying double sided tape might work but the reality is that even apparanetly trivial casing work requires tools.1 point

-

Looks decent to me. Seeing as you jumping into 7S26 already this will be very familiar to you as the 700x was the precursor to it. I have a pile of those movements here and main issues I've seen is wear on the arbour bearing on the top plate. No way to know unless you strip it, but those movements are easy to still find for cheap if you need parts.1 point

-

Nope not me. I thought it was used for cooking and rabbit food (salad). I have used my own spittle at times.1 point

-

Thank you for the kind comment. Many years ago my dad was a watchmaker and showed me the basics, but I followed a different career path. A couple of years ago I picked it up again and started seriously studying and setting up my bench. Along with my studies, I am trying to spend a bit of time on the bench every day to gain experience. There is much to learn!1 point

-

1 point

-

1 point

-

These clocks work best on very little oil and it has to be in the right places and a good oil. The main thing with these clocks is getting the clock in beat, slight movement fitting the new suspension spring and you will have trouble. As Bod has suggested photos are needed. This book which is the bible to repairing these clocks is a must, Horolovar 400 Day Anniversary clock repair guide book 10Th Edition by Charles Terwilliger, look around for best price. I forgot to mention you are going to need a clock mainspring winder if you intend to repair the clock properly.1 point

-

Close-up photos might help, not only to identify the exact clock, but if there are problems that an experienced eye could see. A clear photo of the back plate is the one needed for identification. Bod.1 point

-

People have been known (won't mention names) to launch a movement across the room because of those two little diashocks on the gear train...1 point

-

Working with 2 tweezers, always keep the tip of one pair inside the spring, to stop it escaping. You could try a line of Rodico across the centre of the spring to stop it pinging off, but there's not much room for that. Better to use some wood - a cocktail stick or meat skewer will suffice.1 point

-

Hi All, just wanted to share that I added a hacking lever to an ETA 2789 movement. I used the same lever as specified for ETA 2824-2. All worked fine except the watch hacked on the date set position of the crown. I had to put a very slight bend in the lever so that there was a small gap between the lever and the balance rim in that position (as shown in photo). It was a fine adjustment as too much bend caused the lever to touch the barrel teeth in the crown pushed in position. All very doable without too much pain. Well worth it for £1.68 from Cousins. Steve.1 point

-

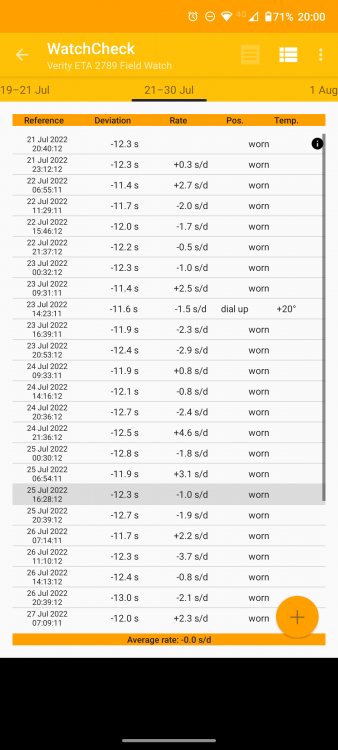

I'm not highly experienced and I didn't photograph this service enough to give a walkthrough and it was a straightforward thing, going smoothly for the most part. I just wanted to share the only glitch that I got on this one. I used a K&D mainspring winder and I made the mistake of rotating it the wrong way for just a couple of rotations. I then rotated the right way and went all the way through the process and loaded it into a barrel. Once I pulled it away, I saw that the loop end of the MS was completely kinked, folded over on itself. I imagine that rotating the wrong way caused the loop end to fold in under itself and then winding it up in the winder smashed it home. Of course, trying to bend it back caused it to break. I am guessing this could happen with any winder and nothing against the K&D. This picture is before that happened, after cleaning everything: In this photo is the MS that I broke. I had another laying around and used it instead. I couldn't remember where it came from, but I think it was an older one that I had re-loaded into a washer. I just grabbed it and threw it in, but in hindsight, I should have unloaded it and checked it for shape and hygiene before reloading it. You can see from the time graph that the amplitude is on the low side. It drops down to 175º in some positions. But otherwise, it is running well. I think it would be best to replace the mainspring. It will be interesting to see the difference in this amplitude with only that difference. If I do and see a noticeable difference, I'll come back here and update the post. Here's the completed watch, which also needed considerable case work, done a few days ago. What looks like an anomaly on the pic is actually refraction caused by the faceted crystal. From 1975, the Seiko 6106-7729:1 point

-

Thanks Mike. I've finished the rewiring, not much to it, and it seems to be working 100%. It must be older than yours because it's much simpler. It has three controls: 1. An on/off toggle switch that operates the heaters. 2. The large sliding lever manually allows the jars to spin when depressed. (same as yours). 3. The small sliding lever controls the on/off and the speed of the agitator motor. It does so by sliding along the large tube rheostat. The motor doesn't change direction, but the sliding agitator allows you to operate it far faster than anyone in their right mind should ever attempt. That's it, no timer, no fuse, not even a real on/off switch. Simpler times. Probably the most interesting thing is that the heater elements are from a WWI Era electric cigar lighter, and were designed to get hot enough to light a cigar in a matter of seconds. With two of them side by side they produce a LOT of heat (see photo). https://www.ebay.com/itm/334472065241?hash=item4de016b0d9:g:vZEAAOSwbeNinp2h Jay1 point

.thumb.jpeg.47a54c96c07cb7d64b695e5ff6c0bcf0.jpeg)

.thumb.jpg.7054cd4077d4ffc8467ab1049f416591.jpg)

.thumb.jpeg.a2898f120fd62b57f850717d223f50c8.jpeg)