Leaderboard

Popular Content

Showing content with the highest reputation on 04/03/22 in Posts

-

2 points

-

2 points

-

2 points

-

Here's a PowerPoint of removing a refitting the so called 'fixed' centre seconds wheel, which should be removed, cleaned and properly lubricated. Enjoy Lesson 21. Baumgartner 866 Removing centre second wheel and oiling movement.pptx1 point

-

Many years ago in my work as a lubrication advisor, I visited factories to 'survey' them for lubricants requirements. I always asked the incumbent 'oiler' what he currently used as a first step. Normally I would get a list of several lubes, but at one factory the response was "ground floor machines use thick oil, first floor machines use thin oil". Says it all?1 point

-

We were probably at that point a very long time ago but? Excluding the specialty location like as you mentioned Rolex reversers or basically any of the automatic reverser wheels or even the ball bearing assembly for the weight. Excluding the most important the escapement basically everything else could be almost anything I don't really think it's all that important. As long as the lubrication is a horological lubrication designed for long-term use. Not sure why but personally I still find it just a very amusing subject. Gathering up horological lubrication guides suggestions books whatever over time. Being amused with the various suggestions in the tech sheets that seemingly don't make a lot of sense. Like insanely thin oils on the setting components and not always telling us that they surface treated to keep those insanely thin lubricants where there supposed to be. Or Seiko is confusion over whether they should oil a pallet fork pivots are not. Some watches they do some they don't and some as they revise the document multiple times will alternate as to whether they do or do not. Then the greatest amusements is the discussion groups as people are trying to figure out what the heck they're supposed to be doing and everyone has an opinion.1 point

-

1 point

-

1 point

-

You also have to be aware that it may be listed as "Vostok", "Wostok", or "Bostok" !1 point

-

I think is good to put all this money talk in context with figures, GBP since the OP is from there. Basic tools, not considering the most important ever which is setting up work posture, £100 will be plenty. In a pinch, even 50 will do. Oil and greases, one can do with two or three, so maybe £25. Plus 10 for petroleum ether and isopropyl alcohol. Timegrapher, unfortunately if someone is serious, that is needed since day 1 because as a beginner one can't really tell by eye and sounds if a mov.t is running good, unlike it was done in the good old times. These are increased in price and are now less than £150 for a basic model 1000. All the other stuff, microscope, washing machine, pressure tester, expensive opening and closing tools, etc, these are not needed for a beginner, until he has says 20 successful servicings and restorations under his belt and is willing to take up the game a notch. Means you should be to aiming to learn (mainly, how to not break or loose) , develop dexterity which in turn will boot self-confidence. As opposed to collecting tools which will be used little, take up space, and can be replaced with some ingenuity. Top video training as in Mark Lovick's is great, but not free, so let's leave that out of the addition (addiction ?) as one will make do with what's free on YT, which is a whole lot really. Total, we're around £300. I understand that not everyone can readily afford that, but compare to any other hobby or even going 2 nights out of town, doesn't seem that much really. Again, the line is drawn between 'being and doing' one side, to 'owning for the sake of'.1 point

-

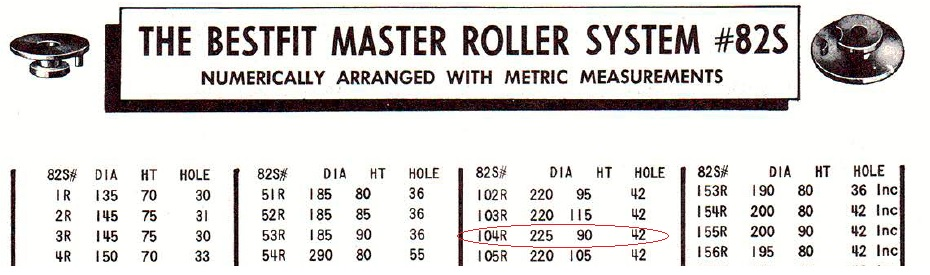

I've looked at the good old fashioned Bestfit catalogue for you... This indicates the roller reference should be 104R where you've been guided to 373R. In fact roller references don't even go that high in this olde worlde catalogue but given your movements is from the 1950s I'd be more inclined to believe it especially as your 373R seems to be referencing much more modern movements. The dimensions btw for the 104R roller are given in the image below if it helps cross reference any. The 104R reference roller is shared across the whole of the Tissot '27' family and a handful of other manufacturers. Specifically if it helps: Cupillard: 233, 233D International: 70, 77, 88, 89 Tissot: 27-2, 27.3, 27-21T, 27-23, 27.53, 27.63, 27B, 27B1, 27B2, 27B-21, 27B-621, 27M, 27T, 27-1T, 27-2T, 27-61T Wittnauer: 17T, 17TT, 651 point

-

1 point

-

The problem with repairing/servicing watches is that you always need this tool or that tool and if not controlled will empty your wallet quickly and you become a toolaholic. Oils etc cost a fair bit as you have found out . thing is to buy good quality (not always the most expensive) and look after them. Cheers1 point

-

1 point

-

Are you talking about the stud screw? These can handled with sort of very small pin vices, the same used for balance weight screws. Not made anymore, something these sets appears for sale.1 point

-

I think jdr is suggesting you buy a book on the subject. He probably meant this one: The Modern Watchmakers Lathe And How To Use It (Archie Perkins). I don't have that one, but I can recommend TheWatchmaker's and Model Engineer's Lathe: A User's Manual (Donald der Carle) or The Watchmaker and his Lathe (Hans Jendritzki).1 point

-

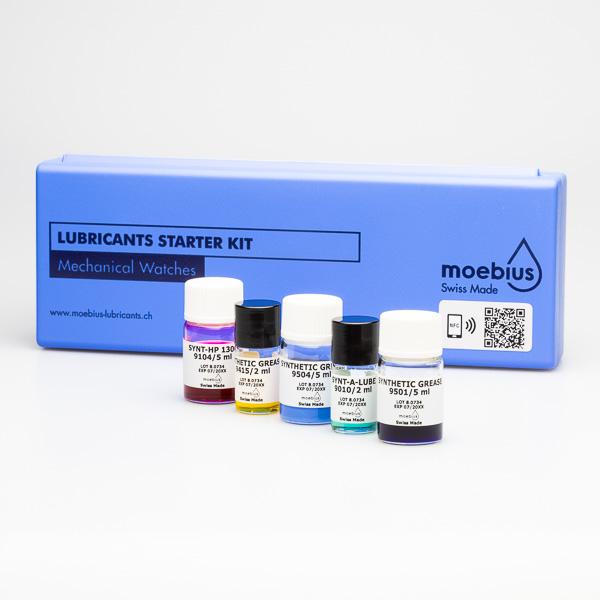

Actually have two Kits I've only ever seen the one for mechanical watches though. Unless they're giving away a bottle or two for free I'm not sure it's really a good price. Then for me it definitely would not be a good price as I never use 9010. I prefer 9020 which is not in the kit. Then there is the peculiarity of 9501 and 9504. Which are basically identical except 9504 as additional boron high-pressure lubricant mixed in. I don't know why you would need both of them 19504 would work just fine. But if you excluded my preference and 9020 versus 9010 other than the extra bottle of grease and that the price was good which it probably isn't it might be that it would be a fine kit. Then googling came up with that link $209. Problem with the website is we can apply these lubricants in the sizes that they have in the kit but casually it looks like the kit might actually be a good price if you could use all the various lubricants. https://www.jewelerssupplies.com/lubricant-kit-for-mechanical-watches-moebius-640.8500.K.html1 point

-

Which screws are not there? You will face issues getting everything to fit together if you don’t have all of them. Have you tried getting a screw assortment? You should take photos of the spring positions to help you put them back later.Also be very careful as they tend to fly off easily when removing. Try doing it in a ziplock bag. When you say that there’s a gray cloud when your left eye when you close your right eye, do you mean that you only notice it when the right eye is closed? Or is the gray cloud still there, just don’t you don’t notice it. You may want to use a microscope (usb digital/ or a proper two eye microscope for electrical work) for all watch work to reduce eye strain. https://www.cousinsuk.com/product/cousins-microscope-with-articulating-arm-camera1 point

-

The first part of this video shows how to remove the hairspring from the stud arm and regulator. This is the first step needed to remove the balance wheel from the balance cock. This is a tricky procedure for a beginner. There is a real possibility of damaging the stud arm. My advice is to enrol in some watch repair courses first. Mark, our forum creator, has some excellent online courses. There are actual hands-on courses conducted in Singapore too.1 point

-

1 point

-

I've never seen a manual on a Wolf Jahn lathe in 25 years of looking. I figure they figured you'd know how to use it if you bought it, but that's 60+ years ago. Do you have any specific questions about it?1 point

-

Some of John's comments are directed at how lubrication has changed over time for the same caliber. This is a matter of progress in lubrication tech i.e. better lubricants, as well as practical observation. Regarding epimamage, old docs from John recommend it on most of the usual places. It's one of those things that definitely helps, but you're ok if you don't do it. Unless- you do this professionally and want to ensure *factory level service. One thing that kills me on some modern pieces is they just won't work right long term without very specific oils and procedures. I know the purple Rolex inversers won't work right if not epilamed, that's a decades old thing. But aside from that, I would like to think we got to a state where a slight difference in viscosity or whatever doesn't make or break. Anyway, if working on stuff from the last century, you can go by what some early tech guides say, thin oil here, thick oil there, grease there. If done carefully, with whatever make of oil, you're still ahead of some "factory service" I've seen. *from above, I've been handed things "ex factory service" where the customer was ready to toss the watch, and after fishing out a screw dancing aound (under tightened) or cleaning out the Incablocs that had been flooded and then run dry, they're happy and the watch is happy. Of course it means a whole new overhaul as you have to to guarantee the work. I remember one of my classmates went to a factory service center and 1st day his boss implored him to "fill up the incablocs, they keep coming back as returns bone dry!". He found a new job.1 point

-

Yes but you need to follow certain specifications on that? And understand I'm going to snip something out like fully wind is not fully wind tight you need to let it run for a little bit of time so you have a window were you doing this. The same as at the end 24 hours and usually the watch companies get more excited about things at 24 hours. We tend to get really obsessed on this group with minimum amplitudes on a fully wound up tight but the watch companies are more concerned with timekeeping and stuff at 24 hours.1 point

-

I also ordered a mainspring since I don't have my own winder. I'll pop open the barrel and pop in the new spring. My next steps will be to run my parts through the wash (in small batches). I'm planning to keep like-with-like as (unlike you guys) I still have no confidence that I'll be able to figure out where they all go if they're just lumped in one big pile. Somewhere along the line I'm going to need to figure out winding it up outside of a case. My only goals with this are to: a) see if this is something I can do and b) get this un-running movement back to life. Thanks for watching...1 point

-

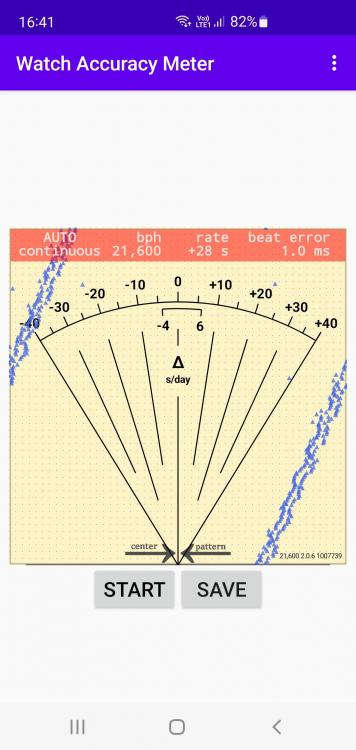

Just for future reference when you see basically snow on the graphical display the numbers are usually worthless. Often times people will think the numbers are valid numbers when the graphical display looks like crap and they usually will not be. Which is one of the reasons we always like to see a picture like you gave us because often times people say how wonderful it looks and not show us the graphical display image of how wonderful it does not look. Which doesn't work well if you're trying to troubleshoot and help somebody out so thank you for the picture. I find is sometimes when the pictures don't look right that the website below is nice because usually get a better picture? It's really hard unfortunately with the picture but it looks like your terminal curve isn't quite perfect but I guess it just depends on how perfect you want your watch to be. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Tissot_2700 The stud position isn't really important at all. What is important is where the hairspring is which is unfortunately attached to the stud. So typically use the stud providing the hairspring hasn't been bent to make sure they hairspring is flat. The problem with the hairspring that's not flat is no longer floating and it tends to be putting pressure on one pivot or the other. This will often show up in the timing machine As uneven timing between dial-up and dial down depending upon how bad it is. But it's not the only thing that can cause problems of dial-up and dial down. One of things it's interesting with this movement is supposedly it's an equivalent to an Omega movement? This becomes interesting because if it was the Omega movement it is meant to be regulated. It looks like the picture of the Omega movement matches your movement so because of that I snipped out the timing specifications for your watch. I also found the parts list for the Omega watch. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_1100 429_1100_complet_2272.pdf1 point

-

Go on to Dr ranfft's site to see all calibers of the family T27-t is a member of, notice the family beats 18000 per hr , roller tables interchange. Profile of impulse jewel has to do with lift angle and the table steers the guard pin, a roller table and iimpuls jewel assembly may interchange between caliber of different beat as well.1 point

-

You should be able to tell which it had originally, as it says on the movement. They should both fit the same spacer rings and cases. Keep in mind that there are two different hand height versions of these movements The center wheel, hour wheel, and sweep second wheel are different. Is the watch an old one, 1988-1989? I think Seiko switched from the the A and B around then. 6A5A looks like an old model, so it might have had a 7T42A.1 point