Leaderboard

Popular Content

Showing content with the highest reputation on 01/12/22 in all areas

-

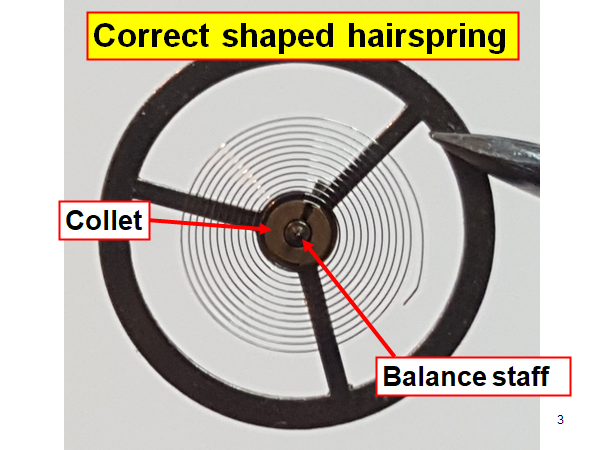

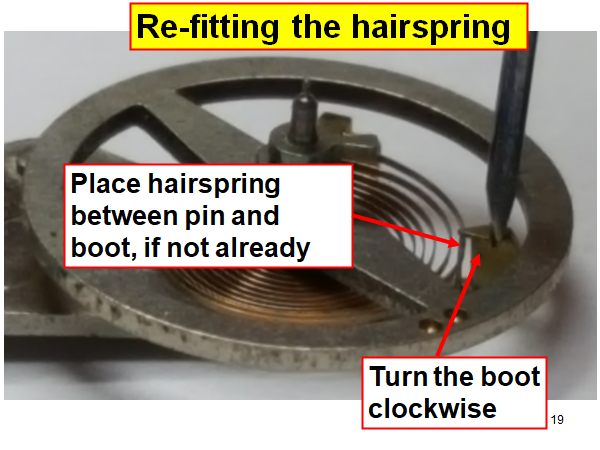

Is the process of adjusting beat error on a movement without an adjustable stud carrier just trial and error by rotating the hairspring collets by small amounts? Even 5 degrees rotation drastically affects the beat error, and I am extremely wary of damaging the hairspring by repeatedly taking in and out of the regulator pins and removing the stud from the fixed stud carrier.1 point

-

Here's a PowerPoint of removing a refitting the so called 'fixed' centre seconds wheel, which should be removed, cleaned and properly lubricated. Enjoy Lesson 21. Baumgartner 866 Removing centre second wheel and oiling movement.pptx1 point

-

The idea hit me...the microscope is stored in the closet in its pretty little wooden box--I do not work on Accutrons. My Dad bought it. I remember him asking my opinion--I was graduating engineering school. It is pristine. I have a stereo microscope with a very nice and huge boom stand...too big for the bench. I use it for inspection often. So...why not use this cute little thing on the bench. It has limitations of course. I am going to give it a try and see just how useful it can be. I am sure @JohnR725has an opinion. I am sure he has one.1 point

-

1 point

-

Thought i would share. I had ordered the bad chinese screw-type press with the top and bottom arbors that aren't aligned before i had come across the discussions describing that they are, well, terrible. I mostly got it for the method of acrylic crystal installation where you deform the crystal slightly under pressure and then lift the case up around it, and it'll still work for that regardless. I have a hand press tool around here somewhere. Yesterday i realized i had tools and supplies to make it less terrible. I would still say 100% don't buy this model. But if you were saddled with it anyway, and you already have or can beg an M6 helical insert kit, you can make it less worse. I took the screw out of the base and filed the hold out, toward the verticals, until i could fit the specially sized drill bit from the helicoil kit through the hole. Then I applied some A9 aluminum cutting fluid to the special tap from that kit and hand-tapped it, stopping frequently to clear the threads. If you don't have A9, Tap Magic probably works well too. If not, WD40. But don't try and tap aluminum without any kind of lubrication, or things can get messy in a hurry. After taking the tap back out and cleaning it, i ran it through with my fingers a couple times to clean the threads, further cleaned the threads with alcohol, and then installed the helical insert, broke off the tab, and installed an M6 set screw with a generous quantity of blue thread locker. It's less bad. The easier / cheaper option is probably to just remove and throw away the screw that comes up through the base because it's not totally necessary to keep the bottom die centered - the upper can help center it.1 point

-

I have a Seiko sport watch here where a prior owner pried the back off. I surprised myself by reshaping the back to get it to screw on again.1 point

-

One of my classmate's father was also a watchmaker. Classmate told me someone came in with a stopped Rolex. Dad looked at the guy and was 100% sure it was fake and pried the back off to change the battery (this was the 80s when fakes didn't have screw backs)..... it was real! I asked how the hell his dad managed to pry off a Rolex screw back, he just said with some distant fear in his eyes, "you haven't met my dad..". Luckily back then it was doable to get a new back, expensive but doable. My classmate had been a boilermaker in shipyards before going to watchmaking school, and if there was ever anyone I've known who could crush a golf ball like Oddjob it was him. I know it's impossible but he would have come close!1 point

-

Loose how, are trying to unscrew or lift it? It could be either type.1 point

-

1 point

-

Of course it is much less. Below an answer provided by Google search: a bit more than 90° is quite normal. With more than 180° the escapement would even block, and therefore almost all have curb pins on balance wheel and under the cock, which prevent exceeding 180°. Moreover most movements have dots near the periphery (three on your movement) which allow to check the amplitude. The curb pin is visible when the balance changes its direction, and comparing this position with the dots gives an estimate of the amplitude. Regards, Roland Ranfft https://www.watchuseek.com/threads/question-cylinder-escapement-balance-amplitudes.858325/post-62971851 point

-

You wont get the same action as an escapement with pallets. Have you looked for signs of wear on the cylinder.1 point

-

1 point

-

Start here -> Enjoy... .. and if you make it through that lot without falling asleep you might also like this...1 point

-

https://www.ebay.com/sch/i.html?_nkw=clock+mainspring+winder+&_trksid=p2380057.m4084.l1313 Just to tempt you.1 point

-

Evening Bearman, Here’s a photo of the watch. I just finished putting it back together after a badly needed cleaning. I do not really care if the hands are not original, I just can’t find any the right size. I have no idea if Westclox mad movements for other brands. I’ll probably end up buying one of the Westclox watches off eBay, I just need to find one cheap.1 point

-

I would say that the impact of reducing coil resistance in these ranges is insignificant. That is my SWAG anyway. The model for the coil includes inductance, resistance, and capacitance. All of them change as a result of shorting some turns. Since the coil is functioning as an electromagnet (versus a resonator), I cannot imagine it making much difference. It will likely increase current but that means changing the battery a month or two earlier perhaps. The actual answer requires carefully modeling the driver circuit, the load (the stepper rotor and train wheels), and the coil, and then simulating. Short a few turns and move on!1 point

-

The rotor gear could be pushing on gears of the auto device whereas they should mesh. Loosen the screw so the balance starts tor run, then turn the rotor so to get the gear teeth to mesh and tighten back. Another possibility is a longer screw will protrude furthure out the otherside and exerts stress on the auto device.1 point

-

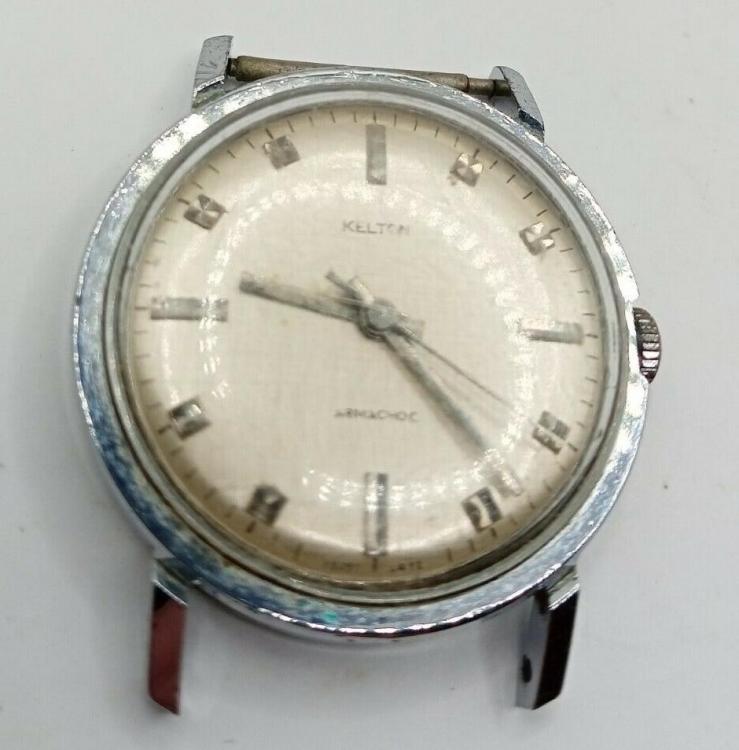

Perhaps not as spectacular as the Tissot, or the Precisa, but both interesting in their own ways. An "overwound" 1972 Kelton Armachoc, and a Kienzle, probably from the late 1980s While I have a number of Timex branded watches of this period, this is the first Kenton branded one for the 404 club. For those interested, there is a short history of the Kelton brand here -> https://www.kelton.fr/story-_l_EN_r_12.html The example here, has a British made case and in fact, from what I have read the entire watch batch may have been produced in the UK, for the French market. Likewise some of the French made components may have wound up in UK made watches from time to time. The simple dial of the Kienzle will make it a nice addition to my small Kienzle collection, assuming I can find or fabricate a suitable stem and get it working of course. Kienzle has a much longer history as a manufacturer of both watches and clocks. More here -> https://en.wikipedia.org/wiki/Kienzle_Uhren Both were 0.99p plus postage, so both will hopefully make it in to the 404 club.1 point

-

Guys firstly I must say that I am impressed on all the fantastic vintage watches you all collect Recently I purchased these 2 from ebay First is a Precisa automatic of unknown year but looks maybe 1960 ish Second is a Tissot manual wind of unknown years as well Maybe some of you may know brand and how old? Both these are very nice shape Precisa is gold and Tissot is rose gold1 point

-

Well sir, whilst not wanting to speak too soon, you may well be my new official hero! I did as you suggested and the watch is now functioning perfectly, or at least it has been for the past few hours or so. A few days wear and if it continues to do so then I think we're good. Thank you so much Thanks everyone so much for taking the time to respond to my pleas for help Cheers Matt1 point

-

Could be a poor contact in the trimmer capacitor, might be worth giving it a turn back and forth.1 point

-

Hi What are the hands made of ? looks like a matt material on the photos. I think the jury is out on the size of the hour hand. My own preference would for it to be a bit slimmer as it seems to take the eye away from the watch its self which looks good.. My own opinion entirely. The Mother of pearl dial feminine or not is a smart addition.1 point

-

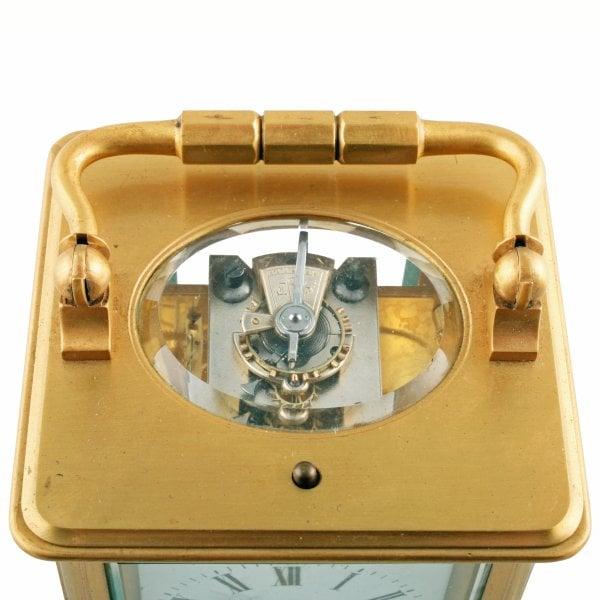

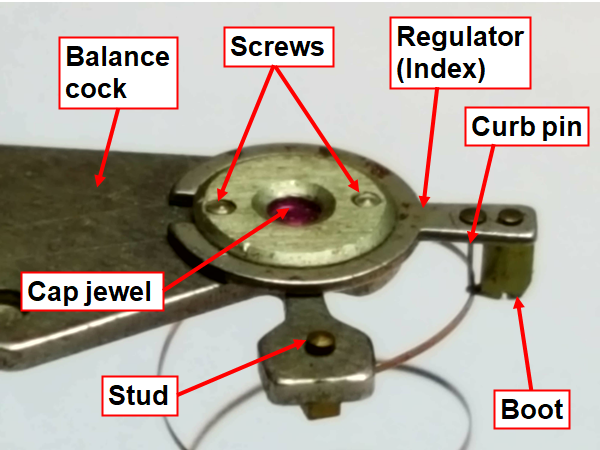

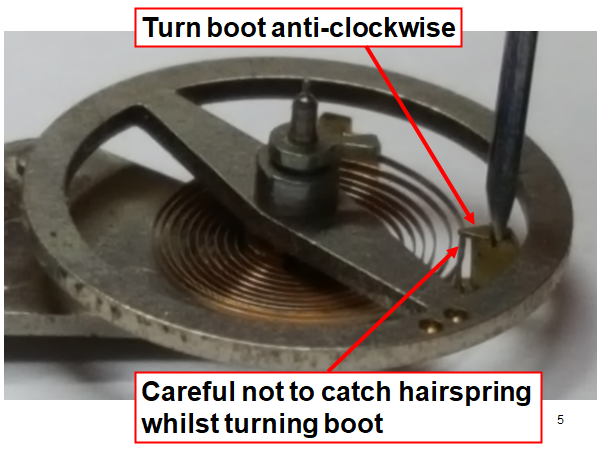

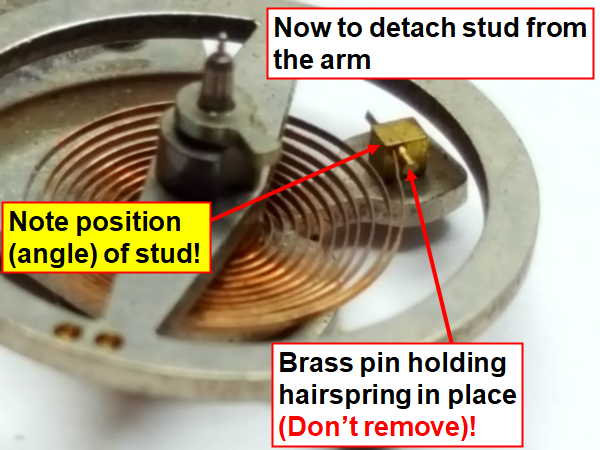

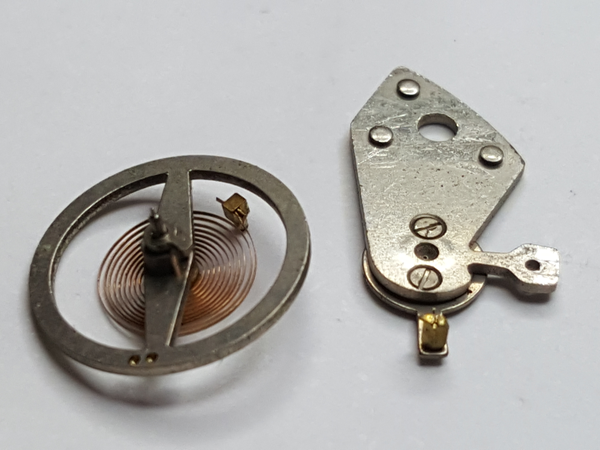

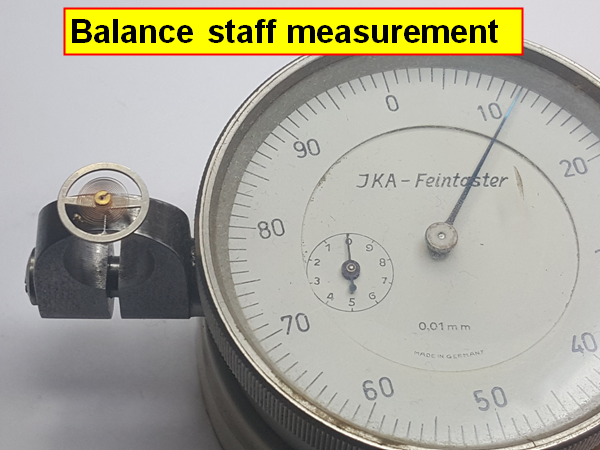

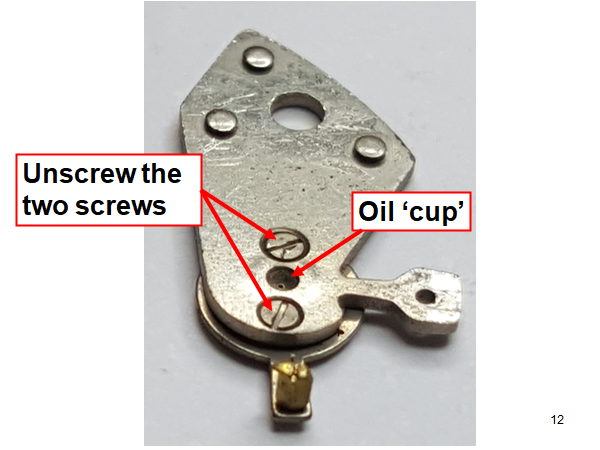

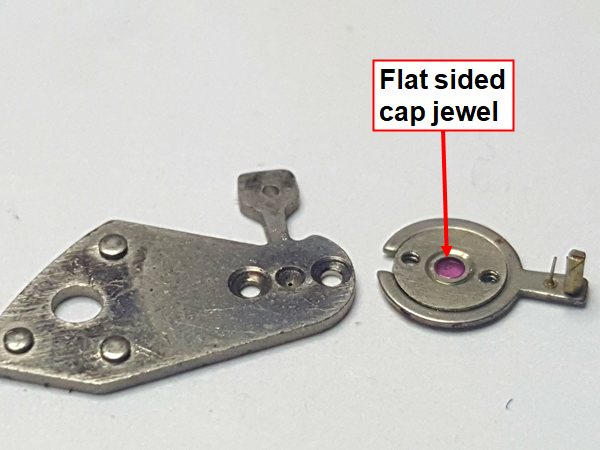

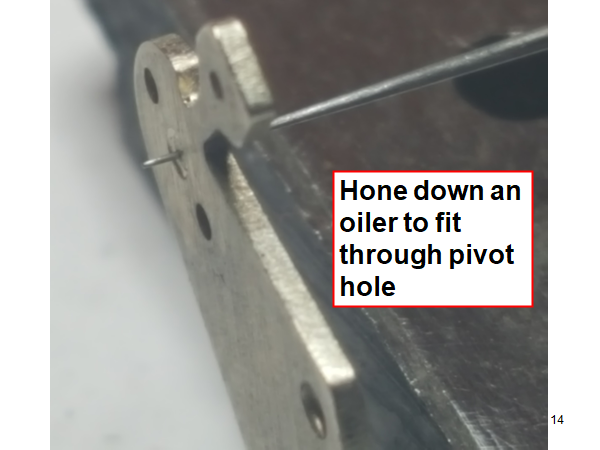

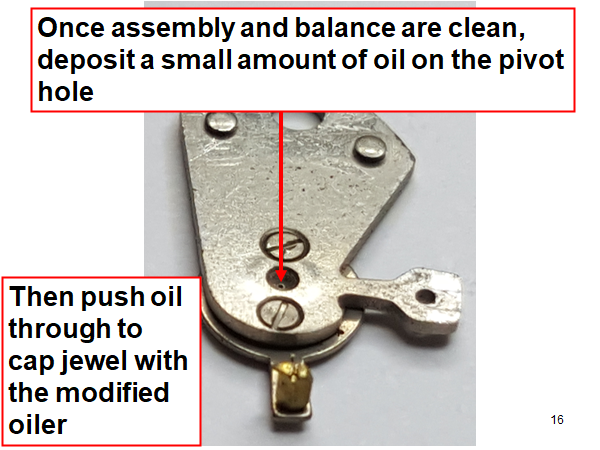

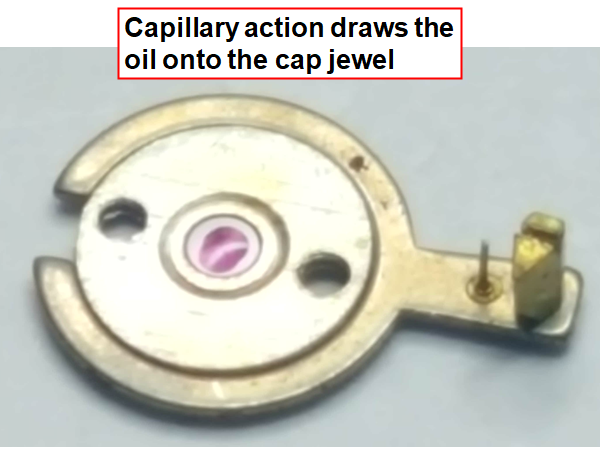

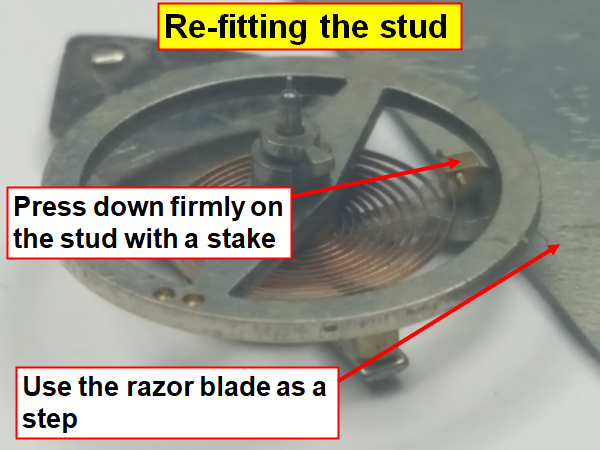

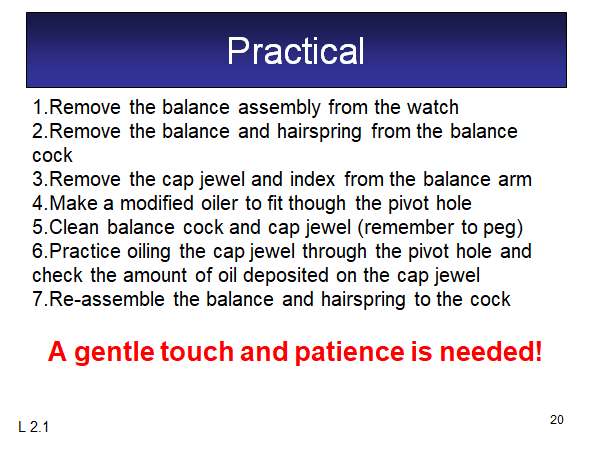

Hi All, I posted a while ago a walk through of the Baumgartner BFG 866 and wanted to add to it, especially as there is little out there to explain how to oil the cap jewels of a non shock proof watch. This is the balance cock of the BFG 866 and as you can see it has a cap jewel held in place with two screws, screwed from underneath. Some pull the hairspring out of the way to oil through the oil sink, but I find it safer to remove the hairspring, but also it is good practice to do so. If the balance and hairspring is removed the shape of the hairspring is seen a lot easier and any manipulation can be done. The hairspring may have to be taken off the balance if it isn't a simple tweak. Removing the balance from the cock is quite simple Measure the balance staff to find out how big it is, so when we make a tool to push the oil through to the cap jewel, we will know the correct size to make We need to unscrew the cap jewel to clean it Now we are going to hone an old oiler to fit through the hole in the oil sink that the balance staff pivot passes through Be careful not to damage the pivot hole Once the balance cock and setting has been cleaned thoroughly, we can then oil the cap jewel through the oil sink with Moebius 9010 If you are not sure you have oiled it enough, or your technique is correct, remove the cap jewel and have a look. Obviously before screwing back the cap jewel it will have to be cleaned properly again This is a safer way than oiling whilst the hairspring is attached to the balance cock. It may take a while longer, but it is a lot safer! It is also good practice in removing the balance and hairspring from the cock, but also checks the state of the hairspring, especially the uniformity of all the coils and how the hairspring is studded onto the collet The other cap jewel in the mainplate would be oiled in exactly the same fashion. Trying to oil the cap jewels and then fixing them onto the setting isn't a good way to oil them, as the oil will probably be smeared when re-fitting them. This is the way I teach my students to oil their non shockproof cap jewels I Hope this helps someone else in the future. More BFG 866 practicals to follow....1 point

.thumb.jpg.0f0d77d371332df92013589f352b2587.jpg)