Leaderboard

Popular Content

Showing content with the highest reputation on 11/26/21 in all areas

-

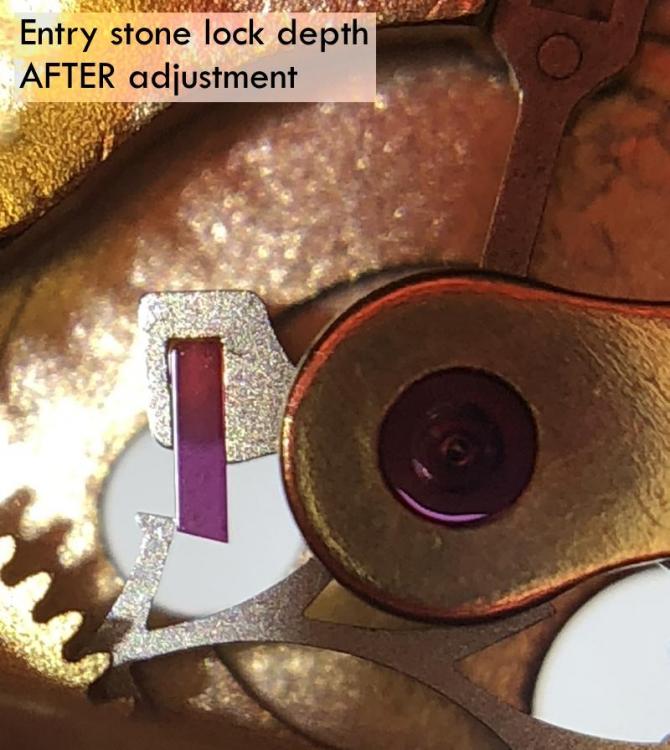

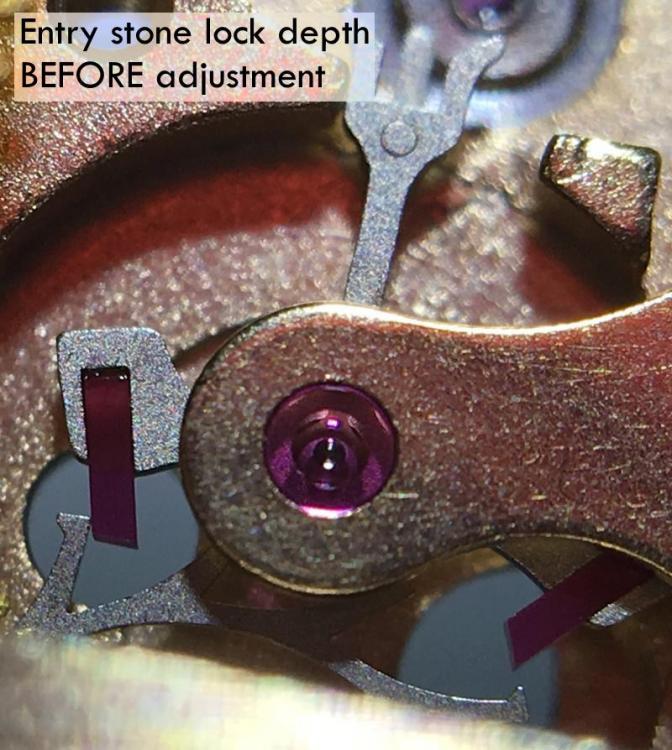

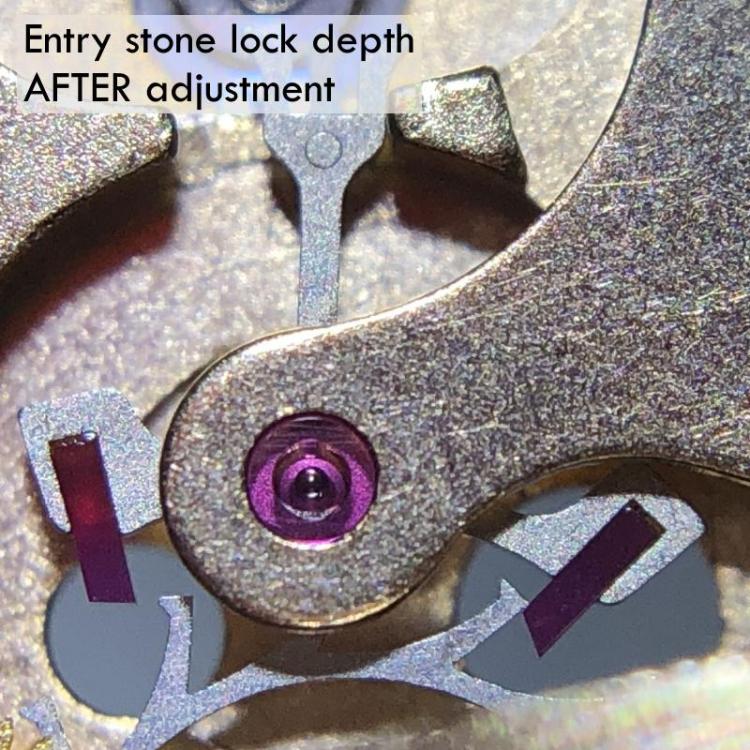

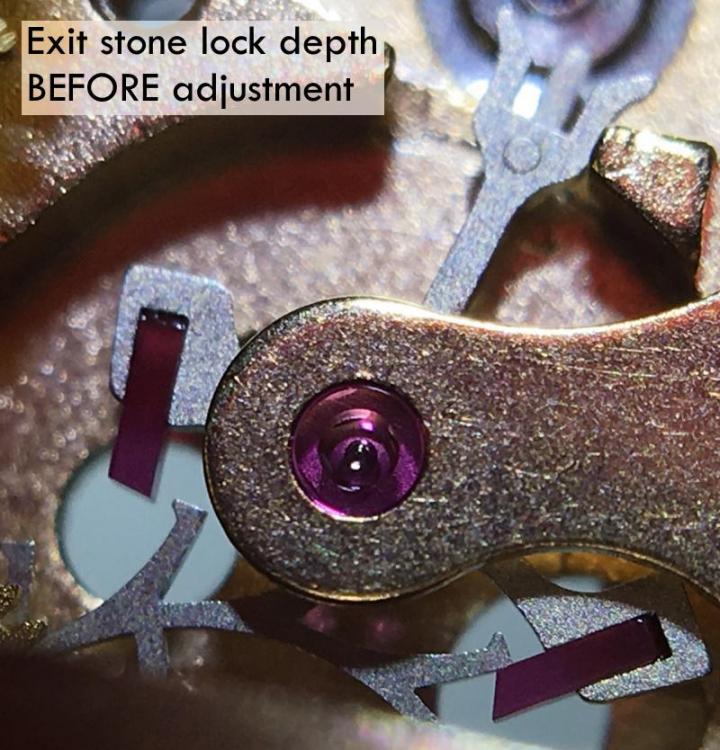

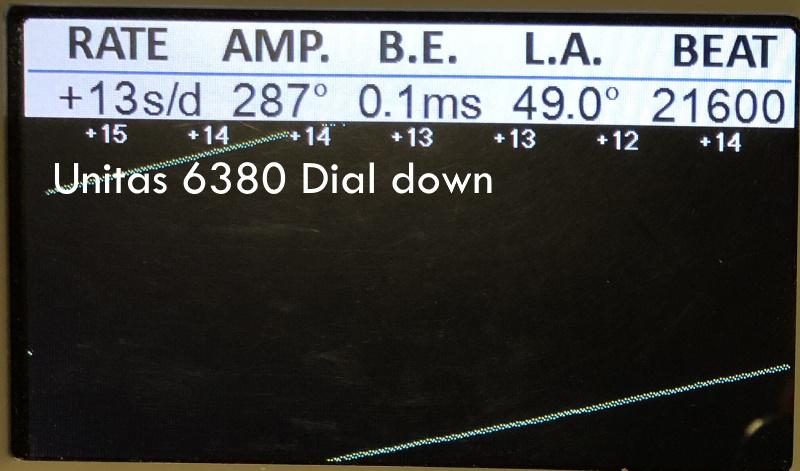

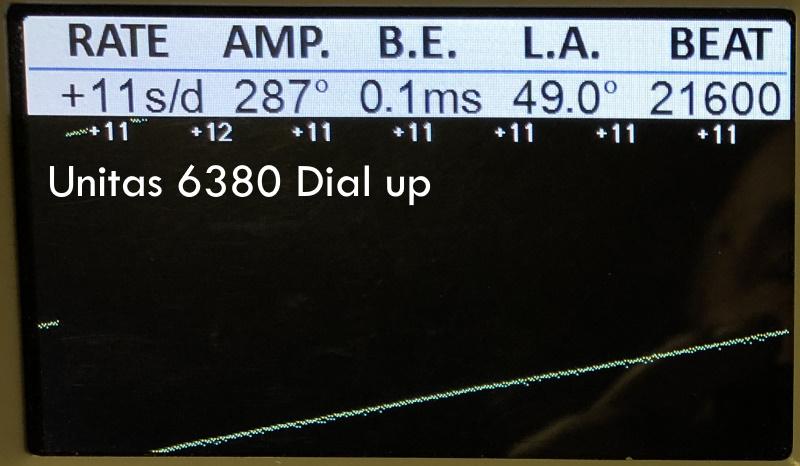

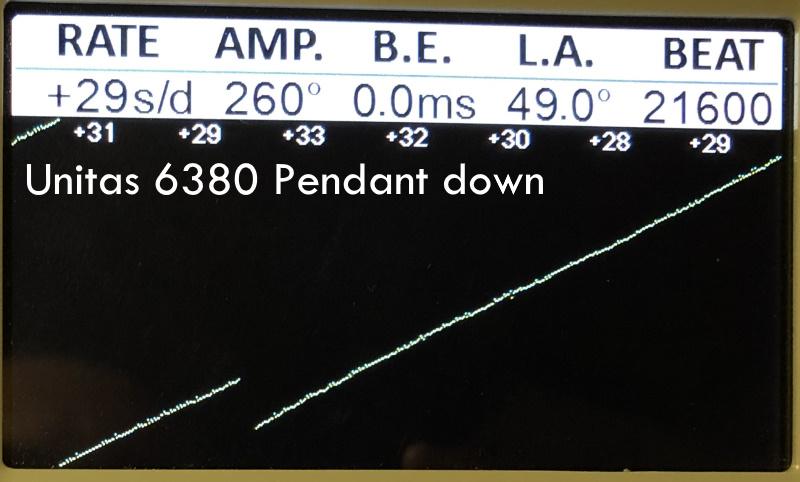

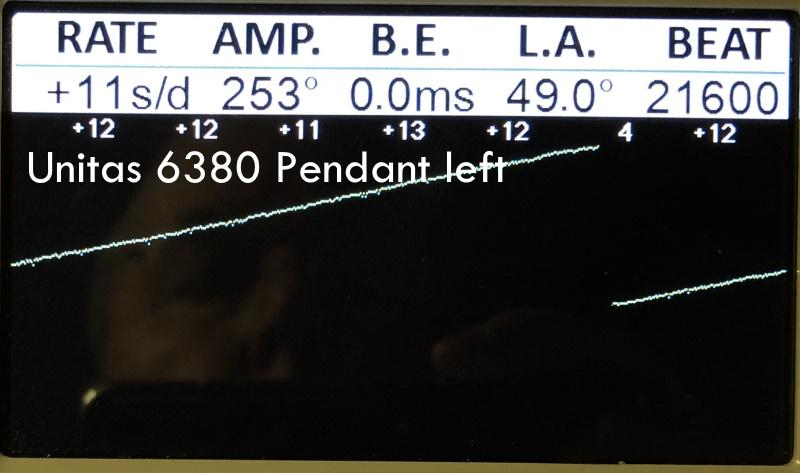

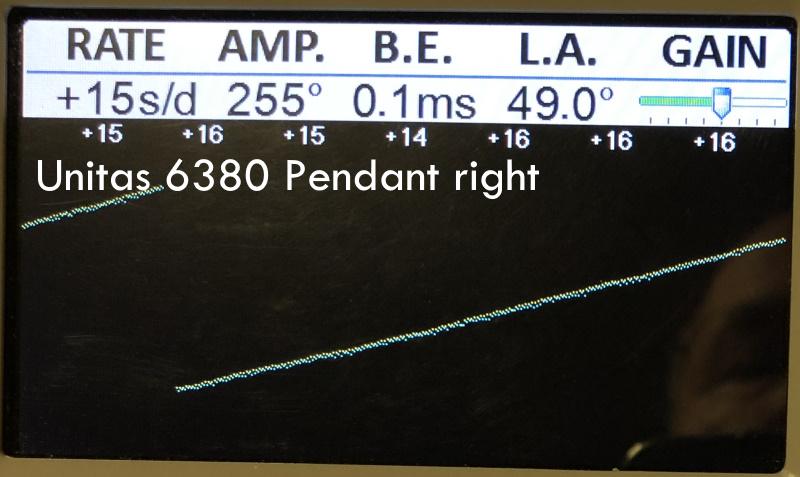

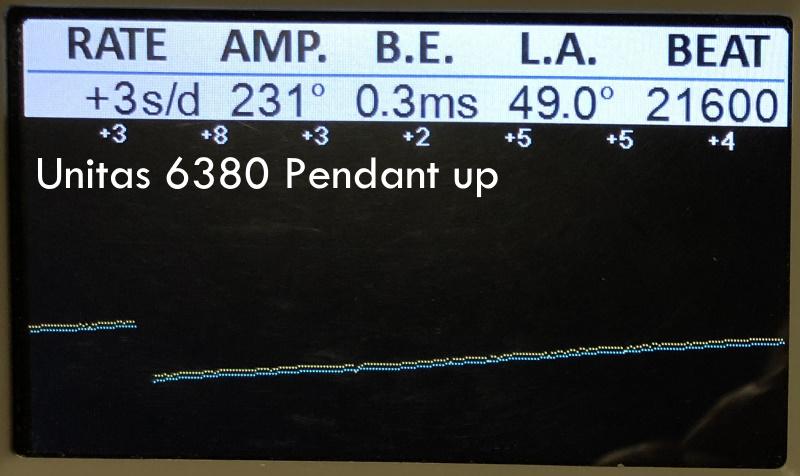

So, I finally got the time to return to my low amplitude Unitas 6380. You were right about that John. There was plenty of room to push both pallet stones back. I didn't just warm them but re-shellac:ed them. The reason for doing that was twofold. Firstly, I wanted to try my newly bought shellac flakes (from CousinsUK). Secondly, it was easier, or at least appeared to be easier, to adjust the lock depth before applying the shellac. The shellac flakes is the best shellac I've tried so far. It's very hard, but not as brittle as the shellac from my clear stick of shellac. To the question of how far I should push the pallet stones back, I tried to follow Henry B. Fried's advice in the book "The Watch Repairer's Manual" where he writes: "In a well-adjusted escapement, the lock should approximate 1/3 the thickness of the pallet jewel." This is a 15 teeth escape wheel 21600 BPH calibre and Fried's example was a 18000 BPH calibre. I believe I read somewhere that the lock depth should be shallower for a high-beat, 20 teeth escape wheel 28800 BPH movement, so I was somewhat ambivalent, but I believe/hope I made the correct decision? I thought about that a lot, and decided, as I was already at it, to re-clean and oil the cap jewels. I also re-cleaned the entire balance and polished the staff pivots with a bit of Dialux green rouge applied to an oil-drenched piece of peg wood. I should really have done this cleaning before adjusting the lock depth of the pallets in order to be able to tell what had the most effect, but hopefully there'll be plenty of new opportunities to test this in the future. Anyway, thanks for reminding me of how very critical this is. With parts being so very small it's easy to underestimate how very critical cleanliness is. Cleaning the cap jewels I made me a new peg wood tool which I was pretty happy about and that I demonstrate in the following video: Anyway, here's the end result of these two activities (cleaning the cap jewels/staff pivots and adjusting the pallets): The pendant up position isn't all that impressive, but I've decided not to dig any deeper at this time but instead reassemble the rest of the watch and wear it for a while to see how it fares. After a bit of regulating I wouldn't be surprised if it turns out to be a pretty decent timekeeper, or at least that's what I'm hoping. Anyway, always being curious, any ideas of why the pendant up position loses about 20 degrees or so?3 points

-

I have, all three courses, and they are IMO worth every penny. When the watchfix.com chronograph course is available I'll take that too without a moments hesitation. I also took the "101 Watchmaking" course on learnwatchmaking.com. Both are good, and in some areas one is is better than the other, but overall I'd say watchfix.com is the most affordable. There's also timezonewatchschool.com which is excellent, but I only took the first course and it's a non-video, read-only course which imo isn't ideal. You can say that again! I share the exact same experience, and there will likely always be that "missing or better tool".2 points

-

This isn't a direct answer to your question because I haven't done Mark's courses. However, what I have learnt over the last 5 years of learning about watch repair is that it definitely isn't a cheap hobby. I've always liked watches and thought I could save some money by learning how to service them myself... I was deluded. Although I love the subject, the amount of money I've spent on tools would have easily equated to a couple of Rolexes... I'm still an amateur and still have things to buy! @VWatchie is right though, if you buy well your tools will not lose value, if anything you can fund your hobby somewhat through trade/upgrade.2 points

-

So there’s good news and there’s bad news. Realising it was going to be hard to reduce the shoulder of the female adapter, I wondered if I could reduce the length of the crown tube instead. The crown tube was flush with the crown and I couldn’t get any sort of cutters in there. The ‘dremel’ with a grinding bit was used instead. I ground off 0.5mm and re tapped the hole (smallest tap I had was 1.0mm so I just used it to ‘start’ the thread). Put back together and.... it’s flush!2 points

-

I am Dennis Anthony Zamora, a 64 year old retiree. I took up this hobby of watchmaking in 2019 in the hopes of servicing my Seiko 6119 which I bought with my first salary way back in 1978. Learning valuable lessons from the videos of Mark Lovick and Mike Bolton, I was able to accomplish my goal and eventually got hooked. I recently finished levels 1-3 of Mark's online lessons and find them so very helpful. Just like any endeavor, the learning never stops and I am grateful to be in this community where information and experience is generously shared. Stay safe and healthy everyone!1 point

-

I have seen and heard of several variants of this cap jewel cleaning method, but none of them have felt really safe so I invented my own variant and was so happy with it that I recorded a video of it. Hope you like it and get use of this "safe" method for cleaning cap jewels.1 point

-

I used to obsess about accuracy, but when I realized I could regulate a mechanical watch (not even an expensive one) to be off by less than five seconds per day, then it was all mechanical for me. Not having to worry about the battery dying and knowing that a mechanical watch made by all metals parts can be serviced and repaired indefinitely just doesn't make a quartz watch all that attractive to me. I don't mind quartz watches one bit (I have several), but I find mechanical watches so much more attractive. The one on my wrist right now and that I've been wearing for the past month, a Hamilton Khaki Mechanical housing an ETA 2804-2, has on average been off by +0.1 seconds per day. It's even better than your average quartz watch I believe. Anyway, that kind of accuracy in a mechanical watch is pretty uncommon so don't expect it. Couldn't agree more. Well spoken!1 point

-

There is a technical guide so it can be rebuilt. Sheet says battery life 5 years. I serviced a Seiko quartz that ate the battery in one month and lost 20 seconds in that time. Been going for 2 years now and barely 5 seconds off since I last set it. Rarely is anything worn out. Usually just gummed up oils. There just isn't a lot of stress on the parts. Not many watchmakers will waste there time with a quartz like this one. Any new movement is going to be decades old and will need to be serviced. Catch-22 situation. Some watchmakers have commented that they will rebuild these because they can have it done faster that searching out and ordering a replacement. You just have to find one with spare time and is willing. There was talk of a more modern movement that fits but I don't know any more.1 point

-

The movement (module) is gummed up so the motor is having to do more work and consume more power than it should hence the shorter battery life. As @jdm has pointed out, it might be cheaper to replace than to service... unless you want the fun experience!!1 point

-

Mass produced, never serviced quartz modules are not guaranteed to maintain optimal battery life forever. I can't read the exact model but it should be possible to replace it for less than 20 GBP.1 point

-

I want to be into quartz watches, but I can't get my head around them in a positive way. When I'm doing precision stuff, it's always via computer instrumentation, but that's not a a watch. Mechanicals are about the craftsmanship and artistry, and a decent one is accurate enough to not matter in any practical way. If there's a way to get that same feeling about quartz movements, I'd love to wrap my head around it, but I have yet to find that hook.1 point

-

Unlike a Barlow lens, the eyepieces don't change the working distance. With a 10x in the left and and 20x in the right, both are in focus at the same time. You can use the 20x with a 0.5x Barlow to get the same magnification as 10x with no Barlow but keep the longer working distance. But the 20x eyepieces are not magic crime drama "zoom and enhance" that create something from nothing. The image from the microscope objective is only so good and like zooming in on an already taken photo, what you see in the 20x isn't as clear as the 10x.1 point

-

Ross, get yourself some basic watchmaker tools, i.e. tweezers, screwdrivers, hand levers, hand setters, a movement holder, a case opener, a case holder and a work mat. Then find a $20 dollar Vostok calibre 2409 watch on eBay and follow the below videos. That's what I did when I started out before taking any courses. Don't worry about oiling. Just take the movement apart and put it together again and see what it does for you. You can also study my service walkthrough of the Vostok 2409 calibre by clicking here. Anyway, if it doesn't do anything for you, at least you've given it a chance without ruining yourself. BTW, used Swiss quality watchmaker tools found on eBay (such as Bergeon, Horia, etc.) are generally of such a high quality that you can easily resell them for what you paid for them. That is, you don't have to worry about losing (too much) of your money. Good luck and we'll all be here to help out!1 point

-

Well done, you got there in the end. That's another thing to check when I'm missing amplitude - too much lock. I like the pegwood tool. I do that with tweezers and it often pings off along the bench.1 point

-

Sorry to disappoint you but it isn't a verge escapement. It's an anchor escapement1 point

-

It looks good a nice flush fit. A fiddly job done with hand tools like you said a lot easier on a lathe but all in all a creditable job and saved from the bag of bits, now its time for a pat on the back and a cool beer well done sir.1 point

-

Hi Hector can you post a picture of the escapement sounds interesting. Regards the mainspring if you can get a tie wrap or a wire round it, ok if not wedge the train and remove the balance and fork/pallet if its possible and let it run down in a controlled fashion using a gloved thumb on one of the wheels. I think the tie wrap/wire looks to be the better option then hold the wound spring in a gloved hand and remove the wrap and control the uncoiling of the spring1 point

-

The OP is the watchmaker. Smart decision by an independent maker to supply (at least) professionals.1 point

-

Well the watch is back on my wrist and the periodic amplitude variation is better but not gone completely. In the process of working on the issue I actually made the situation much worse with amplitude dropping to 180 degrees from 220 degrees. What I had done to cause that was to close the oval upper barrel arbor hole and make round with very little play. What I had done in effect was to move that barrel arbor hole back and away from the centre wheel and fixed the barrel arbor in a slightly tilted position. This caused the barrel teeth to run at the top of the centre wheel pinion and actually ride up the pinion and bind every 5 minutes. I fixed the issue by using cutting and smoothing broaches and staking set (6 or 7 small indents on the side of the arbor hole that was away from the centre wheel) to effectively move the barrel arbor hole back towards the centre wheel. Now getting 270 degrees at full wind and dropping to 255 degrees periodically (probably not solvable without replacing parts, centre wheel pinion and barrel teeth have some wear). All's well that ends well.1 point

-

Finally, finally got my stereo scope. AmScope SM-4NTP along with a ring light & rubber eyepieces. Still waiting for the 0.5 barlow, so I don't have much working distance yet. Still, I'm having a ball looking at the balance wheel pivot on one of my old Seikos, amazing to see so clearly what's going on.1 point

-

sorry about I use dictation software and it doesn't like me at times which means we get goofy wording. in this particular case the word was supposed to be pin. occasionally I've seen this staking set would be really nice here. You can use a bench block but whatever you do you have to make sure everything is flat because of anything as protruding on the other plates you risk damaging stuff like of the balance bridges farther out in the main plate you to break the balance staff. Another way you can do it is the holding your hand? Then gently whack it with a hammer. If nothing is sticking out then staking sets nice pointy punch gently push in the center to get it to start to come out. Because trying to pull the canon pinion off this friction on can be a challenge. to give you an idea I was looking and were lucky I have something on the bench. You'll notice that the end was protruding out of the canon pinion. In this particular case I guess held it in my hand because it wasn't convenient arrested on anything and gently whacked the protruding pin. You'll see a series of photographs this should be helpful. In your particular case put the plates back together again the risk damaging things with that flopping around and trying to push it out without the right supports you still risk damaging things. Then if you want absolute proof that you do have a pin with a squarehead put something on the other end. I have your picture slightly modified notice where I drew the line that's where the pin is coming out. If you stick something on the pin parts and rotate the square you should see it rotate hold the center wheel while you're doing it the center wheel is basically a tube. you will note that mine is slightly different than yours in that the washer is in a brass part. That's so that when you're using your key you hopefully don't slip and scratch the plates up. the problem basically with anything vintage is the longer it's been in existence the more likely people worked on it that didn't know what they were doing that means all sorts of interesting problems occur from that alone. Also vintage has the problem of to some degree sort of almost being handmade usually in the case of pocket watches. Sometimes if you look carefully usually on the dial side you can see with a scribe the lines to figure out where they need to drill the holes. It also unfortunately means that you can't necessarily get off-the-shelf components.1 point

-

Hamish Thank you so much for your suggestion, it worked, the watch just needed a bit of help to get going again. Saved me a trip to the jewellers.1 point