Leaderboard

Popular Content

Showing content with the highest reputation on 11/04/21 in Posts

-

2 points

-

Don't get me wrong, I have nothing but sympathy and admiration for Vincent Calabrese, a self taught independant master watchmaker. I was pleased to meet this affable gentleman and buy his signed book at the Hong Kong Watch and Clock fair in the past. There we have his latest, an attempt to get away with the hairspring. Basically two springy bars make a third rigid one to bounce in between. An (energy hungry) rack and pinion mechanism then mediates to a conventional balance wheel and lever escapement. My immediate feeling is that the elastic deformation of the bars is so small to not have enough isochronism properties. even if they look like one, they vibrate much too slow to resonate like a tuning fork does. https://monochrome-watches.com/vincent-calabrese-presents-calasys-a-new-concept-to-replace-the-hairspring-independent-watchmaking/ Have you ever wondered why the hairspring is a long and thin string as opposed to a short one, because it needs to be to provide both elasticity and isochronism with the smallest energy used. Further to this fundamental defect, I see even some more, as in the large energy absorbed by the impacting between bars, the lack of self-starting, and the difficulty of regulating an "inertial balance", that is with screws. No matter what will be of this, my praise and best of luck to Mr. Calabrese for his invention.1 point

-

Originally when It came out 941 was still recommended for low frequency watches. Then 9415 for high-frequency. But with time the manufacturers probably realizing how cheap watchmakers are changed to an either or and now typically it's just 9415 for everything. Otherwise as stated above before 941 9010 was recommended The only problem with 9415 is it is a grease with thixotropic properties. To understand the meaning of that I have a link. Which from the description brings up a problem for us? So in superthin quantities it slides really really nice. But if you get too much it's basically grabbing the edges of the escape wheel causing the problem you had noted loss of amplitude. The watch companies are recognizing the problem which is why in the attached PDF you'll notice the extreme lengths they go to to get a superthin quantity. No you really don't have to go to these extreme lengths you just have to have less grease. https://en.wikipedia.org/wiki/Thixotropy Omega 8645_WI_40_rules for lubrication cousinsuk.pdf1 point

-

And there…I think we’ve found something we can all agree with…less is best. My plan at this point is: As I am now consistently running at 230 in DU/DD, I’m going to add a wee bit of 9010 to the pallet pivots, just to see what happens, and to satisfy my curiosity. I’ll then remove the pallet fork and escape wheel, clean both, and run with no lubrication, recording the results. I’ll then add some 9010 (instead of 9415), just to the pallet jewels, and record the results. Finally, I’ll strip and clean the movement, and oil based on the from my prior tests. I’ve seen how the watch performs with 9415 just on the jewels (and not on the escape teeth), and will have tried the other scenarios, and will go with whatever delivers the best results. I’ll post my findings… Thanks again.1 point

-

Good news guys! I remembered where I have seen these things before: On some chronographs the pushers are held in place by these little clips. So I took an old worthless chronograph and voila! Exactly the same. I removed one and it actually fits! so case closed, thanks to all who replied. This is the watch by the way: Have a nice day!1 point

-

1 point

-

Hi Glad to see the feet are ok, as jdm said quartz watches just push into plastic mounts whereas the mechanical watches are screwed in from the side so cannot be removed without being undone. Just to add to your interest in the Horological art I have attached a bit of reading for you as an introduction. cheers 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

All strikes should operate where right after the last hammer strikes the strike train stops. Warning pins are set up either to rotate 180 or 90 degrees before interacting with the warning lever. I agree with previous commenter. Loosen a wheel on the back plate and rotate the chime a bit. Also. I set my westminster strikes on the 1/4th or 15 minute. Its easiest because thats the one where the hammers will all fall down in a row 1,2,3,41 point

-

The problem with using a syringe, or other improvised air source, is that getting a good seal to the pendant tube is hit and miss. The dedicated tool below comes with enough nylon tips, is not expensive, and unlike the syringe, has not failed me so far. https://aliexpress.com/item/4000233469611.html1 point

-

1 point

-

1 point

-

The trouble with already made bushes is they are never correct, that goes for size and thickness. If you have the means to make your own then do so. You will need a lathe and various sizes of brass rod. Try to fit something that isn't correct is not good practice. What ever you do make sure you do not damage the plate. I hope you have the right size clock broaches. The original hole doesn't have a collar. The new repair shouldn't have one. Never solder it in.1 point

-

Closest sheet is this one could be part No 425 Cliquet Translated to clicker (clip?) Zenith 2552PC, 2562PC (2).pdf1 point

-

What does the winding pinion engage with ? it looks wrong to me. Having said that looking at Ranfit it looks correct I would like to know how it works thou.1 point

-

@handwoundCousins will take a debit card and give you 2.5% off. For the future.1 point

-

I've got most of it. Calibre = Caliber Inertie = Inertia Frequence = Frequency Hauteur = Height Epaisseur = Thickness Pas = ? Dext = Outside Diameter Dint = Inside Diameter N CGS = Our friend the CGS number1 point

-

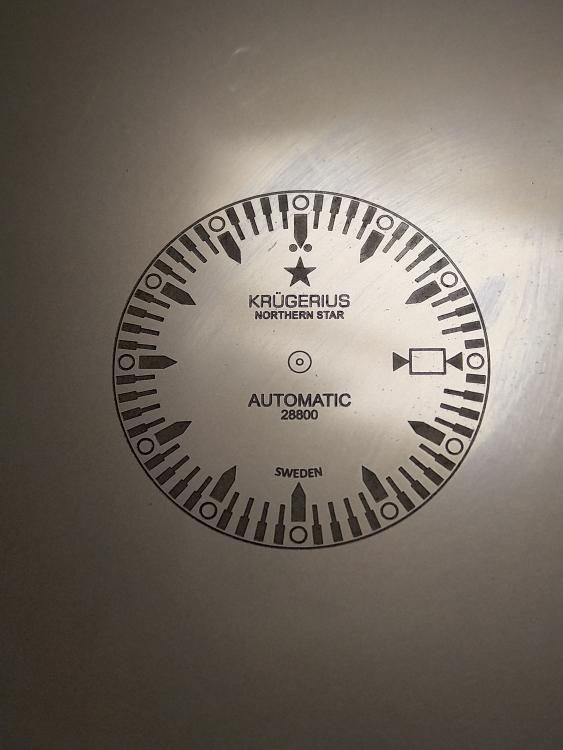

I would think that is a shame since you could show your achivements here, without any strings attached,if you from the beginning suggested it to be a walkthrough would be a different issue. There is probably more than me who likes your achivements here. I can show one of my achivements at the same time, a dial pad printing original etched into a metal plate . The black parts are the etched details ready to be filled with dial paint . Keep up the good work and stay here.1 point

-

I am not about in which section you post. I rest my opinion that your secretive attitude is in contrast with the spirit of this forum in general.1 point

-

Nucejoe was correct. It appears that the fork got displaced on the other side of the impulse jewel. Amazingly nothing broke and it's now working. Thanks to everyone for the help! Charlie1 point

-

UV light or typically UV LED flashlights are interesting in that the wavelength is almost out of our visible range. So if you look at your UV flashlight which you should not because it in real life is very very bright you just see a very dim glow. this means if you shine your UV light onto objects and I don't know the reason why but most objects just look dark some objects seemed to glow some really really intently. Modern synthetic ruby jewels and I have an image attached. I do think the camera makes them look a little more intense then my eyesight indicated but still they definitely seem to have a glow and the surrounding watch in this case does not. So they will stand out when you're looking for them versus hiding really well. Unfortunately if it's a vintage watch this is sometimes problematic. It appears to be that some natural stones do not glow at all.1 point

-

Hi, I uploaded a bunch of my "attempts" over the past few months. Some worked, some are ready for the trash! I have tried a lot of things, but what is working best so far is to: Use waterslide decals to laser print the design and adhere to a pre-cut dial or even just a piece of sheet metal. I am finding that brass and aluminum shined up really well are working best I invert the design (black becomes white and vice-versa) and adhere to metal. Then I use salt-water electro-etching to mark the design into the metal. This can leave either a "raised" or "cut" affect on the metal. If I want to try and have the markers/number have a very small amount of height, (like 0.2mm at best) so they stand-out, then I print the markers/numbers/second track in black and the white space is etched away. I do the opposite if I want the numbers/markers to be etched into the dial. Then I print another water slide decal, the inverse of the 1st one, and use that to fill-in what was etched away. I use 2-4 layers of water slide decals and might even etch in stages to create "layers" in the dial as best I can... Sometimes I etch, then white spray enamel and then put a darker decal on top, so the markers underneath the decal are white. That's what I did for the black dial/white numbers in the pilot style watches below. Like I said, some end up in the trash and a just a small few look OK. I will make a video at some point once I feel like I am making more quality work. Mike1 point

-

In a lever escapement the guard pin and fork horns keep the escapement from unlocking accidentally. In a situation where the watch receives a shock the balance can move away from the fork, which increases the guard pin and fork horn shake. If the escapement is setup so the locks are quite light, but still just safe, when the clearances increase during a shock the escapement could unlock and stop the watch. Not sure why you think lock drop and run to the banking are doubled in a coaxial? The main advantage they say is more stability in timekeeping over time. I personally don't think it is more stable than a good lever escapement, and it is very touchy to work on and delicate as made by Omega; I see it as an interesting escapement but if I had to choose I would take a standard lever myself.1 point