Leaderboard

Popular Content

Showing content with the highest reputation on 10/28/21 in all areas

-

I know that ETA uses a different grade of pallet stones in their standard and elabore' levels, and nickel balance with Nivarox 2 spring. At least that was the case as of about 10 years ago. The upper grades have Nivarox 1 and glucydur balance, and proper ruby pallets (and different shock jewels). Sellita has an elabore' level, but no idea if they actually use different components. If, like ETA their Premium and Chronometer levels use the same components, it's likely as said above a matter of selection there. It's highly possible that a skilled watchmaker could push a Premium to Chronometer. But, that might take 30 minutes or 3 hours. Even at 30 minutes (which is very optimistic) that will carry a price- and you still won't have anything official saying it meets COSC. And- even with a glucydur balance and Nivarox 1 spring and the best effort of a skilled watchmaker not every watch will be able to cut it, that's a risk, and a watchmaker would want a guarantee for the effort without being able to guarantee the outcome...3 points

-

To expand. The balance pivots are plugs (tampons) into the thin, hollow cylinder. In principle it's possible to to replace these alone but the standard practice was to replace the cylinder complete, making small adjustments to the pivots if necessary. The hard part is having access to a large enough assortment that contains a suitable cylinder. When I did that I was fortunate in having my mentor having the assortment and giving me the related directives, in fairness there weren't too difficult to follow. Personally, if presented a cylinder watch I would suggest the owner to do only a conservative repair and restauration. That is, the watch runs stable and timekeeping is within minutes a day not seconds. If that can be done keeping all original parts, even better.2 points

-

Older movements offen had the terminal curve almost imperceptibly developed from the outermost coil, with a pronounced kink just before the stud. What you are describing sounds OK, but as others have pointed out, a picture would be very useful.2 points

-

1 point

-

Thank you, I'll study this and hopefully develop my skills so I dont gauge my eyes because I like them1 point

-

We use a public database (Rannft) for this kind of searches. In this case it was easy to look at all the results as it contains just 4 cylinder mov.ts sized 5.75 x 8.5''', of these none is the one you have. That's not a problem at all because specific spare parts for what at the time was already an obsolete type are normally not available. But small lots of vintage ladie's are abundant and cheap. First find why doesn't run, and go from there.1 point

-

My experience. Cheap wrenches do mostly work, but loose pins (years ago I used silicon grease to keep them in place), and the wobbly handle screw are unpleasant to use. Minus the roller bearing probably, I don't know if "classic Bergeon" have that. I'd rather buy 3 sizes of the "unbranded A*F" drivers. Even my set of Chinese drivers is better than that. I bought various cheap ones for gifting, and kept the less horrible. It still plastic, but has few spare tips inside and it works. You can buy Bergeon original (wow) screw-on tips for it. Yes it's of the sturdy breed. There is another type like that, uglier but even sturdier. These are copies of Seiko which makes four types. What for each type is meant exactly is a Japan's trade secret. We all like these cases as we had them since primary school except they were shaped like Mikey's head and the like. My other memory about that early "kit experience" is that the eraser was either rock hard and ripped the sheet right away, or smelled like sweets - probably harmfuls chemicals. Not having anything less intelligent to add here, I wish you fun using it and leave a link which may be appropriate sometime1 point

-

Sometimes swapped out lenses so you can see 21 point

-

My understanding is that these are in fact just indicative classifications, what happens is that beside better timekeeping obtained using different parts (a micro regulator is almost always one, and sometime different matarial jewels) plus of course factory adjusting, these go together with aesthetic improvements, which in turn can be customized from a customer and batch to another. All details which are only privately discussed with established customer with teh traditional Swiss secrecy. In fact it has been like that for more than 200 years now. Also, the notion I got from different source and meetings is that this manufacturer, and others as well, will not take orders smaller than (about ?) 500pcs.1 point

-

Were you planning on buying in bulk? I don't think Sellita sell to the general public, you might be able to buy what you're after through Cousins though.1 point

-

Only for general work and in cases where the available developers don't master, or have the time to learn another language. Specialized environments, of which there are too many to list, profitably use something else. Just to give you an example, yes one can write mobile apps in JS, but that quite more limiting than true native applications, which are written in Java or C#.1 point

-

ST3600. Never got it in. Using the movement for parts, less the shock spring. Found that placing a very tiny ball of rodico at the base of the spring keeps it from jumping out. It's been very successful and I can finally complete a service 100%. Also, those Seagull ST3600 clones are pretty good these days. After servicing they're only losing 2-3 sec, .7 ms beat error, 252 degree amplitude. I've been wearing my current watch for a week and haven't had to set it.1 point

-

Update, so the ( sample) hairspring I sent to atlasmicrotech metalab has been analyzied and we now know its tech specs. The company has provided excellent customer service, I certainly recommend them to those who may come to purchases part in bulk. Regs1 point

-

I am not sure but I think I understand what you are describing. The bend can be either at beginging or the end of terminal curve or two bends one at the begining the other at the end of terminal curve. What matters is the coil is to breath evenly. Hope I guessed right and this helps.1 point

-

Correct, the big hole on the left is for the winding key, which I removed to access the mainspring.1 point

-

1 point

-

I see what you're saying, but I don't think so. If you look on the movement, there are pegs that lay across those holes, I think it's for holding the movement firmly.1 point

-

do we know if there actually is in a physical differences in the watches? I know some of the Swiss companies use a different hairspring and balance wheel for the higher grade watches?1 point

-

I am sure you are right graded by performance after assembly and test therfore no need to readjust/and replace bits to achieve COSC certification. In a way I suppose its more in the interests of profit saving rework time.1 point

-

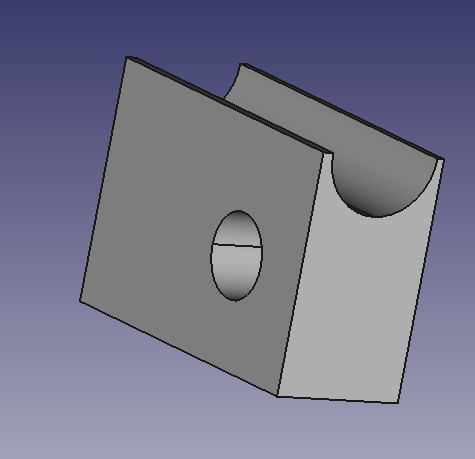

Wouldn't such adjustment be easier to make for the manufacturer as they have special proprietary tools, highly skilled watchmakers you name it. What does a repairman have couple of dull screwdrivers and a tweezers. oh plus a loupe. Here take a look for yourself.1 point

-

I bet they just segregate the best performing movements and charge accordingly.1 point

-

1 point

-

What's the base movement , aren't these parts standard ETA /sellita 2892 or similar1 point

-

1 point

-

1 point