Leaderboard

Popular Content

Showing content with the highest reputation on 10/02/21 in all areas

-

Did you know that watch jewel fluoresce under UV light? I learnt that here on WRT. You can try looking for your missing jewels with a UV torch and the room lights turned off. I wished I knew that a couple of years ago when I lost a pallet jewel.4 points

-

As I understand it the Chronoglide video is saying the larger (well, for a watchmaker) ultrasonics are too powerful. Ultrasonics have been used in watch cleaning machines for at least 60 years though. But that guy also uses automatic cleaning machines that don't have ultrasonic, maybe he's justifying that position (I have the same Greiner ACS 900 he has, and it came to me without ultrasonic. It was 2000 bucks to add the driver board and tank, and I'm very happy to have done it...). I do clean parts in a larger Elma quite often, but mostly components I've made for customers. I have to say I've never had a problem with it damaging anything. I and everyone I know cleans the balance in the cleaning machine, with ultrasonic. I have never had an issue with roller jewels coming out, even when I used a machine that had warm isopropyl alcohol as a rinse. I think Karl's theory of a manufacturing defect is probably correct. Spectre- how long were the parts in the cleaner? I remember someone left a movement in some L&R 111A over the weekend at school once and the plating was destroyed. On that note, with my cleaning machine I can set the time in each bath; with the ultrasonic I find that 5 or 6 minutes is plenty. I think with the non-ultrasonic machines folks tend to do 10-15 minutes, which, if you think about it, might cause more damage than the supposedly damaging ultrasonics, haha.3 points

-

Or more popularly, spontaneous synchronization2 points

-

They are not always fitted inside a washer which is smaller than the barrel inner diameter.2 points

-

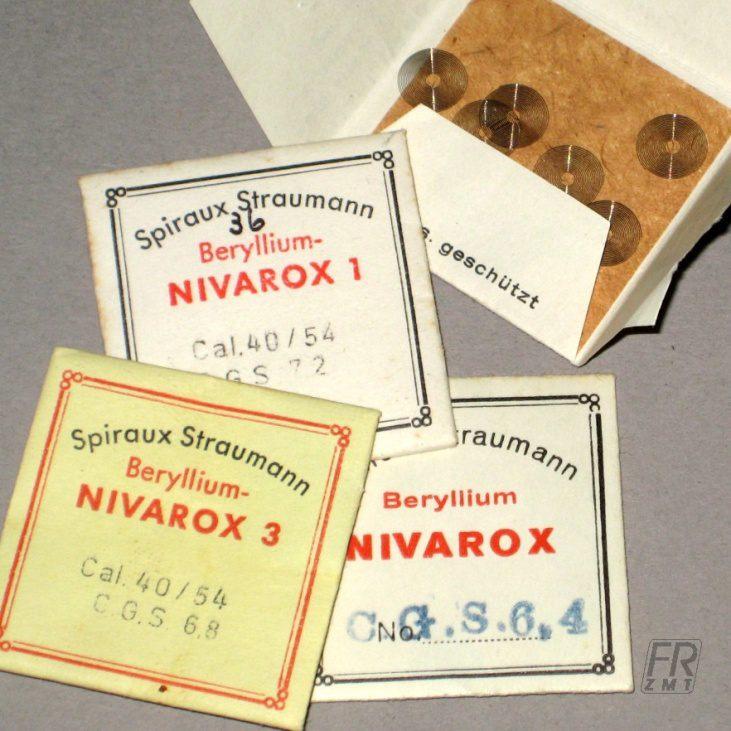

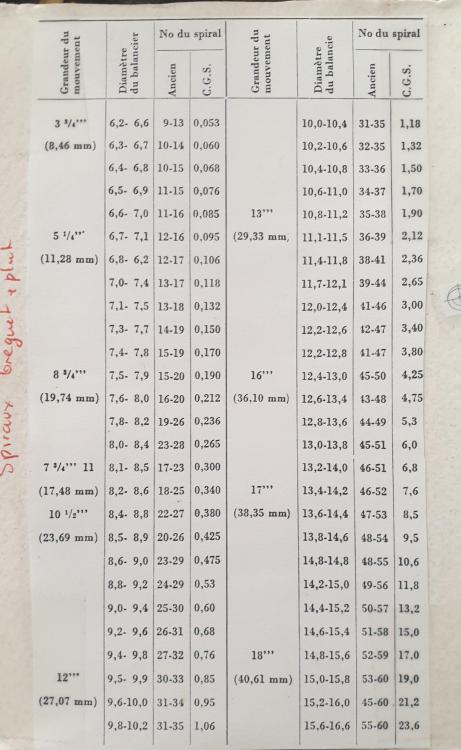

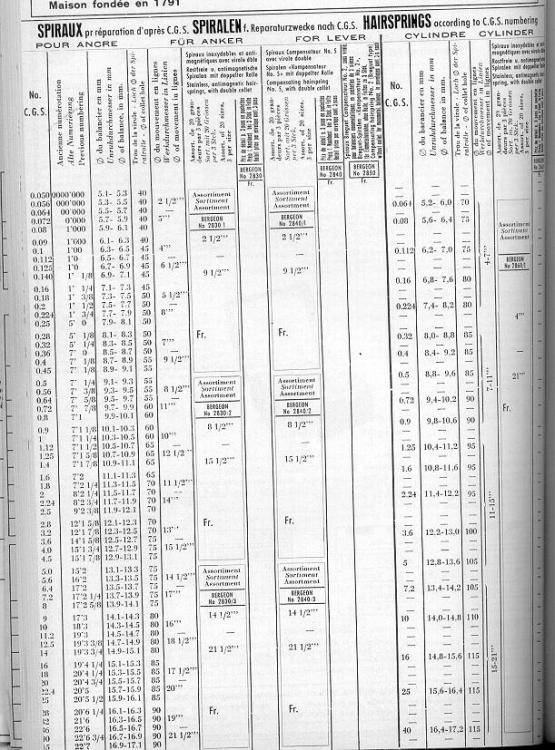

kilogram force? Really funny, fits inches, feet, pound, short ton and other strange units. Agreed, I use "grams" as a weight unit, too, when buying apples on the market. But regarding physics and science we should be clear and use the correct units and terms. I am not talking of these units, Joe. I am talking of the "CGS number" that fully describes a hairspring - and is used since 80 years for this purpose. A serious vendor will supply these CGS with his springs - the above vendor does not. What he calls "Torque" (gm/cm/100deg) is anything but a torque. Anyone who is working with hairsprings (Joe ) should be familiar with the term CGS. You can immediately determine what hairspring you need for a given balance wheel and beatrate when using CGS numbers. What the hell is this CGS now? In short: it is the needed torque to turn a hairspring by 57 deg (57deg equals rad=1) when it has a diameter of 1 cm. Its unit is "dyn * cm^3" Frank2 points

-

A good move might be to reference against the CousinsUK info e.g. https://www.cousinsuk.com/document/category/acrylic-shaped-watch-glasses or https://www.cousinsuk.com/category/acrylic-watch-glasses This will help you decide between barrel, bale, oval etc. Those pattern ones are called faceted and, for Sternkreuz, come under their CP range which they term 'saphir imitation'. There is the complete Sternkreuz catalogue available at http://www.sternkreuz.de/accordion/assets/Sternkreuz_Gesamtkatalog G22.pdf too which may be of use.2 points

-

I designed the synthesizer and VCO for the DSP on an integrated circuits used in disk drives (circa 1995). These designs went into WD, Seagate, and Quantum disk drives. The VCO was slaved to the synthesizer (which was slaved to a crystal oscillator) and was designed to be adjusted according to where the read head was on the rotating disk (inside radius slower than when at the outside edge of the disk). What we discovered was that as you dial the VCO near the frequency of the synthesizer, it just locked in and would not budge until you pushed it well past the reference frequency given by the synthesizer. Wow...we were scratching our heads. Somebody on the team discovered that we were not the first do notice this issue. Christiaan Huygens also discovered that when clocks mounted on the same beam while closely regulated, will synchronize themselves. In modern times, we call this "injection locking." This bit of insight was exciting for me...being the son of a watchmaker.1 point

-

Out of curiosity I was going to order some nispan c springs from britishprecisionsprings.co.uk, the price looked reasonable. Then I found out that shipping to U.S. would be over 30$, and I got un-curious very quickly1 point

-

Oris 671 or 677? For the first check https://www.ebay.it/itm/Balance-complete-ORIS-671-672-680-681-670-Roskopf-s-vis-bilanciere-completo-721/165029680135 The latter should use an available 7750 balance. Maybe diameter not radius? Since a radian is about 57 degrees, to convert from CGS to "torque at 100 deg" the proportion is : 1 / 57 = x / 100, that is multiply for 1.75, according to table posted by dadaistic for an 8 3/4"' that yelds a "british" value of 0.35 and up. I understand that dealing with different units can be irritating. But when running a business there is nothing worse than irritating an opinionated chief engineer, so better to second him and let others figure out.1 point

-

There is contact on the circuit board labeled AC, which you can see on the back of the movement with the battery cover on. Short that to the battery cover. The whole metal back of the movement is ground. It resets the internal state of the IC. After powering it on it's in a random state will probably not being working right in some random way.1 point

-

@Nucejoe, I notice that you have been on this quest for some time. You may have to work your way to an answer, by experimentation. Start with the balance diameter, and from the attached charts get something that is "close", so that you are starting with a known value. Vibrate this spring, get the system oscillating correctly, measure the radius of this spring, and then use the following formula to figure the correct CGS number. K=K1(R/R1)^2 where K1 is the estimated CGS, R1 is the radius of the estimated spring, R is the measured radius, and K is the required CGS. I've swiped this answer from an NAWCC post, but the procedure comes from "Watch Adjusting" by H. Jendritzki. My copy of Jendritzki is in storage, along with everything else. I haven't tried this yet, as I don't have a hairspring vibrator, but I believe you said you do.1 point

-

This UK based company are a great resource for hairsprings. HOWEVER the majority of springs supplied are without a collet so you will need the skill to pin up a hairspring. Also I do not understand their sizing system.Also those that do come with a collet take for ever to be delivered. The last time I used them it was three months and that was after several nagging emails from myself. http://www.britishprecisionsprings.co.uk/html/stock_spring_list.html1 point

-

I've had several instances where I've had the "correct" spring as recommended by Cousins and GR, and the washer has been too big. Just one of those annoyances.1 point

-

If I get really ambitious I may attempt to do a conversion, which should settle the issue. I haven't done any calculating for a very long time, and my arithmetic has always been suspect :-), but maybe I'll try it as a brain exercise. If somebody beats me too it, great! And show your work Cheers!1 point

-

Sorry to disagree, but indeed is a measure of torque, expressed with only the angular component being different from the definition you have written before. That is, the torque (in grams force) needed to turn a hairspring by 100 deg. at the diameter of 1cm. Joe is correct. CGS is an units system which predates MKS and SI. https://en.wikipedia.org/wiki/Centimetre–gram–second_system_of_units There you have the dyne defined in the CGS system in the same Wikipedia article: https://en.wikipedia.org/wiki/Centimetre–gram–second_system_of_units#Definitions_and_conversion_factors_of_CGS_units_in_mechanics When the hairspring industry writes CGS they are simply saying which units system is being used to indicate the value of the torsion spring constant for a particular hairspring. But there are no seconds in a torsion spring constant.1 point

-

This is not the "right" answer, but it looks like you could treat it like a... I can't think of the name of the thing... A blind nut with slots in the side... Secure the movement/rotor, then take a pair of screw drivers, or peg wood if it's not too tight and you don't want to risk scratches, in opposing slots and push. If it were large scale on an engine or some other industrial machine, you'd drop a drift or something in the slot, and hammer it loose.1 point

-

In the 1974 Generale Ressorts book they list the 3196-X for this caliber, and state the ring diameter as 8. Like Rodabod said, they aren't always perfect for every caliber.1 point

-

1 point

-

The Cousins size agrees with the GR database which lists the diameter as 8mm. Surely the wrong barrel wouldn't work ? Very strange1 point

-

1 point

-

Tackled another one without any difficulty...I guess I am getting better.1 point

-

And so Galileo began dropping items from the Pisa tower to prove his point, then Newton introduced the (earth) gravitational constant, then etc, etc, after 3,000 years of science and notation changes we the peasants are left depending on Google while some government keep legal measuring in inches, nails, short medium and long tons.1 point

-

Gram force centimeters, an unit of momentum of torque https://www.translatorscafe.com/unit-converter/en-US/torque/12-9/gram-force centimeter-kilogram-force centimeter/1 point

-

gm = g ?? That would be a unit of mass, not of force. And what shall "g/cm" be? Frank1 point

-

I'm no expert but that doesn't seem very strange to me. k (torsion spring constant) as described https://en.wikipedia.org/wiki/Torsion_spring#Torsional_harmonic_oscillators Since Newtons and meters are too big units for such a small force, they use g and cm. Radians are used only in science only, so a conventional, fixed angle is given instead. There is probably equipment around which can measure that "almost easily".1 point

-

A very strange kind of unit! Some time ago I asked them for a method to convert to CGS, but no reply. I wonder if there is anyone left who has more knowledge about their springs than the price Frank1 point

-

1 point

-

Another toy has been added to my workshop.A AmScope (SE400-Z) 10X-20X LED Binocular Stereo Microscope Boom Arm + LED Gooseneck. It was supplied with two pairs of eyepieces wide field WF10X and WF20X.The reason for this latest purchase is I have a issue with my back and it is suspected it is a condition named spondylitis. There is no medical cure just various pills and exercises to help but stooping over a workbench for long periods becomes very painful and without doubt aggravates it. So the idea (which was recommended on the YouTube site Choroglide) being less stooping by using a microscope and this particular scope has a large working distance of 9” although in reality 8”. But nevertheless I can now work and inspect watch movements with a better posture. Early days yet but it seems to be making a big difference. I have now ordered a pair of WF5X eyepieces which will give an even wider view. I am now the owner of three microscopes. I have a Bausch & Lomb stereo microscope which has really good magnification if required over my lathe for fine work such as balance staff work. My workbench has now two microscopes an Olympus stereo microscope with a magnified light source via a fibre optic cable to a ring light. This scope has superb clear lenses and can also give incredible magnifications. But a very short working height hence the latest purchase. The AmScope has good lenses but certainly does not have the same quality and clarity lenses as the Olympus. The light source is also via a gooseneck led light and again this is not as good as a ring light. However this scope cost just £166 inc. postage so IMO it is still really good value and well worth the investment and I suspect this will be the go to scope for most of my work. I Bausch & Lomb over my lathe. Olympus + light source The new toy.1 point