Leaderboard

Popular Content

Showing content with the highest reputation on 03/21/21 in all areas

-

About the bimorph sensor, my opinion, is that I had more expectations about it than it actually has. I have experimented with piezoelectric discs and apart from the commercial microphones of the timegrapher machines, they are the ones that give the best results. I only have one that he gave me @24h. And I have treated it very carefully so as not to ruin it. I replaced the glass of the commercial microphone of the machine in the photographs, but taking into account that I run a very high risk of ruining it, which I do not want. When doing the test I obtained very low results, without modifying anything in the application chain. It may be that you need to repeat the experiment. Above my skeleton watch with the bimorph sensor in Elma Mic. Above my skeleton watch with the Elma professional Vintage microphone. Above adapting a piezoelectric disc cut to the Elma microphone. I have no results but I remember that it was larger than the bimorph, but smaller than the Elma microphone. Above the cut disk and the original crystal of Elma. It is possible that I did not perform the tests to high standards.2 points

-

Was thinking we recently talked about the green sensor? Then I remembered we did we discussed the mounting it's critical how it's mounted otherwise it doesn't work very well. The reason we know about the existence of the sensor is it's used with some software found at the first and second link below. I had the opportunity to dissect their clip on microphone discovered the sensor and tracked it down. Also we know from other sources that this is the sensor they use in all their devices. In addition to using it with their clip on sensor if you send an existing timing machine microphone it's upgraded with one of these sensors and their circuitry. Original people using the sensor and their software https://www.etimer.net/ http://www.delphelectronics.co.uk/products.html The next to links or where it can be purchased from either the UK which I interpret to be the primary distributor which ships just about everywhere in the planet except the US. The next link is the US distributor. Even if it shows zero quantity in stock I is went ahead and ordered it and they came a few weeks later so that didn't seem to be an issue of having it in stock or not. Then yes you do have to purchase five of them even if it has a individual price. https://export.rsdelivers.com/product/rs-pro/bm15015-06hc/rs-pro-vibration-sensor-15c-55c-dimensions-15-x/0285784 https://www.alliedelec.com/product/rs-pro-by-allied/285784/70637796/?keyword=70637796 Then my best guess is there the original distributor of the sensor. I can't tell if they're the original manufacturer or basically the sole distributor but in a case I do believe there the source.Which probably suggests we could ask them questions and probably purchase thousands of them. https://lprs.co.uk/products/sensors/vibration-sensors.html RS PRO Vibration Sensor.pdf2 points

-

I have had this book on the computer for some time and thought It would be best shared for Beginners and the more proficient watch repairers and hobbyists alike. It contains a wealth of information, enjoy. 971432187_JosephBulovaSchoolofWatchMaking.pdf2 points

-

As far as I can tell everything covering a rather sizable time span they're basically all the same thing. They all physically look the same square with the leads attached. They all seem to have an aversion to moisture. Evolution of the sensors? Conveniently unhelpful for us I disassembled the microphone and the base which has the model number is now somewhere else. Reasonably sure this is a Vibrograph It's an interesting design plastic case italicized on the inside for shielding. The sensor assembly is mounted the black plastic piece that just slides in. The protruding probes as I'll call them go through soft basically like grommets. Then their motion Limited by the black plastic say they can't go very far and then the grommets they go through limit their motion also. Both sensors are identical they appear to be epoxy glued to the probe and they do not connect or the glue is. Otherwise it makes the wiring extremely confusing. You'll notice each one of the probes has been soldered and that goes to one of the terminals so that's the ground that also goes to one side of one of the sensors. Then both sensors are basically connected in series which I find is interesting Then I assume that all that circuitry was there because their coils on the other side because I assume this would do tuning fork watches. But it took the circuit board out there are no coils that circuitry is just for the pickup. It appears to have quite a few little tiny transistors which is what happens when you don't have an op amp.2 points

-

Vostok 2409 Service Walkthrough Disassembly Pictures (Please sort by name in ascending order) Vostok 2409 Service Walkthrough Assembly Pictures (Please sort by name in ascending order) Being able to service the ETA calibre 2824-2 was a long-term goal and a dream when I started servicing and repairing watches some years ago. However, my first “calibre love” was the Vostok 2409; a reliable Soviet/Russian 17 jewels manual workhorse without any complications which has been around since 1970. It is still in production and found in Vostok’s Komandirskie series of watches, by some called the AK-47s of the watch world, together with its bigger brother the Vostok Amphibian dive watch. Modern-day Vostok Amphibians use the automatic Vostok 2415 (w/o date complication) and 2416 (with date complication) calibres, but the Amphibian that I’m servicing in this walkthrough, an Albatross Radio Room, popular among collectors, is from the 1980s and in those days the manual 2409, as well as its predecessor 2209, was commonly used in the Amphibians as well as the Komandirskies. While I was servicing this watch, I noticed that the crystal didn’t fit perfectly in the watch case. Being a serious dive watch originally designed for the Soviet navy this was, of course, unacceptable, so I replaced the crystal and video recorded the event in my “Bergeon No 5500 Crystal Press Review”. For me, the 2409 was a great movement to get started with as it probably is the most affordable movement on the planet, and spare parts are readily available and cost next to nothing. A lost or damaged part never spells financial disaster. Also, eBay offers an abundance of used Vostok watches in decent condition housing this movement for as little as $20 and sometimes less. A brand new Vostok 2409 (www.meranom.com) can be had for as little as $27. Be aware that, almost without exception, the eBay listings always state that these Vostok watches have been serviced, but in my experience they never are. Well, maybe dipped in a can of naphtha, left to dry and then injected with a bit of oil here and there. I’ve seen horrible examples! A somewhat tricky bit about the 2409 is to remove and replace the anti-shock springs. For this, I use a self-made tool made from peg wood. It’s shown in one of the assembly pictures together with a description of how I made it. A very similar tool is demonstrated in this video. Later, as I was working myself through Mark Lovick’s watchrepairlessons.com courses, I trained with the Unitas 6498 pocket watch movement which is the selected movement for the courses. In all honesty, from a learning point, the Unitas 6498 would have been an easier movement to get started with (especially the anti-shock springs), but the tinkering with the Vostok 2409 was a low-cost and fun way to get started and made me better prepared for the courses which answered a bunch of questions and was amazingly instructive. Eventually, I plan to publish a “Vostok 2414 Service Walkthrough”. The 2414 is identical to the 2409 but adds a very uncomplicated date complication. So, if you want a whole lot of fun for next to nothing when it comes to money, there is no other movement I would recommend before the Vostok 24XX movements, and the 2409 is a great starting point if you have a desire to begin tinkering with watches. Be warned though; tinkering may take over a substantial chunk of your life!1 point

-

It is possible that this document can assist in the design of the microphone and preamp. WCE2007_pp624-629 Espectro Reloj.pdf1 point

-

Disclosing the caliber or posting a picture of the movement is a good start and helps to know what we are working on, then you tell us as best you can about the issue, history etc, you might be given a list of test to carry out that helps diagnostics, solutions will be discussed and we'll work with you till your watch get young and happy. Do you see the ratchet wheel turn as you try to wind through the crown? if not, try winding through the ratchet screw. Remove the hands and dial and show the keyless works. Report some such data and advice will pour in your thread. Regs joe1 point

-

Wow, so many piezos. One could spend months trying different ones. I see bunch described as ultrasonic sensors. Add I understand it, collisions of hard things, like an escapement tooth and a pallet jewel, produce sounds in the ultrasonic range. Most PC sound hardware can do 192 kHz recording now. Good enough, in theory, to get to 96kHz, but that assumes the analog components pass those frequencies, which is likely a significant assumption, given the care with most PC audio hardware is designed and built and that humans can't hear those frequencies anyway. But an amplifier could also be built to heterodyne the ultrasonic spectrum down to the 0-24kHz range. Maybe the signal is cleaner up higher?1 point

-

I have no arguments for the experience of Frank @praezis his trajectory is one of respect. And I will agree with his observations and contributions. What I can definitely say is that it is very difficult for us to improve the commercial microphones of the old time machines. These are my observations. 1.- They are perfectly insulated or shielded to eliminate noise from electromagnetic sources. 2- its design is aimed at the most important frequencies in the sound of the clock. 3.- The cables from the pick-up to the unit are perfectly shielded.1 point

-

Joe, I for one have listened. I am still at the stage where I would never get a watch back together without many detailed pictures. Thanks to you and others I adopted this practice early on.1 point

-

As you are just going to remove the broken link no heat will be needed. It would be different if you needed to do gold soldering. I suggested smooth jaw pliers as you don't want to mark the gold.1 point

-

Hello and welcome to the forum, A little gentle attention with a soft pencil rubber or cleaning stick might be just enough, the lume looks ok but when the crud is removed best to check again.1 point

-

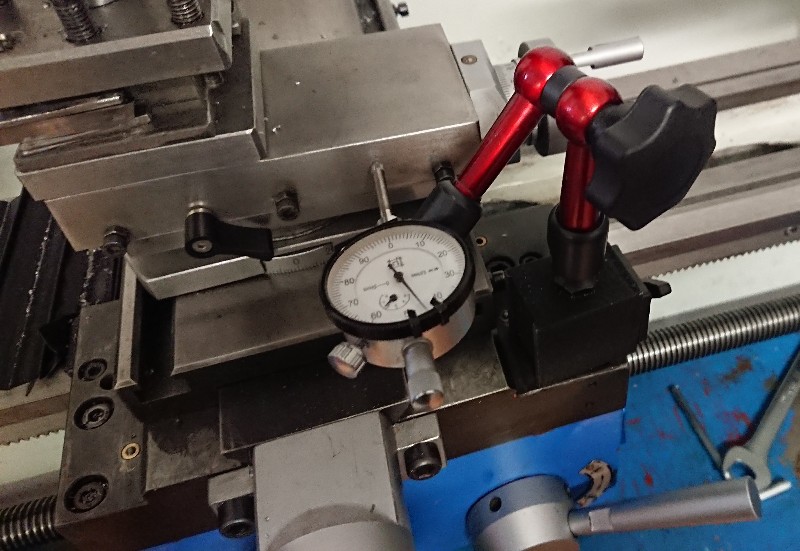

For the OP or anyone that has never done or is just at the beginning with lathe or milling work. The approach above is the way to follow if you have only the wheel dials to rely on, possibly of the non-zearoable type to add pain. But as soon you back off "the controls", voluntarily or not, then returning precisely to the same point just "taking up the slack" does not work anymore. In other words, using dials on the wheels you can't measure distance in both directions, and kind of fastidiously in one direction only. The solution is simply to use an instrument (dial indicator) which tells where your tool holder or workpiece is, on whatever axis you apply it. It does't know or care about backlash, nut play, double nuts, ball bearings, or anything else. It saves you from remembering how much a division on the wheel is, if it doubles for diameter or not, or having to convert from metric to inches. You can get one including mag base and arm for about USD20. Truth is however, real watchmaking work on a watchmaker's lathe do not use dials, indicators and not even slides or wheels mostly. Just gravers, handfeeling, loupe and micrometer. But as my mentor says, better start learning on the large and get to the smaller gradually.1 point

-

Attached document is for all you lathe buffs who like to make your own tools, there are some useful/practical ideas on this one. Toolmaking.html1 point

-

That being a web page is better enjoyed in its original with pictures and all, so here's the source link https://watchmaking.weebly.com/toolmaking.html About this website in general for one side it's incredibly rich in content about toolmaking, machining and watchmaking, a sort of still pictures version of clickspring of the YouTube fame, at the same time it's a bit saddening that the ambitious project of a dual-barrel, tourbillon watch has remained incomplete since many years. We don't know why or even the name of this talented American.1 point

-

Attached is the book by Hope-Jones on electrical time keeping , fot you guys who tinker with the electric clocks etc, must be a few gems in here for you. Hope-Jones F, Electrical timekeeping.pdf1 point

-

They're not the only ones making microphones like this. For instance at the link below there is one. Then there should be one of these lurking in the house someplace according to the receipt that I'm looking at I purchased it in October 2018. It should be lurking in one of the boxes of miscellaneous electronic components that looked nifty and should go into a project someday in my lifetime. https://www.digikey.nl/product-detail/en/knowles/SPU0410LR5H-QB-7/423-1139-1-ND/24209831 point

-

Yes it's nice I have one. Now let's see you pull a rabbit out of the hat? I assume they named it the same thing so we need a (Vibrograf B200 Technical information). At least that's what it says on my B100 as opposed calling it a service manual. I'm not going count the pages but there's probably at least 100 pages here every single aspect of that timing machine. But other than crystal for the pickup that's it for specifications.1 point

-

Beyond the size, I believe MEMS devices are quite fussy about how they are soldered. So for prototyping, one would get a coupon, like the VM1000 eval coupon. But I don't see anyone offering the coupon for the VA1200. Maybe it's too new.1 point

-

1 point

-

http://www.geocities.ws/dushang2000/Vibrograf/Vibrograf B200 User Manual.pdf1 point

-

First. About the Vibrograph microphone. It is a piezoelectric based on Rechelle's salt. In my experience, it is not as sensitive as a 27mm piezo welded to a small alligator clip. I send 2 images. I send 2 images. The first is from Elma's professional microphone and the second from the piezoelectric disc in a small alligator clip. Above. Elma Mic. Above, Piezoelectric disc in alligator clip. In both cases a modified Pyle PP444 preamplifier was used. See the link. https://reparacionderelojes.weebly.com/modifying-pyle-pp444.html Above Elma Mic. About your question. you want to design preamps. But what application will you give it? Are they for timingmachine? or other application. Regarding the other questions, I think they are solved by thinking about the nature of PC microphones. They are not intended for High Fidelity. But the nature of the sound of watches is not out of the range covered by these microphones. And finally. If your preamps are intended for any of the known applications or software, they will handle decent sound from an acceptable vibration sensor, single transistor preamplifier very well. I mean WOS, TG, BIBURO, PCTM, PC-Zeitwaage 54, e-Timer and Tickoprint for android.1 point

-

You could try emailing the company at the link below. Ask them exact specifications for the Vibrograf b200 And see what happens. As it's obsolete they might actually tell you. Several years ago I know somebody who emailed them and asked for servicing information for the B100 and did get a response back. Response was normally they don't give out technical information but it's obsolete here the schematics. My amusement with that answer is that he gets the schematics. But years later on eBay I find the complete service manual for the B100. So obviously they did release that to somebody? Then yes it does have the microphone all the components how it goes together etc. But all it says for the pickup itself is that it is a single crystal. Typically with any of the schematics that I have if it shows the microphone it's the symbol of a crystal. The easiest way to look at this would be to look at the specifications either for a crystal microphone or pretend were making a phonograph and look at the crystal pickup used in those. They should have a similar specifications to what were using. https://www.greinervibrograf.ch/1 point

-

By "Bergeon red" I assume you mean the super fine Ergonomic oiler? That's what I use. I spread a very small amount of 9415 across the bottom of an oil pot. This thin layer allows me to pick up a very small amount - but even then it's often too much, so I touch it to my thumb nail to remove some1 point

-

tHi Brilliant , its all working now great attached a couple of sheets on the 6139 for the future Job. all the best. 6510_Seiko 6139A (1).pdf 483_Seiko6139B (3).pdf1 point

-

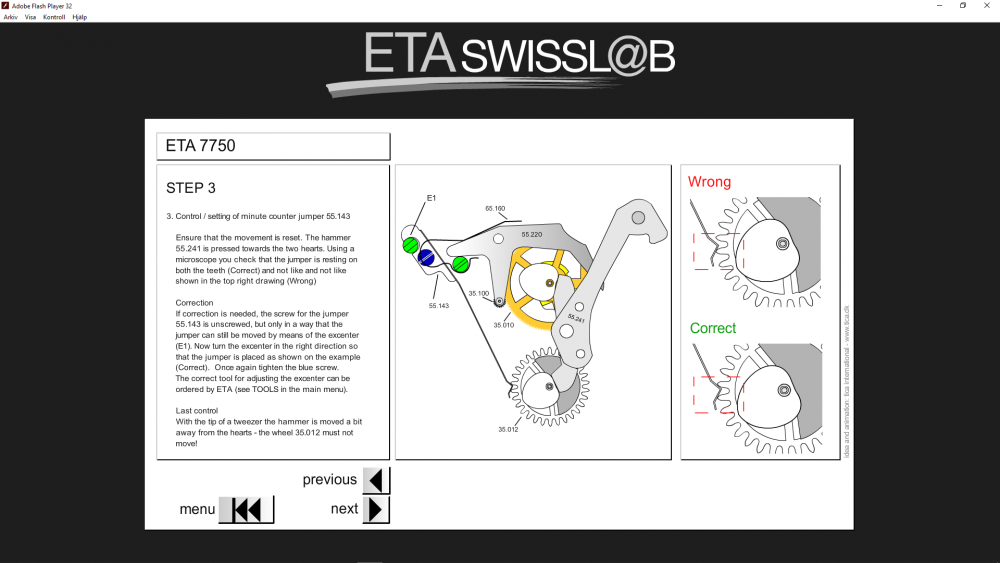

For those who were curious of what the 7750 flash-files contained and didn´t have time to download the swf files I did a small compilation of the Swissl@b application a while ago. In this PDF you also get some extra information. So no need for a flashplayer..... ETA 7750 HSL EDITION.pdf And after a quick glance at this issue here is an alternative if you really want to look at these files. For windows users I attached the reader in the zipfile. Just unzipp the zip file to a good place on your harddrive, read the attaced short instructions and happy viewing. [email protected]1 point

-

It's good that you're panicking Early because the technical communications are still there. Like for instance 30 seconds ago I just downloaded from this link As you are using an example of 7750 PDF.They just don't jump off the website like they used to you have to stare at the website and then go all I know what I'm supposed to do and then you'll get there and you can get your technical communication but don't worry at some point in time they will all be gone. I doubt there's anything they could do to cousins other than just not give them anything new not that they probably give them anything at all anyway. https://shopb2b.eta.ch/catalog/product/view/id/69714/s/7750-7750-5/category/24/ The access the soon or someday to be forbidden knowledge under penalty of death Start at this link https://shopb2b.eta.ch/ Get confused okay maybe that's just me. Notice how the top of the page it specifies mechanical or quartz pick whichever one you like and then go from there. Then under each of those categories you can pick whatever you want view all will work. Then you get the images of all the various movements that are left that we can look at click on those and it looks like 2019 is the age of all the technical bulletins.1 point

-

It looks like horotec.ch has the new files. Better download as much as possible before it is removed. For example: http://horotec.ch/file/TECH_ETA.7750.pdf http://horotec.ch/file/CT_2836-2_ESI_482114_15.pdf1 point

-

I think the Vibrograf B200 Microphone might have a little more space in it. Then whatever I saw somebody had used a piezo disc and they do come in a variety of sizes. Then because the originals are water-soluble I'm reasonably sure that they're made of Rochelle salt (sodium potassium tartrate tetrahydrate) It's amazing what you can find on Wikipedia. So what will happen with time is They will absorb moisture and just disintegrate.1 point

-

1 point

-

I could not find a single video on how to wind a mainspring back into the barrel after cleaning. I purchased a three set tool and figured it out myself and then made a video for others to learn. Thanks Sent from my iPhone using Tapatalk1 point

-

0 points

.thumb.jpg.073f338e6e0d8fb8186f15cc462a9323.jpg)

.thumb.jpg.90abbbef3d064b40a6a727019d5828dc.jpg)