Leaderboard

Popular Content

Showing content with the highest reputation on 03/11/21 in Posts

-

If anyone knows the current location of the Elgin 900 mainspring arbor that shot silently from my tweezers and into an adjacent wormhole, there maybe a sizeable reward for it's safe return. I spent over three hours last night looking for it in a small but crowded work space. ? If seen, it answers to "LITTLE $#!+". ? Shane5 points

-

I usually put a piece of paper on anvil, place the watch hand on top of the paper and atttack the from the underside with LIGHT TAPS , that paper somewhat protects the hand from getting scratched. The art of it is so it wouldn't be noticable once installed. Hands of pastors watch, tells watch destroyer have been at it long ago, polishing hands is one painful job, there was a video showing such polishing. Regs Joe3 points

-

The minute hand does attach to the cannon pinion and the hour hand to the hour wheel that goes over the cannon pinion. The domed stake advice is the right technique: I have done this a few times.3 points

-

2 points

-

Did no one else's mind go to a sprung/absent spring washer between the dial and the minute wheel? It seems odd that the hand would come loose enough to jump around, and still be well attached enough to do everything else. Meanwhile, a jostled minute wheel could pop up above the plane, skip a few teeth, and come right back down and be as functional as ever when one is looking at it in a normal way. It's easy to test without even opening the case too, just turn the watch DD, bump it to loose it from any grease stiction, and attempt to set the time. If it moves, maybe I'm wrong. If it's loose, find a spring washer in your "art" drawer. EDIT: Disregard. Brain fart. This would only apply to the HOUR hand, not the minute hand. Minute hand is attached to the cannon pinion. That's why it didn't occur to anyone else. Come on morning tea! Kick in!2 points

-

That is the clean one. The watch came to me with a pretty good (to my eye) repro dial. This one was purchased on ebay in rough condition and I took some excellent cleaning advice from this article: https://watchguy.co.uk/cleaning-and-preserving-original-finish-on-dials/ The next challenge is that the dial feet for the correct dial are in the wrong place. I can use dial dots but would prefer to put on new feet, which is another whole can of worms on techniques and tools that I do not have and do not want to invest in. We shall see. The before and after (after then before). Like many things, there was some improvement and I also did some things wrong. Thankfully the mistakes done really present themselves to the naked eye. We all bear the scars of our journeys through life, and while I am responsible for some of those on this watch, it is overall the better for it and it is mine.2 points

-

Just to echo some other responses, it is wise to place the hand on plastic or paper to avoid scuffing it on the staking set. I prefer to peen the bottom of the hole. The bottom part of a hand is the first part to contact its respective wheel or pinion, so it is the side that needs to be tightest. If you peen the top of the hole, it might not "grip" until the hand is a bit too low on the pinion. It also makes for cleaner work in terms of tooling marks. As for the earlier questions about hands with tubes, like hour and seconds hands, Archie Perkins recommended using a staking set. You can use the "taper mouth closing stakes," which are used for diameter reduction (mostly closing tubes and tightening collets). Just lightly tap the tube with a few "tap and test" cycles. A pin vise is fine, but depending on the type, many pin vises won't provide consistent pressure around the full tube, which can lead to bowing, dimpling, or crushing. A taper-mouth punch provides consistent pressure around the circumference of the tube, with little risk of deforming it.2 points

-

2 points

-

@Nucejoe mentioned the cannon pinion and it didn't strike me at first, but if the crown feels very loose when you set the time, it could be that the cannon pinion needs to be tightened. Anyway, my impression reading your post is that it's only the minute hand sliding on the cannon pinion. If you jostle the minute hand and it doesn't make the cannon pinion rotate but just the minute hand then surely it is time for the doomed stake. BTW (and silly question perhaps), should the doomed stake be placed on the hole on the underside or on the top side of the hand? I would assume the underside. Thanks!2 points

-

You know, @VWatchie, you got a point and it woke me up. We're talking minute hand - not hour hand. So it's not the canon pinion. That hand probably needs a tighter hole. Why it didn't come all the way off, I have no clue.2 points

-

I finally took action to fix my Formula 1 Haikonen bumpers. I keep thinking how Tag could put plastic outside the watch? And on a Formula 1? The perfect everyday watch? Well I imagine some people wont agree with me on that... I removed the broken ones and that rubber was just so dry and broke like chalk. Had to try so many prototypes till I could get the perfect fit. The resin 3d printer is just amazing the amount of detail you can get at home. Also the rubber resin worked perfectly for this one. I could sell those on Ebay as I imagine there are a big number of Formula Tag owners pissed off with these bumpers and no official replacement. A couple things I think still need improvement. I have to dye the resin in black a bit more. I got to learn a way to create the plastic texture while modeling the object. I got really curious about exploring a laser engraver. I have a little pad print machine but yet to decide how to make the cliches for dials. So far the photopolimer idea get stuck on an inkjet printer capable of printing a motif, specially dial's tiny small lines. I just saw a laserpecker and I think that would be a better idea. Have anyone tried to create a cliche with a laser engraver?1 point

-

As i buy a lot of stuff from Cousinsuk i wonder what will happen to them when we enter Brexit. Will there be tax and custom on the parts we buy if we are outside UK. As it is now it's free as long as it is inside EU. If i have to pay an extra 25% tax i would seek elsewhere. Would get very hard to find spare parts to. Maybe they could open a filial in Germany or Holland for us inside the EU .1 point

-

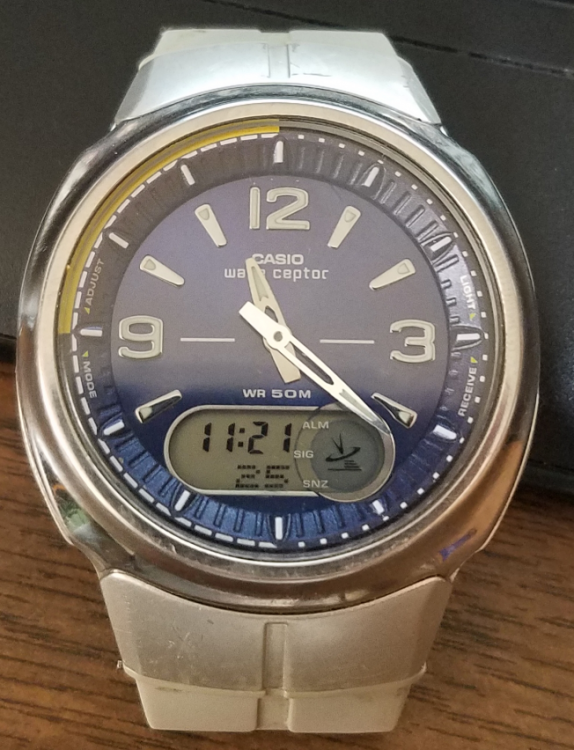

I got this watch years ago. Some time after that it quit working. Then I tossed it into the watch bench that ways dormant. Sat there for years. After I learned about accelerating hands using my demag, I decided to try spinning the hands on this watch. Yay...they spun. So, I installed a battery went through the setup procedure and set the time. Now it is working fine. Receives WWV and calibrates itself. Now I need to get a band for it. I do not know what I did with the one that was on it.1 point

-

Hello to you all i am Wasim I have a watch repair shop in London and I have join this group to share my experience and learn from other knowledge in here too. I am looking forward to getting to know you guys. Thank you1 point

-

Hi Try daveswatchparts.com ,, explain the predicament in an email he is a very helpful guy on Elgin / Waltham. Even better he is in the USA. cheers1 point

-

Looks like you have had all the good advise except on the hosiery front 1. make sure they are not the wife's best tights 2, she is not wearing them at the time . Try putting out some bait it might get hungry.1 point

-

1 point

-

https://www.academia.edu/25543173/Samuel_Harlow_of_Ashbourne_and_his_Longcase_Movements A little more history of Benjamin Harlow. He is distantly related to one our members Vich Newcastle upon Tyne, There is an old post of his dated 10/02/17 where he mentions the connection.1 point

-

Benjamin Harlow Macclesfield listed in Watch and Clockmakers of the World Vol 2 1834 Your watch was made around the date. That case is silver but the hall marks is so worn you can’t see it. The dial is enamel and it has its original hands. Key wind from the back and hand set by the front. If you could take a photo of your pocket watch like this. That is what I need.1 point

-

Thank you for the kind response. The case marking is JH. The back plate says: B. Harlow / Macclesfield I have very little experience working with watches. A local jeweler opened it for me to photograph the back plate. I could probably provide you some pictures of the movement if you could provide me a little direction on how to expose it. Thank you again.1 point

-

By the way, "The basic specification of the Standard wristwatch caliber is a minimum of 17 jewels, 21,600 bph (beats per hour) escapement, a minimum 40-hour power reserve and an average rate within +/-30 seconds per day." The ones I have perform better than this, but an average rate within +/-30 seconds per day is the figure to shoot for.1 point

-

If you are careful, and take your time, there is a pretty good chance you will get it working.1 point

-

I think this is getting a bit beyond my capability (and aspirations)! I'll wait for the watch to run down and take another picture as requested, but I'm minded to carry on with the tiny tweaks until I get reasonable performance and if I don't manage it I'll look up somebody local to service it once things start opening up again. The internet is a wonderful place for help with anything and everything, I'm grateful for your advice. If any of you experts happen to live in the East Devon area and would do a service that might be of interest!1 point

-

Don't worry you will find it on your bench in either 6 months time, or just after you receive a replacement arbor. I remember finding a cap jewel on my work table about 3 months after I lost it and had bought another junker watch to get a replacement jewel. We have all done it too.1 point

-

After posting the pics I realized they are not the same! ? Sorry guys! Serious brain fart.1 point

-

I,d be tempted to clean this dial, I think a( rubber) pencil eraiser the would work, go easy over the writtings, you are sure to get a cleaner dial. These are now collectable, specially the subsecond ones.1 point

-

Hi If its a genuine seiko you want try cousins in the UK or Jules Borel/esslingers in the states, you may gain somthing from having a look at "The Watch Site" they are predominatly Seiko Citizen and have a market place for bits1 point

-

Should scrub up beautifully they are nice little clocks, mine in in the display cabinet with the others, Brasso the scourge of clock plates, although never seen it on 400 day clocks be sure you get it all out of the pivots and the holes. Keep you busy for a day or two.1 point

-

Yes, this was a bit of a "frankenwatch" ebay purchase. Fairly knarled hands for sure. I didn't pay much for it and as I learned more, and then eventually opened it up, I learned why. Does that sound like a familiar experience to anyone? The setting lever spring was broken and not inside the watch, so it was re-built that way at some point. There was no movement/case clamp and that created a stress on the winning stem which broke. The wrong crystal was installed which I discovered when cleaning it from the inside and it popped out with almost no pressure. It did work well and keep acceptable time for a number of years before I opened it though. So I had a nice-fish watch for a few years and now I have a project that I am enjoying and is the source of lots of learning. All is well.1 point

-

1 point

-

I think, between a dyslexic mind and being dead tired at the time and second guessing my terminology, I have been confusing the minute wheel with the canon pinion again. Either way, my concern was that if the minute hand was *not* what was loose, then there may be a need to look for worn or broken teeth. In the past I have needed to replace wheels where the owner used force when a part in the movement had jammed and, being that $h!t rolls downhill, the force found a weak tooth or pivot or other, and took it out. Having seen such in the keyless works of a watch before, I was hoping this was not the case here.1 point

-

Hi How true over the years I have amassed a fair collection of bits but none fit what I am looking for. I think its down to Murphys Law Of probability.1 point

-

I have checked through my stash some AS hairsprings are marked in lignes. But that is not always correct. Hairsprings are now a difficult problem when needing a replacement when they come up on eBay I purchase but despite a reasonable collection I never seem to have one that fits. This part of my hairspring collection.1 point

-

If you are concerned about keeping the original balance wheel, and if all other balance parts are in good state, and you have the needed tools and experience, you can replace the balances staff only for a very small cost.1 point

-

Before I confirm what I think it is. I need to see a good photo of the movement side on, one of the dial a better one of the whole case which I think will be silver, are there any hallmarks in side the back lid of the case? The name on the back plate can you tell me what it is as my eyes are not good these days. I should be able to tell you more if you could do those things for me. On another note I see this is your first post. We like new members to introduce themselves first before posting questions. Don't worry many do this the wrong way round you are one of many. ?1 point

-

1 point

-

Lovely damaskeened full-plate movement there! And the case and watch-overall are rather pretty. It's a shame the dial sustained a bit of damage, but still pleasant to tell time by. I like it. So glad it still runs.1 point

-

It,l be nice if you can find a donor, a hairspring can be salavaged off of a scrap balance complete with which you have a chance to build your new balance complete. Dr ranffts list the entire family of AS1187 calibers, hairspring off of any of those is sure to have the same CGS as 1187, it fits onto your balance wheel, your new balance complete usually beats at the right rate, occasionaly you find the donor too short which runs the oscilator too fast and sometimes springs are longer which you can cut to get the right beat out of your new balance complete. Vibrating hairspring with balance wheel is very useful task to master when you work on vintage or antique watches, since old stocks are destined to run dry and have already in some cases. A hairspring even off of an AS 1187 might not vibrating with your wheel as is, in which case you would need to remove material off of the rim or file balance screws. Regs Joe1 point

-

Meaning you suspect that the diameter of the cannon pinion might have been reduced somehow for some reason, or is the wrong cannon pinion? I completely fail to see how the minute wheel could have any bearing on this as it in no way is connected to the minute hand (unless this calibre is somehow special in this respect), but I sure like to know and I'm all ears! To me that sounds like a plausible explanation and so I suspect the hole to be too large.1 point

-

I saw what Nucejoe wrote, and I think you should check that first. With the crystal still on, hold the watch face down, dial aimed at the ground, and see if you can gently shake the minute hand off. If it comes off then it's almost certainly the hole. If not, then I would take a long hard look at the canon pinion and the minute wheel. Either way, a domed stake is ideal, but a pin vise should work if you're very careful - if it turns out to be the hand.1 point

-

Dear all, i would like to join in in Chris' question. For a lose hand there is always the quick and dirty solution of squeezing the hand's tube in a pin vice. But what is the proper way to tighten a lose fit? All the best from Hamburg Alex1 point

-

The great Archie Perkins, in his restoration books and his staking set book, recommended using a domed staking set punch. You'd place the minute hand on the staking set plate and lightly tap the hole using a domed punch. The peening will slightly reduce the diameter of the hole by compressing the edge inward. To avoid tooling marks, you can place the hand on plastic and peen the underside of hole.1 point

-

Are you sure its the hand? If so loose to slips the hand should fall off. I would check the minute wheel and canon pinion.1 point

-

1 point