Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/21 in Posts

-

5 points

-

Hi Joe! I don't know the actual regulations (legal or whatever) surrounding the number of adjustments. What I do know is the U.S. imposed tariffs on foreign watches that were adjusted, to protect the domestic market. So now when I get a beautiful Lecoultre on the bench marked unadjusted and then unfailingly with a cryptic 3 letter code on a bridge, it was intended for the U.S. market. I believe some makers just marked everything unadjusted as a simplifying measure for this reason. Marking a movement as adjusted in any way just knocked out a major market. High grade pieces from early last century were labor intensive and expensive. So a really high grade piece would say "a bunch" of adjustments, a little lower fewer adjustments, then a high quality piece that was a cut above commercial quality would just say "adjusted". There's surely more to the story but that's the gist. As an Oris fan I'm sure you've seen that some pretty pedestrian pin lever watches were quite capable of hitting a 20-30 second delta. I've done jlc movements for a major manufacturer that required 20 hours of nerve wracking skull sweat to break 30. These were marked adjusted (just that or to some number) quite often. Ok these are often extra small and/or ultra flat pieces*, but just goes to show that that word , "adjusted", doesn't necessarily mean that much. * there were different guidelines for different sizes. Obviously a 30mm movement will be easier to regulate than one that's 5x7 ligne.3 points

-

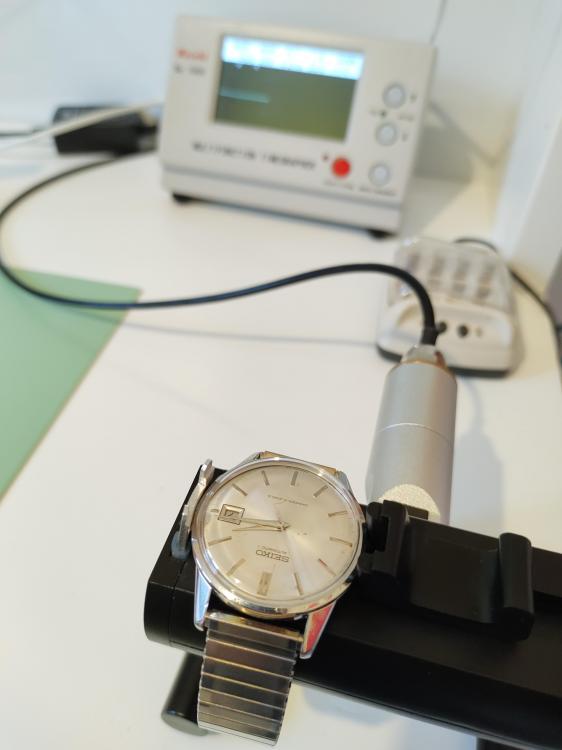

Well I have an update. Gave up with the jacot. I soon realized that it would take more time and spare balance wheels than I had available. I think it is one of those tools that you would need to spend 100s of hours in order to master it, especially for small watch pivots. I did manage to get a donor movement however. After a lot of work on the hairspring, centering, flattening, demagnetising I have the watch running really well. It's now within +-10 in all positions with 275 degrees amplitude in horizontal and a small beat error. Regulator pin spacing was left a bit wider than I would normally aim for. If I made that very narrow it had the effect of making the vertical positions too fast and also lowered amplitude.3 points

-

3 points

-

Thought I'd share another triumph, for me anyway. I'm still new to this game and don't have a dedicated work space and only functional tools. Picked up this 1970's "30" jewelled automatic wonder just before Christmas. It wasn't without issues. In it's past someone had poured a load of oil into it (smelt a bit on opening) and it took a while to clean it all by hand, soaking this and pegging that. I was lucky enough to find parts which proved invaluable and educational. I even plucked up courage and practised removal and lubricating shock jewels which was a first for me, still have a healthy respect of them though Replaced the double toothed hour wheel, missing three teeth. Date wheel, ruined by the old oil. Rotor as the brass bushing was too worn, and it sounded like a bag of spanners, now it's gloriously silent. It then turned into a labour of love as I even had a go at the hands. After much deliberation I applied lume by way of my own improvement, they were originally painted white but the oil had affected these to the point the paint had dissolved. It's now my favourite watch, it's been running really well for over a month now and keeping great time, so I must have done something right. Anyway I thought I'd share it, as perhaps what can be achieved at the dining table with determination.2 points

-

Agree with “handwound” this is a job only to be attempted with the correct tools.2 points

-

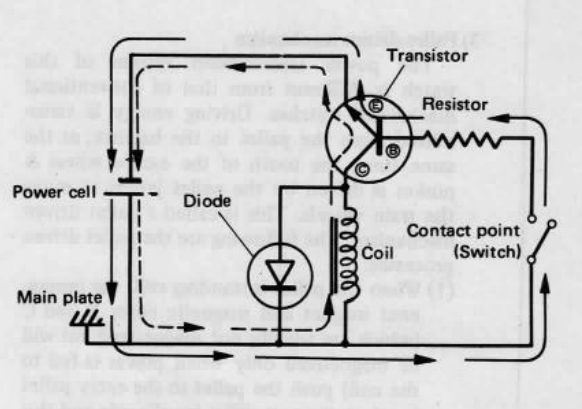

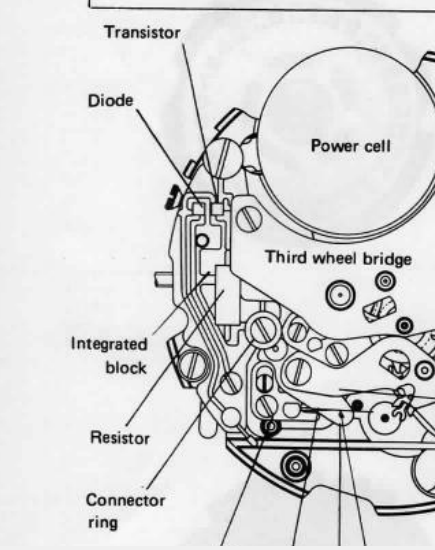

I posted about trying to figure out how to get the movement out of the case. I will share that information here as well. It is a front-loader. Remove the crystal and push the lever that is visible through the edge of the dial and the stem comes out. Then the movement can be removed. After removing the movement, I connected 1.5 volts at the battery terminals--nothing. It turns out that this is an unbranded Seiko 3302 movement and I found the manual for it.1 point

-

Hi all, I just joined the forum. I'm new to watch repair and about to undertake my first movement dismantling and putting back together. (No problem with taking apart, It's the putting back together that's the challenge).. Been watching Mark's videos for a while and they are the best out there! Jack1657 Florida, USA1 point

-

1 point

-

1 point

-

Hello, everybody. I wanted to share my restoration stories that I have done for a long time and thrown into my archive. First I discussed the Atomic Mars 71 Brand using Valjoux 7734. As it was seen, scratch and dial is broken. To begin with, I tried to brush the Case as Brushed and make it the first day. If it is decorated, I polished and re-painted the indexes (with acrylic paint). I usually do this in three layers so that the paint is not deleted in a short time. I replaced the case buttons and tubes with aftermarket buttons. Since the condition of the dial was in very poor condition, I had it re-painted. The quality is not so good. In Turkey, unfortunately, not doing the job well. Caliber 7734 (Valjoux) is a special and robust mechanism for me. With good maintenance and lubrication, you can reduce deflection values up to 3-4 seconds per day. I added a short timelapse video about it :) As a result, such a result came before us. Thank you Taskin https://www.youtube.com/watch?v=XKH6yTKUfpM1 point

-

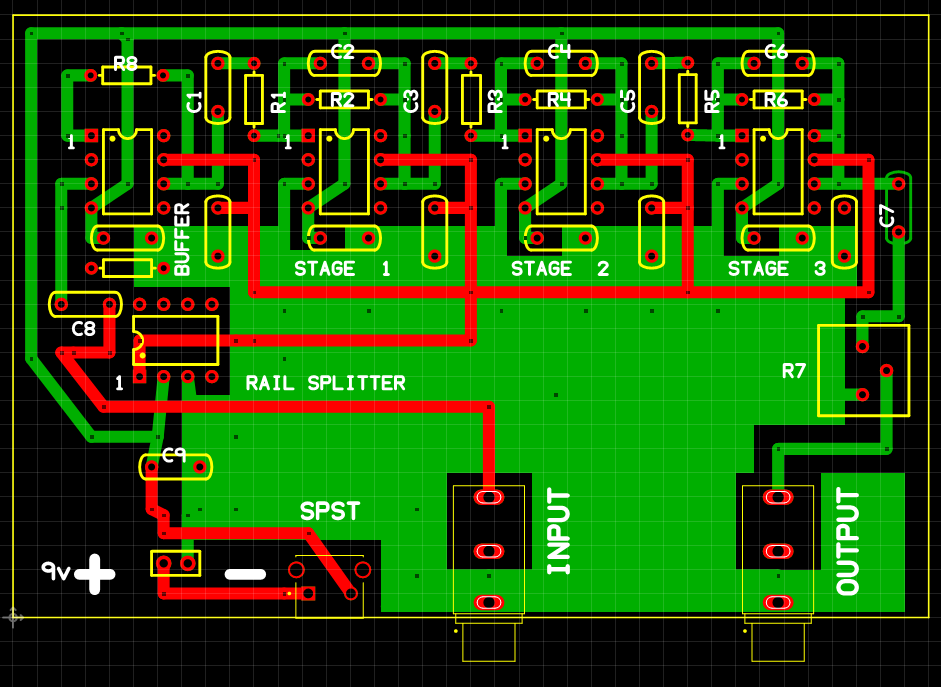

Yeah, this has moved from a "watch" forum to an "electronics" forum. But, hey, there are a few guys on here that have a healthy understanding of electronics!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

If one never attempts anything nothing will get done and there are always those who know more than you do who will hopefully share that knowledge to make your path easier. Thats what we are all here for, good luck with the project.1 point

-

1 point

-

I would say with skills and experience more than anything else. You can see great work done by a master with mediocre tools, but never the other way around.1 point

-

1 point

-

Thank you for responding. I actually sold the jacot, it's gone to a good home, the British school of watch making based in Manchester of all places. I've just purchased a staking set instead with the cash (Bonelli, made in Italy, looks decent and complete). Should me much easier to replace a balance staff rather than burnish a tiny pinion, for me at least.1 point

-

It most certain looks like a Landeron 48, almost complete. The minute recorder jumper looks homemade. The cam on the hammer looks a little worn. The regulator is in full – position so the hairspring is probably sticking to something. One screw is missing as you say. Otherwise it looks complete and running. The case is to an Landeron 148/248 so this is probably an transplant.1 point

-

Often times you'll see in discussion groups that their idea of cleaning a watch is to use this feature. It's assumed that quartz watches really don't need to be cleaned and if you spin the train fast and it runs that's equivalent to cleaning which it's not. But it does get stopped quartz watches running and buys them extra life. Which he used to have a really nice one with little knobs to adjust to change the poll's web then the rate and unfortunately was expensive. Here's a link to a cheaper one. https://www.startimesupply.com/merchant2/merchant.mvc?Screen=PROD&Store_Code=1&Category_Code=HOME&Product_Code=MSA19-107 Then thinking about witschi here's something they have on understanding quartz watches https://www.witschi.com/assets/files/sheets/Knowledge Quartz Watch.pdf1 point

-

I think for a little light reading you can start at the link below. We already have an ongoing discussion. Then the problem with this entire discussion is it's not black and white. Radium is definitely bad but? If it's on your wrist shooting little particles of whatever into your wrist to have any proof of cancer caused by that? On the other hand if you had one of the early dollar pocket watches covered with radium on the hands in the dial like equivalent to several wristwatches worth and of course you carried in your pocket faithfully for 20 years that we would probably have a different discussion. I think simplistically the basic rule is if you leave it alone it will leave you alone. Which works out fine for dials anyway because always problematic if you're trying to clean a refinished them yourself. https://www.watchrepairtalk.com/topic/10726-should-i-be-worried-about-radium/1 point

-

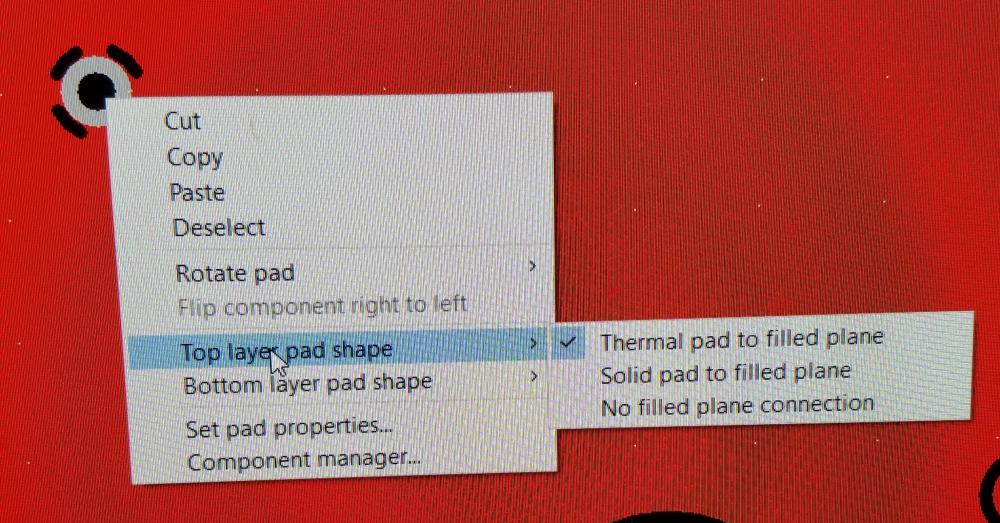

Bypass capacitors should be place from v+ to ground and from v- to ground. Placed as close to the package is possible with the shortest possible leads.1 point

-

Frankly, I am surprised the circuit works at all. You have not provided a path for biasing the input stage of the LT1115. You need a resistor from the non-inverting input to ground. Pick a value to place the pole where you want to get your flat-band response.1 point

-

Well @PastorChris it wasn't the hat. Theologists are good with words, , need your help, how would you compose a post asking this question? Joe1 point

-

Hi, new to watch repair and collecting. I seem to always prefer to learn a skill rather than depend on others. dom1 point

-

Normally with a quartz movement like this you would just replace the whole thing. But if you want to just change the coil you can do that. I'm attaching the technical information. 559_Ronda702,703,705,708,712,713,715.pdf1 point

-

Just wanted to post up update in case anyone else with a similar issue ever stumbles across this and to thank all the members. It appears the erratic behavior was due to the watch being maintained at a low charge, not due to being broken but due to my lack of movement and naivety of the state of charge. Others will know if this is normal but it seems reasonable. If manually wound to ensure a good charge (shaken) the watch behaves consistently. If wound and worn with descent levels of movement the watch behaves consistently. In both cases when the watch is given a fair chance at being charged it maintains consistent behavior on wrist and for over 24 hours off wrist. At some point after 24 hours off wrist it starts to drift a little from it's usual rates and become more susceptible to positional variation as the charge diminishes. For me the watch will still run after 36 hours off wrist but has lost approx 45s during the last 12 hours of that 36. Thankfully my escapades have not broken the watch, I know a little more than I did before and it's now regulated at +8 rather than -30 ish, but time will tell on this, and it has a new greased gasket. TLDR - Check it's got petrol before you disassemble the engine, unless you wanted to see what the engine looked like.1 point

-

If it is the difference of one size it will be fine. A tip to remember. The spring in the barrel should take up a third of the space, the other being the arbor and the gap between the arbor and the spring, if you follow that you won't go wrong.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. Let's hope we can help you out.1 point

-

Seiko dial codes are a mere part number identifier. A R in there doesn't mean, and has never meant Radium, which has been completely been banned in 1968. And even before then, it's use in the industry had already dropped to almost zero, because the potential health issues were well known already. So, no need to be paranoid, you can wear and work on any Seiko in total safety. You can also check SCWF - thewatchsite.com for any discussion about.1 point

-

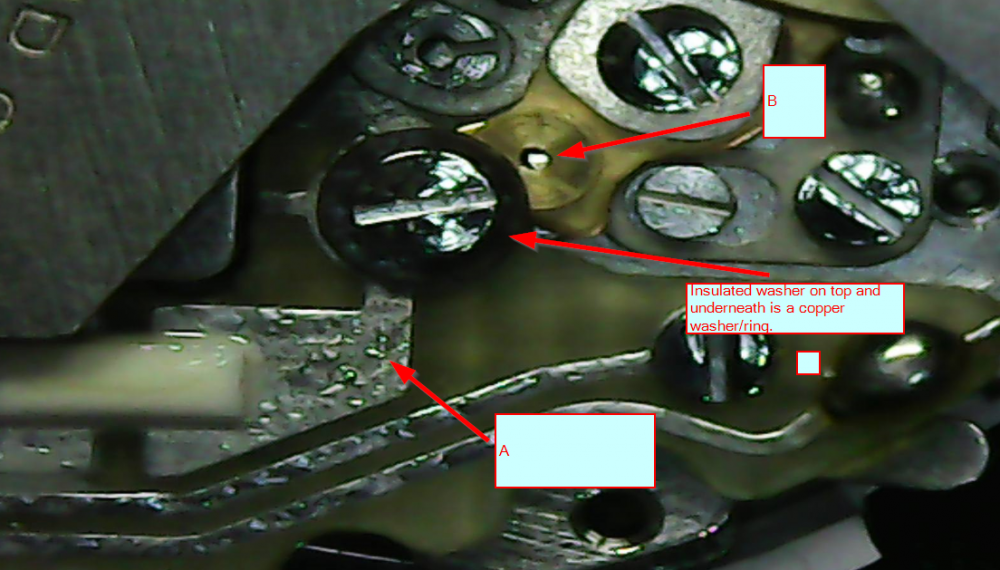

This watch continues to run fine in a static position--have not found a band for it yet, so no dynamic tests. I have another identical Stellaris. I have opened it up and found the same problem with the connector ring. Fixed that. However, there is more to this puzzle. The contact spring was not engaging. It is adjustable and I did that. Still does not run. I know that the electronics are working to some degree because of the rest position of the balance wheel when power is applied (different than when power is disengaged). I have the technical manual for this movement. I am liking this movement less and less. One of the procedures is to clean certain elements using freon. Really? Who does that. I will follow up as I make progress.1 point

-

1 point

-

Hi All, I am new here. I am a new hobbyist and really enjoying working with watch movements and trying to get them back to life. I live in London. :) I look forward to meeting new like minded friends with an interest in watch repairs. I hope some are also local to me to share knowledge and to learn from. Many Thanks, Kind Regards, Yasser.1 point

-

Please refrain from making comments on my threads that are obviously intended to promote yourself as a dial maker. I find them unwelcome and not at all constructive.1 point

-

OK, I am gonna call this one "done" for now at least. I cleaned up the case, polished the crystal, installed a battery. It ran all night and kept perfect (to my resolution. This watch does not command any value on Ebay, but it is a very nice movement and kinda pretty. I set it to the right day, but did not want to have to go around to the correct date.1 point

-

I don’t understand why you would make such a comment here. It seems strangely out of place.1 point

-

At this point, I walked away for an hour or so. I came back with the theory that there was a break in the circuit somewhere and my speculation was that it was along the contact point spring and associated interconnections. So, here is where I focused. I did not take a picture of the insulating washer on the bottom. Interesting feature. Insulation on top keeps the screw out of the electrical path. The copper ring underneath connects point A to point B. I removed it. It appeared to have some slight discoloration (oxidation on the PCB trace). I just reinstalled and cranked it down nice and tight (not over tight!). Then I connected a battery and VOILA...the balance wheel takes off. In retrospect, I think a different order of tests were in order. 1) testing the coil first was right on. 2) running a curve tracer on the components should not have been the second step...too involved...required building a testing platform...yadayada 3) checking continuity along all paths should have been #21 point

-

1 point

-

Returning the original topic now... I have an ISA 389 movement in a watch that I gave to my wife years ago. Also years ago, it quit working. I recently took it apart to see what I could learn and started looking for a replacement movement. Today, I decided (in the spirit of this thread) to troubleshoot it and attempt a repair. I discovered that the coil was an open circuit. This is due most likely to a battery leaking and the acid eating away at the wire on one end. I could see the green sludge on the wire. As soon as I touched it, it disintegrated. However, there was still enough pigtail that I could carefully grab it and unwind it by one turn. All of this done using a stereo microscope at 40x magnification. I did unwind it and laid it over the PC board where it need to be soldered. Moving to the electronics workbench, I used a relatively large (by these geometries) tip and super fine solder and soldered the other end of the coil. A quick measurement indicated that I should be back in business. Installed the battery and VOILA!!! I wish I could have taken pictures of this, but I do not have the right gear for that. At the end of the day...you can repair these quartz movements!!!1 point

-

Hello Andrew and welcome to the forum, If you are thinking of watch repair as a hobby or even as an interest I have attached the tech sheet for the 7S26 and a general glossary regarding watches. I you venture in to the horologic word there are plenty of members on this site to help you along and over hurdles. 7S26C_36C (2).pdf TZIllustratedGlossary.pdf1 point

-

Hi Andrew, Welcome to the forum.1 point

-

Thanks Clockboy. It is automatic movement - watch has missing parts therefore looking for quartz replacement as an option. OmEGA details: Dm= 27.9mm, Do= 28.4mm H= 5.0mm F= 1.75mm T= 2.15mm 24 jewels f = 19800 A/h power reserve 50h Balance staff U2769 Stem W2790 Hands 1.50 x 0.80 x 0.18mm1 point

-

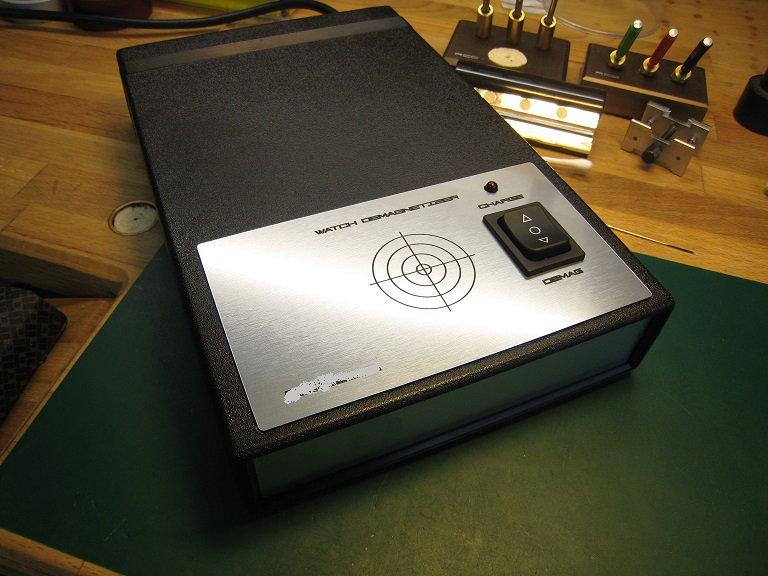

If you like to build electronics - build your own - it's simple! Basically it is a coil that you connect a capacitor to, in parallel. The created magnetic field is "automatically" decreased as the capacitor discharges. Here is a picture of a simpel version I made using 2x12V PCB transformers (to get mains insulation) and a modified audiotransformer.1 point

-

Anilv, Sorry that you're taking this so seriously over myself moving your Seiko walk-through to a temporary location until completed. It is now back to the original place, please be aware that my housekeeping wasn't meant to diminish your work in any way. If you desire to correspond on the matter with me in PM I'm always here.1 point

-

Yes they were common on old chronographs. In the past telephone calls were charged in intervals of three minutes and the markers made it easier to time phone calls and get value for money. By that I mean if you went over three minutes by a second or two you were just as well talking for another two and a half minutes as you were going to pay for the next release minutes anyway.1 point

.png.9f239cb746dd5f348005a3cabfa6b164.png)