Leaderboard

Popular Content

Showing content with the highest reputation on 09/06/20 in Posts

-

2 points

-

Hello everyone! My name is Benjamin Marn, I am a 20 year old college student who has been interested in horology for about 4 years now. I have since aspired to be an independent watchmaker, most likely as a hobby or a side gig but possibly as a full time career, assuming people appreciate the watches I would design and build. More immediately, I have been planning to make my own bespoke, finely finished watchmakers tools, everything from tweezers to mainspring winders, to jeweling and staking tools, as I am fortunate enough to have access to a 1934 South Bend lathe, a 40's LeBlond lathe, a surface grinder, and a Bridgeport mill. Eventually I would like to build my own watchmakers lathe in the style of a Bergeon 50, from my own iron castings (I also have access to a furnace that is hot enough to melt iron), and after that, perhaps even a rose engine.Hopefully, I will build up a collection of tools that exceeds the quality of brands like Horotec and Bergeon at a price of only the raw materials and the time taken in the machine shop, which I enjoy anyway. In the meantime, I have slowly begun to build up my library of books, starting of course with the great George Daniels' Watchmaking, but I am always looking for more books, especially on the theory behind horology and movement design, as right now one of my biggest struggles is grasping the concepts behind gear trains, tooth counts, mathematical ideas, etc etc. I am also a bit of a visual learner, and another thing I struggle with is visualizing the complex diagrams and explanations of the complications in Daniels' book. Perhaps that's why I like Mark's channel so much, I can see things like keyless works in action.1 point

-

1 point

-

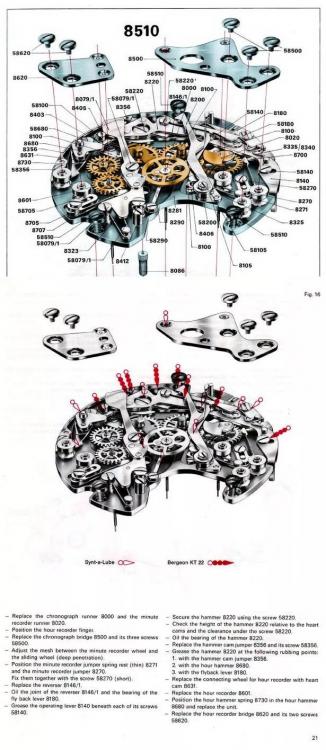

I think the base caliber for the Tag Hour Caliber 12 is an ETA 2892A2 so for the movement side you could just use that one. But then the chronograph part use to be a 8510 and it isn't any special with that either, chronographs usually isn't that hard to lubricate, just in case your calibre 12 also has this module i can paste the lubrication procedure.1 point

-

1 point

-

And Seiko. Give it to my way, wheel and cock in brass tweezers, better if top jewel is removed to minimize chances of bending it. Find the best angle to look at the hole, leave cock on its posts or there about, then grab the rim alone and drive the pinion looking. After learning to do this you can also make the impulse fall in straight. Otherwise just lift the wheel a bit and in it will go.1 point

-

1 point

-

1 point

-

I think most people do the same, or a slight variation of the same principle which is to lift the balance cock with the hairspring hanging and carefully lower it in such that the pivot lands in the jewel hole and the impulse jewel on the roller is on the correct side of the lever notch. Some people use tweezers to hold the balance cock and balance wheel together, such that the balance wheel does not dangle. I’ve never had an issue with hairsprings being deformed by dangling balance wheels. I use my balance tack regularly.1 point

-

It may be absolutely fine, but your stud height is potentially slightly high. As a very vague rule, usually the top of the stud will be roughly flush with the surface of the balance cock. Check that the entire hairpring is flat as you look across the side.1 point

-

As long as the pallet stones have oil on them it makes no difference how you go about it. Just make sure you do not flood them.1 point

-

I have no balance tack. I've been wondering if I should get one, and what all would be done with it. But so far, I also have just been getting by with carefully placing the balance complete upside down in the parts tray. I will read a bit more about these balance tacks, but I don't know if I will get one if I do not need it. I like my brass tweezers very much. They require attention sometimes to keep them straight and the tips lined up. But I don't mind that. They grip fine and do not mar the parts. My steel ones have their place for other things, but I reach for my brass ones most often. They work plenty fine.1 point

-

Thanks to you both. Rodabod, a picture of the balance is attached. Not sure you can make it out. I don’t think the spring is perfect, but nothing is stuck together. Full disclosure, I bought a donor that was actually running in order to get the balance complete. On the original I messed up the hairspring trying to put it in poise. However the wavy trace issue was preexisting, and I was hoping to tackle that before the positional variation. Second, John, you are definitely right about the Russian calibers. I think part of the issue is that their caliber numbers are not caliber numbers, but actually describe the movement’s capabilities - thus for example 2602 just means manual winding, no shock protection, subseconds. Seems like a great system but useless for identifying generations that may have succeeded each other over decades in production. That being said, I am quite sure that both movements I have here are first-gens, and likely to be compatible. And lastly, I think (hope) I have identified the issue, and sadly I think it is fatal to the original movement. The issue is, there is way too much sideshake in the barrel. Going back to look again, I can actually see score marks in the original barrel bridge because under torque the barrel is leaning over too far. Even after using the donor bridge, the slop is still too much, because the bottom bush is also out of round. I cannot find any other problem with the train, although I would add that I did try swapping out the lower train and the free running was nicer. I don’t have the knowledge or capability to fix these bushings, so sadly I think the original movement is toast. Fortunately, I have a donor that was running before I stripped it for parts. So I think the plan is, the donor becomes the donee.1 point

-

Exactly my thinking and experience. Hairsprings are supposed to be flat, a dandling weight cannot help in retaining that property. Once I asked a member here what is the exact benefit of a balance tack, he said that it to see things, he didn't said what exactly so I tried myself, sadly I couldn't see anything really. Which of course is the correct technique. And I put it back the same way, even if that means that sometime it won't be in between the fork on the first try. Previously my mistake was that I wasn't looking at the lower pivot while driving it to the hole, sometime I spent hours trying going blindly. Nobody had told me, I don't know if it's in the books, found by myself and it works for me. Another great improvement was to go to cheap brass tweezers from the expensive steel one which some people think one can't do without. They grab perfectly and there are no more minute scratches on the cock or balance.1 point

-

I think it might help to start with one of those Chinese pocket watch movements there only around $40. Start with something big then have fun try all kinds of lubrication because I think you'll find that you can go really really bad before it's bad. Makes it a lot easier to see things just overall better to go with the pocket watch Chinese movement. the nail thing I like the. If you watch school at some point in time beget the play with the lathe and make things. One of the first thing is is a balance tac. as I like your terminology a nail on a base. The purpose of which is to torture your balance wheel. They will place the bridge on the pointy nail that the balance hang Byatt snack stretching out it's hairspring. They sell these commercially almost every students makes one obviously the super popular my experiences been it's not good for the hairspring. Then I don't like ;-) things anywhere where I can get my fingers on them. Then unfortunately it's really hard to describe what I do pictures would be better except I'd need five hands to do it. When I left the balance bridge out I'm very very careful to try not to pull on the hairspring too much so the balance doesn't move I set the bridge back down an attempt to get the tweezers under the bridge the pool of both up together. Then and this is the part that hard to describe what I set it on the bench I flip it over. If the balance bridge is down the balance is resting on the bridge there is no pressure on the hairspring everything is fine unless you put something on top of it. for lubrication I'm attaching an image it's only a sampling it was one watch was done for a purpose of a lecture. In see the effect of as I went through lubricating the watch and you can see that nasty horrible grease putting on the escape wheels didn't seem to really be in effect. But much later today we might get a better answer I was thinking of going to work today and I have a practice 6497 that I was using for another lubrication experiment I think I'll go wild and crazy with the escapement grease for you and will see if I can make it run really bad. then there are probably some minor technical errors in that chart in that the final amplitude of 340 Something Is Way too high. But it kinda gives you an idea of what happens with lubrication. Strangely enough lubrication actually causes a decrease in amplitude at least initially. If you left the metal dry expressly metal on metal it would weigh hair and wearing out metal would introduce new worse problems. So in the long term lubrication is good and on the short term at least for the picture I have it doesn't necessarily look the best but in and things looked better. This is why you would have to try really really hard with lubrication to have a amplitude that both of you for seeing it's probably something else.1 point

-

The little slotted gages are kind if sketchy, one of my teachers called them "pivot breaking tool". But for small diameters, say under .13mm or so, a micrometer poses a real threat of making tiny flats on the pivot even with a very light touch. Best is jeweled hole gages, available in .01mm, .005mm, and .0025mm increments. Without those you can get close using a micrometer and then use the actual jewel as a gage, look for about 5° of "tilt" for the correct freedom. The drive finger is often a pair but a single one works fine.1 point

-

Hi folks. I just got a Jacot tool from eBay. I'm working through Practical Watch Adjusting by Donald de Carle which has been a brilliant guide. Just a couple of things I'm not sure on. First, can anyone explain the scale on the pivot measuring tool? Why are the numbers on the left and right side different? I don't see how they relate. Also, can anyone explain how to secure the work piece to the tool? The ones I've seen on YouTube have two "snake teeth" that clasp the wheel but this only has one. I can't see how it can hold anything securely. Thanks all.1 point