Leaderboard

Popular Content

Showing content with the highest reputation on 08/06/20 in all areas

-

This is one of my first watches. I own it for more than 40 years and I stored it for years after it fell and the crystal snapped. Seven years ago I decided to restore it . I went for two or three watchmakers for an estimate but In the end I decided to do it on my own. Had to Redial/Relume, find a new crystal, gaskets, hands, bezel spring and movement overhaul. Took me a while and finally finished it a few weeks ago. I’m very pleased to wear it again (though I’m not planning to dive with it) The original watch looked like this: There was a lot on my list: There were scratches on the dial and the black lost its depth, The lume was in bad shape (though the lettering was better.) The hands were missing, and I had to find something that resembles the original hands (“Hens teeth”) The Mineral Crystal broke long ago and I had to find crystal and gasket(s) The rotating bezel had to be polished and repainted. The bezel click spring was missing. The crown gasket over the years became black goo and had to be replaced. The crown tube gasket was missing (I didn't know it at this point) The movement was in fair shape, but has to be serviced. As I wrote I decided to do it all by my own after I received several estimates from watchmakers (I guess this was my intention from the beginning but I didn't have the know how nor the confidence.) Took this as a project and had to dig for information. Since there are few versions of this watch I had to find the right info. Some restored a similar but not the same version and I had to dig for the right info. The dial: I sent the dial to Robert Miller at international dial company. He told me he has the original dies for the “professional” sub (The orange sub) for this watch he had to change it to sharkhunter. (this was seven years ago, now I see the company changed its location and website) You can compare the before and after. The Hands As the original hands were lost, and there are no originals to be found.I Found very similar ones at Yobokies. This sub uses Eta 2472 movement (aka doxa 118), which uses the same hand size as seiko. Yobokies (and dagaz) sells seiko mods, one of them is the soxa mod or axos mod which mods the seiko to look like the doxa sub. The ”soxa” hands looks very similar to the sub’s hands. Since they were meant for slightly bigger dial, I had to shorten the seconds hand. I was also happy to see that the lume color on the dial and hand were the same. The crystal and the crystal gaskets. Since the crystal broke years ago I had to find one that fits. I was a little bit confused from what I saw on the net until I realized there are few versions of the sub. In the synchron sub for example (A later version of this watch- from the time synchron company purchased doxa) the crystal is a thick flat mineral glass. It is inserted from the front and held by a thick visible orange gasket. In this version the the crystal is a stepped glass, 3.6mm thick approx, it is inserted from the back of the watch and held by a screw in retainer ring, with no visible gasket. Because it is not manufactured anymore, some watchmakers produces a close clone by bonding two flat crystals in different thickness and size. This guy on the bay produces this crystal by copying an original one(as he said). He posted it as a “DOXA SUB 300T Sharkhunter” crystal unaware of the various possible versions for this title. At the time I wasn't sure it will fit mine, so I made one using the watchmakes method by bonding two crystals to one using ultraviolet curing bond. At the same time I was looking for a fit gasket when I stumbled on a post in this forum . Now You can’t see the original post’s images, but in this image (from the post) I found that the Crystal was held by two (probably the same) gaskets (the gaskets on the center of the image). Ordered some gaskets in various possible sizes and choose what fitted best. The gaskets fits the inside of the watch and around the wider bottom side of the crystal. It is all held by a screw-in retainer ring. (bottom left ring in the image above). Can’t tell if this was the original design, and I didn’t make any pressure test (yet) This is the crystal and gaskets I used: The rotating bezel At the time I didn't notice the bezel has polished and brushed parts, so I polished it all, and colored the marks and numbers using nail polish lacquer. On the luminous dot I used epoxy glue mixed with luminous powder. It was one of the first things I did on the watch and left it as is. The bezel spring Had to create a new bezel spring following this post. I used dentist's 0.8mm stainless steel wire but I wasn't sure what of the exact wire girth, so I ordered from AliExpress various wire sizes. Made this spring. It's not perfect but it's doing the job. The crown gaskets The original crown gasket became black goo long ago. Couldn't find any information regarding this screw down crown. The closest design I found was Rolex twinlock crown . From the shape of the crown and tube I assumed the possible sizes of both case and crown gaskets. I ordered some possible gaskets sizes and used the ones that fitted best. I added even one more gasket around the case tube to imitate the Rolex triplock (obviously unnecessary...) The Movement In this watch doxa used the Doxa 118 movement - a slightly modified eta 2472 movement. The movement had to be serviced. On some point on this long period I decided to service it on my own. It was the most intimidating part of this restoration because I had to learn this from zero. Bought some old movements on the bay for cheap, bought some required tools and started to take them apart and rebuilt them again. After I gained some confidence I did it on the doxa. I made some damage but found the right replacement parts (One of my discoveries was that movement springs tend to fly and disappear while flying…). It took me longer than I thought. For couple of years I left it in the box, but the covid19 period gave me little time to get back to it and finish the job. more to do Need to regulate the watch, probably after I will build a proper timegrapher mic. Maybe pressure test: just to check how waterproof is it. I’m not planning to dive with it. Bor bracelet: maybe yobokies. found this on alibaba but minimum order is 200… Thanx Gabriel (This was also posted on Watchuseek doxa forum few weeks ago)3 points

-

It never ceases to amaze me what you can stumble across whilst looking up something else on the web. I was looking for help on replacing the failed hydraulic disc breaks on my 15 year old mountain bike, but instead discovered a gem of a video on how bicycles were made in Britain back in 1945. Enjoy the video if you have nothing better to do for the next 17 minutes and 22 seconds.1 point

-

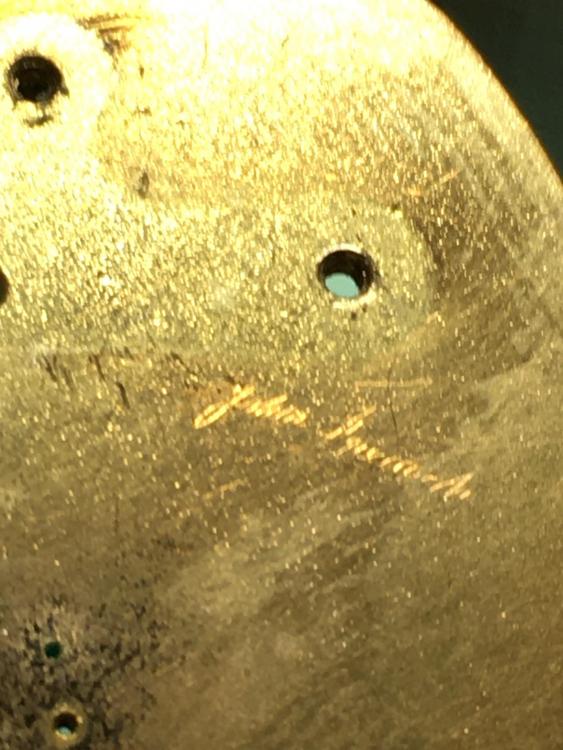

ENHANCE! First letter: I, F, or possibly T Second letter drops, so that's gotta be either P or Q, and looks pretty solidly like a Q with the body to the left. English (assumed from John as the first name) practically requires a U to follow a Q, and an I typically after that. The next section is very difficult, but the last letter goes high, making it an h, k, l, or t. There looks to be something to the right of the high part, so I'm going like H or K So... Iquimork... OK... I tried.1 point

-

1) - got the case straightened. That was some slow and gentle work. It was bent wide open to about 160 degrees, so I had to reform the whole hinge area to reduce that flex by (jeez) 70 degrees! Many gentle taps with a soft-faced mallet over a small scrap of oak I shaped into a "buck" of sorts. Couple days I spent on this, off and on. It paid off. 2) The cleaning and fresh grease & oil worked wonders. The she ran crazy fast, until I demagnetized her. She runs so very silent that the mic I used for my timegrapher app can't hear her. *I* cant hear her. You can see her running and not hear a thing. So I've been regulating the old-school way - over time. Got her down to only half an hour fast per 24 hours. I think there could still be residual magnetism on the hairspring. May try zapping her again. 20200801_223144_001.mp41 point

-

I was wondering: were *you* able to remove the canon pinion? Because, by the look of the picture, a gorilla was not able to. re the inscription: first name is John (that was easy). Last name might be Tremere, or Tremiere. I have some forensic science background but I'm still just guessing here. Man, that's tiny!1 point

-

1 point

-

Thank you Nickelsilver, Rodabod and Jdm, It was a success! First getting rid of the part already started and full of bumps with a hacksaw took only a few minutes. Not difficult, and the saw came back still good, not blunt... I will adopt this approach whenever possible. picture 1 Then overcoming the lack of rigidity by working close to the chuck, with minimum overhang worked fine. Good chips, and a nice sound of metal actually being cut.. finally. Funny thing, and in accordance to what nickelsilver said, the recommendation to cut stainless at 115-135 feet per minute of surface speed does not apply to parting, and with a much lower speed the parting was easier. I used 140 RPM and it was fine. picture 2. Nice chips Then to the end. At some point the tool got stuck, and had to be resharpened. I was going straight, without any lateral clearance, encouraged by the smooth operation. Apart from this, a good experience. I finished the blank with a hacksaw, but only because the tool could be off-center after resharpening and was cutting less towards the end. picture 3. With these tips, I guess other people will find easier to part 316L. The lathe is still waiting for the granite bed. Eventually I will bolt it better. Thank you again for the help!1 point

-

your title makes a reference to poising right now you're having a timing crisis are you also suggesting that your balance wheel is not poised? first off let's look at the normal things that make a watch run fast just to eliminate the problem ignoring at least I'm going to ignore that you have the wrong hairspring. So make sure that the wrong hairspring is only touching at the collet the stud and the regulator pins. Make sure it's flat is not touching the balance arms for instance. As it has a over coil make sure it's not touching the top of the balance bridge. A lot of people don't pay attention to the over coil and it can rub on the bridge. So providing the hairspring actually fits within the space you're really screwed for running fast. so timing washers typically are applied in pairs that's to keep the balance wheel poised. The assortments are typically in minutes per day and the typical numbers you would have would be one, two and three you might be lucky and have a set that has four minutes per day. Last week when I was adding a mantra balance wheel that I poised after restaffing that set only had three. So I needed to pairs of washers and the regulator to get it back in time. You're going to require a tiny bit more like two hours is equal 220 minutes divided by the three minute washers that equals 40 pairs that you need to add. That is considered an extremely unacceptable number seeing as how you only have six pairs of screws that you can add them. Now you do not put them under the mean time screws and the mean time screws will not adjust this grade of time so just leave them alone. So with six pairs of screws each screw would have to have a unequal number you need about 6 to 7 under each screw that is considered unacceptable. I don't suppose the balance wheel has any extra holes? Because the only way you're going slow this down more in anything resembling something acceptable would be to add new screws they'll get you around 15 minutes and that would be per screw. Because typically if a screw falls out your watches running 15 minutes fast it stands to reason adding a pair will slow you down about 30 minutes that made to date about you than do the math. Or to take the screws off you have now and see if he can find something bigger and heavier or perhaps made out of gold that would be even better. as this is a vintage watch really vintage I don't suppose the hairspring pinned at the stud as any extra length sticking out? A lot of times on vintage watches things weren't as exacting as they are now and there would be a little extra space? Sega just unpin and lengthen your hairspring that would help considerably. Did I mention up above that you have the wrong hairspring? So unacceptable fixes would be you need a balance wheel that has greater in this gets confusing? Notice how with the mean time screws all you're doing is moving the mass farther out not changing the way to the balance wheel? Adding a timing washer increases the weight. If all of the fixed screws were moved out by a Maybe one full turn that would be like they would all become mean time screws but you would have to Loctite them in place because otherwise are going to fall out and what I'm suggesting is not considered appropriate. I think it probably be better if you could find a hairspring that was closer to what it's supposed to be. Because two hours fast is considered extremely fast1 point

-

Hmm I think all three Fried, Nucejoe and rodabod says the same thing but in different ways, moving or unscrewing the meantime screws outwards will slow the balances oscillation down, Fried just do it the right way by adding a washer"weight" will assure the screw stays in place, just threads will not assure this. By adding the washer it will move the meantime screws position outwards and add a slight weight and by that slow the balance oscillation down. Taking meantime screws off or tighten them will make the balance increase the oscillation and the watch goes faster.1 point

-

1 point

-

Just bought this one and it stumps me. Lady I bought it from says her grandfather worked for the factory and made this watch. I can find the vulcain cricket models but not any reference to the vulcain remind-o-date. I do find the Lejour remind-o-date tho which looks identical... Any info on it would be helpful.. Sent from my SM-N975U using Tapatalk1 point

-

Turning screws outward slows the oscillator, but you should check the wheel for poise. You are assuming you have a poised wheel to begin with and furthure that with equal turns the poise is kept unaltered. To slow down an oscilator, adding weight is not a neccessity, in fact is a minus since you are increasing the weight on pivots. As you turn the screws outward, you are moving the meanweight of the wheel outwards, which increases the tendency of the wheel to resist change in its motion( inertia), while the mass dose indeed remain the same. In watchrepair inertia is refered to as weight, just to make it simple for folks to invisige the concept. As you move the meanweight outwards the wheel puts up more resistance to any change in its motion ie; accelerate or decelerate, which the oscilator dose go through in each beat. The increased resistance slows down the velocity of the wheel, think of velocity as speed for now. The problem you will have is if the screws are not tight( on washers you were suppose to have added) screws may turn loose, unlessthey feel tight enough not to loosen during years of oscillating to come. In short you are regulating as you poise or keep the poise the wheel had. The two go together for a healthy balance and to avoid excess positional variation. Hope this helps. Good luck.1 point

-

That jewel is cracked. It's hard to see the train layout from your photo, but if the side-thrust pushes the pivot into the crack then it would very possibly reduce amplitude.1 point

-

With lockdown there's been a mad rush for bicycles over in the UK so you can't find a decent bike at sensibly price at them moment. (Good news if your selling of course [emoji3]). Give it 6 months and things may be different. Picture of my hack attached, one of the last of the Nottingham built Raleigh's from the mid 90's on our usual post work stress buster. Sent from my moto g(8) power lite using Tapatalk1 point

-

With a 370W motor, it should be a geared headstock type? However parting 44mm is hard work even for lathes much bigger than your. Definitely an hard proposition. Check what the carriage does. Even when fully locked it may still move a little. When it does, all bets are off, chatter comes, the cutting point wanders, machinist swears and the suppliers get a chance to sell. Below, good machinist receives 316 work just to be parted off1 point

-

Great video! I enjoyed watching you disassemble the watch. If you're asking for comments and feedback, there are two things I would say... You might find it easier and less likely to damage the movement or lose parts by putting the parts tray closer and to the side, as you are reaching over the movement to put the parts away . One more thing is, get some descent tweezers. It'll make the process much easier and far more enjoyable with good tools. Yes, you can take apart and assemble with cheap tweezers, but you'll be surprised when you use a quality pair how the experience is totally different. Get a piece of folded over 1000 grit wet & dry paper with water and give the insides of the gripping face of the tweezers a slight brushed finish as you squeeze them together and draw the wet and dry through. It'll make gripping a different story as well! Apart from that, good job! Keep it up and look forward to seeing more of your work...1 point

-

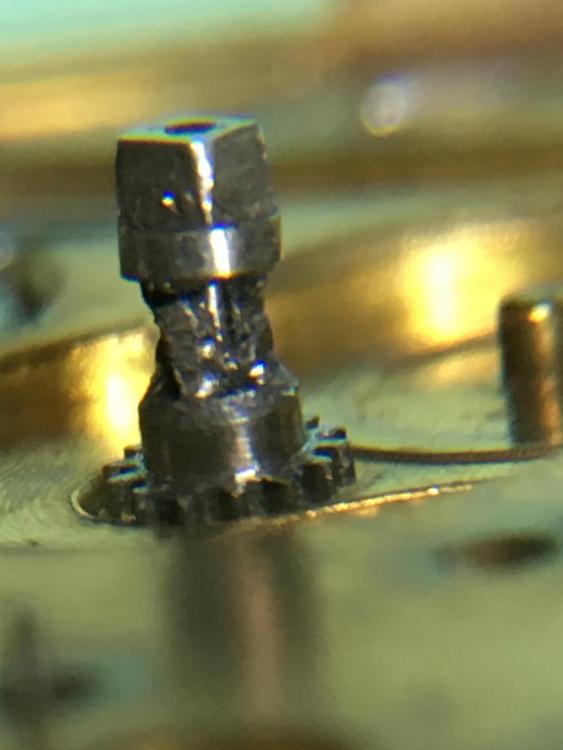

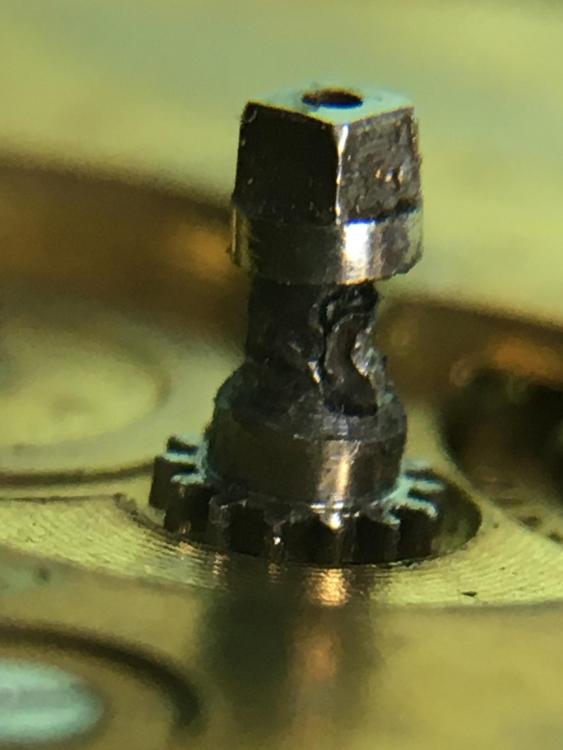

Well whilst working out some other issues on another project I thought I’d make a start on this rather Handsome pocket watch “H Samuels” with the climax trip. Have not for a date for this one as haven’t done full research on it yet, but whilst taking it apart I come across the canon pinion........... How, just how can you do that much damage to something and leave it in place? Now I’m going to continue on the strip and clean etc but that’s beyond repair and needs replacing, the hunt begins unless just maybe one of you good fellows might just have one in a spares box that might be exchanged for some tokens of the beer kind?? Just asking0 points

.thumb.jpg.37a99006119088dd18f20e2ccdfd4cce.jpg)

.thumb.jpg.246bc62db1ab9701d3c27b1b6dc28263.jpg)