Leaderboard

Popular Content

Showing content with the highest reputation on 07/26/20 in Posts

-

Finally got round to sporting my Soviet era “Polarski” Elektronika 1 today. Wife hates pretty much all of my collection, but out with her friends last night - they are both into 60s and 70s retro furniture and design. They loved it! The husband especially got a kick out it being stamped in Cyrillic “made in CCCP” Her female friend wants any ladies LED I can find for her - I just happen to have few kicking around3 points

-

First time for me placing my hands on a true watchmaker's lathe to repivot a central wheel (small seconds), under the guidance of my mentor master Lino. Work isn't complete and practically it never will be, because ase the pinion was picked from a box of spares that he accurately set aside. Lots of of technique details were passed to me, probably these are explained in most books, but the experience of learning first hand is priceless!2 points

-

2 points

-

Hey guys I just wanted to share with you my first project, an Omega Genève with the calibre 565. I saw it on Chrono24 for really cheap. It was sold as not working, but for the price I just couldn't say no to it and immediately bought it. When the watch arrived some days later, I opened the caseback to see if there is something obviously wrong with the movement what causes it to not run. A screw fell out and I noticed that it should keep the one missing caseclamp in place. I suspected that the clamp has made it's way into the train of wheels what causes the watch to stop. And indeed: a slight shake and it fell out and the watch started ticking, it wasn't running great at all but at least a sign of life so I hoped a service would recover it. Movement before service The movement was quite nasty, everything covered in small pieces of dirt and old oil. Stripping the movement down went quite smooth and I took photos of some parts to remember their location. I cleaned it in an ultrasonic cleaner with Elma Red and then rinsed it in distilled water and isopropanol. After all parts were dried I started to inspect them and I thought that they would all be fine, but that assumption turned out to be wrong later. All parts cleaned and dried (with expeption of the automatic assambly) When the movement was assambled again I was really happy to see it ticking again, but the joy only lasted for a short time, because it stopped after about a minute. I first inspected the balance again but it was moving freely so I assumed that the problem would be in the train of wheels, because the watch was running nice at first. When I checked the third wheel I noticed a small black dot between to teeth, barely visible even under magnification. I cleaned this spot and also all other wheels again and pegged out the pivot holes. After reassembly it was now running nicely. On the timegrapher the watch is running with around 240° in dial up and down position and around 220° in hanging positions. Beat error as well as positional error a quite low. I know that these results are far from perfect, but it's my first project and if I consider the condition it was in before I'm quite happy with the result The lession I've learned from this: spend more time on inspecting the parts, as it can save you a lot of time and nerves later I found a new original Omega Crystal for this case reference, now I just need to wait for it to arrive and it will be a nice watch again. I hope you enjoyed this short report and I wish you all a nice weekend1 point

-

Most times you can set the hands with the crown but they don'y move in normal mode you need to tighten the cannon pinion. There is a special section for help and advice here too https://www.watchrepairtalk.com/forum/4-watch-repairs-help-advice/1 point

-

Good to see you are making progress. That's looking a lot more healthy and truthful. Were either of the two end stones in the wrong way up, or is the "improvement" just down to having a better contact to the microphone? The microphone is situated under the metal "claw", so it is a good idea to put the crown up against it as you found out for yourself already. The crown transmits the vibrations better than the casing, especially if there's a plastic movement holder in between. Also, adjusting the gain to maximum I find often works to clean up dirty traces. As it's an automatic, there's a good chance the mainspring is slipping too soon, and you aren't getting a full wind. You say you did't clean the mainspring too well, but (whisper it) they are not really that sensitive to a bit of dirt. There is a lot of energy in there, so contamination will increase wear and tear, but it is unlikely to cost you much amplitude. Did you lubricate the spring and barrel, and if so what with, how much, and where did you apply it? Another possibility is, you are applying too much oil at the escapement end, where a little bit of drag has a big effect.1 point

-

1 point

-

1 point

-

Take a slo-mo video of the balance with your iPhone and determine the amplitude in both positions. If there is a significant difference, then go to all the other advice. Sent from my GT-N5110 using Tapatalk1 point

-

No unfortunately not, to get the CGS numbers one still have to meassure the hairspring or use a bunch of old lists.1 point

-

The other day I was flipping through some auction sites and stumbled across an offer to buy a Moeris pocket watch movement for about €19 (22$). Took a look at it and thought it would be a shame not to bid on it. The UNITAS 6498 is a quite nice movement and been cloned by many Chinese companies. Later on it became named ETA 6498. Most people start their practice career working on a ETA 6497 clone which is a cousin to this movement, they are slightly different in the layout. So here is a PDF as a small introduction to the UNITAS / ETA 6498 which shows my standard service approach to a movement like this and a small tutorial in how it ends up in a Chinese watch case. The PDF is optimized for use online to save server space. ETA 6498 Service Notes.pdf And here are some example shots from my service notes.1 point

-

Well , it's a few years later and I came across another AS 1746/47 With the Identical problem of the second hand moving , but not the hour or minute hand , or they work intermittently . This time I knew it was the same two parts mentioned earlier , The gear whose pinion protrudes through the baseplate , and the "clamshell Gear " on the dial side of the plate . The drivetrain side gear was running , but the clamshell gear was slipping . I now know that the two gears can't be separated cleanly and reused . I used my hand levers to separate the gears and replaced BOTH gears to get the tight friction fit necessary . The clamshell gear is not made to be reused .1 point

-

Had one these back in the day. Found this at a fair price going to take some work.1 point

-

a problem with this particular numbering system is that the numbers represent a part. Such as a stem is referred to part number 401. But part 401 without the movement number could refer to literally hundreds of different stems. So it's kind of a two-part system the number as opposed to the word stem bike 401 and then the movement number. Otherwise ordering a 401 all by itself it isn't going to fit. helpful when looking for parts is the third link where you can see the differences of the watches you're looking for they appear to be in the same family. Then the first in the second plank are the parts. If you click on the part number in each of the listings it give you the cross reference the parts. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2773 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2783 http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_27831 point

-

1 point

-

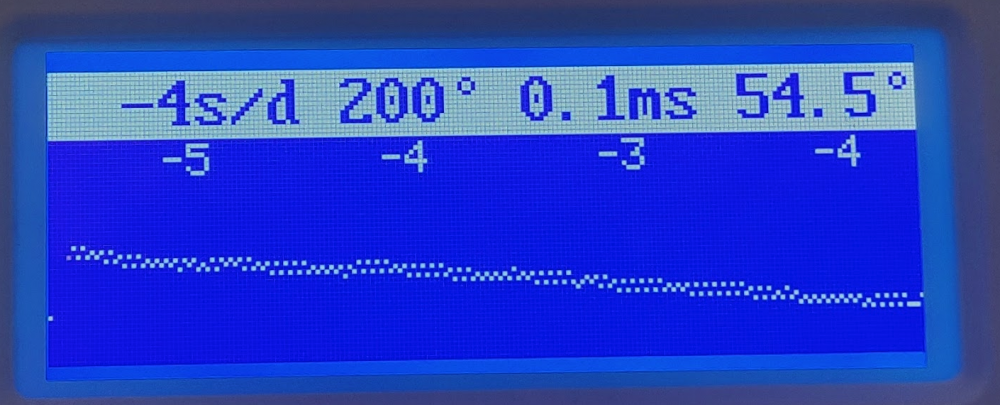

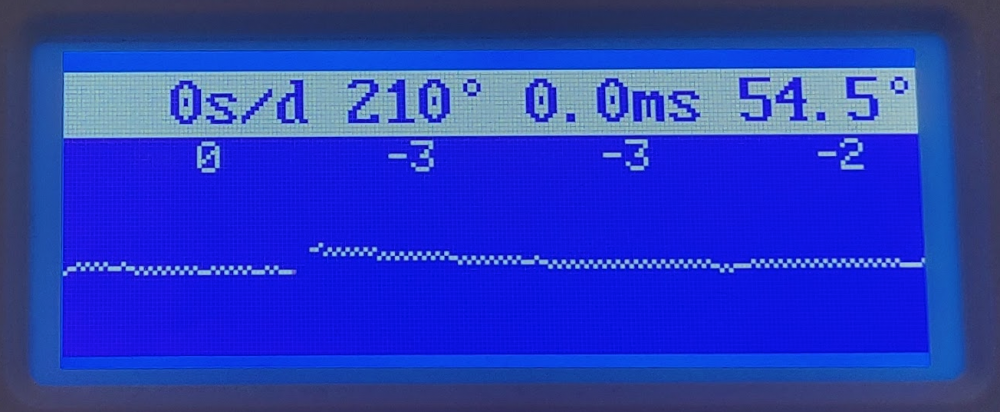

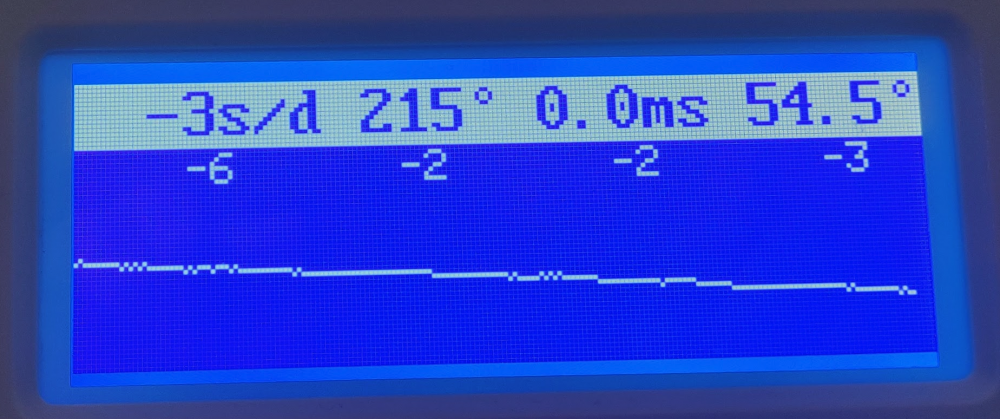

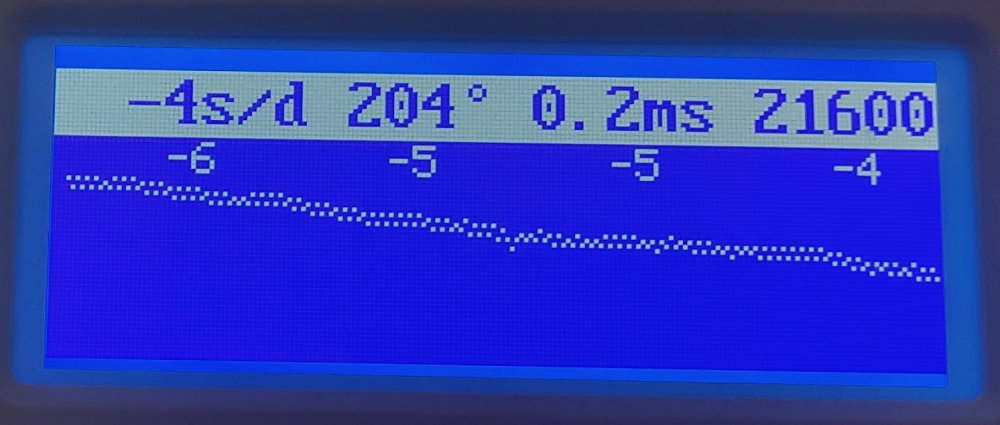

Hey all, Thanks for all the replies and suggestions. To begin, I took out, wiped off oil with Rodico and re-lubricated cap jewel, making sure to lubricate the flat side, which would contact the pivot. I then set it and took care make sure the spring was secured in place. Here are the readings: Pendant Down: Dial Down: Dial Up: Pendant Up: So I know there is low amplitude, but it does seem like the escapement itself is working decently well. I wound the watch by winding the ratchet wheel with a screwdriver. I think the weird readings were caused by my positioning of the cased watch on the timegrapher, as when I have the crown facing right, the readings come out dirty, and when facing left (away from spring handle as pictured), the readings come out clean. Pretty strange to me, but I guess there was some kind of interference or shaking with the crown? I think my amplitude issues might be mainspring related, as this was my first time servicing a mainspring and I definitely didn't give it the best clean possible. The positive thing is, the amplitude is about 50-70 degrees better than what it was before the overhaul1 point

-

several things need to be in agreement before the timing machine is telling you the correct information. Otherwise it's telling you you have a problem. The graphical display and numeric display should indicate something similar. then visually looking at the balance wheel it should resemble what you're seeing on the timing machine. For instance timing machine tells you have a 300° aptitude the balance wheel looks like it's barely moving you have a problem. this particular example is a common problem with all timing machines. If the amplitude is too low the machine reads the wrong part of the waveform gives you happy numbers it just aren't there. then if the graphical display is showing totally random dots then the numerical display is totally worthless also. So many times people look at the numbers and and totally ignore the graphical display because they like the numbers better. Then there's a problem you're having that 4.9 ms the line spacing is not right. I'm giving a link below you'll have to scroll down to the pictures and you'll see that 4 ms lines are easily twice as far apart as yours. then when giving us timing results it's always nice if you would give us one crown position like crown down for instance. another test to try for train freedom is backspin? This is where with the pallet fork out you start to wind the barrel and stop. As you start to wind the mainspring will supply energy to the train the train will spin when you stop winding the trains momentum will carry it past the stopping point it will actually back wind the mainspring just a little bit. as you're watching the escape wheel spin and your winding when you stop the momentum of the train will continue forward you can see that then it will ask he stopped for just a second sometimes you can see it sometimes you can't and then the escape wheel will spin backwards. So if you see the backspin that's usually a sign of a train this properly free. Doesn't occur on all watches for variety of reasons though usually watches with sweep second hands it has Springs associated with them. usually for dial-up and dial down you will see an amplitude drop if the pivot is bad but? But here we have a graphical display indicating a problem in both images. There is a problem beyond dial-up and dial down plus having numbers that we do not believe on the timing machine at least I don't believe them. then there is the other problem I seriously doubt that that's a 4.9 ms beat error because it just isn't.with a small graphical display of the Chinese 1000 machine the graphical display cannot indicate the same thing the numerical display indicates. So in a certain points you'll get a rollover effect where the lines are closer together than what they should be for the same numeric results. At 4.9 ms you should be just about on the extreme of the graphical display and that looks much closer to one or 2 ms so your graphical display is not agreeing with numeric results this is come up before you can see it in the link below scroll down you can see images. https://www.watchrepairtalk.com/topic/9683-hi-strange-timegrapher-reading/ I am curious about how do you lubricate the escapement? then visually or definitely having an escapement issue. I'm also suspicious of the numeric results for the amplitude. If you're amplitude is below 200° then you getting interesting affect on the timing machine everything gets magnified as the amplitude drops all your problems get much much worse. So as others of set up above you seem to be having more than one issue perhaps classically with the end stones one side is flat and one side is curved. The curved side goes out the flat side goes in. It's a really easy mistake for new people to make. If you not sure which side is which look for a reflection off the top of the jewel. Like a fluorescent lamp reflection is much more noticeable you'll see the curvature the jewel. They were definitely design with the flat side going in.1 point

-

Greetings, I completed all three levels some time ago and thoroughly enjoyed it. Does anyone know the status of future plans for additional courses? A previous post asking the same question seems to have disappeared. Regards, Kevin1 point

-

1 point

-

It sounds like nlapietr was inspired to build his/her own watch, which I get. It's great to build one's own custom watch, and a basic build is within most persons abilities. I'm just trying to assist, if I can.1 point

-

Its actually LuciusAtelier that announced the Explorer-style cases mentioned above. My apologies. I have bought from all three. The quality is great from all and shipping is usually fast.1 point

-

There are now many suppliers of aftermarket cases for Seiko 72XX and NHXX movements. Have you looked up CrystalTimes? Theirs are SKX-type (diver) cases that accept the parts you have (in addition to others required). Namokimods just announced "Rolex Explorer" style cases (two vintage sizes) that accept the parts you have. The later are currently pre-order. There are others as well. My apologies if you've figured this out already!1 point

-

1 point

-

Ricoh 61 finally completed today. Feels great. Love the winding sound, Zip zip zip. Sent from my Moto G (5) Plus using Tapatalk1 point

-

Maybe instead of finding a case that fits your dial/movement, you should look for a dial that fits your case/movement?1 point

-

If you are not opposed to used parts try speedtimerkollektion. You can buy used cases in lots. 28.5 mm dial diameter is pretty much a seiko standard size. Pay attention to stem location. It varies1 point

-

If you have a 3d printer then it's possible to make a movement holder to position the movement correctly inside the case. I've done this for a custom watch I made. I also printed a dial is it was a skeletonised movement. It takes some time and effort to get right, here's my prototypes...1 point

.thumb.jpg.5fbd78a8a0bec65cf76186494a419d6d.jpg)