Leaderboard

Popular Content

Showing content with the highest reputation on 03/04/20 in Posts

-

Since I've already featured the wristwatch I'm wearing today, I'll highlight today's pocket watch. It's a 1913 South Bend 16s. It has gold inlaid engravings on the movement and the jewels are in gold settings. The dial is double sunk and it's in a chrome plated, salesman's case with an exhibition back. I haven't had to touch this watch since I bought it other than to polish the crystals. One of my favorites.5 points

-

Hi Guys for all you chaps who work on seiko movements you may find this information usefull Cheers Servicing_Guide.pdf3 points

-

Hi all, I thought some of you guys and gals might find this very interesting. It gave me some ideas for restoration of vintage watches. https://watchesbysjx.com/2019/08/patek-philippe-pendant-watch-restoration.html3 points

-

3 points

-

Hi all , have you ever talked to someone and stopped and thought ...........I wonder who ties your shoelaces2 points

-

Hi can you PM me your postal address I can maybe send you some scrappers to play with. Cheers2 points

-

Looks to me like that movement is just for time. Does the day dial change when you wind? So the sub dials are just for show perhaps.2 points

-

Thanks for advice Jdm, that explains why I only got one finger left.1 point

-

1 point

-

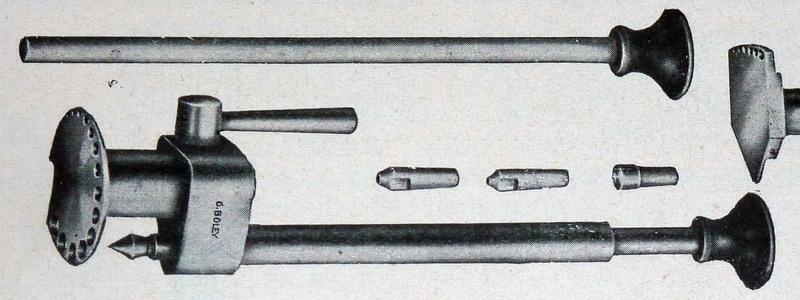

In addition to some serious skills on display, there are some truly awesome tools shown in that post. I'm sooo jealous.1 point

-

Sure eats amplitude,. Lots of friction. Yes the extent a watch maker would go to for his love of fine crafts, interesting. Thank you for sharing.1 point

-

Hi Nucejoe, as far as I know mass produced escape wheel teeth are polished with compound loaded disks of wood on a machine.That one looks like it was cut from a coke can. Surely it was finished off before final assembly. One would think that it would go without saying in the watchmaking industry that the escapement must highly polished and hardened to specification for reliability, accuracy, longevity. Anyway I reckon that was an interesting story1 point

-

I agree, that escape wheel could have been more "Patek-y". Normally a Patek escape wheel from that time would have been thinned in the center, on both sides, leaving raised teeth. The center would have a very uniform matte finish, and the sides of the teeth would be black polished. The teeth would have also been beveled on the impulse surface with a very fine finish. I'm a bit surprised as Korpela normally is a maniac for doing things 110%.1 point

-

1 point

-

1 point

-

Hi Graziano I have a nephew like that he is a Dr in Psycology reads latin like a comic but common sense passes him by he is also a musician. Glad we are not all the same though.1 point

-

1 point

-

Hi Graziano has given you some sound advise to try There is also speedkollection.com in europe who is a purveyor of parts and part watches. also welwynwatchparts.co.uk. If you cant get any bits I have some brass sheet which i have made bits from so if all else fails i can send you a bit to try and make another clamp it should not be too difficult.1 point

-

1 point

-

1 point

-

1 point

-

I wouldn't clean the movement just yet .I would get that battery clamp sorted first ,then check for pulse . get back to us when you have achieved this .If the watch has no pulse you may have to try a 1.45 volt battery .About 60 percent of early quartz watches that where to designed to run on 1.35 volts will run on a silver oxide 1.55 volts however some won't so a lower voltage one may fix this .Also do not oil a 352/3/4 pg movement when servicing because the staffs run on the tiniest bearings you will see and watch oil will mix with the nylon dust and turn to glue .......do not oil this movement .......Hope this helps https://www.oldswisswatches.com/watch-parts-branded/girard-perregaux-calibre-movement-and-spares/ try emailing if you need parts.When your ready to check the movement if it runs or not .remove the white plastic wheel before inserting a new battery. It just pulls straight up off the metal post. If the small gold gear starts to move in jumps then the circuitry is good and it is the gear train that is the problem. If it doesn't move then the circuitry or stepper motor is bad1 point

-

Thanks for the advice. I'm going to try the electric conductive epoxy and see if it works. Only concern I have is the strength of the bond but we'll see where it takes me. Couple of questions 1) cleaning the movement. Should I try and clean the movement in some lighter fluid and see if it removes all the gunk and dirt? 2) is the battery I am trying to use the wrong one? There is a small silicone spacer inside of the movement where the battery goes. But when I lay the battery down it doesn't seem to lay correctly. This could be because the battery clamp isn't on but I would have expected a more solid fit. Sent from my iPhone using Tapatalk Pro1 point

-

Hi there , very hard to find new clamp ,but it looks like it has a bit of meat there , I would solder it or try wire glue A soldering iron in a jar. Wire Glue is a electrically conductive adhesive that enables you to make solder-free connections when you don't have a soldering iron handy, or aren't able to apply heat for some reason. Hundreds of hobby, trade and electronics uses. Lead-free, cures overnight.https://www.ebay.com.au/itm/Wire-Glue-9ml-electrically-conductive-adhesive-/221088138781#rwid .you should be able to get it wherever you live great stuff1 point

-

Yeah that's a fake dial. The movement is a basic time only movement. The dials will never move I'm afraid. There is a similar level of watch made by Guess (fasion brand) which surprisingly has real subdials for date/day/24hrs. I was very impressed when I cracked that one open.1 point

-

Isn't Canon pinion mounted on the driver wheel? If you oiled the groove on Canon pinion, just rinsing the oil off may work. Cost free to text.1 point

-

Some wheels can be tighten. But usually best is to replace . I think it's the one with 3 arms on a 2772? I have tighten a few of those . A large round stake. And give it a small blow with a hammer . And turn it around. That works . But not sure how long as the wheel gets thinner in the middle . Could give each arm a small blow to with a thin round stake . But it's harder to get the exact same on all arms. If not the wheel will wobble.1 point

-

The extra hundredth thing is a thing with pretty much every jeweling tool I've used, including Seitz, Favorite, Chatons SA, and Horia. I tend to use the lever types, but Horia screw types are similar. Think of the stack up of parts- the stump, the watch plate, the jewel, the pusher, the interface of pusher to spindle, then finally the micrometric screw. A micron or two of slop or mushiness here, another there, that it's typically only a hundredth is pretty fantastic. As for orienting the jewel, if it's truly symmetric put it however you want. If there is an oil sink (however slight), that goes opposite the wheel.1 point

-

If you want to push a jewel 0.02mm you actually need to push it 0.01 extra. does anybody know if the centre jewel has to be pressed in a certain way up? thanks1 point

-

Hi I forgot to mention its under the Girard Perrgaux 352 Same movement.1 point

-

Hi On possibility is to test the module from using a battery out side of the watch and a couple of probes to contact what remains of the negative terminal and the posative (plate of the watch) If you do this over a bench mirror and the circuit block is working the second hand should beat.. I have looked for a tech sheet on this module but so far no luck. To make an external power source is a handy device when working on quartz watches. There is a ref sheet on Dr Ranfft's web site1 point

-

Can you post a pic of the movement and broken battery clamp? I don't think you can reliably solder it back together, but you may be able to either find a replacement or adapt one from another early quartz that uses that large of a battery (or even an electric movement). If I'm not mistaken it's a 357 or SR44SW battery. If you can get a battery in and connected, and it at least tries to pulse, then a general cleaning and oiling should get it running. It likely has never been serviced, and the oils will be totally dried out and/or gummed up; also, any sliver of steel (think screwdriver shaving a bit off a screw) will find its way to the rotor and stop it.1 point

-

1 point

-

Chrome will be attacked by acid. The higher the acidity, the faster it will be removed. Perspiration, or sweat, has a slight acidity and therefore a chrome-layer will, in time, be eaten away. How fast and how much depends on many factors like the acidity of the persons sweat, the contact duration, the quality of the chrome layer etc , etc. I don't know how the front of the case looks like, most likely the "damage" is restricted to the back-side. If you want everything a 1000% perfect, the old chrome layer has to come off and the case needs to be re-chromed. High-gloss chrome is used and that is not a DIY job. Applying a nickel layer is another story, has another appearance and is not as per original. The watch has had a life and a story to tell. You can erase all the age/life tell-tales, but where do you stop? Re-chrome the case, remove all the patina, install a new dial, new hands and while you at it, a new movement? Also, it seems to be on the back-side of the watch, a place normally nobody sees .... Polishing too aggressive and too much and you will go through the chrome layer making things only (much) worse. Considering the fact that you may do more harm than any good, I would leave it "AS IS" is .........but that's just my opinion1 point

-

The Bergeon is definitely too expensive. The Lorch above looks great, but it's a reversed lathe; the Germans sometimes liked working with the headstock on the right. The lathe itself can be oriented as you like, but the cross slide can't be reversed.1 point

-

A fine looking 1969 Timex Marlin (20282469) back from my healing bench and ticking away nicely. It wouldn't wind and was held together with sticky tape. The pins were 19mm so I had to chop them out, and there was no strap, but the usual residual muck from the previous one. The winder issue was due to a broken crown retaining arm, which I swapped with one from a donor. It then got a clean and polish, and a service. The winder crown is a little worn, so I will probably address that too once it has proven that it can run for 24hrs. Looks like we have a few signs of spring on its way in the garden too, although what you can't see in the photo is that there is a steady flurry of wet sleety snow hitting the window. Oh well, nothing else for it but another cup of tea and a seat by the fire.1 point

-

Recieved this Timex electromechanical quartz the other day. It was running strong the moment I opened the package. It is running the same movement as the Falcon Eye. I really like the smokey, grey dial. The caseback Is engraved with initials and a date. I'm guessing it was someone's Christmas gift. I haven't opened this watch yet to check the actual year of manufacture, but it can't be any later than 1973. Another birth year for me, lol.1 point

-

1 point