Leaderboard

Popular Content

Showing content with the highest reputation on 02/26/20 in all areas

-

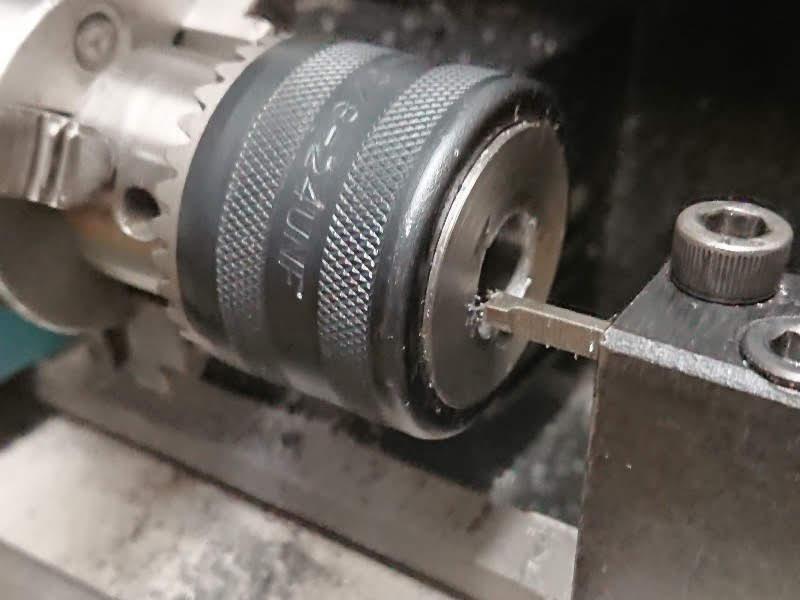

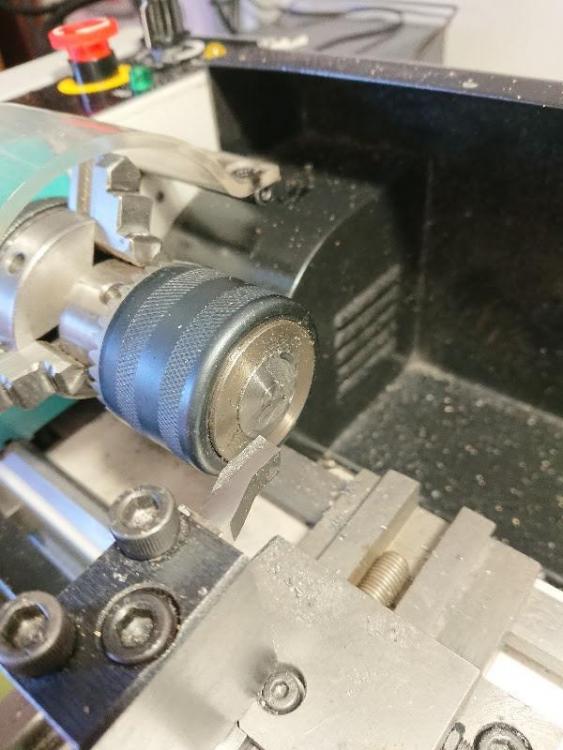

So far I don't have a tailstock chuck. The original one is stupid expensive and only 6mm max. So I got a cheap 13mm one and tried to re-thread to M14x1. The first attempt came so much off center and crooked that I was ashamed to post about it. I could not throw away such a valuable part, so put it on the the lathe securing it with a 10mm threaded rod through the spindle, to a female threading section in the drill chuck I bored the mounting hole to 19.5mm, turned a matching plug, pressed it in and gave it a first facing. The friction fit was perfect but being the plug not tapered I wanted to stay on the safe side, so drilled 3mm centered on the edge of the edge, and pressed in matching pin. I felt like having invented the steam engine in doing that. To avoid repeating my earlier mistake I decided to bore not just drill the hole. That involved a short fight to replace the press drill chuck with a shorter one, drill 12.5mm then move again to the lathe At this point I ran out of time, I'm a very very slow machinist.3 points

-

When I pulled this little omega 484 down I noticed that the escape wheel was turning under duress so I thought I would show how I polish these tiny pivots on the escape wheel and pallet folk before I ultrasonically clean them. It gets a nice shine, I can do my hair in the reflection. Using a very fine pin polisher2 points

-

2 points

-

Hi JD, that tool is much the same as an anvil. You can place your balance wheel on with the pivots in the hole selected or in the sliding groove. Or you can place hairspring on with collet in selected hole. Then manipulate till your hearts content. For hairspring manipulation I personally like to use the round glass hairspring table with the collet holes.2 points

-

Normally you should push from the dial side towards balance. But if you were to go that route, you would need to push the housing all the way out, to insert the spring in the housing groove. I cheat a little push in other direction so I could insert the spring in without having to fully remove the housing. Either way should you see the housing not refit snug tight, you can gauge to make bumps on the outer face of the housing to get a tight fit. I leave the hole on the main plate that housing fits in, undisturbed. Good luck2 points

-

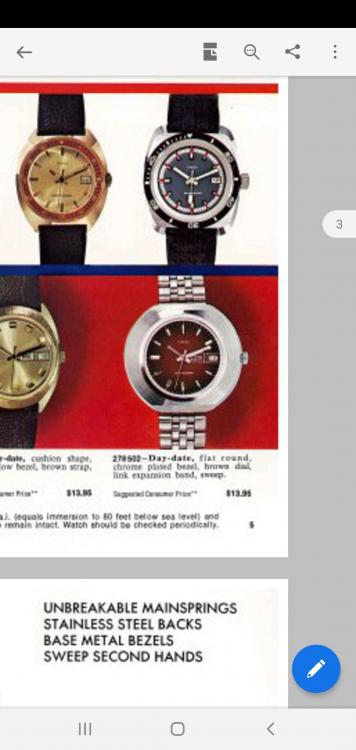

I see the pic now, just opened. Missing the roller too. Lucky you are in the US, not many were marketted in my neck of the woods.1 point

-

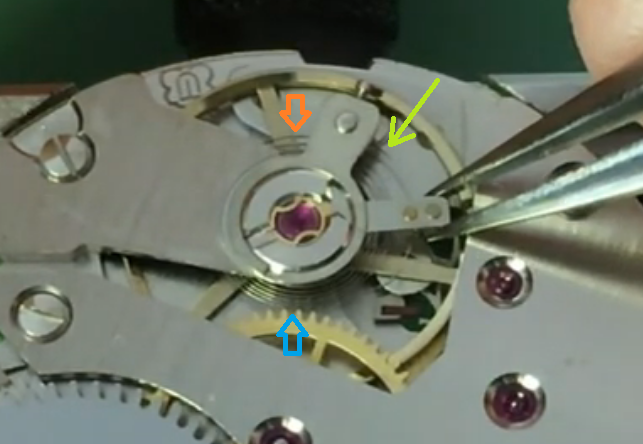

Your options are few I'm afraid @Bill3. Your best bet is to either acquire a complete balance with the roller table and jewel already installed, or find a donor movement with a good balance. If by chance you find just the table with a jewel, you set the jewel perpendicular to the "spokes" of the balance wheel away from the balance cock. See the image below for reference.1 point

-

No it doesn't taper the edges, in fact you can also polish the pinion shoulders at the same time. No abrasives used as such. Just a 3mm very fine pin polisher which I push over the pivot and gently rotate until shiny. I also do the balance wheel pivots. I do this before the ultrasonic wash it's a sure way of getting the pivots in optimal cleanliness. Hope this helps1 point

-

1 point

-

Hi Curtis and welcome to the forum. If you can get the back off the watch and post a few pictures of the movement the members will have a better idea what they are looking at. cheers1 point

-

Thank you for your introduction and welcome to this friendly forum. There are a few members on here who are into Timex watches I'm sure one of them will be able to help you.1 point

-

1 point

-

From your photos I would also say you have one good pivot (with a hair on it) and the other is sadly bent.1 point

-

Hi there, acrylic crystal with straight walls will work with uv glue or slightly bigger than the diameter of the opening. However you will lose any water resistance in that manner. But if you like the look of it then why not. Just remember to take it off before getting wet. On second thought I would go the slightly bigger method as the glue may end up on the chapter ring and you'll have to do it again. Use a crystal lift to put it on. Hope this helps and if you look around you can find thicker acrylic crystal for diver watches then you can glare at the crystal distortion from the side you will enjoy. That's a nice watch1 point

-

Yes..your stem will have two pieces..that go together in a sort of Male Female arrangement.1 point

-

Hi there , yes it will make a big difference . If it is a one piece case you will need a split stem to remove the movement from the case .You need to pull the stem and split it ,then remove crystal and the movement will fall out the front . If it where a full stem you wouldn't be able to get the movement out . Hope that helps1 point

-

1 point

-

It's a pretty common part. But you will need to measure it's dimensions. For this you will need a set of calipers. You will need to know it's length and diameter. Then you can order the part. You will probably also need a stem and a crown as well. These parts are pretty universal. You can find them on the esslinger website.they have a considerable variety. Removal isn't too tough. Needle nose pliers.just be careful not to bugger the case. Correction...the stem is not universal..they are particular to the movement and the threaded end comes in different diameters as well..they are known as tap sizes.1 point

-

Try dipping the assembly in naptha. Unfortunately my eyeball is out of calibration. Lighter fluid or carburetor cleaner would also work.be very careful around that hairspring. Mangling it will be easier than anything you'll ever do again. Whatever you do don't spray it..1 point

-

In the video of the hairspring it looks to me like the hs needs an adjustment ,this will affect the amplitude .What I suggest is thake the balance off complete turn it upside down on bench and move the regulator from side to side .You will see if the hairspring is pulling or not .You can also make adjustments to the boot .If the hairspring needs adjustment watch this video , note the amplitude on this video. no time better than the present to upgrade your skill.1 point

-

I doubt the hairspring being out of true is affecting your amplitude, unless it has also thrown the beat error way out. If you look at the pic the first thing I would try would be to push the hs in at the green arrow. You can see it is bunched up near the blue arrow and spread out at the orange arrow- this should correct this (mostly) as well as bring the regulating curve more in line. Then you will want to push it one way or the other right at the stud, just a little bit, so that it bounces evenly between the boot and pin.1 point

-

Hi Watchie you might find this interesting its an old book by FW Brittan on springing and adjusting watches cheers practical springing.pdf1 point

-

Hi If you are looking for movements/watches to practise on then I reccomend the Russian watches Wostock Raketa Plojot etc they can be picked up for a few pounds each, in most cases working. If you make a mistake working on them you have not lost a lot. Worth checking out.1 point

-

Hi I have had a good search round and the one thing missing is the 3330 sheets. I have some for 3313t the elusive 3330 is a no go I Have attached 3301 and 3603 in the vain hope they might prove useful. Cheers 1454_Omega3303 Part 1.pdf 1455_Omega3303 Part 2.pdf 1987_Omega3603 Pages 1-19.pdf 1988_Omega3603 Pages 20-29.pdf1 point

-

Cousins UK has the largest choice. If you want to try a new gasket let us know how it goes.1 point

-

You can press an acrylic crystal with a tension ring. For example GS Diver Tite. I would go with a 38mm or 38.1mm. Because if you dont you will never be able to press it in since it expands when pressed and in some case tension ring slips out. GS Lo/Hi dome can be compressed in using a brass jaw type crystal remover. In this case you will need to go 38.4mm because the jaws grip the crystal and it compresses it then when set into the bezel or case the jaws are released expanding the crystal to set in the case. flat crystals will need to be glued and any acrylic crystal can be glued except tension ring crystals.1 point