Leaderboard

Popular Content

Showing content with the highest reputation on 02/22/20 in Posts

-

I think I've seen a "Mumbia special" HMT with *more* oil in it than that. I believe the term used was "recently serviced". Well i guess they needed to put something in there to stop the dirt from rattling about.2 points

-

I suppose if you leave a bubble there and a cross hair in the middle of the dial you could use it as a sprit level for your balance wheel poising2 points

-

First of all, as of often answered to the same query, no need to worry about the noise, as long the watch winds all is good. Then you can get another rotor for much less on Ebay, no need to buy a brand new mov't. Or PM me you address and I will send one for free.2 points

-

Just another gimmick. I am not about to go in to space, or down to depths of 1000m so why would I subject the watch to this treatment. Yes, it probably works, but so does a Timex mechanical movement completely submerged in lighter fluid, as I have previously demonstrated. The fact that it works, doesn't mean you should do it. I suspect these watches will run fine, but the long term effects are unknown. If you want to do it, give it a shot, but bear in mind that the lifespan of the watch may be affected, and that other than the "because I can" factor, there is no real benefit to it that I can see. Having said all that. I do have a couple of clone F-91Ws in my junk pile, and a bottle of 0W30 from the car, so if you see me heading off to the garden with a filler funnel, stop me.2 points

-

2 points

-

Very nice, a good condition OEM bracelet makes the watch . About 5 years ago, I was attempting to restore the very first Seiko that I bought in 1973 but the bracelet was falling apart and someone on SCWF kindly gifted me a very good condition original bracelet for it ....2 points

-

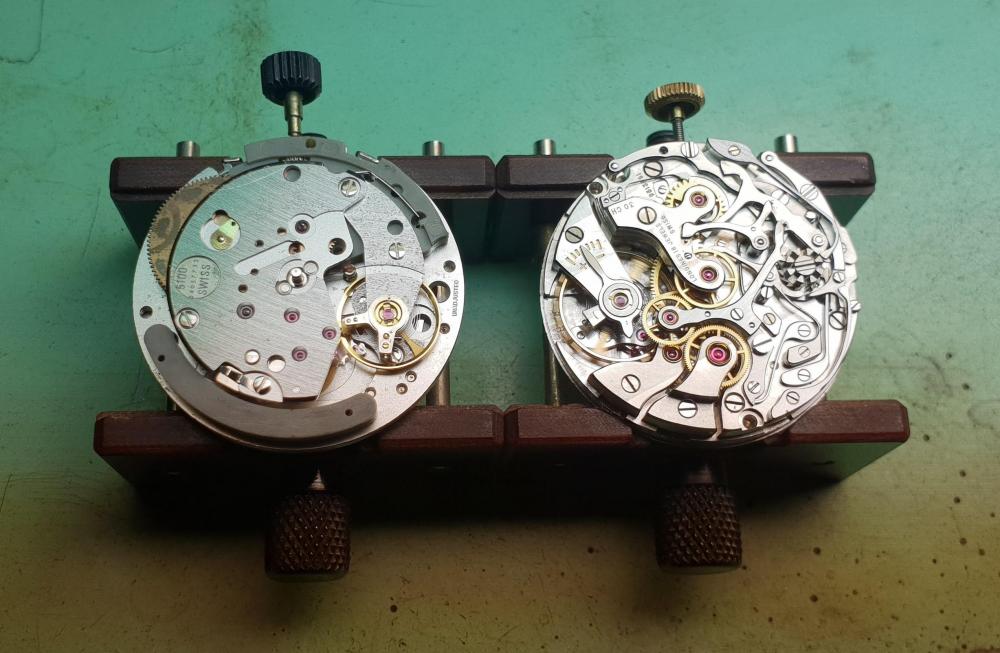

Have these two on the bench this week, thought it was a funny contrast. The left is the Lemania 5100, perhaps the epitome of industrialization and use of injection molded plastic in a mechanical chronograph; almost the whole chrono mechanism is on the dial side, under an acrylic plate that supports the date rings. Vertical clutch with nylon gearing in it, plastic all over. Extremely reliable however! This one had suffered some sort of chemical exposure in the past, with pock marks in the rhodium plating and harsh staining on the barrel great wheel. Ended up running fine with 11 second delta in 6 positions. The right hand one is a Longines 30CH, one of the most beautiful chronos ever made in my opinion. This one was in fine shape other than a non-original, ugly, and nonfunctional minute counter jumper. The one present in the photo is the replacement I made. This beauty had a whopping 16 second delta, and still hit near 270 degrees amp at 24 hours. Amazing.1 point

-

Hi there seems to be no manual for the 3330 the closest I can ger is this one for the 3301. let me know if its ok . If not I shall continue the search. cheers Omega_Omega 3301 (1).pdf1 point

-

1 point

-

If they are any thing like "oil filled pressure gages" IT'S NOT GOOD ! vin1 point

-

Considering it occurs in same time span and in static position, I looks for the fault in the minute train including canon pinion, hands, hands tubes rubbing. Elimination would,nt do much good here, since you would eliminate the min hand which is what you need to observe the reocurance with..Unless you set the hand 12 hr ahead, then the fault is to be ran through in day time, when you have a your eyes open and better chance to catch the guy red handed, if you did, your tg can help confirm. I make an observation with the dial removed, hands installed too.1 point

-

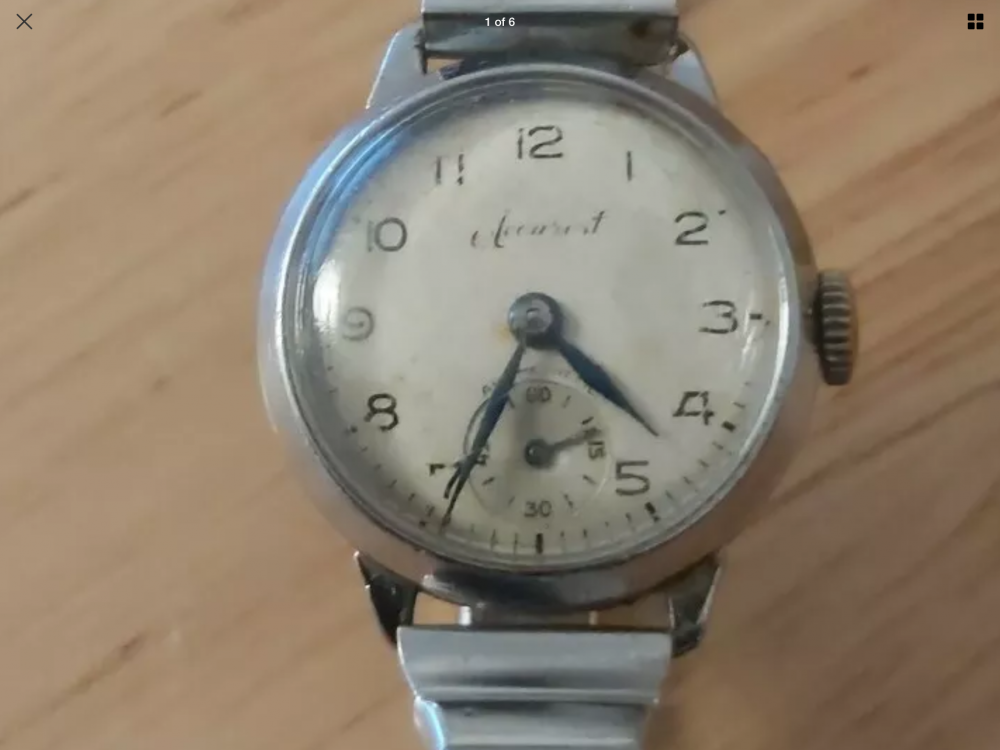

Back in "sunny" Perthshire after our India trip. Back to floods, snow and high winds (and an exciting flight in to Edinburgh last night in a Dash 8 Q400 in "marginal" conditions), so I swapped my favorite little workhorse 19 jewel Sekonda TV face, (which performed flawlessly I might add), for something a little more sunny. A bright champagne dial "Crown Watch" with gold hands. Now I'm about to take advantage of a lull in the weather to take a quick look round the garden and see what is still there, and what has been washed away or blown down.1 point

-

https://klocksnack.se/threads/oljefylla-klocka.64347/ This is in Swedish so maybe not for all. The last picture on a Tissot the owner used a white spirit in the watch. He tested with oil at first but it would work. I think white spirit would destroy hands and dial in the long run.1 point

-

I think someone did an experiment on a Swedish watch forum . He first used an oil that was to thick . The watch didn't work . Changed to a thinner silicone oil. And that worked . Think it was a Casio . See if i can find it.1 point

-

1 point

-

1 point

-

I'm truly mystified that the rotor in an analogue quartz watch would still turn with all of the extra drag imposed on it by being submersed in any liquid, it is designed to work in air. I can see this working on a digital quartz watch but then only if the movement was specifically designed for this use, i.e NO 'pressure' electrical contacts, all electrical connections being soldered or lazer welded and the layers of the display being edge sealed so that the oil could not get between them over time, but then one has to ask 'WHY?'1 point

-

As one would suspect this is gimmickry, The silicone oil is non conductive (fombilin) and therefore a quartz watch will work whilst immersed but as mentioned the long term effects of the oil on the working parts has yet to be determined. The extra drag applied to the gearwork will cause problems and probably over time ruin the case. The movements in the watches were Miyota and are genuine little workhorses in their own right and should not be subject to this sort of exposure. In conclusion NOT recommended for ANY watch.1 point

-

Much the same as yours. Apart from anything else surely any plastic parts will degrade with oil immersion?1 point

-

1 point

-

Through a generous donation of a stellar OEM timex bracelet from a fellow WRT member, I now have a nearly pristine 1978 Timex Falcon Eye! It looks and runs like a dream. It's honestly one of my best time keepers! Not too shabby for 42 years old! A huge shout out and thank you to @yankeedog for the kindness! My old cruddy one on top So much better!1 point

-

Hi as you have already found out lubrication of watches is a minefield every one has there own ideas and theories. As jdm remarked some of the products mentioned on the sheets have been superceeded by more modern products. I have attached the moebius book and the rules of lubrication (omega) so by reading both and making an informed choice. cheers moebius-specsbook.pdf 1472711985_8645_WI_40_rulesforlubricationcousinsuk (1).pdf1 point

-

I finally got round to fitting a “proper” balance and it works great! I was a little worried at first as the timegrapher was showing snow, but managed to regulate it to at one point 2s/d and BE of 0.1 - so well happy [emoji2] The moral of the story if don’t be tight and get cheaper OEM parts.... [emoji2357] Thanks for all your input[emoji106] Regards Carl Sent from my iPhone using Tapatalk1 point

-

Today I am enjoying this Seiko 5 (7009 movement). I bought it for almost nothing and it really didn't need much. The crystal was in bad shape and I replaced it with a magnifier (like that look and this watch does not have to be 100% original). The lume on the hour marks is gone, hands still glow fine. This thing moves right along and keeps excellent time.1 point

-

1 point

-

Technically tissot has lemania beat in "industrialized" chronograph movement. C01.211 is basically the 5100 but takes the use of plastic even further by replacing the escapment with plastic. The longines is pretty. Job very well done on that minute counter jumper spring.1 point

-

Today I'm wearing my Seiko 5 Automatic field watch. I absolutely love it. Yes, it's got a Malaysian 7S26 movement and it cost me way less than $100 half a dozen years ago. But I love this thing. It runs amazingly accurately (after I regulated it very slightly) and after I have adorned it with a domed sapphire crystal it got a whole new look and feel. The band is getting real old and I will be making a new one for it reusing the nice SS hardware from the old band. This watch has not been babied and the original mineral glass crystal was very scratched up and cast very hard shadows on the dial. Now it's clean and clear and so far not a single scratch in almost 6 months of non-babying wear.1 point

-

I am wearing a Seiko Arctura Kinetic. It's from the 90' of last century. I repalced the capacitor in it, as well as the crystal and made my own leather band. Love this thing!1 point

-

1 point

-

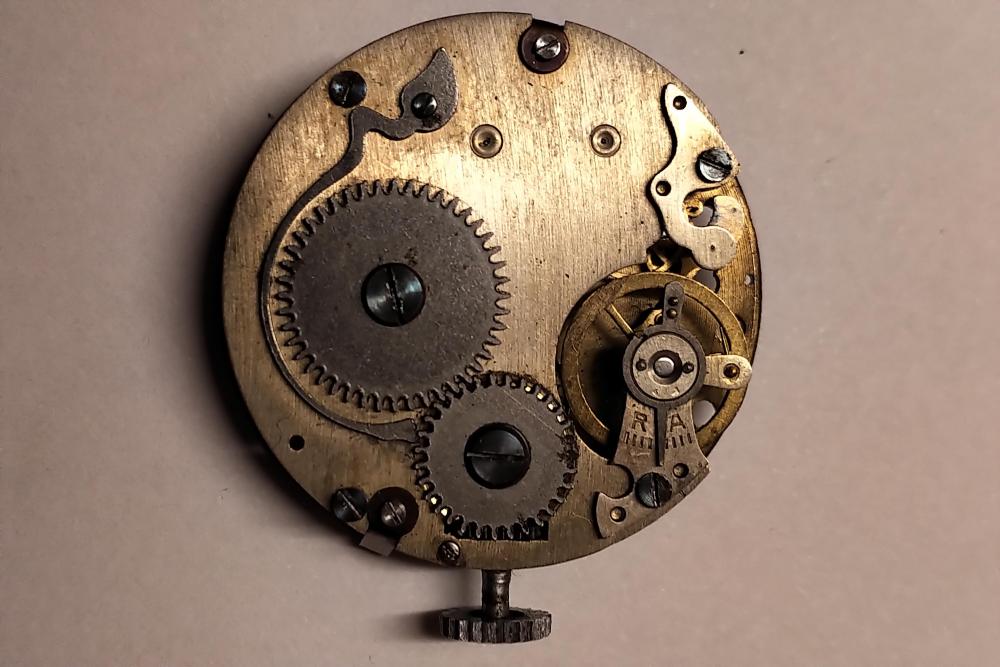

The hairspring is destroyed. That it even ticks is surprising!1 point

-

1 point

-

1 point

-

I have to confess I just picked up this blue dialed specimen. It has one minor problem (apart from being a few pennies over budget), although it is not a ladies size, it is a nurses fob watch. The dial was irresistible, and I almost certainly have a non fob watch donor Ingersol case it will drop right in to.1 point

-

1 point

-

Greetings all! My first post here so I'll try to start with a good one... I've been fixing and servicing watches full time for a few years now but this one that came in recently is probably one of my biggest saves. It belongs to a guy called Paul who's a pretty serious Seiko collector and sends me a couple of watches each month for servicing. He spotted this 6105-8000 on ebay which appeared to be in good cosmetic condition but was listed as non-running / needs a service - There was no picture of the movement with the seller saying the back was too tight and he didn't have a case back tool. Paul took a chance on it but when it arrived the case back was only hand tight and this is what he was greeted with - Now obviously Paul wasn't happy with what he'd bought and was going to raise a case with ebay, but in the end he decided to keep it and send it to me to see if it could be saved. Now I mentioned that Paul is into his Seiko's but he's also a great customer. When he sends a watch that needs a new crystal for example he sources it first before he sends it to me which then saves me having a partially finished watch on the bench while I search for a crystal and then wait for it to be delivered. Most customers won't even think about this but if you fix watches or cars or whatever for a living and a customer comes in with all the parts needed it saves you so much time and hassle. With this one he had a good stash of 6105 parts so they were sent with the watch - So onto the strip down... The dial side wasn't too bad but pretty much all of the screws on the train side were rusted in place, so the movement was placed in a tub of penetrating oil and the tub was placed in the ultrasonic cleaner to agitate the oil. It spent about an hour in the cleaner like this and soaked in the oil for 24h - So after soaking for 24h it was time to start the strip down. The auto winding bridge came off easily enough but the train wheel bridge screws were very tight and I couldn't get enough grip on my Bergeon screwdriver, so I used an electricians terminal screwdriver and ground the tip down to size on an oil stone for a bit more torque on those stubborn screws - The click spring had dissolved with rust and turning the screw on the ratchet wheel only turned the mainspring so it was out with the Dremmel - The strip down wasn't totally straightforward as the heads on two of the screws had corroded away. One of the screws was on the train bridge but there's still two other screws holding it in place so not a problem and the other one was the dial foot screw, again not something that is critical to how the movement performs. The main thing was that the main plate could be salvaged as this is the one movement part that isn't readily available. With everything stripped it was back into the cleaner again and then inspection. Obviously a lot of parts would be replaced but it wasn't as bad as I'd initially anticipated. The parts above the mainspring in this next picture are all reused and below it are the scrap parts - From the state of the movement I suspect it had suffered a crown gasket failure, taken some water on board and was then left dial-up for the movement to soak for a few years, as evidenced by the back of the movement being a rusty mess and yet the front and dial were pretty much unscathed. The state of the train wheels would back this up with the top pivots being corroded yet the bottom ones were fine. The balance was the same and I thought I might at least be able to save the hairspring but there was some rust or rust residue on it and it was beyond mine and my cleaning machines ability to remove it. Not a problem I thought as Paul had supplied a complete nos balance but it wasn't going to be so easy - I tried straightening it out and got it looking like this - Not bad but far from perfect but when viewed from a different angle it looked like this - I've fixed a few bent hairsprings before but twisted ones are beyond my ability, so it was into my own spares stash to harvest a hairspring from a 6139. The only thing left to do now was to put it all back together - The movement scrubbed up pretty well cosmetically but the amplitude was only 200 degrees dial up and there was around 30s variation over four positions. I tried a different barrel and mainspring from a 6309 that was previously putting out around 230 but it made zero difference. I then went about pressing out the fourth wheel and barrel arbour bushings from the train bridge and replacing them with the bushings from the 6309 movement, and the third wheel bushing was replaced with one from a 6139 (the 3rd wheel bushing from the 6309 was a smaller o/d so not interchangable) but still no difference. At this stage I was getting kind of tired with it - I could have bought a new mainspring and/or complete balance in an attempt to improve the amplitude but it was running again and keeping reasonable time for a 47 year old watch, plus I'd already spent around 4x the time on it than I would on a regular 6105 service, so all that was left was to relume the hands and bezel pip (the dial lume was in good condition so wasn't touched), fit the new crystal and get it cased up. I also fitted the nos crown that was supplied and was glad to see it passed a 60m pressure test - If you know your 6105's you'll notice that the hour and minute hands aren't correct and are the same as what you'd find on a 6139-6002, but it appears that Seiko fitted these hands to 6105's when they came in for service. I know that Paul is currently trying to source the correct original hands and when he does then I'm sure I'll see this watch again for them to be fitted, but I'm pretty happy to see how it's turned out regardless. If you've got this far then thanks for reading! David.1 point

-

I think I may opt for saving and buying the gauges, I have the outlook that if I don't use them enough I can always resell them later. I bought the jeweling set for £40.00 thinking, that it may be useful one day so I now have a project to use it on, I have been practicing on old movements pushing jewels out and resetting so think I will be able to manage the job( famous last words). I shall keep my eyes peeled and hopefully I can source them at reasonable prices, Many thanks for your help, Wayne1 point