Leaderboard

Popular Content

Showing content with the highest reputation on 08/31/19 in Posts

-

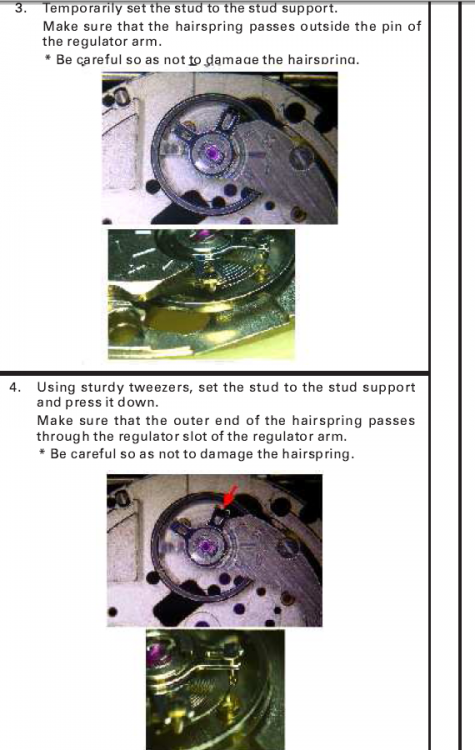

The following sequence of pictures shows how to disassemble the date mechanism of ETA calibre 2472 and ETA calibre 2474. Previously I posted a sequence of pictures showing how to disassemble the automatic device of ETA calibres 2472 and 2474 as well as ETA calibres 2450 to 2454. You’ll find the post here.3 points

-

2 points

-

Serviced a felsa 690 today . That screw is not right for the movement. Someone took what they had. You need to find the right screw or one that sits flush with the movement. BTW mine was also butchered around the hole. Why can't people use the right size screwdriver. Or i see now that you probably did forget to place the screw between the plates. If you do it would not stick up like that .2 points

-

Great teardown, I really enjoy all your write-ups, in fact I download them and use them to practise my "skills"......thanks for sharing bro2 points

-

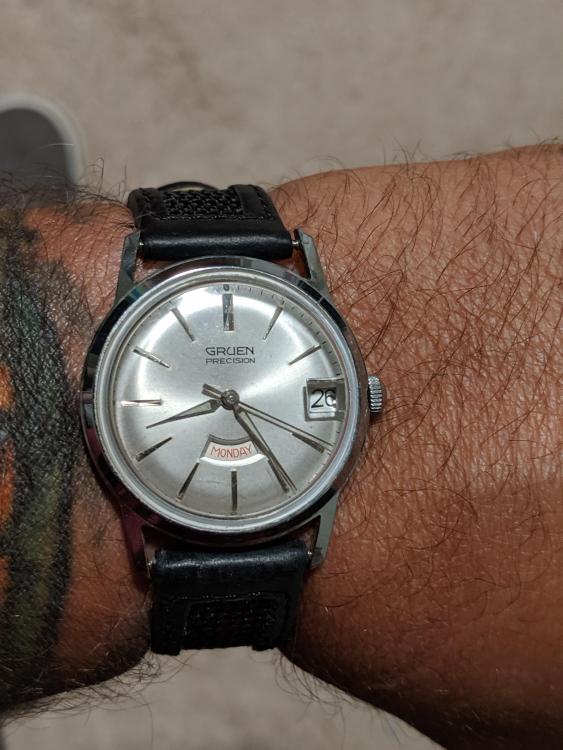

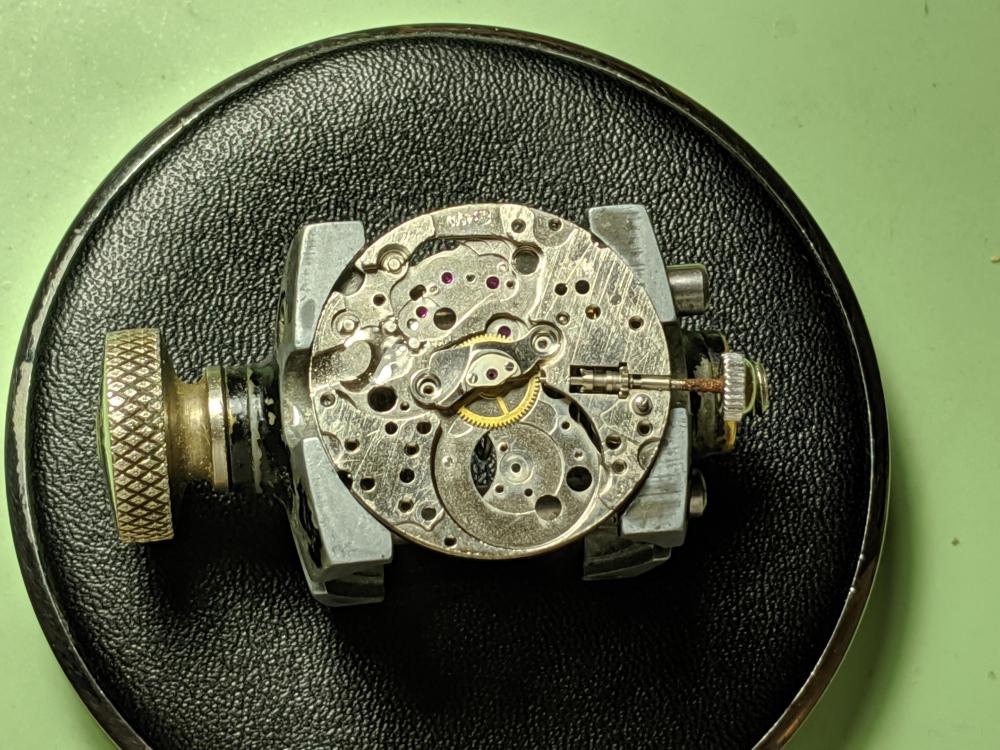

I just finished this 1966 Gruen Date Miner. I had three of these movements just sitting in a do to bin. I was waiting on getting a case. I finally found one and now it's back in action. I was able to use me new old LnR master. It is running really good. New service including gaskets, new stem. It is now my favorite for the movement. Thx,2 points

-

As a general first rule I ignore anything with military images on the watch face. Not that I've got several thousands to spend on a watch2 points

-

Just went to a wedding and decided to wear my vintage Heuer Ref. 73473, circa 1971-72. This watch is very unusual when compared to other Heuers, and not many made. But interestingly not very sought after by Heuer collectors. As for me, I love the Classic 70's look. It is powered by the Valjoux 7734 and fitted on a vintage beads and rice bracelet.1 point

-

I am not the picky . A nice vintage Omega for Christmas is okay . No we are happy we can help . Have done that to . It's always a PIA to put that set lever screw back when you have forget to put it in . And you see it when the whole movement is built up and ready to go in the case.1 point

-

Regarding the question about the car it came from, I'm trying to find out. Currently the clock is mounted in a wooden mounting to hasn't been in the car it came from for many years. Thanks also for the spring calculations above. I've been backing this up by reading the section in George Daniels Watchmaking book. So I'm now in a position to know what I need, but where can I get 2.4mm height x 0.26 spring material from? M&P sell it annealed and I can't see anything from HS Walsh or Cousins. The closest I can get is my pocket watch mainspring which I got from Cousins... it is however far too short and not thick enough. It runs for a few cycles at very low amplitude. I feel if I had the correct spring as calculated above it would work...1 point

-

If you look in the book "German Military Timepieces of World War II Volume 3 German Army/Waffen-SS" by Ulric of England and on Page 33 you can see how a genuine should look like, Helvetia made a similar watch before like in the early 30's and after the war so they became popular to sell from countries like Ukraine where they just popped in a Helvetia caliber 82A or similar in a fake case. Germans are known for their efficiency and during a raging war they wouldn´t care to engrave the movement with the amount of jewels and so on the barrels and thats why the most confirmed genuine are just blank inside with just 82A stamped on the side; while one from the 30's would have some text and even some serial numbers on the train bridge. All the casebacks in the book has the 3190 engraved in them and so do the fakes, but the most genuine has a CB mark stamped on the inside. The things to be aware of here is the serial number on the trainbridge, looks like a 6-9 number serial, what you would expect on a pre war (81-24) movement. The movement mostly provided during the WW2 was the 82A-24. On this specimen you also can see the text General Watch Co , Helvetia's parent company on the movement which I think never occures on the real deal. The D 15004 H looks a bit familiar to a case I bought from the bay in 2017 just for reseach purposes, think the serial was D 15009 H or something like that. But who knows progress in identifying these gems might have progressed but I wold want to see the inside of the back and a better closeup of the movement before buying it.1 point

-

You chaps are blinders, thank you!! Much appreciated! If I had a Christmas card list, you fellas would be on it1 point

-

Såja, riktigt fina bilder! Now you can relax and enjoy a Gin & Tonic...1 point

-

1 point

-

I'm sure members will find this very useful. Nice clear photos. Many thanks.1 point

-

1 point

-

It's marked 4 days on the dial, so figuring one day reserve that's 120 hours, at 10.4 hours per turn of barrel you need 11.5 turns. That's a lot, most available springs are made figuring on around 6 turns. This site has some really great info on mainsprings, with good calculators. According to them you need a spring 0.225mm thick, and betweed 1420 and 1550 in length to get 11.5 turns. As for hardening and tempering a mainspring, I don't know how it can be done without specialized equipment.1 point

-

My God what a mess. An easy why when it comes to mainspring size. The spring takes up 1 third of the barrel, the arbor takes up 1 third of the barrel and space left between the arbor and spring takes up a third. Just looking at that photo tells me that is not the correct spring.1 point

-

How correct you were, oldhippy! Thanks to JerseyMo, I received a new stem today and the old Marlin is running again--54 years after I received it. The last time it ran for any significant amount of time was circa 1970. (It was then affixed to one of those horrid wide woven leather "gladiator" bands. I'm certain it looked great with the leather patched bell-bottoms with the "guitar-strap" material at the hem.) Just might have to service it, but for now I'm just going to enjoy watching the hands going 'round whilst recalling the folly of youth.1 point

-

1 point

-

Hi Old Hippy One assumes by the pictures he has done that already, But you are correct it will remove the back to expose the gear work. If he follows yours and Joe's advise No Problem. Sometimes we assume too much1 point

-

That will just take the back of the movement of if you are lucky. Besides you will need to remove the hand set first.1 point

-

Hi To get to the works, remove the two cross head screws on the back and carefully prise the back cover off, some have lugs on each side nwhich you release , but looking at the pictures it is a prise off back. they are quite easy to do and putting them back on is easy too just be carefull all is lined up and in the correct slot before closing. I have done a lot of these quartz movements and repaired most of them no problem. If it is beyond hope they are cheap enough to buy although the better quality ones are better units, Herchinger, UTS, Keinzle, Seiko etc. good luck1 point

-

Most movements have like a rubber washer between the movement and the back, this prevents the movement from moving about. They also sometimes stick like glue so a little force might be needed.1 point

-

Hi Mark after some research it looks as though you are right as listed.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point