Leaderboard

Popular Content

Showing content with the highest reputation on 02/26/18 in all areas

-

I wonder if its galvanic reaction between dissimilar metals that is causing the corrosion. Looks like the platform you hang the watches is stainless steel and the screw and C clip are just steel and the shaft is aluminum. All that sitting in water is a prime for galvanic reaction. http://www.anzor.com.au/blog/galvanic-corrosion-keep-those-metals-apart/3 points

-

What's up WRT peeps! I finally have some updaaaaaaaaaaatees The story with the watch above was that it needed a case back and a replacement LCD panel. I have been watching eBay for a while, there have been 3 watches sold since: $850, $450, $280 for working examples. The former of which was a mint example. The prices have doubled from 3 years ago, where a mint NOS example cost $300-400. Anyway - I bought a nice B grade donor watch which was 100% complete, however it had a cracked/bleeding LCD panel. It only cost me $25 from germany (eBay) which is surprising because nobody else bid on it. Luckily I knew that Northern Watch Clock Co had a 4510-841 replacement LCD panel for sale for 15 gbp. It was the correct panel for the donor watch as the original had the dark dial which was possible rarer? I ordered the part, after paying an absolutely eye watering 25GBP for postage, (it arrived with an 8gbp postage stamp - 14 days after ordering.waaat...). It wasn't packed that well considering how incredibly rare this part is. Cousins as an example posted me a 30x30x30cm carboard box just for a mainspring - atleast it was protected haha!!! https://imgur.com/uOMXVxu.jpg[/img]3 points

-

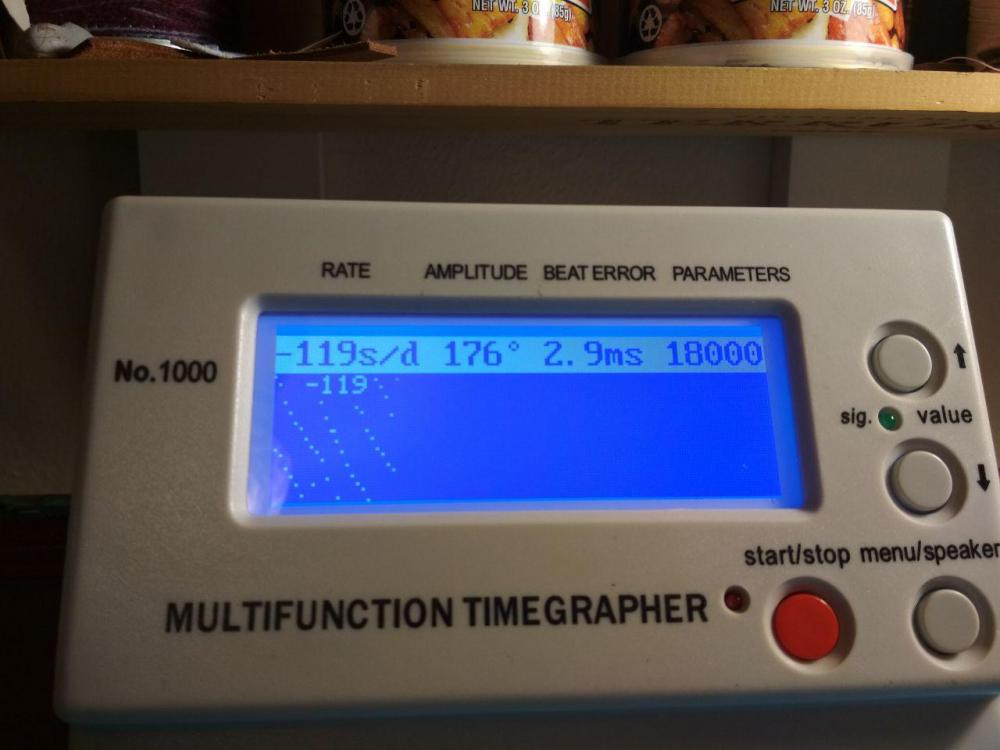

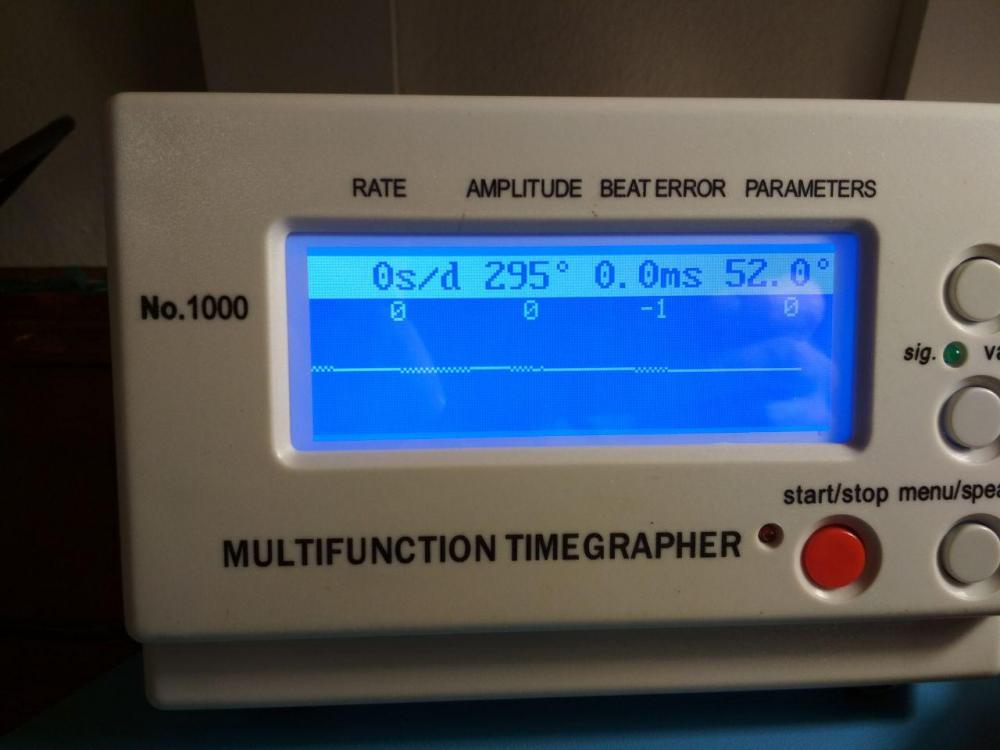

Hey guys, not sure if you'll find this interesting. My girlfriend's Timex was fitted with a jewel-less, unadjustable movement, which was losing quite a bit of time. I picked up an NOS ETA 2540 for a few dollars, cleaned and serviced it and with the help of a trimmed plastic movement ring, fit it into the Timex. The sticker is a temporary fixture...2 points

-

2 points

-

Restored, looking and running good. Sent from my iPhone using Tapatalk2 points

-

I just finished painting this and thought you guys would get a kick out of it. Its a Hauser M1 watchmaker's jig borer. I normally worry about getting my machines in good mechanical shape and don't care about paint (if you're using them, the paint will look like crap after a year of chips and coolant in any event) but this little one was worth it. Its primary used by watchmakers as a jig borer and mill. Its direct reading off the dials in ten thousands of an inch with lead error correction (the marker for the dial moves and follows a profile to correct for any screw error). Now it is a jig borer, but I'll say it is the nicest machine I've put my hands on, and that includes many of the worlds best names including other swiss stuff. Exceptionally well made. i bought yet another mill and lathe before Christmas and ended bringing this one home as well, they don't come up often and it just too cute. Wear is negligible with the original scraping well defined everywhere. The only flaw was the paint was literally falling in big chips - another good reason to paint it. I chipped all the old paint off, it was so thick, feathering it was a real challenge, so just took it all off. I have the spindle (8mm collet) and drill gimbal but I'm going to have to make the microscope. Used for locating, the microscope is an important accessory as they are also used as an very toolmakers microscope. I have the original stand, but no room for it at the moment. They powered these things from a motor hanging from post, much like a foredom. The ideas was to isolate the machine from vibration....not sure yet how I'll go about it but I've some ideas1 point

-

I have a timegrapher, but also find this useful http://forums.watchuseek.com/f6/open-source-timing-software-2542874.html, the only hardware you need is a pc with a soundcard and a set of headphones from a phone.1 point

-

Try using an old drill bit and a dremel, you won't be able to cut it with a graver, but it's sure to be hard enough. Chuck the bit into the lathe, then use the dremel to rough it down while turning it, then finish with a stone. Stone the tip when done. You may have to anneal slightly so it won't be too brittle.1 point

-

If it were mine, I would disassemble and have the cast aluminum (zinc ?) parts cleaned by glass beading, then I would paint them with this... http://shop.masterseriesct.com/product.sc;jsessionid=09891C0B584416E173AEA791283838F0.p3plqscsfapp001?productId=8 I'd suggest thinning it a bit and using thin coats so as not to affect dimensions. MCU is moisture cured urethane, I've used it for many things outside the box.1 point

-

I remember once trying to make one of the round clock hand pullers using a small offcut of some GI water pipe thinking it would be easy to machine true. It was horrible my cutters either dug into it and pulled it off my lathe chuck or just chattered terribly, ended up chucking it in the bin. The wonders of 'Mystery metals'1 point

-

When I very first started with watches I purchased a similar kit. However as time progressed I replaced most of the tools with better quality ie the screwdrivers in the kit I purchased were crap.1 point

-

You mentioned this often but in my own experience (practically limited to current Seiko only) I've never had a problem with amplitude reading. When it was visually poor -unfortunately happes a lot with these watches - the instrument showed a consistent value, if any at all. But I have seen that sometime the caseback needs to be removed or the gain slightly adjusted for a clean reading. We all agree that the machine is not a substitute for our eyes, and ears as well as discussed In other threads.1 point

-

I would say no chance unfortunately, almost no sparkles off the sparks so very low carbon1 point

-

It's older than a Landeron 248 its a earlier Landeron variant and is a calibre 48 it can be distinguished by the rather distinct minute recorder jumper spring, and would date from the late 40's early 50's, the following site is useful for identification : https://www.time2tell.com/category-database/landeron/1 point

-

All up it owes me around $110 + $50 for the crystal. Not bad considering I know its an honest watch with several parts replaced (LCD + Crystal + case back gasket) - rather than buying an unknown watch on ebay for $800 which could have a cracked dial.1 point

-

Geo got it right, a light tap on the mandrel with the handle removed from the jeweling tool, using one of the above punches or similar will do it.1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point