Leaderboard

Popular Content

Showing content with the highest reputation on 09/18/17 in all areas

-

Also my preferred tool for tightening cannon pinions. I purchased a set of end cutters for about £5, drilled and tapped M5 and fitted a cap screw, job done!2 points

-

While we're talking cannon pinions. This is a must for that gigantic tool box. It's basically a fancy pair of nail clippers with a micro adjuster. Made by Bergeon and comes with a fancy price. It's the best tool I've ever used for tightening cannon pinions and in my opinion, more accurate than using a staking set. Sent from my SM-G920F using Tapatalk2 points

-

2 points

-

The top one is the best IF you can purchase a vintage version. The reason is for some reason Bergeon changed the design and as result the new one's do not work with the small cannon pinions.2 points

-

Hello! I just bought a Boley Staking/Jeweling tool and it's missing some punches. Do you know where I could buy some old/original Boley 4.7mm punches? Thank you!1 point

-

It's a standard for the eta movements, the wheel that sits under the cannon pinion has (in this case) 3 arms that provide pressure for the hands to run, and let the cannon pinion slip for hand setting. The drive of the movement comes through the 4th wheel pinion (7 o'clock on the picture shown) directly to the wheel under the cannon pinion. I don't recommend dismantling the wheel, unless you have a spare, as the tension is critical to keep the watch running. Tom1 point

-

Thanks the link worked for me. The first thing that you are doing which with practice, is you are moving the graver up and down, not just from side to side. The graver needs to be tidied up, it has round shoulders, these need to be squared off and the cutting edge is not straight, blow away the cut metal more often, at the moment it is becoming in the way causing a rough cut.1 point

-

Whatever method is used it is important to pull straight and even because it is so easy to break the pinion.1 point

-

I will look foe the video. The main reason i bought a boley lathe was to make balance staffs. I dont care how long it takes to learn, i will eventually master the art. of course i may ask you guys a question from time to time. Sent from my iPhone using Tapatalk Pro1 point

-

Cousins was a miserable company to deal with. Their only redeeming quality was their prices were a little better than other distributors but they jacked up them up and they now have no redeeming qualities. david1 point

-

If you get stuck ordering from Cousins then I could maybe order some and forward to you.1 point

-

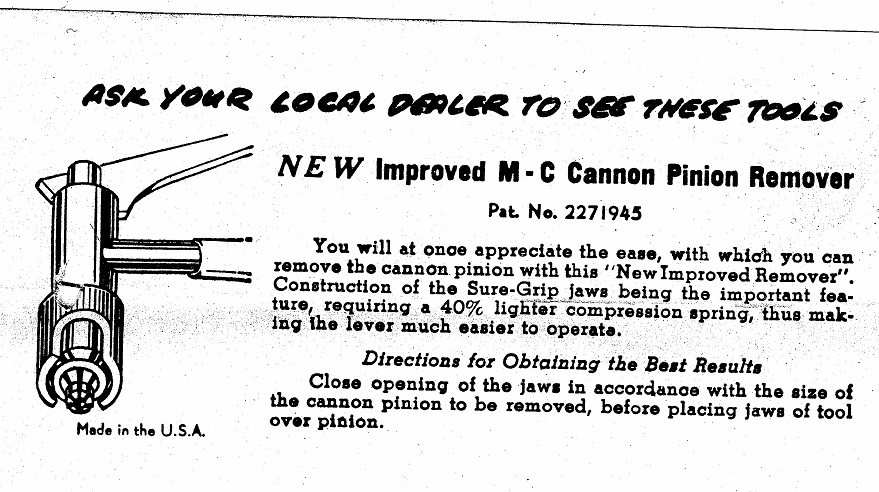

Newbie poster here. I have the vintage version and I have found it works well for pocket-watches and wrist-watches. The fibre tip doesn't mar the pillar-plate, etc. And it has a nice straight pull. This is probably more important with wrist-watches than with pocket-watches, but it's surely always a good policy. I'll attach a scan of the promo/instructions that came with it. Maybe a search under the name "M-C Cannon-pinion Remover" will get you some results? Good luck.1 point

-

That is assuming that these companies make all of their watch parts in house. The SWATCH GROUP manufactures a lot of watch parts that are supplied to the Swiss watch factories. There are also companies that supply items such as jewels and hairsprings but as far as I know SWATCH has been buying these companies in order to monopolize the Swiss watch part business. To me the whole thing looks like a marketing scam. When you think about it, a part cut out with a wire EDM in Switzerland and a part cut out with a wire EDM in any other country is still a part cut out on a wire EDM. Watches are produced in these quantities using engineers, toolmakers, set up technicians, inspection departments, assembly lines etc. They are not produced by watchmakers. Roger Smith is a watchmaker, as are his employees, and he can only produce 10 or so watches a year. The major Swiss watch factories are cranking out around 150 or so watches per work day. david1 point

-

It really depends on what you're getting into as time goes by. On larger movements you can even use hand levers but keep that lift vertical ! Nailclippers concern me as you may squeeze and pull at the same time which could severely damage the pinion. But they are a great "Lazy" way of tightening a pinion whilst still attached. I've come across several movements where accessing the pinion base has been difficult and the above pictured Bergeon tool has been the only effective way to remove it. As for the second photo. I just regard these as a waste of money if only even cheap but they do make good crown pullers, if you're dealing with a split stem. As for buying tools in case you may need them (Excellent Philosophy) definitely buy yourself a large tool box but don't let the Mrs know what you're up too [emoji16] Sent from my SM-T585 using Tapatalk1 point

-

Interesting reading about making balance staffs. It is one of the hardest things to master if you want to become a watchmaker. I learned on a Boley lathe with a foot control. You need to be very good with your grave and have complete control and bags of confidence. I had disasters lots at first, but my master would explain where I went wrong, many times, it was down to me making the wrong cut or not holding the graver at the correct angle and sometimes speed, you do not need high speed to make the final cut. . There are a few videos on YouTube showing how to make a balance staff.1 point

-

1 point

-

As far as I am aware 4.7mm is pretty much standard for all stakes, European or American. I think the initial American standard was 3/16", I don't know if that is what is still used or it changed to exactly 4.7mm but the are pretty much interchangeable. The only ones I have seen that are different are the Indian made Pearl sets you can buy as new which are 5mm. Of course there could be others I don't know about. The difficulty comes in the fact that different companies use different reference numbers for stakes, so it's hard to know which number to get. The following pdf was posted last year by tomcolson, this has some compatability details: https://www.watchrepairtalk.com/applications/core/interface/file/attachment.php?id=10978 Stephen1 point

-

In my other staking tool that is now sold. I had a few Star punches. They are made in Switzerland. Sold by Boley.de. They are 4,7 mm . You also have a comparable list here. https://boley.de/en/shop/3159.rivet-punches cousinsuk has Bergeon punches that are 4,7 mm in dia.1 point

-

There are a number of second hand tool sellers in USA/Canada (Uncle Larrys Watch Shop, Dashto, Daves Watch Parts, Watch Tools Online) but they mainly have American made tools. If you specifically want Boley you may be better looking on German Ebay, there are often good quality tools listed there. I don't remember seeing anybody listing specific stakes though. I do remember seeing once a chart that compared the different stake numbers across the different manufacturers, but I can't remember where sorry. Stephen1 point

-

You could try ebay. I have only just found out that Uncle Larry sells second hand watch/clock makers tools. Here is the link. www.execulink.com/~lfoord/tools.html1 point