Leaderboard

Popular Content

Showing content with the highest reputation on 06/06/17 in all areas

-

All links and content removed. We take a dim view here of members who sign up with a sole agenda for promoting their wares, much much better to become an established and respected member of the community by contributing in a meaningful way like everybody else does4 points

-

Please don't . There are already full of custom Seikos on Ebay. I think it's really hard to buy from Ebay then repair and sell on for profit. Prices on good watches are already high. If you should make a profit you should buy the watches at flea market and such. Sell as is or sell the movement for spare parts. I have notice that it's usually easier to sell non serviced watches. And if you sell serviced watches you will have to have some kind of guarantee. Which will end up in lots of extra work if a watch doesn't work as it should. And maybe negative feedback.2 points

-

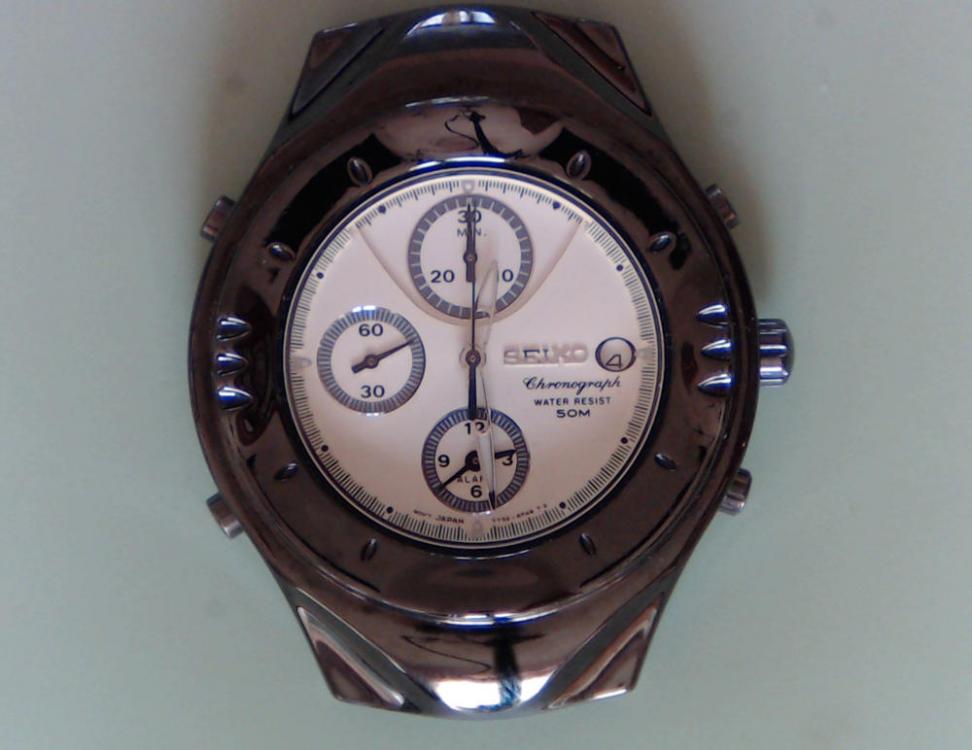

I've been looking for one of these for a very long time. I've just got my hands on a Seiko Macchina Sportiva from the 1990's, but this one is quite rare. It's the 7T32-6L20 Black ION with its original black rubber strap. I've given it a full service but need to realign the date ring, that's not a problem. But what is a problem is the case back. There's video I've made to show it off a bit. The back on these was a silicone based black finish and this had deteriorated over time. Again, not too much of a problem, I'll completely strip back the back plate to bare metal and reapply a new decal to original spec.1 point

-

So it's been a few months since I posted here...but I've been regularly checking in. Hi Mark and Geo! So as a few of you know, I have a hobby of building watches. The one thing I hated was relying on some of the very few companies that actually print dials. Here is the USA there are only a handful that do this type of work! I was lucky enough to find an antique dial printing machine on eBay. It was just a vessel to move the dial from printing plate to paint application. I found a willing company to "Fill in the Blanks!" I won't name them here because I don't want to seem like I'm Selling this company! Anyway, they were a very big help when it came to me having questions. The sales, engineering and billing staff were first rate! They helped me pick the proper printing pads, helping me design and then produce my printing plates and then help me choose the proper ink and also recommended how to prepare the inks, pads and thinners to get the best results! So, here I am....First try at printing a dial.... I designed the dial myself using a free online software. The dial is printed in 3 stages. The first step was printing the hour chapter. Then, the second step was to print the sub seconds chapter. Lastly, I printed the name of the manufacturer that I will be using for this build. This was more of a proof of concept to me...Now, I can't wait to try new designs and styles! And, Now I have more control of what I build! That's very important to me...Cheers!1 point

-

1 point

-

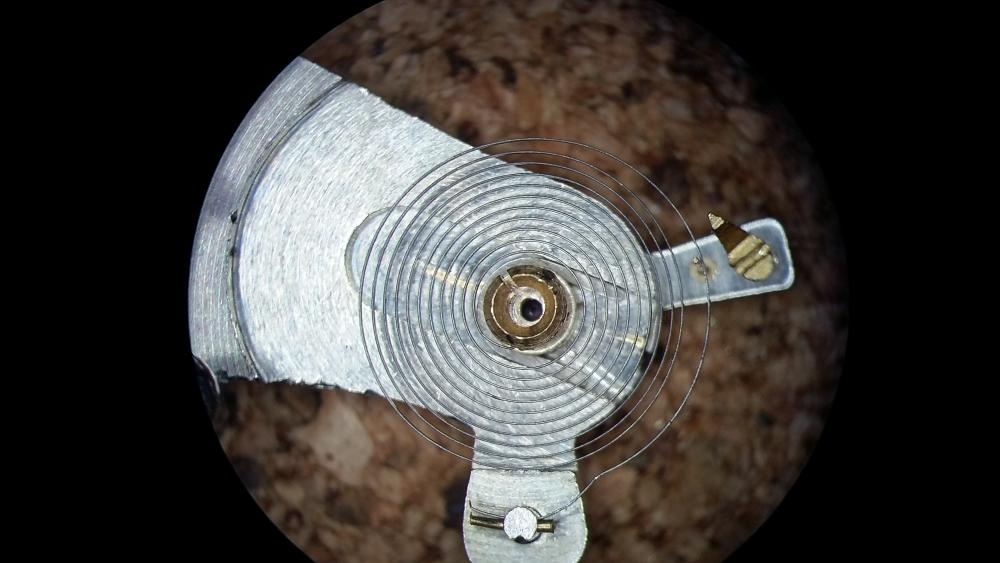

I have used seitz bushes in a mainplate and found them to be a good choice as they are slightly tapered so easy to get a good fit... although you do have to remove the excess length carefully - if you have a faceplate for your lathe this should be straight forward. They are made of "hard brass" and John Senior sells them individually by size making them quite economical. http://www.obsoletewatchandclockparts.com/Jewels-and-Bushes.htm Recently I also bushed a mainspring barrel, but turned a custom bush from brass rod. The barrel wall was very thin and I elected to solder the bush in place. Either way, you should plan on finishing the bush hole with a smoothing broach which will work-harden the surface.1 point

-

1 point

-

Today's watch! Not my creation but I've always wanted one..I just picked this one up off eBay for $80. Its from 1995 and its a Seiko Diver model 7002-700a. It has di directional automatic winding, but without manual wind or hack. Popular with "modders" today, you can buy all different kinds of dials, hands and bezels to totally change the look of the watch. I think that's awesome! Whatever brings more people into watch collecting I'm pretty much for... speaking of which, though this looks pretty much stock, it has a new dial, chapter ring and bezels insert. It was "serviced" as well...so the listing said. But when I received it, it was running about 3 minutes fast a day.... Oh well, I regulated it and now it's running very accurate now... This is kind of my "beater" watch. I'll wear this if I'm doing work and the house or in the car. Great watch!1 point

-

Yes, I've spent quite a bit of time looking at that, and som while back I asked the site owner if he could send me a better copy of the oiling chart, but never got a reply. The Girocap was used on the Omega 540 balance and there's a description in here http://watchguy.co.uk/wp-content/uploads/2012/12/Omega-540.pdf There's a good picture her and also a useful reference for identifying shock spring types https://watch-wiki.org/index.php?title=Kategorie:Picture_gallery_archive_shock_absorber I also found this on eBay, so definitely not a one off1 point

-

if my memory serves me well I think that was the issue with the watch i repaired.1 point

-

That makes perfect sense if play becomes that extreme. My watch repairing activities pale into insignificance compared to other people on the forum so I seem to have managed to escape this malady statistically so far for watches I've worked on! It's certainly something I'll keep a better eye out for from now on though. I learn so much on this forum! :-)1 point

-

The previous forum post clockboy mentions must be... This is a very interesting video! Bushings are usually made from brass btw. This being the case you could follow the great engineering approach above or you can buy modellers brass rod in all kinds of diameters relatively easily where you might strike lucky with the dimensions you need (or at least the external diameters and use straightforward drilling to refine the internal diameter you need). I see your main aim here is to reduce play and mainspring barrel wobble. This is an interesting topic in itself and not something I've ever been conscious of in watches I've repaired. Is this a matter of professional engineering pride or is the wobble causing tangible issues in the watch you're repairing?1 point

-

And that also on "Svenska Flaggans Dag" in Sweden. As alway you are most kind and helpfull Roger.... Thanks a lot!! And that gos for all you that have helped.. Thanks a lot!!1 point

-

Call of the searche people! Managed to find the screw here in Norway. Managed by the way to add som more shellac, besides the end stone. So thim Im good.... When I got the screw, I hope the watch then will run good... :-)1 point

-

The only problem with jewels is their expense. Plus, not always easy to obtain certain sizes for barrel arbor diameters. And finally you may find that the barrel bridge material may be too thin to support a friction jewel in certain movements. If the wear is minimal then it may be possible, although not attractive, to use a hole closing punch then broach and smooth broach in order to open to the desired diameter, smooth broach creates a kind of hard skin on the metal. Using bushes may not be desirable if the metal is too thin. Sent from my iPhone using Tapatalk1 point

-

Yep. It was a struggle before when I had a full workbench. But now I work full time on this project it's easier. However, it's still amazing how many hours can go into making just a few minutes of video. Sent from my iPhone using Tapatalk1 point

-

The biggest problem Mark is time. I have considered making vids when I repair a clock or a watch but I do not have the room, equipment or the time and I am retired (supposedly) I sometimes wonder how you do it i really do.1 point

-

What about a jewel. Soft barrel bushing are a common defect for Seiko. Maybe they do that so they don't last forever and a new watch has to be purchased.1 point

-

Good lesson , one that I will remember. Thank You for being brave enough to share with us.1 point

-

1 point

-

Yes it is possible to buy and repair watches for a profit, but it is a learning curve and you will end up with loads of unknown movements and bits and bobs, it will be time consuming and probably won't come close to paying your bills but will buy you few pints each week if you make enough profit. As for buying parts there are your usual material houses but sometimes I end up popping into my local smith and buying a part from him as it saves on postage, or I'll have to scour ebay etc for another watch of the calibre to get the required part to fix the first watch. It can be a mine field but also a good classroom for learning repairs, go ahead and have some fun, seikos are always plentiful but for a non runner (rusty) diver you will expect to pay approx £30 for a non runner then factor in a new aftermarket set of hands from the USA only about £8 but then put another £10 on for postage each extra part you buy you will need to put a mark up on to cover it's cost and postage and so it goes on, until you then factor in your hourly rate, for and full renovation if all parts are on your bench factor a whole day for the job going on into the evening so say a good 10 hours of solid work if all goes to plan. I'm not trying to put you off im just giving you the knowledge I have gained so far, you will eventually have a stock of spares and won't have such along turnaround time for each piece, and try to stay focused on one brand of watch like seiko, or be like me along nd buy loads of random stuff and then be stuck with it haha, enjoy and have fun along end good luck mare1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)